#Battery cell assembly

Explore tagged Tumblr posts

Text

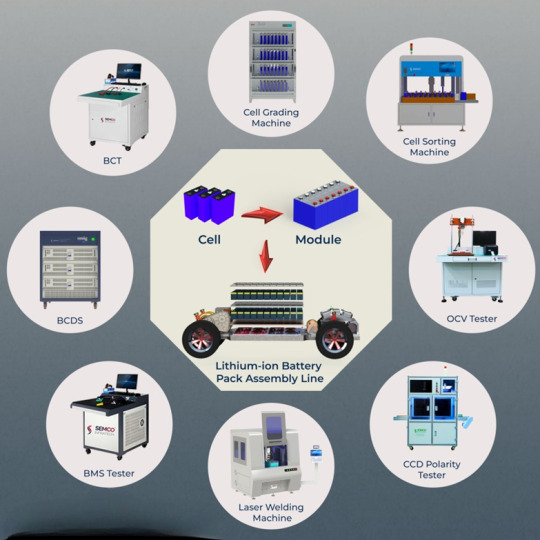

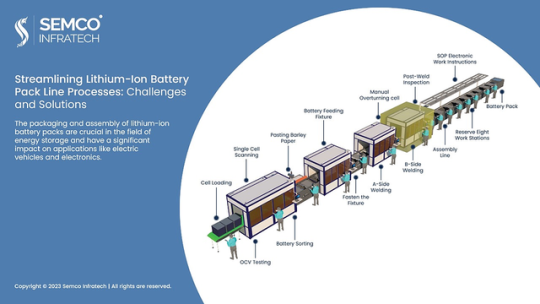

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

Look Behind You

Main Masterlist - Bucky Masterlist

Read on A03!

Tags: Bucky Barnes/Female Reader, smut (p in v, fingering), light angst, fluff, humor, action, no use of y/n, semi-linear story telling, enemies to lovers

Summary: You've made a mistake. You've been reckless and fallen in love with Bucky. There's only one way to deal with this.

Make a list.

Author's Note: This is one of my favorites, I think. Thriving in the semi-linear story telling, feelings, and list making. Gotta love a good list. Enjoy!

Word Count: 11.9k

The pen in your hands feels more like a weapon. The last line of defense against the unthinkable.

The only thing holding your sanity, dignity, and life by a single thread, set to snap if you’re not careful.

Nobody will bother you in this coffee shop. Not even Bucky will look for you here. You’re in public. You’re somewhere obvious and simple, and that’s the whole point. Sam and Bucky will lose themselves down dark allies and in hidden corners of the city before they think to check an emotionally significant landmark in downtown Manhattan. They won’t believe you’d be that stupid, make it that easy for them. They’ll think that—because you’re dodging calls, because you were gone when Bucky woke up and you didn’t meet with Sam before lunch—you don’t want to be found.

And you don’t.

So they’re not going to find you.

There’s a lingering fear that a search team might be assembled, and the city may be barricaded in until you’re found, but you don’t think Sam will abuse his power like that.

Bucky might try to convince him to.

You’re about fifty percent sure Sam won’t cave.

It’s a bridge you’ll burn when you reach it. When they do—eventually—find you. When you—hopefully—have your answer, and you have to look Bucky in the eyes and keep finding a way to live with yourself.

If this goes as you hope, that will be quite easy. You’ll lie through your teeth and say you lost your phone—it’s right next to you, the SIM card removed and battery purposefully dead, but they never need to know that—and thought that Sam and Bucky would be able to find you if they needed you. They’ll look embarrassed and make a silent vow to each other that you’ll pretend not to see—swearing that they’ll never tell you how they almost called the coast guard in—and then everything will go back to normal.

If it goes the way you’re afraid of, that will be more complicated. You’re not entertaining that possibility with things like plans or strategies, because you simply won’t allow it to happen. This will work. You have the pen, the paper, and at least eight hours before Sam and Bucky grow a brain cell and figure out where you are.

Deep breath. The coffee in front of you is sweeter than you’d usually want it, almost sickly, but it can be a motivation. The coffee shop is crowded, and the tables are blue. You can smell the decorative roses on the windows. You can hear the music in your earbuds. The pen is heavy in your hands, but all that means is it’s real. And this is going to work.

List of Reasons to Hate Bucky-

You pause, and scratch out Bucky. It’s too intimate. You’re setting yourself up for failure.

List of Reasons to Hate James Barnes.

You have reason one locked and loaded. You’ve been rehearsing the whole list for a week—since the revelation that can’t be spoken of, because that will make it real—and you know half of your pre-planned reasons will drift into nothing as you go through the list, but at least you’ll have one.

It’s better than none of them.

You’re a little worried a hundred won’t do the job.

You have to try anyway.

1. He stares.

——————

You don’t know how you got here. Sitting across from Captain America, kicking your feet slightly and humming to yourself as he and his very angry looking sidekick glare at you.

It seems like a contest, trying to figure out who will break and speak first.

It won’t be you.

Captain America is out of his suit, and, logically, you know his wings won’t just spring out of his body. They’re mechanical, not biological. Part of you is still wondering—should you move suddenly and startle him—if he’ll squak and take off like a real bird.

He won’t, and you don’t think either of these men will find that as funny as you will. The Cap seems intently focused on trying to puff out his chest in his chair—like an odd sort of intimidation ritual or mating dance, done more on instinct than logic—and his sidekick is looking at you as if you’re the most disgusting thing he’s ever seen.

You’ve gotten that look before. It doesn’t shake you on his face any more than it does anyone else, but there is something… different. Most people will glare with that revolted look at what you’ve done, and for what expression, and it won’t sink deeper than your skin, because they don’t understand. They don’t know what the shadows and colder nights feel like, they don’t know how long you’ve been broken and alone, they don’t know that—whatever loathing for you has wormed its way into their heart—they don’t hate you. They hate what you’ve done, and they really don’t fucking understand.

This guy looks like he understands you perfectly, and it’s viler to him than anything in the world. Like he knows exactly who you are, like every marred and twisted organ is visible to his unwavering stare, and it’s the worst thing he’s even seen.

You’d laugh, if it didn’t cause an odd sting in your heart. Because you know who Bucky Barnes is. You know that any blood on your hands is mirrored on his, and if he really knows who you are, he’ll think better than to turn the violent glint behind his eyes into action.

Especially because you know he won’t hurt you. He can’t, but you don’t think he’ll even try. He’s cured. He’s free. He doesn’t hurt people anymore, and you’re technically a person.

You’re also starting to be incredibly certain that this is some sort of staring competition. There’s no other reason for the silence to be stretching on this pointlessly long. It’s a little amusing, how they seem to have started a game they’ll never win, but it doesn’t change what’s happening. You’re handcuffed to a chair in an unknown location, Captain America and the Ex-Winter Solider are trying to break you with only very angry expressions, and you could escape in a second but you’re bored, and you don’t care about winning, but you want them to lose.

And they do.

Because Captain America breaks first, and smile pulls at your lips that you don’t bother to hide.

“You know why you’re here?”

You shrug, keeping your voice bored and amused. “Should I?”

He blinks at that, looking over his shoulder at Barnes, and letting out a long breath as his companion just keeps glaring at you. “Buck-“

“Don’t say my name, dumbass-“

“She already knows who we are-“

“She hasn’t been in damn public for a decade, we don’t know what she knows-“

“Man, c’mon, Fisk has TVs.” Captain America rolls his eyes, and turns back to you. “You know who we are?”

“I don’t think so?” You look between them with your best, perfectly innocent and confused expression. “Should I?”

Barnes narrows his eyes, scanning over you with an unblinking fury that’s almost scary. Not quite, but almost.

“You know who we are.”

“I don’t think I do-“

Barnes scoffs. “Don’t lie-“

Captain America shakes his head, cutting Barnes off with a firm glare. “I dunno, man, you’re the one who said-“

“I know what I said, but- You’re really falling for that?” Barnes gestures to you with a scowl, and you give him a sweet smile in return. “She’s clearly lying, Sam-“

Sam rolls his eyes. “Who’s sayin’ names now, Bucky-“

You clear your throat, and they both look back to you with almost twin, venomous glowers.

“What.” Sam snaps, and you let out a long, dramatic sigh.

