#Lithium-ion battery production

Explore tagged Tumblr posts

Text

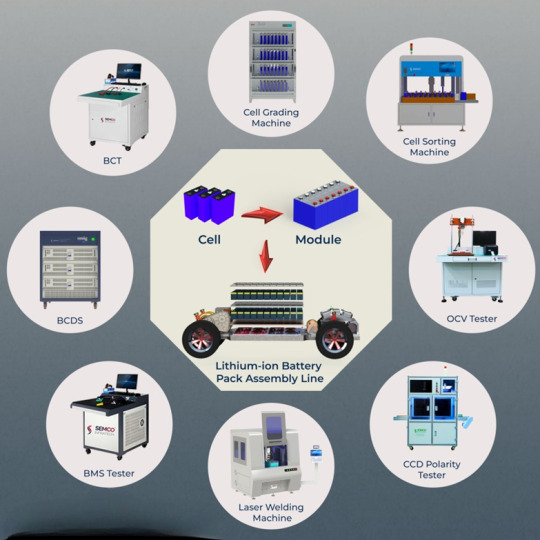

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

#electric vehicles#hyundai#automobiles#electric cars#19th century#1950s#100 days of productivity#35mm#3d printing#CARS#car show#car seat headrest#classic cars#vintage cars#truck#car dealership#lithium ion battery#lithium ion battery charging#types of lithium ion batteries

0 notes

Text

The United States battery market size reached US$ 21.08 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 70.75 Billion by 2032, exhibiting a growth rate (CAGR) of 13.50% during 2024-2032. The rapid proliferation of electric vehicles (EV), integration of renewable energy sources, research and development (R&D) initiatives, adoption of compact and high-intensity portable batteries and the growing need for backup power solutions represent some of the key factors driving the market.

#United States Battery Market Report by Type (Primary Battery#Secondary Battery)#Product (Lithium-ion#Lead Acid#Nickel Metal Hydride#Nickel Cadmium#and Others)#Application (Automotive Batteries#Industrial Batteries#Portable Batteries)#and Region 2024-2032

1 note

·

View note

Text

0 notes

Text

in the end, all ship pairings can be categorized as either squidbob, patbob, squidward x squilliam, or mr krabs x mrs puff. thats just the way things are. if it builds off of a trope theres a spongebob pairing to match it. if you don't understand this then we can't hire you to oversee the production at this lithium ion battery plant

8K notes

·

View notes

Text

Hydrogen vs. Batteries: Why Lithium Reigns Supreme (for Now) in Electric Vehicles

The dream of clean transportation powered by hydrogen fuel cells seems straightforward: burn clean fuel made from water. However, a closer look reveals significant energy losses throughout the hydrogen life cycle, making it less efficient than lithium-ion batteries, the current leader in electric vehicles (EVs). The Energy Drain of Hydrogen Production: Separating hydrogen from water…

View On WordPress

#Battery Charging Infrastructure#Clean Transportation#Electric vehicles (EVs)#Energy Efficiency#Future of Transportation#Hydrogen Fuel Cells#Hydrogen Production#Lithium-Ion Batteries#Sustainability

0 notes

Photo

This Battery Can Put Out Its Own Fire

Scientists recently developed a revolutionary design for a self-extinguishing rechargeable battery that prevents fires and explosions caused by overheating. The study was published in Nature Sustainability and describes how the scientists replaced highly combustible electrolytes (a substance that

http://i-hls-com-2024.s583.upress.link/archives/122766

#anti inflammation batteries#batteries#lithium-ion#lithium-ion batteries#Cool Tech And Gadgets#Dual-use technology#New Products#News#Power#Predictive maintenance#Protection#Technology#Technology News

1 note

·

View note

Text

Solar Battery Producers in india | Getsun Power

Explore India's leading solar battery producers, driving renewable energy innovation. Discover efficient solutions for storing solar power.

#solar products#lithium ion battery#getsun power#energy storage systems#lithium ion battery in noida#solar battery producers in india

0 notes

Text

Green energy is in its heyday.

