#Cell welding in battery manufacturing

Explore tagged Tumblr posts

Text

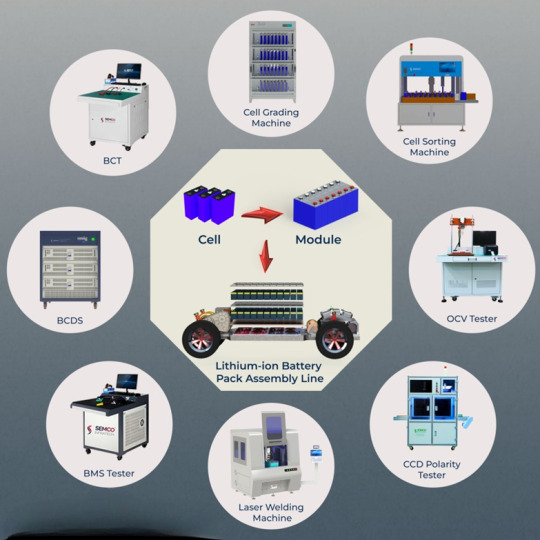

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

Lithium Ion Battery Products of Eco Power

Eco Power Group is more than a lithium battery company. We design, manufactures, and sell advanced lithium-ion energy storage electrification solutions for different types of lithium ion battery.

Our expertise of custom lithium ion battery is based on its know-how in electrochemistry and battery management system to provide safe, efficient and sustainable solutions to various industries such as automotive, commercial transportation, off-highway vehicles/equipment, rail, air, marine, energy storage, solar energy systems, communication equipement, and more.

We are your experienced partner of lithium ion battery wholesale, from the feasibility study to the conception and the final installation with our complete product portfolio.

If you are considering to buy lithium ion battery, we are highly welcome you to consult and cooperate with us.

Different Types of Lithium Ion Battery Products

On-board energy solution at Eco Power Group with complete reference from cell to system to be the best fitting solution for your lithium ion battery types.

Battery Cell

This type of custom lithium ion battery cell is the very basic energy storage unit. Based on many years experience from cell design, battery materials and simulation, we are always at the cutting edge of technology. Our li ion batteries for sale comply with the strict safety standards UN 38.3, which guarantees our customers high quality and safety even after years of operation of charging lithium ion batteries.

Battery Module

In terms of battery modules for different types of lithium ion battery, there we offer standard modules with metal sheet plate for electric vehicle applications, Custom lithium ion battery module with binding tape for energy storage, and VDA size modules for passenger vehicles.

Battery Pack

Standard battery packs for commercial vehicles. Standard battery packs of charging lithium ion batteries in series with DNV certification for marine propulsion. Customized power li ion charging voltage systems for forklift applications ,etc.

Battery Energy Storage System

With a team of experienced engineers, we provide end to end custom lithium ion battery services starting from customer requirement analysis going through battery pack design, testing, prototype production and serial production. During the design phase we focus on the application area requirements as much as the li ion charging voltage battery design itself.

Why Choose The Lithium Ion Battery From Eco Power?

Quality

Our established quality management system of lithium ion battery wholesale, certified according to the international standard DIN EN ISO 9001: 2008, guarantees compliance with our high quality standards.

01

Customised Solution

Customised solutions for lithium ion battery replacement energy storage or mobile applications of electromobility.

02

Experience

As one of the leading lithium ion battery companies, we have more than 10years experience in lithium li ion voltage battery industry with hundreds of different application scenario. With our high quality lithium ion batteries for sale, you can trust us with your project .

03

Technical Support

From customer request input all the way to delivery final different types of lithium ion battery product, we will assign project technical consultant to accompany our customer to solve all of li ion charging voltage questions or problems during the whole process.

04

What Does A Lithium Ion Battery Module Do?

Battery module of li ion batteries for sale contains the energy storing battery cells by laser-welded technology, the mechanically stable against shock demonstrates high productivity and flexibility to make sure the long term performance of li ion charging voltage battery system.

How A Lithium Ion Battery System Works?

A battery system of li ion charging voltage consists of lithium battery cell connected in series to reach the system voltage and parallel to achieve greater capacity.

The li ion battery voltage and capacity can be verified by different combination of packs. The pack contains a fuse and a slave BMS. High security and provide lithium ion cell voltage and temperature to master BMS.

The Lithium-Ion battery system with charging lithium ion batteries in parallel is a composite set of battery electronics, high voltage circuits, overcurrent protection devices, battery boxes and interfaces with other external systems such as cooling, high voltage, auxiliary low voltage and communications.

What Is The Difference Between Lithium Ion Battery Pack And Power Bank?

This kind of battery pack of lithium ion battery types cannot be a power bank, but a power bank can be a li ion battery charging voltage pack with added electronic circuitry to prevent over charging, over discharge, etc to protect the batteries.