“Do I have to stay tied to the chair while you two fight? Or can I go home?”

“Home?” Barnes gives you a pointed look. “You gonna head right back to Fisk, doll?”

You don’t answer, just shrugging and letting your smile widen, even as the thought of willingly running home to fucking Fisk makes bile rise in your throat.

Barnes holds your gaze with a glare. You don’t think you’ve seen him blink once. It might be the main thing keeping you in this chair.

You want to see what they have to say, and you’d really like to see if Barnes can blink, or if it will make his circuits fry and heart go into an arrest.

You get the former first, when Sam runs a hand over his face, leans forward in his chair, and mutters your name. Your real name.

He knows your name. That’s interesting.

“Look, we-“ He glances at Barnes—still glaring at you—and lets out a long breath. “We know who you are.”

“Oh?” You look between them will well-practiced, faux innocence. “Do you?”

“Fisk’s pet.” Barnes grunts, and Sam sighs again. He seems to do that a lot.

“I- Coulda phrased it better, but yeah. You’re his hit… woman.” Sam’s voice drops as he continues, watching you carefully. “Look, we got an opportunity for you. Help us bring down Fisk, you get a full par-“

“Okay.”

Sam frowns. “I wasn’t done-“

“I don’t care.” You shrug. “I’m in. Can you let me out now?”

“Uh-“

“That’s it?” Barnes cuts Sam off with a snap, his tone full of a disgust that’s a little dramatic. “You’re just- You’re gonna flip like that? No questions, no loyalty? Out of fuckin’ self-preservation?”

You snort, not bothering to sit up as you hold his gaze. “Of course it’s out of self-preservation. Would you rather I hold my moral high-ground and keep working for the evil crime lord? Would that be better for you? Cause I can flip back, you just need to say the word and I’ll go tell Fisk that Captain America tried to cut a deal with me-“

“Hey, no.” Sam holds up his hand, letting out a long, slow breath as he glares at Barnes. “C’mon, man, you know we get one shot at this, stop antagonizing her-“

“She’s antagonizing me.” Barnes mutters, and you scoff.

“You’re not the one cuffed to a chair, dipshit-“

“You-“ Barnes’ jaw clenches, and his hands curl at his side. Maybe he’ll punch you. That feels like it’ll help, somehow. “Sam, this cannot be our only option. She,” he gestures to you, and you wink at him. It doesn’t help. “Is not the only person in the whole damn city that works for Fisk. We’ll find another-“

“I’m the only person he trusts that will flip.” You hum. “Everyone else in his inner circle believes in the cause, or something. They love him, worship the ground he walks on. I’m the Stockholm puppy, they’ll never assume I flipped, and they’ll tell me whatever I ask because they don’t think I’d have this,” you give a vague wave of your hand in Sam and Bucky’s direction. “In me. I’m not just your only option. I’m your best option.”

There’s a long silence as they stare at you— incredibly uncuffed from the chair—and before Barnes can lunge at you with what might have been snarl, Sam stands up, shoves him away, and they exchange low, angry words.

You settle for examining your nails as you wait, and Barnes’ glare pushes right under skin and sticks to it. You don’t know how you know, but there’s a very certain feeling that for the rest of your life you’re going to feel a buzzing, electric heat under your skin that’s entirely made of James Barnes, glaring at you.

You really don’t think he can blink.

But you’ll have plenty of time to find out, because when they return it’s with the news that they’ve come to an agreement—more likely Barnes lost an argument, but you don’t really care—that you’re in.

Barnes won’t stop staring at you. And you could leave, if you wanted.

But you’re interested in seeing how this plays out. And Barnes may be rearranging every nerve point and organ in your body with only his attention, but that isn’t nearly as important as getting away from Fisk.

So you stare right back.

——————

Reason two is a little harder. You’d had it lined up as well, but it hurts to even think.

You have to. If you’re going to get through this, you have to write down all the reason, even if you’d punch anyone else square in the jaw for saying them.

Bucky doesn’t deserve this. You need to pretend he does.

For your own sanity, you need to pretend he does.

2. He can be an asshole.

You don’t make it three second before something rattles in your body, and you add-

But so can you.

——————

“You know,” Barnes drawls behind you, and it’s amazing how bad he can be at shutting up. This is supposed to be a stealth mission. He hasn’t stop talking to you since Sam put you two on a team and then fucked off to go fly around the warehouse. “The spider kid’s told us all about you, doll-“

“Parker?” You hum, and Barnes blinks.

There it is.

“How’d you- No-“

“I know Spider-man’s Peter Parker.” You give Barnes an overly sweet smile, and you’ve been their double agent for a month of back-alley meetings and careful exchanges in noisy rooms, but it hasn’t seemed to stop getting under his skin. “I’ve known for like, five years.”

Barnes shakes his head, as if he doesn’t believe you. Like you just somehow guessed. “But Fisk doesn’t-“

“I didn’t tell Fisk.”

You turn back to the path ahead of you, and you can still feel Barnes’ glower.

“You think you’re fuckin’ smart, kid-“

“Yes, I do.” You throw him another smile over your shoulder, and his glare deepens. “What did Peter tell you about me?”

“That you’re kind of a bitch.” Barnes grunts, and you roll your eyes.

“He’s just still mad I gave him a concussion.” You mutter. “I didn’t mean to-“

“You didn’t mean to give him a fucking concussion-“

“I didn’t know how strong he’d be. It was new, I thought I’d just be breaking his nose-“

Barnes grabs your arm, yanking you back without warning and covering your mouth with a gloved hand, muffling your yelp.

“Be more careful.” He grunts in your ear. “Almost walked right into the open, you’ll get yourself shot.”

If you lean a little further back, your skin will touch his. Maybe he’d be stronger than Parker. Maybe you could hit hard enough to knock a new personality into him.

Because for the past week, Barnes has been a fucking dick. You understand not trusting you. It’s a reasonable conclusion to reach.

But he doesn’t listen. He shoots down all your intel and acts both like you’re a weak little child, and an atomic bomb set to go off any second. You’re neither. You want Fisk dead more than anyone, and you’re in complete control. If you weren’t, you would’ve killed him days ago, and never even fucking blinked.

It’s a testament to that control, that you shove yourself away from him without tapping into Parker’s strength. You could’ve sent him flying out the window, if you wanted. But you’re being diplomatic, and you’re trying to do the goddamn mission, so you don’t.

“Don’t grab me.” You snap, and Barnes scowls.

“I was helping you-“

“Did I ask you to?”

“No.” He narrows his eyes, taking a firm step forward until you’re almost nose to nose. “But if you die, Sam will yell at me. So be more damn careful.”

The staring contest lasts another minute before Sam’s voice crackles in both your ears, and you have to get back to work. By the time they’re fighting some of Fisk’s men—you’ve been, fucking stupidly, sidelined so as not to blow your cover—Barnes has called you incompetent in ten more ways. You’re too loud. Too smug for someone who’s not doing anything. You’re slowing them down, and he’s stuck babysitting you for your shitty intel—shitty intel that got them here, but he seems to be selectively ignoring that—and you’re too willing to kill people and run into fights with no powers.

He’s used that one a lot, after you’d convinced Fisk to give you a vacation and started to crash with Sam. Barnes has muttered countless times that he can’t believe you’re the woman everyone in New York is afraid of.

“Who says I have no powers,” you’d snapped after the third low comment, sprawled out on Sam’s couch and watching TV, and Barnes had rolled his eyes.

“Whenever you’re ready to prove you got some, doll, I’m ready.” He’d raised his brows in a silent challenge, holding your glare. “Until then, get off my couch.”

“It’s Sam’s couch. And I’m watching TV.”

“All you fucking do is watch TV, doll, can’t be good for you-“

“Aw,” you’d shot him another sickly-sweet smile. “The old man is worried about my screen time-“

“You’re hogging it.” He’d grunted, ignoring your teasing, and you’d flipped him off.

“Sam doesn’t have any good books, and I’m not allowed to have a phone. What the fuck else am I supposed to do?”

You’d won the argument. Barnes had circled back to you being a waste of space—and you were, but he didn’t know that—and not actually having any powers, so in your eyes, that meant you won.

