#valve and instruments

Explore tagged Tumblr posts

Text

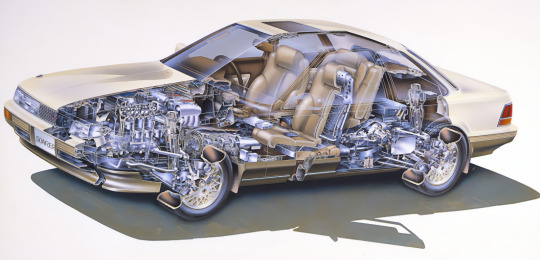

Toyota Soarer 3.0 GT-Limited, 1986. The second generation Z20 Soarer shared its platform with the A70 series Supra. It introduced the Electro Multi Vision digital vehicle information display. The 3.0 GT was powered by a DOHC 24 valve turbocharged straight 6

#Toyota#Toyota Soarer#Toyota Soarer Z20#1986#sports coupé#straight 6#24 valve#DOHC#digital instrumentation

307 notes

·

View notes

Text

Still Alive (Radio Mix) // Portal (2007)

#portal#portal (game)#still alive#playstation 3#xbox 360#PC#valve#game#instrumental#2007#oktaviaslabyrinth

36 notes

·

View notes

Text

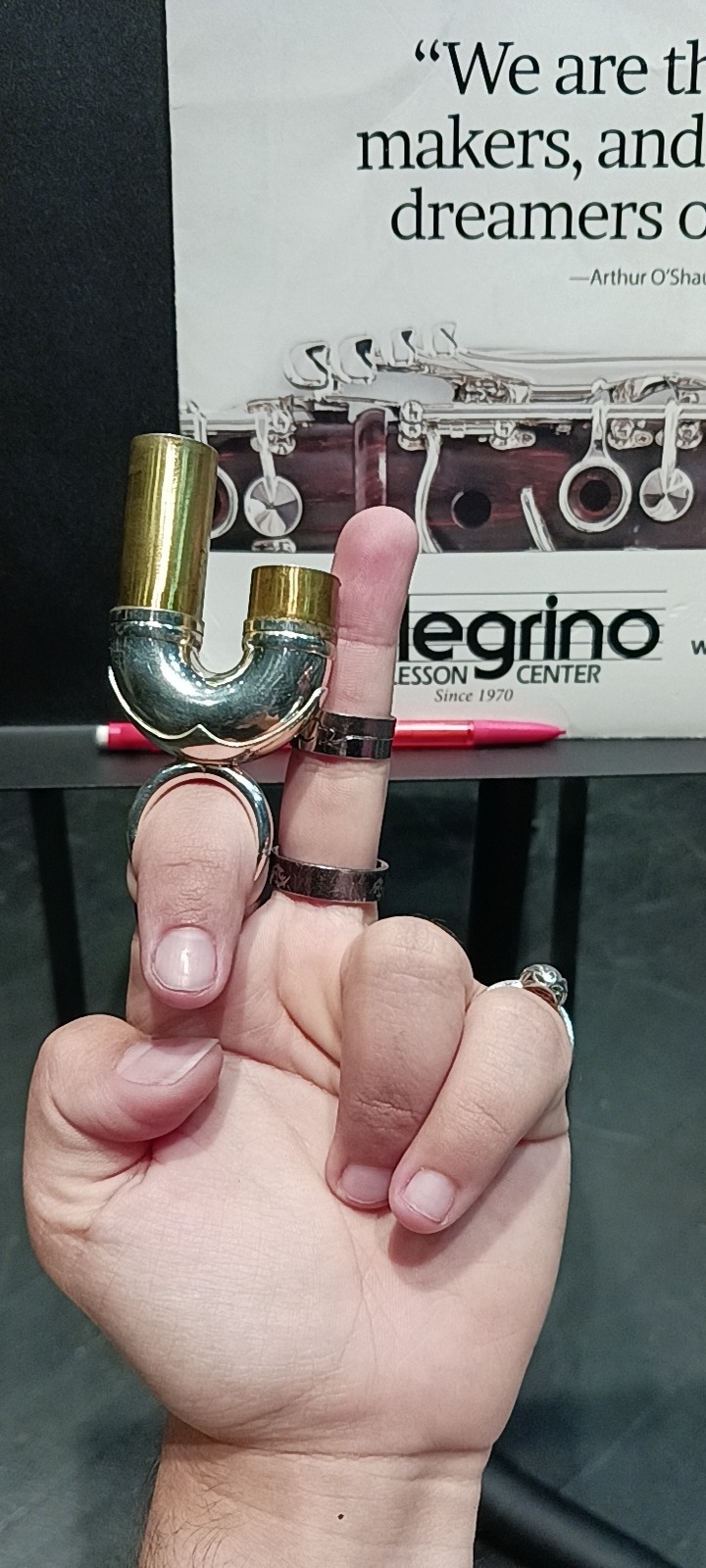

They need to add more stupid attachment thingies to instruments. Instruments need to get scrunklier.