Renewable energy sources now account for 22% of the nation’s electricity, and solar has skyrocketed eight times over in the last decade. This spring in California, wind, water, and solar power energy sources exceeded expectations, accounting for an average of 61.5 percent of the state's electricity demand across 52 days.

But green energy has a lithium problem. Lithium batteries control more than 90% of the global grid battery storage market.

That’s not just cell phones, laptops, electric toothbrushes, and tools. Scooters, e-bikes, hybrids, and electric vehicles all rely on rechargeable lithium batteries to get going.

Fortunately, this past week, Natron Energy launched its first-ever commercial-scale production of sodium-ion batteries in the U.S.

“Sodium-ion batteries offer a unique alternative to lithium-ion, with higher power, faster recharge, longer lifecycle and a completely safe and stable chemistry,” said Colin Wessells — Natron Founder and Co-CEO — at the kick-off event in Michigan.

The new sodium-ion batteries charge and discharge at rates 10 times faster than lithium-ion, with an estimated lifespan of 50,000 cycles.

Wessells said that using sodium as a primary mineral alternative eliminates industry-wide issues of worker negligence, geopolitical disruption, and the “questionable environmental impacts” inextricably linked to lithium mining.

“The electrification of our economy is dependent on the development and production of new, innovative energy storage solutions,” Wessells said.

Why are sodium batteries a better alternative to lithium?

The birth and death cycle of lithium is shadowed in environmental destruction. The process of extracting lithium pollutes the water, air, and soil, and when it’s eventually discarded, the flammable batteries are prone to bursting into flames and burning out in landfills.

There’s also a human cost. Lithium-ion materials like cobalt and nickel are not only harder to source and procure, but their supply chains are also overwhelmingly attributed to hazardous working conditions and child labor law violations.

Sodium, on the other hand, is estimated to be 1,000 times more abundant in the earth’s crust than lithium.

“Unlike lithium, sodium can be produced from an abundant material: salt,” engineer Casey Crownhart wrote in the MIT Technology Review. “Because the raw ingredients are cheap and widely available, there’s potential for sodium-ion batteries to be significantly less expensive than their lithium-ion counterparts if more companies start making more of them.”

What will these batteries be used for?

Right now, Natron has its focus set on AI models and data storage centers, which consume hefty amounts of energy. In 2023, the MIT Technology Review reported that one AI model can emit more than 626,00 pounds of carbon dioxide equivalent.

“We expect our battery solutions will be used to power the explosive growth in data centers used for Artificial Intelligence,” said Wendell Brooks, co-CEO of Natron.

“With the start of commercial-scale production here in Michigan, we are well-positioned to capitalize on the growing demand for efficient, safe, and reliable battery energy storage.”

The fast-charging energy alternative also has limitless potential on a consumer level, and Natron is eying telecommunications and EV fast-charging once it begins servicing AI data storage centers in June.

On a larger scale, sodium-ion batteries could radically change the manufacturing and production sectors — from housing energy to lower electricity costs in warehouses, to charging backup stations and powering electric vehicles, trucks, forklifts, and so on.

“I founded Natron because we saw climate change as the defining problem of our time,” Wessells said. “We believe batteries have a role to play.”

-via GoodGoodGood, May 3, 2024

--

Note: I wanted to make sure this was legit (scientifically and in general), and I'm happy to report that it really is! x, x, x, x

#batteries#lithium#lithium ion batteries#lithium battery#sodium#clean energy#energy storage#electrochemistry#lithium mining#pollution#human rights#displacement#forced labor#child labor#mining#good news#hope

3K notes

·

View notes

Text

#Toyota#all-solid-state batteries#electric vehicles#EVs#next-generation technology#enhanced range#rapid charging#Tesla#automakers#lithium-ion batteries#solid electrolytes#miniaturization#cost-effective production#BEV Factory#competitiveness#Honda#Nissan#giga casting#manufacturing efficiency#japan#tokyo#innovation#clean energy#environmental impact#decarbonization

0 notes

Text

The Challenges of Scaling Up Battery Production to Meet Growing Demand

As the global shift toward electrification accelerates, the demand for battery-powered products is surging. From electric vehicles (EVs) to renewable energy storage, industries are increasingly dependent on lithium-ion batteries. However, scaling up battery production to meet this demand presents a series of challenges, from raw material sourcing to supply chain stability and quality control.