Because you do have powers. You’ve been saving it for a good moment. Just to prove your point, you’ll use them in a way that blows his stupid fucking mind, and really makes him feel like a dumbass.

That moment comes when one of Fisk’s men is aiming a gun right at his back, he’s turning a little too slow, and Sam is all the way on the other side of the room.

You’re on the ceiling.

You drop down with the dramatic, fancy landing you’ve been practicing since you got skin-to-skin contact with Parker, and punch the grunt backward into the wall.

There’s a sickening crack sound from the impact, and it rattles over your ribs and skull. You memorize his face, and add it to your tally. Your graveyard. Another piece of you that will never get to be whole or clean.

When you turn back to Barnes, he’s staring at you, a look of borderline amusing confusion on his face.

“You-“ He glances up to the ceiling, and shakes his head. “You just fucking killed that guy.”

Your teeth almost snap in your mouth, and you feel a little bit of bile in your throat.

“Obviously.” You mutter, flexing your fist as you let Parker’s powers go dormant once more. “And it saved your life. You’re welcome.”

Barnes narrows his eyes. “I didn’t say thank you-“

“You should work on that, then.” You snap, storming past him as Sam wraps up the last grunt. “It’s rude.”

——————

Your coffee is finally finished, but it’s more bitter than normal on your tongue.

You think you might just miss Bucky, and it’s having a physical effect on your body.

You need to keep going.

3. He’s bad at using his words.

——————

You jump out of your seat when the book slams down in front of you.

“What the fuck-“

“Go read.” Barnes grunts, dropping down at your side. “My turn with the TV.”

You gape at him, not bothering to hide the slight amusement in your voice. “Your turn- Are you fucking five-“

“No. Read.”

“I-“

“Read.”

You scowl, and whack him on the arm with the book. “Stop interrupting me, Barnes-“

“Stop calling me Barnes,” he snaps your name in a mocking tone, catching your book before it can land on his arm once more, shoving it fully into your hands. “Go read.”

“I-“ You swallow, watching him wearily, hugging the book to your chest without thought. “What?”

His jaw ticks slightly. “Read-“

“No, why don’t you want me to call you Barnes.”

He’s silent for a long second, staring at the black TV screen with an unreadable expression.

“You call Sam his name.” He finally mutters, something bitter in his voice. “And the spider kid Peter. We’re supposed to be a fucking team. Use my name.”

You narrow your eyes. “You never thanked me for saving your life. Teammates thank each other.”

“That’s your thanks, genius.” He taps the book, still not fully looking at you. “Read it.”

He won that conversation. You don’t have a good response to that, so Bucky won. The asshole.

He buys you five more books in the next two weeks. One for every successful mission. And when you end up with a large gash on your leg, he half shoves you down onto the couch and kneels at your feet, patching it up without a word.

You don’t like the silence. It’s too heavy around your throat.

Only half a second later—like he can hear the stutter in your every breath—Bucky breaks it.

“You didn’t need to jump in front of me.”

“You were going to get shot, dummy.” You snap, crossing your arms and leaning back on the couch. “I did you a favor. Say thank you.”

He doesn’t. He won’t. But you know you’ll get another new book tomorrow, and that’s enough.

“Didn’t know you could get hurt.” He still won’t look up from your leg. “Thought I saw you get shot last week and walk it off.”

“I was ready for that.” You mutter, wincing as Bucky presses the rubbing alcohol to your leg. “This- fuck- I got caught off guard. Won’t happen again.”

He grunts, frowning at your leg. “You’re… selectively invulnerable.”

“If I chose right, yeah.”

That gets him to look at you. There’s the usual confusion clouding his eyes, along with… something else. Something deeper and vaster than the ocean, that’s almost jarring to see. Not frightening. Just different. Strange.

“What the fuck are you?”

His tone isn’t hateful. There’s a strange kind of light in it. Like awe.

Not awe.

But like it.

“I’m-“ You swallow, and you haven’t ever really explained it. Once Fisk made you, you just were. Once he figured out what you could do, it was all you did. Nobody asked. They never had to.

Bucky bows his head again, glaring at your leg as he speaks. “You don’t gotta tell me-“

“Shut up. I’m a mimic.”

He looks back up with raised brows, and you take a deep breath before you continue.

“Fisk created me. Partnered with some crazy scientists, saved me out of a home, and made me into his little pet hero. I can mimic anyone’s DNA, if I touch them skin to skin. It’s just- I only use it on superheroes. Otherwise it’s not really useful.”

Bucky glances down at his gloved hands with a small frown, then back to you. “You stick to the ceiling a lot.”

You nod, and shrug. “I’ve touched Parker, if that’s what you’re asking. That’s how I know who he is. I beat him in a fight, unmasked him, and he was-“ You swallow, a knot tightening and grinding in your stomach, and Bucky finishes for you.

“Just a kid.”

“Just a kid.” You echo. “Couldn’t kill him. Never want to kill any of them. But there’s-“

“Not a choice.” He mutters, and the strange thing in his eyes seems clearer. “Bite down on this.”

You blink at him. “Wha-“

Bucky shoves the glove from his flesh hand into your mouth, and starts the first stitch.

The next day, there’s a phone and a book waiting for you in the kitchen.

——————

It takes too long to come up with the next reason. You get lost in thoughts of how you’ve read that same book a dozen times, and you’d caught Bucky reading your annotations with adorable concentration only a few weeks ago.

He always spends more time reading your thoughts than the actual story.

And it had hit you then, too. You can’t think about that, because it’s making this impossible. You can’t think about how Bucky had fallen asleep reading your annotations and looked adorable, or how the phone he gave you is the same one on the table next you right now. How the case on it is the one you bought as he hung over your shoulder, muttering how phone cases were stupid.

You’d made him show you his phone, after he’d said that. The screen had been cracked and shattered, and it had taken a month to get him to buy another.

That can be a list point. You’re back on your game.

You almost write stubborn, but you substitute it for something stronger at the last second.

4. He can be controlling

You stare at it for a long moment, because something is off. Bucky can be controlling. He can man-handle you and order you around, his voice low and smooth and the intensity in his eyes a little dizzying-

“Shit.” You mutter under your breath. You messed up again.

Because you’re right.

But, fuck, it turns you on.

——————

“You need to stop fucking doing this,” Bucky mutters your name, his metal arm holding you in place as he pressed another round of rubbing alcohol over your gut. “One day you’re not gonna get lucky.”

You wince, but give him a weak smile. “I got shot, Buck, I wouldn’t call that lucky-“

“You got shot.” He hisses, scowling up at you. “Because you were fucking reckless.”

“I saved you-“

“That is not your job, kid-“

“Then stop almost getting shot!”

“I-“ Bucky lets out a slow breath from between his teeth, shaking his head slowly. “No. That’s my job. You’re not even supposed to be in the field-“

“But I am.” You snap. “And I’m not just going to let you get hurt-“

“You’re not letting me do anything.” He mutters, setting down the bottle as he moves back to the medkit. “You’re done in the field.”

You gape at him, the words too slow to sink it. Bucky said them too casually. He said them like they were his call to make.

“What the fuck are you talking about-“

“You’re not going out there again.” He grunts. His metal hand is still on your leg. “We’re almost done anyway. You’re best for intel.”

“Int-“ You cut yourself off with a scoff, glaring down at him. “You are not my boss, James-“

“No. I’m not.” His jaw ticks slightly. He still won’t meet your eyes. “But if I see you in the field again, I’m handcuffing you to your bed.”

He says that so easily, and a heat you have to ignore pools in your stomach.

“What the fuck are you talking about.” You hiss, leaning down to try and drag his attention fully to your glare. “I am not going to just sit at home-“

“Yeah.” He grunts, still not looking up. “You are.”

“I told you, you are not in charge of me-“

He snorts. “If I was in charge of you, doll, you’d be on full fucking lockdown.”

“What the hell is that supposed to mean-“

“Don’t worry about it-“

“James Barnes. Fucking look at me.”

He tenses, and drag his eyes to yours as if the action pains him. “What.”

“I am going to keep working.” You hiss. “Because it’s my job. And if you’ve got a problem with that-“

He rolls his eyes. “Obviously I have a fucking problem with it. And I’m deadly serious,” he grunts your name, holding your gaze. “You try and go on another mission, you’re getting cuffed.”

