#such as aluminum to copper.

Explore tagged Tumblr posts

Note

Who are the top 5 elements when it comes to taking care of children?

These 5

81 notes

·

View notes

Text

I wanna be made out of steel and fiber optics so badly you don't even know

#no more nasty squishy greasy hairy imperfect bulbous flesh just metal panels forged exactly as they should be slotted perfectly into place#any defect down to a physical actual flaw that can be identified and fixed like an object should be#processes and systems laid bare and made manifest in steel and aluminum and copper#i need it so bad#i need to be made into an object and used and possessed by someone

23 notes

·

View notes

Text

Balancing the seesaw: Simultaneously enhancing strength and elongation in metallic materials

Just as one side of a seesaw rises while the other falls, in the realm of metallic materials, "strength" and "elongation" typically conflict with each other. However, a collaborative team from POSTECH and Northwestern University has recently introduced a groundbreaking technology that enhances both properties. A research team, consisting of Professor Hyoung Seop Kim from the Graduate Institute of Ferrous & Eco Materials Technology and the Department of Materials Science and Engineering, Professor Yoon–Uk Heo from the Graduate Institute of Ferrous & Eco Materials Technology, and Ph.D. candidate Hyojin Park from the Department of Materials Science and Engineering at POSTECH, collaborated with Dr. Farahnaz Haftlang from Northwestern University's Department of Materials Science & Engineering. Together, they have tackled a long-standing issue in metals research: the tradeoff between strength and elongation. Their breakthrough involves designing an alloy that boasts both high strength and high elongation.

Read more.

#Materials Science#Science#Strength of materials#Ductility#Alloys#Phases#Phase transitions#Copper#Aluminum#Iron#High entropy alloys#High entropy materials

10 notes

·

View notes

Text

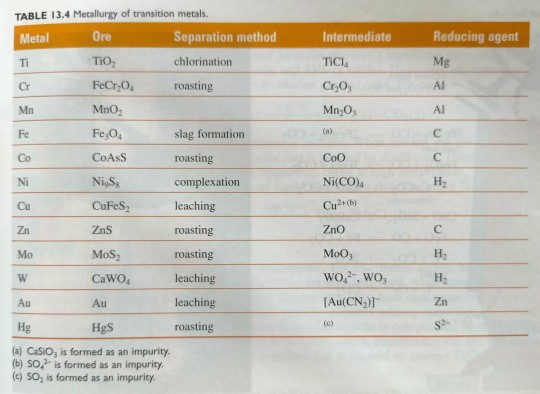

Table 13.4 on the next page provides a summary of the chemical species and processes involved in the metallurgy of many transition metals.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#metallurgy#transition metal#titanium#chromium#manganese#iron#cobalt#nickel#copper#zinc#molybdenum#tungsten#gold#mercury#magnesium#aluminum#carbon#hydrogen#sulfur#chlorination#roasting#slag#leaching#complexation

14 notes

·

View notes

Text

#wrapbymm#wordsbymm#mmybsdrow#pourbymm#connecting#copper#galvanized wire#colored aluminum wired#hashtag poetry#Ukraine#the War continues#past two years

2 notes

·

View notes

Text

Trusted Dealer in Copper Millberry Wire Scrap Worldwide

Trusted Dealer in Copper Millberry Wire Scrap Worldwide Commodity: Copper Millberry Wire Scrap. Ordered Quantity: 20 MT (regular). Payment/Shipment: Telegraphic Transfer (T/T), Ship by CIF , Deliver 7 days upon confirmation. Target Price (Per Unit): None. Category: Copper Scrap.

More Information

#aluminum#hms scrap#metals#Copper Scrap#CopperMillberryScrap#MetalRecycling#CopperWireTrader#ScrapMetalDeals#GlobalMetalSupplier#CopperScrapMarket#TrustedMetalDealer#SustainableMaterials#BulkMetalOrders#InternationalScrapTrade

2 notes

·

View notes

Text

Anyone else do any scrapping? I absolutely love it and it's a lifesaver during hard times when cash is hard to come by.