Key Challenges in Scaling Battery Production

1. Raw Material Availability and Supply Chain Risks

The production of lithium-ion batteries relies on essential materials such as lithium, cobalt, and nickel. These raw materials are primarily sourced from regions with geopolitical instability, leading to supply chain disruptions and price fluctuations. Securing a stable and ethical supply of these materials is one of the biggest challenges for battery manufacturers.

2. High Infrastructure and R&D Investments

Battery production requires substantial investments in manufacturing infrastructure, advanced machinery, and cutting-edge R&D. Developing high-performance battery cells, improving energy density, and enhancing charging efficiency require continuous innovation. Additionally, hiring skilled professionals in battery engineering and manufacturing automation adds to the cost.

3. Logistical Challenges in Storage and Distribution

Due to their size, weight, and safety considerations, batteries pose significant logistical challenges. Efficient transportation, storage, and handling of battery cells are crucial to preventing damage, maintaining safety standards, and reducing supply chain inefficiencies. Manufacturers must strategically locate their production facilities near key markets to minimize shipping costs and lead times.

4. Quality Control and Safety Regulations

As production volume increases, ensuring consistent product quality becomes more complex. Defective batteries can pose serious safety risks, including thermal runaway and fire hazards. Implementing automated testing systems, stringent quality control measures, and compliance with industry regulations is essential to maintaining battery performance and consumer trust.

5. Environmental and Social Impact

The environmental footprint of battery production is a growing concern. The process involves high energy consumption, carbon emissions, and waste generation. Additionally, ethical concerns surrounding mining practices, such as child labor and habitat destruction, highlight the need for sustainable and responsible sourcing. Manufacturers are now focusing on:

Eco-friendly battery materials (e.g., solid-state batteries, sodium-ion batteries)

Recycling and second-life battery solutions

Reducing carbon footprint in manufacturing

Solutions to Overcome Battery Production Challenges

1. Strengthening the Battery Supply Chain

To reduce dependency on limited resources, battery manufacturers are exploring alternative materials and recycling technologies. Establishing local supply chains and investing in battery-grade material refining can help mitigate supply disruptions.

2. Advanced Manufacturing Automation

Leveraging automation, AI-powered quality control, and robotic assembly lines can enhance battery production efficiency while minimizing defects. Industry 4.0 technologies are playing a crucial role in improving manufacturing speed and precision.

3. Sustainable Battery Innovation

Developing next-generation batteries, such as solid-state and sodium-ion batteries, can reduce reliance on scarce raw materials while improving performance and safety. Companies are also prioritizing closed-loop recycling to recover valuable materials from end-of-life batteries.

4. Expansion of Gigafactories

The rise of gigafactories—large-scale battery manufacturing plants—is accelerating production capacity while reducing costs per unit. These facilities are strategically located near EV manufacturers and renewable energy projects to streamline logistics and improve supply chain resilience.

5. Commitment to Sustainability and Ethical Sourcing

To address environmental concerns, battery manufacturers are implementing sustainable sourcing policies, reducing carbon emissions, and adopting green energy solutions in production. Collaborations with governments and non-profits help enforce ethical labour standards in mining operations.

Conclusion

The rapid growth in battery demand requires innovative solutions to overcome challenges in scaling production. While raw material shortages, high production costs, and logistical complexities remain key hurdles, investments in R&D, automation, and sustainability initiatives are paving the way for a more efficient and responsible battery industry.

As battery technology evolves, manufacturers must balance cost-efficiency, quality control, and environmental responsibility to meet the world’s increasing reliance on energy storage solutions. By embracing advanced production techniques and sustainable practices, the future of battery manufacturing looks promising and resilient.