“We’re so fucking close, you asshole, you don’t get to bench me now-“

“That exactly why I’m benching you-“

“Because we’re close? What, you worried I’m gonna flee the moment we wrap this up?”

If you were furious with Bucky, you’d be worried he was going to break his jaw. “No.”

“So it’s not because you don’t trust me?” You sneer, and he shoots you of a look practical shock.

“Of course I fucking trust you-“

“Then why Bucky?! You can’t just fucking bench me and not tell me why! This is my fight too, and if you think fucking handcuffs are going hold me-“

“I won’t cuff you if you listen-“

“I won’t listen if you don’t speak fucking clearly-“

“It’s- fuck- It’s because Fisk is going to know it’s you soon!” He roars, and you freeze. You’ve heard him yell before, but not like this. There’s something hot behind it. Something almost pained. “You know what he’ll do when he’s figures out where you went off to?! What you’ve been doing, that you’ve been working with Me and Sam?!”

“I-“

“I’m not gonna be the one they’re aiming at anymore, doll. And they’re gonna be shooting to kill. And what if I’m not fast enough?!” he squeezes your leg, his lips curling as his eyes dart down to the wound ripping open your stomach. “What if they’re shooting you, and you’re not ready, and I’m too fucking slow?!”

“Bucky-“

“I’ll fucking lose you.” He hisses, and you’re not even sure he knows what he’s saying. “I’m not fucking losing you. I only just goddamn got you, and you are not allowed to bail on me because you’re reckless and stupid.”

He finishes with a long, ragged breath, and you blink at him. Your skin is hot, mouth dry, and it’s as if you’ve been wandering in the desert for a million years.

You haven’t been, though.

But nobody’s ever looked at you like that before. With that fervorish awe, and unyielding fury like a tidal wave. Your hands feel clean. For the first time—maybe in years, maybe in your life—you don’t feel any small amounts of blood or grime under your fingernails. It’s that ocean, you think. The one trapped inside of Bucky, that’s slowly been flooding your senses over the past few months. A tide rising with every traded joke and shared book, every mission where he’d trusted you more and more, every story you’d told each other about the heavier, tainted parts of your shadows.

You move to touch his face without thinking, and his skin is soft. The stubble of his beard is almost grounding—a small, rough reminder that he’s changed since you met him, even if the only obvious part of that is the length of his beard—and he’s looking at you like he’s afraid. Parted lips and blown out eyes as his hand catches your against his face, holding it there as he stares at you with that same fucking awe.

“I’m not losing you.” He repeats the word like they’re a prayer. An oath. “I’m not fucking losing you.”

——————

You need to take a ten-minute break.

He hadn’t kissed you then. Fucking Sam had interrupted, because you’d been closer to the end than you thought you were.

Fisk had fallen the next week. He’d never know it was you until he was sitting in a cell, and you spoke to him through the bars.

That had been a… long and confusing day. Bucky had been waiting the entire time. He’d almost killed you the moment you walked out of the cell.

6. He’s bad at reading situations

——————

Your eyes sting.

You don’t know why you’d cried. Fisk had made your life hell. He’d ruined it, and you’d won, and you’d still cried for him.

“You were like a daughter to me,” he’d hummed your name, nothing but sheer fucking disappointment in his eyes. Like you’d failed him. Like he was more hurt for you than angred at your betrayal. “You know, I always loved you for exactly what you were. Nothing more, nothing less.”

You’d only swallowed, any sharp words dying in your throat as Fisk continued.

“Do you think the Winter Soldier will like the reminder? Of who he was before?” Fisk had shaken his head, and sighed as if he’d been mourning you. You’d almost thrown up on the tile floors. “No, not as you are. And you don’t change, my girl. You’re not meant for… soft things. You could’ve ruled the world and now… You’ll be nothing. Alone.”

You’d found the words to cut back, somehow, but you don’t remember them. You only remember the knot in your stomach and bile in your throat.

You hope you’d held the tears until you were hunched over the toilet. You’d only just managed the vomit.

And you hadn’t reacted, when Bucky had come up behind you. You want to think it was because you were off your game.

It was probably just because it was Bucky.

He’d held your hair from your face. He’d rubbed your back with the metal hand, and it had eased your breathing too fast. And when you’d finally sat up, he’d pulled you into his chest like you were something delicate.

Fisk’s words are too loud in your head. Your voice, when you finally speak, is too soft.

“This is the women’s room, Buck.” You mumble, wiping your eyes with the back of your hand. “Don’t think you’re supposed to be in here.”

“’S fine.” He shrugs, the movement shifting you slightly against him, settling you more comfortably in his hold. “You’re here. This is where I’ll be until someone moves me.”

You hum, pressing your face to his shoulder, as if you can’t fucking help it. “Miss me that much?”

He grunts, and you could swear you feel him nod. “Needed to talk to you.”

“Now?”

“Yeah.”

There’s a long pause, and when you lean back, he’s staring again.

You think he’s going to rip you apart. At least then, maybe, he’ll keep some of you in his pocket. A little bit, to always be held like this.

“Bucky-“

“Go on a date with me.”

——————

Number seven is easy. Number seven flows right off of six, because you’d said yes like you were only breathing—even as all the air in the world became too thin, and you almost passed out from the branding focus of Bucky’s gaze—and Bucky had grinned like he’d never seen the sun before, and now it was shining just for him.

It had been cute.

Too many parts of Bucky could be cute.

7. He can be unbelievably sweet at the worst possible times.

——————

You’re going to strangle him.

The date was perfect. Horribly perfect. Impossibly perfect. Fairy tale, romance movie, only-exists for valentine’s day propaganda perfect.

Bucky bought you flowers. A big bouquet of yellow roses, because he knows how much you both hate red. You went to a fancy restaurant, and walked in the park for five hours just holding hands like idiots, until he was spinning you around and swaying you in his arms, and you were giggling.

You don’t giggle. You didn’t even know you could make that sound.

But Bucky had guided you through a romantic, smooth dance—his body warm around yours, nothing to see you in the dark but his bright eyes and the slowly clouding night sky—and you’d giggled. He’d smelled like pine aftershave, a deep, slightly spicy cologne, and something earthier that was just Bucky, and you’d giggled.

You’d been vulnerable. In public, in the dark, in the open. But Bucky had been there, and there had been a secure feeling over your skin like the sky could split open with fire and hail, and you’d be alright. Bucky was there, so you’d always be alright.

And you’d giggled.

It was dangerous. It was dangerous when he’d kissed your cheek after handing you the flowers, standing in your doorway as if you didn’t fucking live together. It was dangerous when he held your car door open, and when he helped you into the seat at the restaurant. When he took your hand like touching you was the most natural thing in the world, and started to dance as if that had been what he’d been planning to do the whole time.

Given the small smirk on his lips when the first giggle had escaped you, it might have been.

But the most dangerous thing had been when it had started to rain, and he’d picked you up. Hauled you into his arms without a grunt and run you into an all-night coffee shop, keeping his body folded over yours as if you’d melt into a puddle if he didn’t shield you from the world.

You’d found a little table, ordered some drinks, and lost track of time.

He was so handsome, with messy, wet hair and eyes bluer than the rain could ever hope to be. He was warmer than the heater of the coffee shop.

You knew he’d taste better than the small scone he’d bought you, too.

And then again, like he could read your fucking mind, he’d shaken his head.

“We’re not doing that tonight,” he’d drawled your name, grinning at you from across the table, and you’d blinked at him.

“I-“

“We will.” He’d shrugged. “Trust me on that, I’ve- Shit- We will. But not tonight.”

You blinked at him, shaking your head slowly. “Bucky-“

“We’re not fucking, doll.”

And now you were here. About to kill him.

“I never said we were-“

“Didn’t have to.” He shoots you a wink, bumping your knee with his under the table. “Saw it all over your face, baby.”

“You-“ You swallow, and he can’t fucking do that. It’s not fair. He can’t say no sex tonight and then wink and call you baby. That’s not fair. “I- Why?”

Your words are almost a whine, and Bucky’s grin widens. It’s too adorable, too gleeful and affectionate, and his knuckles are brushing against your hand and he smells so good-

“I want that to be its own thing. This is our first date. We’re doing number two because this was fun and we,” he gestures between your bodies, watching you carefully. “Work. Not cause I fuck you until you can’t walk.”