A lithium ion battery pack in series is merely a bunch of batteries connected in Series/Parallel configuration with one positive and one negative terminal.

A power bank contains one or more batteries in mostly parallel but could also be a Series/Parallel configuration. These types of li ion batteries for sale are connected to a battery management circuit (module) which controls the charging of the batteries. All this is housed in a compact enclosure.

2 notes

·

View notes

Text

The Ultimate Guide to Choosing the Best Laser Welding Machine for Your Needs

In today’s fast-paced manufacturing and metalworking industries, precision, efficiency, and durability are critical factors. A laser welding machine is an advanced solution that meets these requirements, offering superior welding performance compared to traditional methods. Whether you are looking for a fiber laser welding machine or want to understand the laser welding machine price, this guide will help you make an informed decision. We will explore the laser welding machine uses, advantages, and applications to help you choose the best one for your needs.

What is a Laser Welding Machine?

A laser welding machine utilizes a highly focused laser beam to fuse materials together. This method offers a precise and clean weld with minimal heat-affected zones. The technology is widely used in industries requiring high accuracy and superior welding quality. Unlike traditional welding techniques, laser welding does not require physical contact, reducing wear and tear on equipment and enhancing the longevity of the welding process.

Types of Laser Welding Machines

When selecting a laser welding machine, it is crucial to understand the different types available:

1. Fiber Laser Welding Machine

Uses fiber optics to deliver the laser beam.

Highly efficient with low maintenance costs.

Best suited for high-speed welding applications.

Ideal for industries such as automotive, aerospace, and medical devices.

Offers excellent beam quality, which enhances precision and reduces material wastage.

2. CO2 Laser Welding Machine

Uses a gas mixture to generate the laser beam.

Suitable for non-metal materials like plastics and ceramics.

Less efficient compared to fiber laser welding machines.

Requires higher power consumption and has more maintenance needs.

Typically used for welding applications where high-speed processing is not a primary concern.

3. Nd:YAG Laser Welding Machine

Uses a neodymium-doped crystal to generate the laser.

Suitable for precision welding applications.

Requires more maintenance due to flashlamp pumping.

Offers moderate welding speeds but is effective for deep penetration welding.

Commonly used in the medical and electronics industries.

Laser Welding Machine Uses

A laser welding machine is widely utilized across different industries. Some of the most common applications of laser welding machines include:

Automotive Industry: Used for joining car body components, battery packs, and other intricate parts.

Medical Industry: Essential for welding surgical instruments, implants, and microdevices.

Electronics Industry: Ensures precision welding for circuit boards and connectors.

Aerospace Industry: Used for high-strength and lightweight welding applications.

Jewelry Making: Helps in repairing and manufacturing fine jewelry without affecting delicate designs.

Manufacturing: Suitable for high-volume production lines requiring seamless welds.

Tool and Mold Industry: Utilized for repairing molds and fabricating specialized tools.

Shipbuilding: Enhances durability and precision in marine equipment manufacturing.

Battery and Energy Sector: Used for welding battery cells and energy storage components.

Advantages of Laser Welding Machines

Understanding the laser welding machine advantages will help you determine whether this technology is suitable for your needs:

High Precision: Laser welding delivers highly accurate and controlled welds.

Minimal Heat Affected Zone (HAZ): Reduces the risk of material distortion and damage.

High-Speed Welding: Enhances production efficiency and reduces processing time.

Versatile Material Compatibility: Works with metals, alloys, and even some plastics.

Minimal Consumables: Unlike traditional welding, laser welding does not require filler materials.

Automation & Integration: Easily integrated into robotic and CNC systems for industrial automation.

Lower Labor Costs: Reduces the need for highly skilled manual welders.

Better Aesthetic Results: Produces clean, strong welds with minimal finishing requirements.

Reduced Thermal Damage: Preserves material properties and prevents microcracks.

Eco-Friendly: Reduces material waste and energy consumption.

How to Choose the Best Laser Welding Machine

When selecting a laser welding machine, consider the following factors:

1. Power Requirements

The power output determines the machine’s capability. Higher power is required for thicker materials, while lower power is suitable for precision applications. A 500W fiber laser can handle thin sheets, whereas a 3000W machine is better suited for industrial applications.

2. Material Compatibility

Ensure that the laser welding machine you choose is compatible with the materials you need to weld, whether it is stainless steel, aluminum, titanium, or plastics. Some metals, like copper and aluminum, require specialized laser wavelengths for effective welding.

3. Welding Speed and Efficiency

For high-production environments, opt for a fiber laser welding machine, which offers superior speed and efficiency. A machine with pulsed or continuous wave modes can provide versatility for different applications.

4. Automation and Integration

If you require high-volume production, choose a machine that can integrate with automated manufacturing systems. Robotics and CNC compatibility ensure seamless industrial workflows and enhanced productivity.