#Battery production#Battery manufacturing#Battery manufacturers#Lithium-ion batteries#Battery-powered products#Battery supply chain#Battery technology#Battery industry#Energy storage solutions#EV Batteries#Solid-state batteries#Sodium-ion batteries#Battery energy density#EV battery supply chain

0 notes

Text

As the electric vehicle market booms, the demand for lithium—the mineral required for lithium-ion batteries—has also soared. Global lithium production has more than tripled in the last decade. But current methods of extracting lithium from rock ores or brines are slow and come with high energy demands and environmental costs. They also require sources of lithium which are incredibly concentrated to begin with and are only found in a few countries. Now, researchers at the University of Chicago Pritzker School of Molecular Engineering (PME) have optimized a new method for extracting lithium from more dilute—and widespread—sources of the mineral, including seawater, groundwater, and "flowback water" left behind from fracking and offshore oil drilling.

Continue Reading.

97 notes

·

View notes

Note

okay so i’ve never really grasped this, might as well ask now — how exactly does the cyberspace & nft stuff mine resources? i’ve heard the basics (i.e. crypto mining uses energy and what not) but i’ve never been able to understand how internet connects to real resources. could you sort of explain that (along the lines with the spam email post) in a simpler way?

ok, put very simply: it's easy for people who only interact with the internet as users to treat 'cyberspace' or 'the virtual world' as immaterial. i type something out on my phone, it lives in the screen. intuitively, it feels less real and physical than writing the same words down on a piece of paper with a pencil. this is an illusion. the internet is real and physical; digital technology is not an escape from the use of natural resources to create products. my phone, its charger, the data storage facility, a laptop: all of these things are physical objects. the internet does not exist without computers; it is a network of networks that requires real, physical devices and cables in order to store, transmit, and access all of the data we use every time we load a webpage or save a text document.

this is one of google's data centres—part of the physical network of servers and cables that google operates. these are real objects made of real materials that need to be obtained through labour and then manufactured into these products through labour. the more data we use, the more capacity the physical network must have. google operates dozens of these data centres and potentially millions of servers (there is no official number). running these facilities takes electricity, cooling technologies (servers get hot), and more human labour. now think about how many other companies exist that store or transmit data. this entire network exists physically.

when you look at a server, or a phone, or a laptop, you might be glossing over a very simple truth that many of us train ourselves not to see: these objects themselves are made of materials that have supply chains! for example, cobalt, used in (among other things) lithium-ion batteries, has a notoriously brutal supply chain relying on horrific mining practices (including child labour), particularly in the congo. lithium mining, too, is known to have a massive environmental toll; the list goes on. dangerous and exploitative working conditions, as well as the environmental costs of resource extraction, are primarily and immediately borne by those who are already most brutally oppressed under capitalism: poor workers in the global south, indigenous people, &c. this is imperialism in action. digital technologies cannot exist without resources, and tech companies (like all capitalist firms!) are profitable because they exploit labour.

all commodities require resources and labour to make and distribute. digital technology is no different. these are material objects with material histories and contexts. nothing about the internet is immaterial, from the electromagnetic waves of wi-fi communication to the devices we use to scroll tumblr. it is, in fact, only by a fantastical sleight-of-hand that we can look at and interact with these objects and still consider the internet to be anything but real resources.

394 notes

·

View notes

Text

"Swedish battery maker Northvolt has developed a new sodium-ion cell technology and could ramp up production of batteries in the next few years. The demand for critical minerals such as lithium, cobalt and platinum has surged in recent years as electric vehicles (EV) become increasingly popular, prompting car manufacturers and battery makers to look for alternatives. Northvolt’s sodium-ion batteries do not contain lithium, cobalt and platinum, which can pose cost and environmental challenges."