He finishes with a shrug, and even though he’s still grinning—he knows exactly what those last words did you to, the asshole—there’s something firmer in his voice that tells you he’s being serious.

That’s annoying. And sweet. So fucking sweet.

So you let it go.

“Aw.” You give him a teasing smile, pressing your thighs together to relieve just a little bit of your need from his attention. “You think we work?”

“Yeah. I do.” He’s staring at you again. You might have started something you can’t finish. “Do you?”

You swallow, and lying feels pointless. You’re trapped. He’s handsome and amazing and he’s not going to fuck you, but he promised he would later, and you’re trapped.

“Yeah.” You whisper, and you don’t know when you started holding his hand again. You don’t really care to let go. “I do.”

——————

This isn’t working anymore.

All you can think about is how that might have been the moment. The one where something sparked and grew and razed through your body, reshaping your organs and tissue to all mold a little better for Bucky. He’d said I do like it was the easiest thing in the world. Less of an answer to a question and more of a statement.

There had been a finality to it. Like that was all he’d ever have to know again. You were all he’d ever have to know.

He’d made promises and kept them. You’d remained warm every time it had stormed, and through the following winter, and it was because that had been the moment and this strategy isn’t fucking working.

Bucky had told you later, and now that later is all you can think about. Bucky is all you can think about, and every single thing you cast to mar the picture of him in your head just makes it stronger. Makes every memory sharper, every thought of Bucky in your head more beautiful.

8. He’s perfect. It’s impossible.

——————

You don’t know exactly how you got here. There were flowers involved, and a dark theatre, and Bucky had whispered something low in your ear that made you gape at him in the dark, and then he’d kept his hand on your thigh the rest of the night, and the whole world had become unbearable hot.

It’s only a haze now. A big, warm haze that’s cooled by one metal hand on your hip as you burn and burn and burn, and Bucky hasn’t even done anything yet. But he’s been teasing you. Keeping you pinned cruelly under his body for what feels like hours, kissing and sucking over your neck and slotting his knee between your thighs, letting you grind against him and pull at his hair until you were whining for more, you need more-

“Think you can take more, baby?” He murmurs against your lips, and you don’t know if he’s doing the anticipating thing again, or just teasing you a little more. “You even know what you want?”

He uses your responding moan to push his tongue down your throat, kissing you heavy and long and deep.

And Bucky’s kissed you before. A lot. There had been one, world-making kiss that had grown into an addiction, becoming kisses in the corner of every room and against the wall of every hallway, into the cushions of the couch until Sam groaned and walked away—promising to never come over for movie night again—and right up to every edge, but never further.

Bucky seems to be under the impression that he needs to be a gentleman. That there needs to be a right moment to stop pulling away with heavy, shallow breaths, swollen lips, and flushed faces. That he needs written permission to go further.

You’d given him that permission this morning. You’d slid him a small paper over the counter, and when he’d read it, he’d raised his brows at you in amusement.

“This says fuck me.”

“Yep.” You’d hummed, holding his gaze as you’d taken a large bite of your banana.

It had been a warfare strategy. It had seemed to work then—his eyes had darkened, nostrils flaring and fist closing around the paper as he stared at you—but you know it’s worked now.

Because this kiss is different. It’s another, newer tidal wave that’s all thirst. Desire.

Need.

Bucky’s holding himself by a tether. You can feel it when you bite his lower lip, he groans down your throat, and his hips jerk forward.

“You’re- Shit-“ Bucky grunts as you suck a small, dark mark on his jaw. “You gotta be sure, doll, I can’t-“

“I’m sure.” You whisper, leaning back to hold his gaze. He looks almost nervous, and it makes your brow furrow slightly. “Buck, are you-“

He crashes his mouth back down to yours, his metal hand playing with the hem of your skirt.

“Don’t ask stupid questions.” He mutters, pulling back to scan over you once more. “I’m- If we’re doing this, I’ve gotta be- I need to-“

“I know.”

He blinks at you. “You do? How- Sam.”

You giggle slightly at Bucky’s violent glower—you’ve been doing that a frightening amount lately—and raise a hand to trace over his jaw.

“He says he- uh- Heard you. Once. Months ago. And it’s okay.”

He shakes his head, still watching you with that caution. “I- It doesn’t have to be, doll, I know that your past isn’t all sunshine and daises and bein’ in control either-“

“I- I’ve had to do most everything for myself. For survival.” You whisper, tracing your thumb over his cheek. “I’ve never had- I trust you. And with what Sam mentioned-“

“Gonna fuckin’ kill him-“

“I don’t think it’s as dramatic as you think.” You finish, ignoring Bucky’s muttered threat.

His jaw ticks slightly, his words suddenly so low you can barely hear them. “If it’s too much, you gotta tell me-“

“I can take it.”

Bucky sighs your name, and you shove his chest. Not hard. Enough to move him. Jolt him. Make him look at you with wide, shocked eyes.

“You-“

“I can take it, Buck.” You grin at him, raising your brows pointedly. “I’ve got you.”

His eyes widen as he understands—you’ve got him, his strength and durability mirrored in your body—and there’s a slight shift in the air. It’s hot. Everything is suddenly so hot under Bucky’s attention, expect for the cold, metal hand, trailing under your skirt and cupping you over right over your aching pussy.

“Fuck, you’re wet, doll.” The awe has creeped from Bucky’s eyes to his voice. You can only grind against his fingers teasing over your slit, and moan when a metal thumb starts to rub firm, rough circles over your clit. “And no panties on? All fuckin’ night, just waitin’ for me?”

“Yes,” you moan, our hips jolting when he pinches your clit lightly, a high whine leaving your throat. “Bucky-“

“That’s my name.” He mutters, resting those two fingers right against your pussy, his eyes never leaving yours. “If you’re already so wet, I wonder what’ll happen when I do this?”

With that last word, Bucky slams the metal fingers into your cunt, and starts to finger fuck you like it’s a mission. It’s so fast. Metal whirring in your ear as the pace becomes impossible and mind-numbing, hitting you so fucking deep, almost massaging and taunting at the sensitive spot, and it’s only just started but you’re already going to explode-

“Bucky-“ You moan out his name, trying to somehow meet every thrust of his fingers with your hips, but only managing to grind your clit against his wrist and sending your brain into a dizzying blur of pleasure. “God, I- Close, Bucky, so close-“

“Hold it.” He grunts, not letting up pace, and you almost whimper at the idea. “Need you to hold it for me, baby, can you do that?”

You can’t.

You nod anyway, because Bucky’s still here, still holding you and touching you and looking at you, so you have to try. For Bucky, you need to try.

“Good girl.” He mutters, and you clench around him with a squeak. “Oh, you like that? Like me talkin’, tellin’ you how good your doing-“

“Oh- Fuck-“ You gasp, your back arching off the bed as he somehow hits deeper. “Please, I- God-“

He hums, dropping his weight slightly to keep you pinned to the bed. “Say my name, doll.”

“Buck-“

“No.” His voice is slightly softer, and he leans down to hover his lips right over yours. “Other one.”

“I-“ You take shallow breathes, each one rounded with another moan as you search Bucky’s face for the answer, and his fingers never slow their movements. “Please-“

“C’mon, baby, you’ve got it-“

“James!” You half scream it, writhing under him in desperation for release, and start to repeat it like a prayer as his eyes shine in approval, and his cock twitches against your thigh. “James- James please, I- I need it- Need you-“

He swallows your words with another deep kiss, squeezing your hip with his free hand as he mutters against your lips.

“There you go, babydoll.” He smirks at your whimper, his eyes trained on yours as you give him another, pleading look and whisper of his name. “Cum for me.”

The sound that leaves you is undignified, needy and loud and made of slurred curses and shouts of James. But you can see the stars, and feel them bursting through your body, and it’s all just good.

When you come down, Bucky’s brushing your hair from your eyes, looking down at you with that same wide awe everywhere over his handsome features.

“Was that good?”

You hum, still panting heavily, and he raises his brows.

“More?”

You nod a little stupidly, and Bucky’s grin splits his face.