5. Maintenance and Operating Costs

Check the maintenance requirements and laser welding machine price to ensure a cost-effective investment. Fiber laser systems typically have lower maintenance costs compared to CO2 or Nd:YAG machines.

6. Portability

If you need a mobile solution, look for portable laser welding machines that offer flexibility without compromising performance. Handheld laser welders are gaining popularity for on-site applications.

Laser Welding Machine Price

The laser welding machine price varies depending on factors such as power output, brand, features, and automation capabilities:

Entry-Level Machines: $5,000 - $20,000 (Suitable for small businesses and jewelry makers)

Mid-Range Machines: $20,000 - $100,000 (Ideal for automotive and medical applications)

High-End Industrial Machines: $100,000 - $500,000+ (Used in large-scale manufacturing and aerospace applications)

For the best deals and advanced laser welding machines, check out SLTL Group, a leading manufacturer of laser technology solutions.

Conclusion

Choosing the best laser welding machine requires careful consideration of power, material compatibility, welding speed, and budget. Whether you need a fiber laser welding machine for industrial applications or a compact solution for small-scale production, understanding the laser welding machine uses and advantages will help you make the right investment.

A laser welding machine is not just a tool; it is an investment in efficiency, precision, and innovation. By carefully assessing your needs and the available options, you can ensure that you select the perfect machine for your business.

For high-quality and reliable laser welding solutions, explore SLTL Group and find the perfect machine tailored to your needs.

0 notes

Text

Ultrasonic Welding of Lithium Battery Components: Technical Insights and Application Advantages

Ultrasonic welding is an efficient and environmentally friendly bonding technology widely used in lithium battery manufacturing. It achieves molecular bonding between materials through high-frequency vibration energy, ensuring the durability and conductivity of welded components. This article delves into the applications and advantages of ultrasonic welding technology in lithium battery components.

1. Principles and Characteristics of Ultrasonic Welding Technology

Ultrasonic welding uses high-frequency mechanical vibrations to generate frictional heat at the contact surface, causing the materials to interweave and fuse. No adhesives or solder are required; welding is achieved solely through vibration and pressure.

Key Characteristics

2. Applications of Ultrasonic Welding in Lithium Battery Components

Lithium batteries are complex structures comprising cathodes, anodes, separators, electrolytes, and casings. Ultrasonic welding plays a critical role in the following components:

1. Tab Welding

The cathode and anode tabs are welded to conductive plates or busbars, ensuring efficient current transfer.

2. Cell Connection

In multilayer cell stacks, ultrasonic welding enhances electrical conductivity and mechanical strength between cells.

3. Module Assembly

In battery modules, multiple cells are welded into a single unit to support high current output and stable performance.

4. Protection Circuit Welding

The protection circuit module (PCM) is welded to the cells, ensuring the safe operation of the battery pack.

3. Ultrasonic Welding Process

Process Flowchart

4. Comparison Between Ultrasonic Welding and Traditional Welding

Technology Comparison Table

5. Advantages and Precautions of Ultrasonic Welding

1. Advantages

2. Precautions

6. Future Trends

With the rapid growth of the electric vehicle and energy storage markets, the demand for lithium batteries is soaring, driving the continuous advancement of ultrasonic welding technology. Key future trends include:

0 notes

Text

What are the Key Features of a Battery Pack Line?

What is a Battery Pack?

A battery pack is a collection of individual battery cells that are connected together to provide the required voltage and capacity for specific applications. Battery packs are widely used in various industries, including electric vehicles (EVs), consumer electronics, and energy storage systems. The battery cells within a pack are typically arranged in series or parallel to achieve the desired performance specifications.

Battery pack components:

Features of a Battery Pack Line

A battery pack production line is a manufacturing setup that assembles individual battery cells into a finished pack. These lines are designed to ensure efficiency, precision, and safety in the manufacturing process. Key features of a battery pack line include:

Cell Selection: Cells are selected based on their specifications, including voltage, capacity, and health.

Cell Sorting and Grouping: Cells are sorted by type, capacity, and quality before being grouped into series and parallel configurations.

Battery Welding: The cells are connected using welding techniques such as laser welding or ultrasonic welding.

Battery Testing: Testing includes voltage, capacity, and performance tests to ensure that the cells work correctly in series and parallel configurations.

Battery Pack Assembly: Cells are placed into protective casings, and the pack is assembled with necessary components such as the BMS, wiring, connectors, and thermal management systems.

Quality Control & Inspection: Ensuring that the final product meets required safety, performance, and reliability standards.

Applications of a Battery Pack Line

Battery pack lines are used in the production of battery packs for a wide range of applications, including:

Electric Vehicles (EVs): High-capacity battery packs are used to power electric cars, buses, trucks, and two-wheelers.