"The researchers have developed a recycling method that allows recovery of 100 per cent of the aluminium and 98 per cent of the lithium in electric car batteries. Swedish researchers say they have developed a new, more efficient way of recycling electric car batteries. The method allows for the recovery of far more valuable metals found in EV batteries. The process does not require the use of expensive or harmful chemicals either, the scientists say. “As the method can be scaled up, we hope it can be used in industry in future years,” says research leader Martina Petranikova"

Not exactly related to good manners, but some good news I heard today that I was too excited about not to share.

There's been quite a few technological breakthroughs recently that could make electric car batteries, and just batteries in general, more environmentally friendly, more ethical, and more sustainable.

184 notes

·

View notes

Text

At the end of March, it emerged that the Trump administration was making a new push for Ukraine’s natural resources, including its now famous rare earths. It’s no surprise that the United States wants access to the precious commodity, since relying on the world’s top processor, China, is hardly sustainable. But very little is known about Ukraine’s actual rare-earth deposits, and a large part of them sit in Russian-occupied territories. Building the infrastructure for extraction would take years—and require peace first.

Here’s a better idea, one that would make the United States dependent on no one and create jobs at home (not to mention do a good deed for the environment): recycle rare earths in Americans’ used gadgets.

On March 23, the Trump administration sent Ukraine a proposal on its natural resources that went far beyond the draft agreement on which the two sides agreed in February, the Financial Times reports. The draft agreement, the Times explains, “would apply to all mineral resources, including oil and gas, and major energy assets across the entire Ukrainian territory.”

It also marks the latest salvo in U.S. President Donald Trump’s long-standing quest for Ukraine’s supposed rare-earth riches. “I told them [Ukraine] that I want the equivalent of like $500 billion worth of rare earth, and they’ve essentially agreed to do that. So at least we don’t feel stupid,” Trump told Fox News on Feb. 10.

Ukraine’s rare earths are the core of the natural resources agreement Trump has been pushing President Volodymyr Zelensky to sign. A softer version of the now proposed deal was supposed to have been signed during Zelensky’s visit to Washington in February, but it was derailed by the acrimonious meeting between the two sides.

And now Washington has upped the ante with a proposed agreement that covers the entirety of Ukrainian natural resources and would send revenues directly abroad, with the United States receiving royalties before Ukraine, the Times notes. The deal, which also foresees a U.S.-majority board, would effectively give Washington ownership of Ukraine’s rare earths.

Getting the minerals out of the Ukrainian rock would, alas, be extremely difficult. Three of Ukraine’s four major rare-earth deposits are within or near Russian-controlled areas, as Erik Jonsson, a senior geologist with the Geological Survey of Sweden, told IEEE Spectrum, a journal published by the Institute of Electrical and Electronics Engineers.

There’s also the matter of how large the deposits actually are. “The numbers are believed to come from Soviet surveys dating as far back as the 1960s,” Spectrum notes. Rare earths are notoriously difficult to mine because they appear in tiny quantities within larger pieces of rock, making the commercial aspect of any deal highly sketchy. Spectrum concludes, in italics to emphasize the fact, that “there are no deposits of rare-earth ore in Ukraine known to be minable in an economically viable way.”

For years, the United States has tried to solve its increasingly painful dependence on rare-earth imports, which it needs mainly for electronics, from smartphones to F-35s. (An F-35 needs 920 pounds of rare earths.) Though rare earths are mined in different countries, usually African ones, nearly 90 percent are processed in China, which during globalization’s heyday was not a problem. Now, though, it is.

Since 2020, China has blocked exports of graphite—which is, like rare earths, a crucial component of electric vehicle batteries, though it doesn’t belong to the rare-earth group—to Sweden, where lithium-ion firm Northvolt had been trying to jump-start European EV-battery production before declaring bankruptcy last month. China has also threatened to withhold rare earths from Lockheed Martin, the U.S. maker of the F-35, and is imposing a wide range of controls in response to Trump’s trade war.

The U.S. government must reduce America’s dependence on China. But restoring U.S. industrial chains is a long and painful process that can’t be conjured up overnight. In 2022, the Biden administration awarded $35 million for rare-earth processing to MP Materials, whose mine in Mountain Pass, California, is the United States’ only scaled site.