#-Loki#instruments#trombone#F trigger trombone#trumpet#euphonium#compensating valve euphonium#french horn#double french horn#triple french horn#Music

10 notes

·

View notes

Text

AHHHH THE SPIT. THE SPIT GOT ON ME.

hee...heugh...heeeughh...

#i HATE this instrument#i love tjis instrument :)#the spit valve...finger in the wrong spot...#AHHHHHH#trombone#band!!!!

5 notes

·

View notes

Text

Wait fuck I’m learning a wind instrument. The band kids fucking won.

#chit chat#DAMN it#all throughout high school the marching band kids wanted me to become one of them#and i said I’d never take up mouth instruments because they were gross#and now...#sigh#i do admit that i do find the harmonica a little gross and i do have to try and wipe it down after every exercise#but i don’t have to deal with spit valves or reeds or whatever the flutes do#so there is that#harmonica adventures

6 notes

·

View notes

Text

Shitty soldering job, right?

WRONG

That, my friends, is epoxy.

This one got filed under "haha NOPE" because the cost of the repair would not have been worth it. Epoxy does not melt and wipe off the way solder does; I would have had to basically chisel it off, and who knows how long that would have taken me.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#cornet#epoxy#this is what we in the industry often refer to as a “dad fix”#because 9/10 times it is a kid's dad that does stuff like this#moms do it too but in less destructive ways#like telling the kid who forgot to bring valve oil to just use vegetable oil on the valves because oil is oil#less damaging but still a pain#it is well-intentioned but please just don't#or do since then I get paid to fix the problem

2 notes

·

View notes

Text

Band of 107th U.S. Colored Infantry at Fort Corcoran, Arlington, Va. holding saxhorn brass valve instruments. These saxhorns were the type of instruments played at the funeral of African Civil War hero and Captain Andre Cailloux. Many of the instruments were played over the shoulder to play to the army following the band. Instruments today face forward and bands can be in the middle or back of a procession.

Library of Congress

Smith, William Morris, photographer

Created / Published

1865

#african#afrakan#kemetic dreams#africans#brownskin#brown skin#afrakans#library of congress#william morris#1865#fort corocran#arlington#va#saxhorn brass#valve instruments#civil war heros#photographers#photographer

16 notes

·

View notes

Text

Whoever pioneered making a valve this shape should be shot

#euphonium#baritone#tuba#low brass#brass#brass instrument#valves#brass valves#valve instrument#2nd valve

4 notes

·

View notes

Text

I started renting a valve trombone from my school a few days ago and I can say, with full confidence, that it is now one of my favorite instruments. It’s like a trumpet, but bigger and lower and 1000 times cooler. The only thing cooler than it is the tuba, because nothing can compare to the tuba.

4 notes

·

View notes

Text

From my experience with the more cursed instruments I gotta say they all would make really great spell focuses for bards and even better magic wands adjacent things. The three most cursed instruments might have to be the Bassoon, Sarrusophone, and valved Trombone, each something that feels magical all differently...

#Sarrusophone#bassoon#wizard#wizard posting#band#valved Trombone#bard#musical instruments#having tried playing them all the Bassoon is the only one that i ended up buying

5 notes

·

View notes

Text

Types of High-Pressure Check Valves

Different types of high-pressure check valves are available in the market, each designed for specific applications and requirements. Among these types, spring-loaded and ball check valves are particularly popular.

Spring-loaded check valves are known for their reliability and versatility. These valves operate by using a spring mechanism that allows forward flow while preventing reverse flow. In many cases, these valves are preferred for their ease of installation and maintenance.

Ball check valves, on the other hand, utilize a spherical ball to prevent backflow. This design offers minimal pressure drop and is highly effective in high-pressure situations. These valves are commonly used in applications where sudden pressure changes are frequent.

Additionally, diaphragm check valves are another option that is often utilized in high-pressure systems. The diaphragm acts as a sealing element that prevents backflow, ensuring optimal performance. Such valves are favored in sensitive applications, including pharmaceuticals and food processing.

Training personnel involved in the maintenance process is equally important. By providing regular training on the latest maintenance techniques and safety protocols, companies can ensure that their staff is well-equipped to handle valve maintenance effectively. Understanding manufacturers’ specifications and operating manuals can further enhance the maintenance process, ensuring that all activities align with industry best practices.

In conclusion, the upkeep of high-pressure check valves is paramount for ensuring operational efficiency. Regular inspections, testing, and adherence to a maintenance schedule are recommended practices that can enhance the reliability and performance of these critical components.

#instrumentation valves#high pressure check valves#one flow direction valve#freture techno#manufacturers#india

0 notes

Text

Understanding Instrument Valves and Their Importance in Industrial Applications

In industrial systems, precision and reliability are paramount, especially in processes involving the measurement and control of fluids. Instrument valves, a critical component of these systems, ensure safe and efficient operation. At Avlok, we take pride in manufacturing high-quality instrument valves designed to meet the rigorous demands of modern industries. In this blog, we will explore the types, functions, and applications of instrument valves, highlighting their significance in various sectors.