Energy Storage Systems (ESS): Large-scale energy storage solutions for utilities and industrial applications to store electricity from renewable sources.

Consumer Electronics: Batteries for smartphones, laptops, tablets, and other portable electronic devices.

Power Tools: Cordless drills, saws, and other power tools that require rechargeable batteries.

Medical Devices: Battery packs for devices like pacemakers, portable oxygen concentrators, and medical monitoring equipment.

Aerospace and Defense: Specialized battery packs used in military equipment, drones, and space exploration.

Factors Affecting Pack Line Configuration

The configuration of a battery pack production line depends on various factors that influence the overall design, capacity, and efficiency of the line:

Production Volume: High-volume production lines will require more automation and efficient processes to maintain low costs and high throughput.

Cell Type and Size: The type (e.g., cylindrical, prismatic, pouch) and size of the battery cells will dictate the configuration of the assembly and welding processes.

Customization Requirements: Some applications (such as EVs) may need custom battery packs with specific voltage or capacity, which will affect the configuration of the line.

Quality Standards: Ensuring that the battery packs meet safety, performance, and reliability standards may require more sophisticated testing and inspection systems.

Automation Level: Higher levels of automation reduce labor costs but may increase the initial investment in machines and equipment.

Space and Layout: The physical space available for the production line may limit the layout, requiring careful planning to optimize workflows.

Factors Affecting the Price of a Pack Line

The price of a battery pack production line can vary significantly depending on several factors:

Automation and Technology: Highly automated lines that use advanced robotics, AI, and sensors tend to have a higher initial cost but may offer lower long-term operating costs.

Production Capacity: Larger, higher-capacity lines are typically more expensive to set up but may be more cost-effective per unit produced.

Customization and Complexity: Custom features such as advanced testing, special welding techniques, or non-standard pack configurations can increase costs.

Quality Control and Inspection: The need for sophisticated quality control systems, such as high-precision testing and inspection stations, can add to the cost.

Equipment and Tooling: The choice of equipment (e.g., laser welding vs. ultrasonic welding) and tooling will affect both the upfront investment and ongoing maintenance costs.

Labor Costs: The level of automation in the pack line will influence the number of workers required for operation and maintenance, impacting the price.

Energy Efficiency: Energy-efficient machinery may have a higher initial cost but lower long-term energy consumption.

Regulatory Compliance: Compliance with local and international standards (e.g., UL, IEC) for safety and environmental considerations may require additional certifications and equipment, influencing the overall cost.

Supplier of Battery PACK Line

Huiyao Laser Technology (Luoyang) Co., Ltd. is a high-tech enterprise focusing on the research and development, manufacturing and sales of equipment for the new energy industry. Huiyao Laser provides comprehensive high-performance laser systems designed for the automotive, electronics, medical equipment, aerospace and other industries and committed to providing customers with comprehensive laser welding equipment, battery cell assembly line equipment, module PACK automatic line equipment, battery structural parts automation equipment and other high-end intelligent equipment. It can tailor the most suitable production line solutions according to the different production needs of customer companies.

#energystorage#huiyaolaser#laserwelding#new energy#productionline#yaolaser#pouchbattery#aviation#electric vehicles

0 notes

Text

spot welding machine welding battery 18650

Precision battery spot welding machines use resistance heat for welding. Welding current, pressure, power-on time and their combination have an important influence on the welding effect. Welding current and density, pressure uniformity, and power-on time all affect welding quality and heat distribution. The combination of appropriate current waveform and pressure time, as well as the removal of oxide film on the surface of the material, are the key to ensuring welding results.

The equipment has a beautiful appearance, is controlled by a microcomputer, and has LCD display settings for easy operation. High-frequency inverter technology makes the welding sparks small, the spots do not change color, and the welding time is short, with little impact on the battery cells. The power supply has strong adaptability and the welding pressure is directly displayed. Compared with traditional welding machines, the welding surface is cleaner, the heat is uniform, the pressure is adjustable, and the welding is more reliable. It has a wide range of applications in the field of battery manufacturing.

0 notes

Video

youtube

215kWh air-cooled energy storage cabinet

Dagong New Energy Technology Luoyang Co., Ltd

Official Site:www.energystorageltd.com/

Mail:[email protected]

WhatsApp :8619337982677

Hello everyone!Today, I'd like to introduce our 215kWh combined with cooling system energy storage cabinet。 the cabinet divided into two parts,left part and right。the left chamber is the battery chamber,which include packs high voltage box,fire detector,lighting a 3kw air cooling air condition hammered with the cabin door,each pack contained 16 cells,and each cells is 280 Ah,lithium iron phosphate batteries,the right chamber is the elect chamber,primarily consists of UPS,EMS,EMS accessories various distribute air switch the controllers and the PCS 。if you want to know more about energy storage,or want to know more about our products。please let us know or click our official website,Thank you!��

#photovoltaic #Solar photovoltaic#solarsystem #Prismatic Battery # Lithium Battery Steel Tie # Dagong New Energy # Battery Manufacturing # Industrial Automation # Battery Pack # Battery Capacity # Lithium Battery # Lithium Battery Welding # Lithium Battery Pack#Battery Unit # Module # Battery Pack # Battery # Battery # Lithium Battery Welding # Precision Technology # Efficiency # Innovation # Dagong New Energy # Manufacturing # Laser Welding # Battery Manufacturing # Efficiency # Battery Manufacturing # lithiumbattery # Lithium Battery # Energy Storage # Energy Storage System # Energy Barrier Battery Pack # Automation # Energy Storage # Energy Carrier Battery Pack # Energy Marge Battery # Energy Battery Pack System # Energy # Energy Storage ypack # Battery Pack Metal Battery Pack # Battery Pack Battery # Energy Storage # Battery Manufacturing # by d # Battery Pack Assembly # Battery Pack Manufacturing # Energy Storage Storage # Battery Pack # Battery_ Machine # Battery # Electric Vehicle # Energy Storage # Energy Storage Battery Pack # Energy Storage System # Energy Efficiency

1 note

·

View note

Text

Transplant Diagnostics Market Size, Share, Growth, Trends [2032]

Transplant Diagnostics Market provides in-depth analysis of the market state of Transplant Diagnostics manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Transplant Diagnostics in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Transplant Diagnostics Market Report:

The report offers a comprehensive and broad perspective on the global Transplant Diagnostics Market.

The market statistics represented in different Transplant Diagnostics segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Transplant Diagnostics are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Transplant Diagnostics.

Major stakeholders, key companies Transplant Diagnostics, investment feasibility and new market entrants study is offered.

Development scope of Transplant Diagnostics in each market segment is covered in this report. The macro and micro-economic factors affecting the Transplant Diagnostics Market

Advancement is elaborated in this report. The upstream and downstream components of Transplant Diagnostics and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/transplant-diagnostics-market-100551

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Resistance Welding Machine MarketMarket Forecast

Global Pigmentation Disorders Treatment MarketMarket Size

Constant Voltage Led Driver MarketMarket Growth

Next-Generation OSS & BSS MarketMarket Analysis

Oncolytic Virus MarketMarket Size

Global Dual-Ovenable Trays & Containers MarketMarket Share

Global Concrete Temperature Sensors and Maturity Meters MarketMarket Growth

Polyurethane Dispersions (PUD) MarketMarket

Automotive Transmission MarketMarket Share

Voice Communication Equipment MarketMarket Growth Rate

Dermatology Lasers MarketMarket Forecast

Global Frozen Tissues Samples MarketMarket Size

Cloud Infrastructure Services MarketMarket Growth

Artificial Intelligence in Healthcare MarketMarket Analysis

Abrasive MarketMarket Size

Global Smartwatch Bands & Smartwatch MarketMarket Share

Global Finance Lease MarketMarket Growth

Low-Power Geolocation MarketMarket

Phytonutrients MarketMarket Share

Cycling Gloves MarketMarket Growth Rate

Agricultural Drones MarketMarket Forecast

Global Direct Air Capture (DAC or DACCS) MarketMarket Size

Airfryer MarketMarket Growth

Single Lead ECG Equipment MarketMarket Analysis

Camera Battery MarketMarket Size

Global Load Cell MarketMarket Share

Global Methyl Tert-Butyl Ether(Mtbe) MarketMarket Growth

Biotechnology Separation Systems MarketMarket

Polyethylene Terephthalate (PET) MarketMarket Share

Parking Management MarketMarket Growth Rate

Employee Assistance Program Services MarketMarket Forecast

Global Personal Care Wipes MarketMarket Size

Atomic Force Microscope (Afm) MarketMarket Growth

Solar Backsheet MarketMarket Analysis

Needle Cage MarketMarket Size

Global Central Reservation System MarketMarket Share

Global Global Molybdenum Carbide Powders MarketMarket Growth

Pharmaceutical Grade Gelatin Powder Market Market

Gravel Paver - Global MarketMarket Share

0 notes

Text

Welding Simulation Software, Global Top 10 Players, Market Share and Ranking (2023)

Welding Simulation Software Market Summary

Welding simulation software is a tool that computationally replicates the welding process, allowing for the analysis of parameters like temperature, pressure, and speed in real-time. It's used to enhance weld quality and minimize defects by enabling users to test various welding scenarios in a virtual environment before actual execution.

According to the new market research report “Global Welding Simulation Software Market Report 2024-2030”, published by QYResearch, the global Welding Simulation Software market size is projected to reach USD 0.12 billion by 2030, at a CAGR of 8.2% during the forecast period.