“Already so fucked out you can’t speak? Haven’t even pulled out my cock yet-“

You moan into his mouth at just the word. “Bucky, please-“

“Please what?” He pulls back entirely, and chuckles when you slam your hand into his chest with a glare.

“Hey-“

“You gotta tell me what you want, babydoll, and I’ll get it for you. But,” he raises his brows, catching your hand when you try to shove him once more and pinning it over your head. “I’m not a mind reader. Tell me.”

You think that’s a lie. You think he can read your mind, and he’s just being mean.

But God, it’s so fucking hot. His shirt is gone—you don’t know when that happened, but you’re not complaining—and he’s looking at you like you’re art, laid out for him to see and touch and have, so you’ll play along. If it will make him finally fuck you, you’ll do whatever he asks.

“I want your cock.” You whisper, holding his gaze. “Want you to fuck me, and I’m clean and on the pill, so I want you to cum inside of me, then leave it there. Wanna feel you tomorrow, James, please.”,

Bucky’s throat bobs slightly, his voice becomes barely a growl.

“Jesus Christ.”

He seems to be done talking after that.

Your hand stay pinned over your head as he rips off your shirt, then his own boxers. There’s a half-grumble of buying you another bra tomorrow, but it’s all you get before he’s ripping that off as well.

When he lines himself up at your entrance, he pauses, giving you one last chance to shove him away.

You tangle your hand in his hair and shove his lips to yours without hesitation, moaning his name into his mouth, and it’s enough.

Bucky slams himself into you with one thrust, diving his mouth to suck and lick at your nipples as you gasp, adjusting to the feeling of him inside of you.

It’s perfect. Big and thick and full, you feel so full, and you’re going to fly out of your skin if he keeps flicking his tongue over your nipple like, throbbing inside of you but not moving-

He can definitely read your mind. Before you can even moan a plea, Bucky starts to drill into you without warning, and any noise turn into more of those loud, desperate pleas.

It rough. Bed creaking and skin slapping, and he keeps tossing you around like no angle is deep enough, flipping you over to fuck you from behind so his balls are slapping against your clit and he’s kissing up your spine, before he’s hauling you up to his chest, wrapping his arm around your stomach to hold you still as he drills up into your cunt, and biting and marking along your throat and jaw. You throw your head back on his shoulder, and he captures your lips in a long, searing kiss, rolling a nipple between his fingers.

Then you’re back on your stomach, with his weight completely covering you and his grunts right in your ear, sending shivers up your spine.

He pauses only for a second there, thrusts slowing as he grabs at your hips, and before you can ask him if he’s okay, if it’s too much or—worse—not enough, you’re moving again.

Bucky rolls over, tossing you up onto his lap so you’re grinding down onto his cock, and this is it. You can see it in his hooded, satisfied expression as he watches you bounce above you, his flesh hand wrapping around your throat the metal moves to your clit, rubbing small, furious circles as he groans your name.

Your nails dig into his shoulders, your every word choked as he pounds up into your fluttering, aching pussy. “I- James-“

He grunts, pressing harder as his dick hits that deep, sensitive spot inside of you. “Come on, babydoll, gotta gimme one more-“

This orgasm washes over you like a wave. Deep, easy pleasure that makes everything glow, lingering in your body long after Bucky gives one last, jagged thrust up into your pussy, cumming with a roar of your name.

You both stare at each other for a long second as Bucky releases your throat, his fingers tracing over the marks left by his grip with a furrowed brow, and you smile at him.

His release is dripping down your thighs as you lean in to press a soft kiss to his lips.

It’s somehow not enough, and still more than you could ever ask for.

And your smile is a little cock drunk and there’s light bubble up your throat, but you don’t care.

So you giggle. Airy and blissful as Bucky rolls your bodies over so he’s on top once more, and you bury your face in his shoulder.

He rises over you on his forearm, raising his brows as you smile up at him. “Somethin’ funny?”

You nod, your giggles almost pathetic. You don’t really mind. “Told you I could take it.”

He sighs, but the grin on his face matches yours.

Wide. Stupid.

Happy.

“Yeah.” Bucky mutters, tracing slow fingers only your cheekbone, and the awe seems to be a permanent addition to his voice. “You did.”

——————

When you get back to your table with ice water, people are staring at you. Whispering.

It’s not in your head. You know the difference between paranoia and caution, and this is the latter.

You scan over for an easy target, and land on a skittish looking man with large arms and a gym bag. When you stop at his table, he looks like he’s going to pass out.

“What’s your name.” You keep your voice cool and even, and he swallows.

“Mike.”

“Awesome. Can I please have your phone, Mike?”

He nods, unlocks it before passing it to your hands, and you give him a sweet smile before you scan over his screen, and let out a long sigh.

Sam abused his power. You’ve been declared a missing enhanced. The city hasn’t been barricaded, but everyone in New York knows to be looking for you, and expect Captain America upon response.

You pass Mike his phone back with another grimacing smile, and stalk back to your table and notebook.

9. He can be really fucking dramatic.

——————

You don’t know how Bucky puts up with you. He’s clean. Neat. Does all his dishes and folds his laundry, vacuums the floors and straightens every picture when he fucks you a little too hard against the wall.

You’re… not.

Taking care of yourself has never been important. Never been allowed. Fisk had men who cleaned up after you, because your priority was walk around and be feared. Be the untouchable princess.

Untouchable princesses don’t clean up. Once, at the beginning, you’d tried to help the crew after a particularly messy job.

Fisk had been furious. You’d gotten blood on his favorite toy.

You’d stopped trying to clean up after that,

But Bucky never gets angry about it. He’ll wipe your face when you get sauce on your cheek, change your sheets—even though you haven’t slept in your own bed for months—every week, and do your laundry, all while never asking for anything in return.

This is another night where you don’t understand him. He made your favorite food, even though he had the long day. He’s not meeting your eyes again, but you’ve learned that he only does that when he cares. When there are things inside of him he can’t work out how to say, so he’ll keep his gaze averted like he’s trying to shield himself from being seen.

He isn’t aware he does that. You only know because you know him. Because he sits across from you like this every night, and wakes up next to you every single morning, and presses his brow to yours—keeping his eyes closed, but his hands on your face delicate—every single day. He’s with you all the time, even when he’s across the city, so you know him and you-

“Move in with me.”

You blink at him in the low light of your shitty dining room. It’s all plastic table and fold-out chairs, because neither of you are good at having nice things and keeping them.

He might be the nicest thing you’ve ever had.

You don’t understand what the fuck he’s talking about.

“What?”

“I- We should move in.” He pokes his plate, frowning at it like he can will it to understand, and explain to you properly. “Together. You and me.”

“Buck, we already live together-“

“In a shit apartment Sam found us.” He grumbles. “In two separate bedrooms. With plastic furniture and a dead plant.”

You sigh. “I told you I’m not good at plants when you got it. I wanted a cat, but-“

“Our lease doesn’t allow it.” Bucky shoots you a pointed look, leaning further over the table. “If we moved in together, I’d get you that cat. I’d get you whatever you wanted.”

“Bucky-“

“Fresh start.” He grunts your name, and you swallow. This is a little stronger than the awe gaze. This is borderline hope, and it’s so rare on his handsome face, and he has you folding for him in a second, but he keeps going anyway. “You and me. We’ll get a nicer couch without any blood on it, and eat off plates that aren’t paper, and- We can get the cat, or two cats- fuck, twenty cats-“

A small smile pulls at the corners of your mouth. “Twenty is a lot, darling-“

“Then one. One is good.” He has the solemn, focused gaze and tone he uses when he’s planning a mission. He’d stood up and crossed his arms. This is serious. “No more plants. I can- Sam will help me build all he furniture, I’ll get you a desktop, and I can have the smaller one, cause you always get annoyed when I break it-“

“It’s called a laptop.” You offer, keeping your voice softer than you’ve ever been capable of with anyone else. “And I don’t get annoyed-“

“Yes, you do. ’S fine, I deserve it-“

“No, you don’t-“

“That’s not the point, doll-“

“It’s important to me.” You snap, and that gets him to stop. “You’re important to me, and I don’t get annoyed. It’s not your fault your bags are always getting smashed-“

He scowls. “I’m the one who smashes them.”