What Are Instrument Valves?

Instrumentation valves are specialized valves used in fluid control systems to regulate, isolate, or vent fluids. These valves are integral to instrumentation systems, ensuring accurate measurement and control in processes like oil and gas extraction, chemical processing, pharmaceuticals, and more. They are designed for precision, often employed in systems that demand high pressure and temperature handling capabilities.

At Avlok, we specialize in manufacturing robust instrument valves that meet international standards, providing reliability and performance in diverse applications.

Types of Instrument Valves

There are several instrument valve types, each serving a unique purpose. Here are the most common types:

1. Ball Valves

Ball valves are widely used for their simplicity and effectiveness. They feature a rotating ball with a hole that allows or blocks fluid flow when turned. These valves are ideal for quick shut-off applications and offer high durability and reliability. We are a leading ball valve manufacturers.

2. Needle Valves

Needle valves provide precise control of fluid flow. They are commonly used in systems where minute adjustments are required, such as in laboratory or instrumentation setups. We are a leading needle valves manufacturers.

3. Manifold Valves

Manifold valves combine multiple valve functions into a single unit, reducing the need for separate valves. They are used in pressure and differential pressure instruments for isolation, equalization, and venting purposes.

4. Check Valves

Check valves allow fluid to flow in one direction only, preventing backflow and protecting sensitive equipment. These valves are essential in maintaining system integrity and efficiency. We are a leading check valve manufacturers.

5. Gauge Valves

Gauge valves are used to isolate pressure gauges from the main process, ensuring accurate readings and protecting the gauges from damage.

Key Applications of Instrument Valves

Instrument valves play a vital role in various industries, including:

1. Oil and Gas

In the oil and gas sector, instrument valves are used in exploration, production, and refining processes to control and monitor fluid flow under extreme conditions.

Avlok's valves are trusted by industry leaders for their durability and performance.

2. Chemical and Petrochemical

Chemical plants rely on instrument valves for precise control of corrosive and high-temperature fluids.

Our corrosion-resistant valves ensure safe and efficient operations in such challenging environments.

3. Pharmaceuticals

Precision is critical in the pharmaceutical industry, where instrument valves are used in processes like filtration, mixing, and sterilization.

Avlok's valves meet stringent hygiene and precision standards, making them ideal for pharmaceutical applications.

4. Power Generation

Power plants utilize instrument valves to regulate steam, water, and other fluids in high-pressure systems.

Our valves are designed to handle the rigorous demands of power generation systems.

Why Choose Avlok for Instrument Valves?

As a leading, Avlok combines innovation, quality, and expertise to deliver products that exceed industry standards. Here are some reasons to choose Avlok:

Unmatched Quality: Our valves are made from premium materials and undergo rigorous testing to ensure reliability and durability.

Customization: We offer tailored solutions to meet specific customer requirements, ensuring seamless integration into your systems.

Global Standards: Avlok's products comply with international quality standards, giving you peace of mind.

Expert Support: Our team of experts provides guidance and support to help you select the right valves for your application.

Conclusion

Instrument valves are indispensable in industrial applications, providing precision, safety, and efficiency. At Avlok, we are committed to delivering top-notch instrument valves that meet the highest standards of quality and performance. Whether you are in the oil and gas industry, pharmaceuticals, or any other sector, our valves are designed to cater to your specific needs.

For more information about our range of instrument valves, feel free to contact us or visit our website. Trust Avlok for all your instrument valve requirements and experience unparalleled quality and service.

#Instrument Valves#Instrumentation valves#ball valve manufacturers#needle valves manufacturers#Manifold valves#check valve manufacturers

0 notes

Text

my euphonium is fighting back and it’s winning

1 note

·

View note

Text

Gas valve train operation guide

The article explains the operation of gas train valve units in industrial systems, focusing on automation, safety, and efficiency. It outlines pre-operation checks, control modes (manual, semi-automatic, and full-automatic), and maintenance and safety tips. The content includes technical insights like using PID controllers for precise temperature and flow control.

0 notes

Text

https://www.baxcell.com/Products.html

BAXCELL range of Instrumentation Valve

BAXCELL manifolds have excellent flow regulation and leak tightness. The operation is smooth, easy, low-torque & long life. Internal surfaces & threads are 100% free from burrs & other foreign particles .Many of the options available with needle valves are available in manifold form. Complete Bonnet assembly will be similar to needle valves.

0 notes

Text

Why you shouldn't use something small and pointy to try removing a stuck piston.

After a bit of work with a dent ball on a stick to smooth down the raised areas.

Small solder patch to seal the hole. Still some small ridges because the sharp edges of the hole just did not want to completely flatten out — leverage is difficult when you can't really brace against anything due to needing to avoid warping the sides of the ports — but at least now it doesn't leak anymore.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#euphonium#piston valve#there I fixed it#sometimes things SHOULD be left to the professionals actually#this is one of those times

3 notes

·

View notes