Figure. Global Welding Simulation Software Market Size (US$ Million), 2019-2030

Figure. Global Welding Simulation Software Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Welding Simulation Software include ESI Group, Hexagon, Dassault Systèmes (Abaqus), JSOL Corporation, ABB, Transvalor, Siemens, Cenaero, Swantec, Wuhan KaiMu (KM Soft), etc.

In 2023, the global top five players had a share approximately 58.0% in terms of revenue.

Figure. Welding Simulation Software, Global Market Size, Split by Product Segment

In terms of product type, currently Cloud-Based is the largest segment, hold a share of 84.3%.

Figure. Welding Simulation Software, Global Market Size, Split by Application Segment

In terms of product application, currently Automotive is the largest segment, hold a share of 59.0%.

Figure. Welding Simulation Software, Global Market Size, Split by Region

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Discover the meticulous process of lithium-ion battery pack manufacturing, where individual cells are sorted, grouped, and assembled into high-performance modules. Key stages include battery sorting and grouping, spot welding, module assembly, and rigorous testing for safety and reliability. Learn how advanced techniques ensure optimal performance, safety, and adherence to industry standards in applications like electric vehicles and energy storage systems.

#Lithium-ion battery pack manufacturing#Battery module assembly process#Battery pack production stages#Cell sorting and grouping techniques#Spot welding for battery assembly#BMS integration in lithium batteries#Lithium-ion battery quality control#EV battery manufacturing process#Battery pack safety standards#Testing in battery pack manufacturing

0 notes

Text

The Surge of Battery Production Machines: A Deep Dive into the Fastest-Growing Segment

The battery production machine market is experiencing unprecedented growth, driven by the increasing demand for batteries across various applications, including electric vehicles (EVs), consumer electronics, and renewable energy storage. Among the various segments within this market, one stands out as the highest growing: machinery for lithium-ion battery production. This detailed research explores the factors propelling the growth of this segment, its implications for the market, and future outlook.

1. Market Overview: The global battery production machine market encompasses a wide range of equipment used in the manufacturing process of different types of batteries. These machines include mixers, coaters, calenders, slitting machines, assembly machines, and formation & testing equipment. The lithium-ion battery production machinery segment is experiencing the fastest growth due to the widespread adoption of lithium-ion batteries in various industries.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=168163488

2. Lithium-Ion Battery Production Machines:

Key Equipment Types:

Mixing Machines: These machines are used to blend the raw materials (active materials, binders, solvents) for the electrode slurry. Advanced mixing technologies ensure homogeneity and consistency, which are critical for battery performance.

Coating Machines: Coating machines apply the electrode slurry onto the current collectors (cathodes and anodes). Precision coating ensures uniformity in thickness, crucial for battery efficiency and lifespan.

Calendering Machines: These machines compress the coated electrodes to enhance density and adhesion. High-precision calendering is essential for improving the energy density and mechanical stability of the electrodes.

Slitting Machines: Slitting machines cut the electrode sheets into specific widths required for cell assembly. Accuracy in slitting is vital to maintain electrode quality and performance.

Assembly Machines: These include stacking, winding, and welding machines used to assemble the electrodes into battery cells. Automation in assembly ensures high throughput and consistency.

Formation & Testing Equipment: These machines charge and discharge the cells to form the solid-electrolyte interface and perform quality testing. Efficient formation and testing are critical to ensure battery reliability and safety.

3. Drivers of Growth:

Electric Vehicle (EV) Boom: The surge in demand for electric vehicles is a primary driver for lithium-ion battery production. Governments worldwide are implementing policies to promote EV adoption, which in turn is driving the need for advanced battery production machinery.

Energy Storage Systems (ESS): The growing emphasis on renewable energy sources such as solar and wind power necessitates efficient energy storage solutions. Lithium-ion batteries are preferred for ESS due to their high energy density, efficiency, and long cycle life.

Consumer Electronics: The proliferation of smartphones, laptops, and other portable devices continues to drive demand for high-performance lithium-ion batteries, spurring investments in production machinery.

Technological Advancements: Continuous advancements in battery technology, such as solid-state batteries and high-capacity anode materials, require sophisticated production machinery capable of handling new materials and processes.

Cost Reduction and Efficiency: Manufacturers are focusing on reducing production costs and improving efficiency. Advanced production machinery with automation and AI integration helps in achieving higher yields, lower wastage, and reduced labor costs.

4. Regional Insights:

Asia-Pacific: Dominates the lithium-ion battery production machinery market due to the presence of major battery manufacturers in China, Japan, and South Korea. Government incentives, strong supply chain networks, and increasing investments in battery manufacturing facilities are driving growth in this region.

North America: Witnessing significant growth driven by investments in EV manufacturing and energy storage projects. The U.S. government's focus on building a domestic battery supply chain is boosting demand for production machinery.