“Because other people are fucking idiots, and you’re good at your job. You don’t deserve me being annoyed, and I’m not, because you’re-“ You swallow, words you don’t fully understand yet getting caught on the edge of your tongue. “You’re important to me, Buck. You’re a good man. You deserve good things.”

He blinks at you, and the hope is almost a tangible, touchable thing on his face. “Move in with me.”

“You already asked me that-“

“Please.” He mutters, and suddenly he’s on his knees before you, his arms around your waist as he stares up at you. “Wherever you want. It’ll be ours, and I’ll keep it clean if you make it beautiful.”

“Bucky-“

“You- fuck-“ He drops his brow to your lap, and you’re trying to tell him yes, but he seems to be trapped in his own head. All you can do is run your fingers through his hair and let him ride it out. “You make everything so beautiful, you just- You- Please. I’ll never ask ya’ for anything again. Move in with me.”

“Okay.”

He blinks up at you with wide eyes. “I- That’s it? Just like that?”

“Yeah.” You smile at him, and it’s hurting your cheeks, but it’s the best pain you’ve ever felt. “You gonna let me up now?”

He nods slowly, but pauses before he stands, and throws you over his shoulder without warning.

“Bucky-“

“C’mon,” He start to move towards his bedroom, ignoring your squirming. “You’re- Got plans for you, babydoll.”

“We have all night, you dramatic asshole-“

“You love it.” He mutters with a squeeze of your thigh, and you have to stop pounding on his back to moan. “And if it were up to me, we’d never stop doin’ this. Never gonna waste one fucking second with you. Ever.”

——————

He’ll be here soon. Someone will have had the balls to report where you were, Bucky will burst through the doors, and you’ll have to know that this didn’t work. That you probably drove him insane and beat your heart to sinew, only to come out of this knowing that you failed.

You have your answer, and it’s the one that’s terrifying. The floor could open into a trench, and the sky could catch fire, but that would be easier.

This is new. This is dangerous and frightening and new, and there’s nothing you can do about it, because you failed. There are no paths forward that you know how to follow, no corners of the world you can hide where you wouldn’t find yourself crawling back to Bucky.

And he’d meet you halfway, because he’d be looking for you, and then he’d pull you into his arms you’d be safe.

Safe and cared for and clean, and awfully, greatly in love.

10. You love him, and that’s not fair.

——————

He sleeps peacefully now. At your side, on the memory foam mattress you made him pick out, wrapped around you like he’s trying to pull you into his body. The sheets are tangled and smell a little like sweat and cum, but nobody seems to mind. Even Alpine has settled at the foot of the bed, on Bucky’s side, because she likes him better.

Of course she likes him better. You picked her because she has the exact same blue eyes as he does, and you feed her, but she likes him more because he’s Bucky.

And this suits him, far more than you think it could ever suit you.

Because this is what he would’ve been. If Bucky had never fallen off that train, he’d have simply been this.

Happy.

Peaceful in the soft, golden-white light of the morning, holding a perfect, faceless woman. She’d clean up after him, and make him food that didn’t taste like ash. He’d never have the nightmares that still sometimes rock him now, but he’d have worse nights—he’d still been a solider, still fought a war—and she’d only give him comfort. Never demand it in return, nights later when she woke up screaming.

And she’d have less opinions, and never make him worried because she kept getting shot, and she’d giggle all the time. Not just when he pried it out of her with dancing and fucking.

She would’ve been easy. She wouldn’t have made him read with her, and she would’ve let him get twenty cats.

You hate her more than anything.

But it would’ve been what Bucky deserves. Has always deserved.

The exact same one you don’t.

You never would’ve been here. Fisk found you in the dirt, and you hadn’t been a lovely, blooming beam of sunlight before he turned you into a weapon. Bucky had earned all his sneers and snarks and scowls.

You’re just like this.

And you somehow have him, in a way you can’t lose. Won’t lose. You’d do anything for Bucky, you’d kill and maim and scratch and scream and rip yourself to fucking pieces just for him, before stitching yourself back together with your heartstrings, because they’d still be beating in a sound like his name, because you-

No.

Oh no.

That can’t be right. You don’t- you’ve never had that. That’s too good.

You don’t deserve that.

You’ll break it.

——————

You wait outside for him. Bouncing on your feet as people shoot you odd looks in passing. You expect sirens. Being turned over and checked from every angle, because this had been a really stupid thing to do when you were you. A problem. An asset until you flipped. An enemy so easily, and an insufferable ally to have.

Bucky still puts up with you. But you think he knows you’d never flip on him. He trusts that the same instinct that made you run from Fisk is the one that will always send you back to him.

It’s been nine hours, and you miss him like you’re drowning. Like you can see the sun, right above the surface, but you can’t remember how to go up.

You can only drift, and wait for blaring red lights that will carry you home.

They never come. And when you feel a tap on your shoulder you don’t flinch, because you know that tap anywhere. The pressure and shape of the finger, the exact placement near the cartilage, always leaving a slight brand of his touch.

“What’re you doing, baby.” Bucky mutters, and you let out a long breath, turning to give him a weak smile.

He’s staring again.

You love it when he does that.

“Hi,” You whisper, and he drops his brow to yours for a long second, right before pulling you right into his chest without a second of hesitation.

You’d thought he’d be angrier. You’re a little sick of being wrong.

“Why-“ He takes a heavy breath, squeezing you a little tighter. “You wouldn’t pick up the phone.”

“I turned it off.” You mumble. You don’t think you can stand to lie to him like this. You’ve already done enough. “I- Can we go inside, please?”

Bucky leans back with a tight frown, scanning over you once more. “Did something-“

“I’m okay.” You duck your head back into his chest, and you understand why he never meets your eyes in moments like this. It’s far easier. “I promise. I just, this will be easier if we sit down, please.”

You can feel him tense against your body, but he guides you inside regardless. Right back to the table you’d been at before, even if he doesn’t know that.

People might be staring.

You don’t really care. You don’t have the energy for it. Everything has to go into this. Into telling him before it’s too late, and you either lose him or, worse, he stays. He keeps tolerating you, not knowing that you’d grow a forest on the moon if he asked—just to hide somewhere safe and quiet, together—and turn the sun into something portable for his back pocket, just so he’d never have to fear ice again.

Bucky says your name slowly, glancing around the shop. “Is this where we had our first-“

“Yeah.” You fumble with your bag, your hands already shaking slightly, and Bucky notices.

Of course he does.

Perfect fucking asshole.

“Are you sure you’re okay, cause I can make Sam call 911 again-“

“Don’t make Sam call 911.” The paper is crumpled, and ripped at the corners. It will have to do. “I’m okay. I- I’m going to be okay.”

That last one is mostly for yourself—no matter how fast Bucky leaves, no matter how much your heart screams, you’ll be okay—but he still hears it, and his frown deepens.

He grunts your name, leaning forward in his seat, and you shake your head.

“Just- take this.“ You slide the paper across the table, watching sleek, black fingers rest on the edge, but not tug it further. “Please.”

There’s a moment of hesitation, but he listens. You look up just in time to see him scanning over your words, and the lump in your throat might choke you.

At least it will be over quicker.

“What is-“ He cuts himself off, and you can’t look away. It’s worse than a car crash. It’s a missile, hurdled straight for your head as you’re rooted in place, bracing for the impact but knowing it will tear you apart all the same.

You know the moment he reaches the last point. His eyes widen, and flick up to you in disbelief.

He reads it three more times before he sets down the paper, and maybe the lump in your throat is your heart. Maybe it’s trying to beat out of your body and run in the gutters, before it can be broken and shattered and-

“You-“ Bucky places the paper flat on the table, and points to that like. “Is that- You mean it?”

You nod weakly, still starting at his finger on the paper—it might be one of the last part of him you get to see, and you’re trying to memorize it—and Bucky clears his throat.

“Can you look at me?”

It takes a second. Ragged, slow breaths and Bucky’s knee, bumping yours under the table.

But you do.

And he’s still so beautiful.

You can see the awe in his eyes. It shouldn’t be there. It doesn’t- not now-

“I love you, too.” He says, and it’s more powerful than the missile. It’s an atomic bomb. “You’re- It’s the only thing I’ve really known, since I got back. You’re the only thing I’ve known-“

The world is starting to sting and blur. Your heart is trying to claw out of your throat. “Bucky-“

He shakes his head, pushing on. “Listen to me, doll, for once in your damn life. I love you. No one but me talking, telling no one but you, I love you. I have been to fucking hell and back, I’d do it all again, every damn time, if there was even a chance it would get me here.”