Over many years, Australian miner Syrah Resources has also received several hundred millions of dollars in U.S. government loans and grants to mine rare earths and graphite in Mozambique, including $165 million in January. Syrah also built a processing plant in Louisiana for its graphite. But as soon as Syrah’s mining of graphite in Mozambique seemed to take off, China flooded the market with lower-priced specimens, the Wall Street Journal notes. It was hardly a subtle signal from Beijing.

But there’s another way for Trump to get the United States the rare earths it needs—and this way would not involve forcing a deal on a savaged country or finding exemptions to global tariffs. In fact, it would involve no country other than the United States. It would even aid the environment, which ought to matter now that the world is approaching the climate change point of no return.

That better way is recycling. Electronics waste is growing rapidly because we all have more electronic gadgets, which we replace increasingly often. In 2022, the latest year available, the world discarded e-waste containing 31 million metric tons of metals, 17 million tons of plastics, and 14 million tons of minerals, glass, and other reusable materials. But only an estimated 19 million tons was recycled—mainly “metals like iron which is present in high quantities and has high recycling rates in almost all e-waste management routes,” the Global E-Waste Monitor, a partnership between the International Telecommunication Union and the United Nations, reports.

The United States throws away nearly 7 million tons of e-waste each year, and as elsewhere, only the easiest parts, such as iron, are recycled. That’s doubly wasteful because discarded gadgets often end up in landfills, where they can poison soil and water—and because they contain the very rare-earth metals that are so desperately needed in new electronic gadgets.

If the United States could marshal the rare earths sitting around in people’s homes and garbage cans, it could slash its dependence on China and create jobs at home. What’s more, it wouldn’t need to impose a rare-earth arrangement on Ukraine, and it would help rid U.S. communities of toxins seeping out from landfills.

Recycling rare-earth metals is extremely difficult and thus commercially unattractive, which is why it’s not yet being done on a large scale. That’s because rare earths are often used in extremely small quantities; while some EV batteries use many pounds’ worth of rare earths, the combined rare earths in a smartphone typically weigh no more than 2 grams. Most other electronics fit somewhere in between. And each rare earth has to be extracted separately.

But getting rare earths out of retired gadgets ought to be no harder than getting them out of remote and unexplored rock in Ukraine. Three days before leaving office, the Biden administration awarded $5.1 million to REEcycle, a small Houston-based recycling company, to help restart a demonstration facility and “advance commissioning of a commercial facility with an estimated annual production of 50 tons of rare earth oxides.” REEcycle specializes in recycling four rare earths commonly used in aircraft, missiles, submarines, and unpiloted vehicles. (The grant, if not yet paid, may have been canceled by DOGE, but DOGE.gov contains no such update.)

There is, in fact, a massive opportunity in rare-earth recycling. Turbocharging U.S. efforts to recover rare earths would trigger more research and development and more innovation at home, and it would help the United states reduce its dangerous rare-earth dependence on China in a way that harms no other country—and creates a variety of new jobs at home. Once scientists and businesses have developed a commercially viable way of recycling rare earths, the United States could reuse these versatile metals over and over. That’s surely a deal Trump should like. In fact, I can’t think of a reason any American would dislike it.

11 notes

·

View notes

Text

Volkswagen California Concept, 2023. A prototype for a new generation VW camper van based on the long version of the Multivan. For the first time, the California is equipped with a sliding door on the kitchen side as well allowing extended use of the space around the vehicle. Using VW's MQB technical platform enables a plug-in hybrid drivetrain with Lithium-ion batteries providing an almost completely autonomous 12V power supply.The concept is described as near-production with sales dues to start next year

#Volkswagen#Volkswagen California#Volkswagen California Concept#concept#camper#campervan#pop top#concept camper#sliding doors#hybrid#plug-in hybrid#2023#2024#RV#recreational vehicle

186 notes

·

View notes