Europe: Rapidly expanding its battery production capacity with several gigafactories under construction. The EU's stringent emission regulations and push for green energy are key factors driving the market.

Rest of the World: Emerging markets in Latin America and the Middle East are gradually investing in battery production to support their renewable energy initiatives and automotive sectors.

0 notes

Text

Explore The Unique Features That Make Quanta Batteries Popular

If you have UPS in your home, you can select the perfect battery. Today, many businesses use UPS to provide a constant power supply that lets them complete projects on time. UPS battery is essential to keep the security system charged and operate medical equipment constantly. There are endless UPS batteries in the current marketplace, but the Quanta battery is ideal for its reliability. The top quanta battery suppliers Mumbai offer the industry standard UPS batteries to the customer. Here are some unique features of the Quanta battery that everyone should know:

Various applications

Those seeking the UPS battery with a low self-discharge rate can try the Quanta battery. It is widely used for various applications such as elevators, utilities, cloud service, fire alarm panels, closed-circuit television, banks, laboratories, etc. In addition, the manufacturer uses advanced technologies to craft UPS batteries that suit all applications.

The Quanta battery has high performance so that you can use it in the UPS. This type of battery is developed to last for an extended period. Besides, the welding connections between battery cells create a low-resistance current pathway, making this battery suitable for high-current applications. The battery should operate normally, and their designs help boost resistance.

Excellent reliability and durability

A significant reason to use a Quanta UPS battery is reliability. Adding numerous features to the battery would offer constant services. The leading manufacturer creates technologically innovative products that make them stand out. In addition, you can stay in peace of mind while using a UPS battery in your working environment.

Many people use Quanta batteries because of their long-lasting durability. In addition, buy premium-quality UPS batteries from the trusted Quanta Battery dealer Mumbai at a lower price. You can use this type of UPS battery in the tropical climate for its corrosive resistance.

Avoid the need for frequent repairs

If you use a high-quality battery in the UPS, it reduces the need for frequent repair. You can save money on repairing the UPS battery regularly. Besides, this type of battery employs a PPCP container with less permeability. Therefore, it helps to prevent water loss from occurring inside the battery. Investing in the Quanta battery for your UPS is the best way to protect your device. It can withstand the power for extended periods so you can access devices in your home or office without trouble.

0 notes

Text

What are Power Electronics? – How it Works - Arya College

What Is Power Electronics?

Power Electronics mean converting electric energy from one form to another form, the output after the conversion is far better, efficient, error-free, clean, compact, and simple to use.

The study of power electronics and electric motors involved in the processing of electric power for a variety of uses. It will provide a wide range of electricity which can be a few watts to megawatts. Like various computers with disk drives, fans with different speeds, lamps with different lightning, an electric vehicle with different modes, electric drives, etc.

The field of power electronics is really huge and vast, every hour we use 12 billion KW of electricity which is more than 80% of generated current, some part of this converted, processed, or recycled. When we convert the current in different ways, at that time we are losing more of the part of this. estimated power consumption in a desktop sold in one year, which is equal to the 17 power plants of 500 MW.

Why Do We Need To Improve The Power Efficiency Of The Power System

When we convert the current in different ways, at that time we are losing more of the part of this. estimated power consumption in a desktop sold in one year, which is equal to the 17 power plants of 500 MW. that’s why we need to improve the efficiency of the power system.

According to calculation if we make power conversion more efficient then we can save 35% of energy in our daily uses.

That’s what Arya College Jaipur offers to learn about power and energy systems, it is greatly significant to students.

Application Of Power Systems

Residential

Refrigeration and freezers

Space heating

Air conditioning

Cooking

Lighting

Electronics (PCs, other entertainment equipment

Commercial

Heating, ventilating, and air conditioning

Central refrigeration

Lighting

Computers and office equipment

Uninterruptible power supplies (UPSs)

Elevators

Industrial

Pumps

Compressors

Blowers and fans

Machine tools (robots)

Arc furnaces and induction furnaces

Lighting

Industrial lasers

Induction heating

Welding

Transportation

Traction control of electric vehicles

Battery chargers for electric vehicles

Electric locomotives

Street cars, trolley buses

Subways

Automotive electronics, including engine controls

Utility systems

HVDC

SVC

Supplemental energy sources (wind, photo voltaic), fuel cells

Energy storage systems

Induced draft fans and boiler feedwater pumps

Aerospace

Space shuttle power supply systems

Satellite power systems

Aircraft power systems

Telecommunications

Battery chargers

Power supplies (DC and UPS)

We can’t assemble the uses of electricity in a list. The electricity is used in approximately each and every sector. The electric devices are easily available in the market due to the easy manufacturing process, that's why these are easily available in the market for everyone to use. In the end, it can be summarized in the words that, the day is not far when all of the electrical energy in the world will pass through power electronic systems.