“That’s- That doesn’t make any sense-“

“Course it does.” He shrugs. “I’m not the me that loves you if I don’t fall off that train and end up in the future.”

“It’s not the future-“

“It’s the future to me-“

“James, we are not having this argument again. It’s not-“

“Is to me.”

There’s that rare, small grin he saves only for you. This is cruel.

“You- I’m not worth hell.” You whisper, and you’re holding his hand. You don’t know when that happened. You’re not strong enough to pull away.

“Yeah, you are.”

“Bucky, I’m being-“

“I know you’re being serious, doll. So am I. And I know I’m,” he taps the paper, giving you a pointed look. “Bad at using my words-“

You swallow. “I’m sorry, I-“

"You’re not wrong.” He mutters, still all but trapping his gaze on yours. “But I got words for this, baby. I love you. Hell and back.”

“Bucky, you don’t-“

“What, love you?” He raises his brows. “You somehow miss that part of my shitty ass speech-“

“It wasn’t shitty-“

“Kinda shitty. Didn’t seem to get through to you.”

“I-“

“Just- Listen.” He leans forward, still holding your gaze. “Would you do it again?”

“Do-“

“Would you walk through your hell, Fisk and the scientist, Parker and that asshole with the horns that made you blind for a week, Sam and me and all the court trials, if you thought we’d end up back here, at this horrible fucking coffee shop, one more time?”

“Yes.”

It’s not a question. You’d do everything, every time, the exact same way, if it meant you’d maybe get Bucky one more time.

And that’s mirrored on his face. Smug, quiet satisfaction as he grins at you, and shrugs.

“There it is.”

You return his smile because it’s easy. You keep holding his hand because he’s not letting go, so you’ll never even bother to try.

You echo his words because he’s right. Maybe the only right thing in the whole universe, right across the table, touching you, and all yours.

“There it is.”

End Note: Love throwing in a bunch of tiny easter eggs for purely my own entertainment. Also love throwing a little plot relevant smut in there, as a treat.

If you like this story, please reblog, share, or leave a comment! <3

Taglist (Fill out this form to be added!)

@globetrotter28 @lordofthunderthr @Youdontknowe @panicking-outside-the-disco @ambiguous-avery

@generalmoonpolice @foxyjwls007 @ilovedeanwinchester4 @tiana-kh @woaheasytig3r

@winchester-whiskey @jsudsgf @deans-yn @jofinka @megara0224

@funkenniffler @disappearintofanfiction @solsborg @sheneedsjesus @bonkydarnes

@whimsicalcherry @charliethemanticore @cats-chaotic-mind @forzalando @roseblue373

@sleepysongbirdsings @angrydragon90 @dumbwhorestuff @biodegradable-glitter-fest @idontwannabehere78

@miss-marmalade @foolinthera1n

#godmadeaterribleerror#bucky barnes#bucky x reader#bucky x you#bucky fanfic#bucky barns x reader#bucky barns fanfiction#bucky barns x y/n#bucky x female reader#bucky barnes smut#x reader#shameless smut#smut#fluff#angst#reader insert#romance#p in v sex#fanfiction#fanfic#female reader#x you#x you smut#no use of y/n#list making#sebastian stan#sebastian stan characters

883 notes

·

View notes

Text

The Night Before the Tribute In Light

September 10, 2003

I.

One month ago today, this long-forgotten photo suddenly popped up in the photo app on my laptop. I took this photo with my Sanyo clamshell phone on September 10, 2003, 21 years ago tonight, from Hudson River Park in Manhattan.

Don't ask me how it survived all these years or where it's been stored all this time or how in the world it could have found its way to me from the long-dead storage servers of a long-defunct cell phone carrier. We're in the penumbra of The Anniversary, and time is out of joint.

I had been back in New York for about a month (after getting violently run out of the place I was staying by a fellow who is now one of my closest friends), homeless and living in that roach-infested HIV crack-house shelter at 96th and Broadway that I describe in "The One Decent Thing I Ever Did" (it’s archived on this blog), and you can imagine my state of head and spirit at this moment, the night before the 2nd anniversary of the terror attacks on the World Trade Center that drove me from my home in Lower Manhattan, four blocks east of the site.

I was sitting on a bench in Hudson River Park on the West Side of Manhattan, somewhere near Houston Street, maybe ten or fifteen blocks north of World Trade. I hadn't noticed these beams of light as I walked, and I think they might have just been activated while I was sitting there. As I recall, it was a full moon in Virgo, and I was positioned just right to snap this shot. I had *no* idea what this was all about, as I recall, but I thought the image was so striking and affecting that I wanted to capture it.

As it turns out, this was the tech run-through for the first September 11th installation of the “Tribute In Light”. Here’s Google’s AI summary of this remarkable memorial:

So there I was, just two years after the blast, stunned by this sudden, mysterious apparition rising from just south of what was still a giant, messy hole in the ground. I was still not fully myself at that time and would not regain my full memory or sense of who I was until the following January (therein lies a tale!), and as I recall I was just numbly stunned, not knowing what to make of it.

As I write, I’m getting the physical sense memory of that moment: the dog in me (my medulla oblongata speaking) feels his hackles rise, it’s not what I expect to see filling the hole in the sky, is it another attack? Do I bark at it, sound an alarm, run towards it, away from it, why is there light there, is this some unholy ruse, another trick being played on me from that big smoky hole where nothing but poison has spilled out for the longest time?

My phone rang. It was a fellow that I had met and hung out with in San Francisco while I was stranded there, and I was stunned to hear from him, especially at that moment. “Hi Dave… well, right now I’m on the riverfront looking at the damnedest thing… [I just wanted to make sure you were ok] hey, thanks for checking in… yeah, take care bud.” I closed the phone and started walking south along the riverfront, toward the light beams.

When I got there, I saw the massive banks of klieg lights assembled in their arrays, a strange and unfamiliar (unwelcome) echo of the shapes and the placement and the footprints of the place I loved so well.

The faces of the artists who surrounded the lights were intense, focused, sober. I still didn’t quite know what was going on, but there was profound reverence in the air, on those faces, at that place, as the beams of pure white light soared upwards, past the point of naked-eye discernment, unending, likely petering out tens of thousands of feet off that spoiled piece of ground, perhaps piercing the ionosphere, did they get clearance from the Federal Aviation Administration for this? Are pilots being disoriented by these columns at 45,000 feet? Do they touch the feet of God?

II.

And I kept walking south, my back to the light,

Down to the oldest part of the civilized island,

Past the Battery, the bronze bull, the buttonwood tree,

The Port of New York dead ahead,

The Staten Island Ferry terminal, ramshackle, ancient,

Entry restricted by terror tape and armed sentinels

No two uniforms alike, a panoply of enforcement,

Heavy weapons at the ready, so jarring in my neighborhood,

And the working dogs with the keen snouts, the trained muzzles,

Jumping up to paw at the brown bag in the soldier’s hand

Is that peanut butter? Apple? Hunk of cheese?

Let’s play! You’ve been so serious, so worried,

You smell sad and scared, are you lost? Let’s play!

Even Cerberus needs break time, belly rubs, treats!

For the first time in weeks, I smile to myself

As I round past the ferry, those strange lights at my back.

Hope I can sneak past the turnstile downstairs,

I won’t have to hike back up three hundred blocks

To that awful low place. Did you know roaches bite?

They shit on you too. Try to sleep, fully dressed,

Watch cap pulled low on my head, long sleeved shirt

Buttoned up to the collar, heavy pants tucked in boots,

Gloves on my hands, one more night without food

Half-bag of speed takes my mind off the pain

Sleep comes in fits if at all. – On the train

Dreading the stop: ninety-sixth street and Broadway.

Tomorrow, this city will jack itself off

In performative weeping and gnashing and cursing

Oh, how we loved them! I snort in derision,

You didn’t lose nothin', you pieces of shit!

Let the dead bury the dead. Beams of light

Don’t feed this refugee reeking of ashes -