0 notes

Text

What is Battery Module Laser Welding?

What is Laser Welding?

Laser Welding is a manufacturing process that uses a focused laser beam as the heat source to melt and join materials together. It is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing because of its precision, speed, and ability to weld complex shapes with minimal distortion.

Features of Laser Welding?

High Precision and Accuracy: Laser welding allows for precise control of the heat input, resulting in highly accurate welds, even for very fine or intricate parts. This precision is crucial in industries where tight tolerances are required.

Minimal Heat Affected Zone (HAZ): The focused nature of the laser minimizes the area affected by heat, reducing thermal distortion and the risk of damaging surrounding areas. This is particularly beneficial for welding delicate or thin materials.

High Welding Speed: Laser welding is fast, which increases productivity and reduces manufacturing time. It is ideal for high-volume production runs where speed is essential.

Automation and Precision: The laser welding process can be easily integrated into automated systems, making it suitable for mass production. The process can be controlled by a computer, ensuring consistent quality and precision.

Versatility: Laser welding can be used on a wide range of materials, including metals, plastics, and ceramics. It is especially effective on materials that are difficult to weld with traditional methods (like high-strength alloys and dissimilar metals).

Deep Penetration Welding: Laser welding can achieve deep penetration with a narrow weld bead, which is beneficial when joining thick materials. It provides strong, durable welds in a single pass.

Minimal Post-Weld Processing: Since laser welding produces clean and precise joints, it often requires little to no post-weld cleanup or finishing, reducing the overall cost and time of production.

Ability to Weld Small or Complex Geometries: The concentrated nature of the laser allows it to weld very small or complex parts that might be difficult or impossible to weld with traditional methods.

Low Heat Input: Compared to other welding methods, laser welding requires less heat, reducing the potential for warping and other thermal issues that can arise with other techniques.

Applications of Laser Welding in Battery Module

Welding Battery Terminals and Tabs: Laser welding is used to join the battery tabs (which are usually made of thin metal) to the battery cells. The process ensures a reliable electrical connection with minimal contact resistance. Since battery tabs are thin and delicate, laser welding allows for precise, high-quality welds without damaging the cells or causing excessive heat build-up.

Welding Battery Packs: In battery packs, multiple cells need to be connected securely. Laser welding is ideal for joining battery cells to each other or to the battery pack housing. The process can create strong, compact, and reliable welds that provide consistent electrical performance and mechanical stability.

Welding of Current Collectors: Battery cells often have current collectors (e.g., aluminum or copper foils), which are responsible for conducting electricity between the electrodes. Laser welding is used to precisely attach these current collectors to the battery terminals, ensuring efficient power transmission.

Laser Soldering of Copper and Aluminum Components: Some battery module designs require soldering of copper or aluminum components, such as electrical connectors or busbars. Laser soldering is a common application for joining these metals, as it offers precise control over the amount of heat applied, reducing the risk of damaging sensitive components.

Welding the Battery Case or Housing: Laser welding is used to join the battery module casing or housing, typically made from materials such as steel or aluminum. The precision of the laser ensures that the housing is sealed securely, providing structural integrity while maintaining a compact design.

Thermal Management Components: Some battery modules include thermal management components like heat sinks or cooling plates. These components need to be securely welded to the battery cells or modules to ensure proper heat dissipation. Laser welding offers the precision needed to attach these components without introducing too much heat into the surrounding areas.

Welding of Safety Mechanisms (e.g., Pressure Relief Valves): Many modern battery modules are equipped with safety features like pressure relief valves or vents, which are welded into place using lasers. These safety mechanisms help to prevent dangerous over-pressurization or thermal runaway in the battery pack, making laser welding an ideal solution for joining these critical components.

Automated Battery Assembly Lines: In high-volume manufacturing, laser welding is often integrated into fully automated battery assembly lines. Robots equipped with laser welding heads perform precise, repeatable welds on the battery modules, ensuring consistency and reducing labor costs. The automation of the welding process also improves safety and throughput.

Price of Battery Module Laser Welding

Types of Laser System: Different types of lasers (e.g., fiber lasers, CO2 lasers, diode lasers) have different costs. Fiber lasers, which are commonly used for battery welding due to their high precision and efficiency` . The cost depending on the specific model, power rating, and features.

If the laser welding system is integrated into an automated production line, there are additional costs for robotics, vision systems, material handling equipment, and control systems. Automation is typically more expensive but improves throughput and reduces labor costs in high-volume production.

Material Type and Complexity:The type of materials being welded (such as copper, aluminum, or steel) and the complexity of the weld (e.g., welding battery tabs or welding large battery modules) will influence the welding process. More complex or challenging materials may require more specialized equipment or process adjustments, which can increase costs.

Supplier of Battery Module Laser Welding Equipment

0 notes