#copper#copperwire#scrap#scrap yard#aluminum#scrapping#scrapmetal#metal#thrifty#money#brass#scrap metal

3 notes

·

View notes

Text

2 notes

·

View notes

Text

Just confirmed the last of THREE Pride events for this June in West Michigan.

If you're in SW Michigan and want chainmail ... go find me on facebook (CCChainmaille) for a list of dates that will be pinned!

Chainmail, more chainmail, costume pieces, spell jars and kits and pendants and some witchy things TO GO.

#CC Chainmaille#SW Michigan#Made in Michigan#Chainmaille#Chain Mail#Scalemaille#Scalemail#Anodized Aluminum#Stainless Steel#Titanium#Bronze#Copper#Dice Bags#Scale Bras#Maille Shirts#Inlays

5 notes

·

View notes

Text

IM VERY HAPPY TO TELL YOU ALL THAT THE LEGACY AND TRADITION OF EA-NASIR LIVES ON TODAY IN ADS ON TUMBLR DOT COM.

come get your 100% excellent silver, we have no bad reviews, we promise

#shitposts#tumblr humor#text#jokes#Ea nasir#the shitty copper is silver but also probably tin or aluminum#Insert quote about history is a cycle / nothing really dies / monkeys and Shakespeare#Bc let’s be fair we are all the monkeys on this hellsite humor and mentality wise#But also evolutionarily ig#Tumblr culture#tumblr history#tumblr ads

3 notes

·

View notes

Text

I dont know. i wish i was as smart as i pretend to be sometimes

#my posts#oh the imposter syndrome.#experiencing The Symptoms#the truth of the matter is i'm not very creative and i'm mediocre at art and writing#and i may act like i understand music and music theory but i don't#and i pretend to know a lot about metal but i really only know anything about aluminum and copper#and i act like i understand planets and stars and their relation to each other#and i think the worst one among all these things i pretend to be knowledgeable about is ethical philosophy.#i've really only taken two and the other philosophy classes i've taken i eked by on#genuinely don't know how i passed my logic course so much of that goes over my head#i like acting clever because it makes me feel better about the simple fact i'm not really skilled at anything#most of the time when people ask me things i supposedly know i do a quick google search and just rephrase it#do i think this makes me a bad person? no.#it just makes Me feel bad#and honestly who Doesn't like the idea of being smart#and tbh is experiencing that Youngest Child Inadequacy which is t fair to my brother at all but oh baby when that sneaks up on you#anyways i don't really have anyone i can talk to about this stuff#i mean i do but i don't like burdening people with my vents so i use my blog sometimes as a journal#negative/#tbd.

5 notes

·

View notes

Photo

Novel durable copper-aluminum-zinc shape memory alloys for energy-efficient refrigeration

The elastocaloric effect is a phenomenon where a material displays a temperature change when it is exposed to a mechanical stress. The change in temperature occurs due to an entropy difference resulting from a martensitic transformation accompanied by material's crystal structure change under stress.

An analogous effect is observed when the rubber band is stretched: its polymer chains line up in an ordered manner, causing its entropy to decrease. This leads to the rubber band discharging heat to its surroundings and becoming warmer. When the rubber band is released, the opposite occurs, and the rubber band cools down.

Like rubber bands, metallic superelastic shape memory alloys (SMAs) can also utilize the elastocaloric effect for cooling. Copper (Cu)-based SMAs consisting of Cu, aluminum (Al), and zinc (Zn) are particularly promising due to their low cost and modest stress demands for triggering the temperature lift. However, Cu-Al-Zn SMAs suffer from cyclical fatigue issues as their coarse crystal grains and numerous grain boundaries are susceptible to fracture from repeated expansion and contraction.

Read more.

#Materials Science#Science#Elastocaloric#Shape memory alloys#Martensite#Copper#Aluminum#Zinc#Alloys#Shape memory effect#Tokyo University of Science

22 notes

·

View notes

Text

Forged Fittings Vs Wrought Fittings

What is Wrought Fittings?

A Wrought Fittings product is a form of steel made from forged, rolled, ring-rolled, extruded or welded components, while forging refers to one of these forms.

What are uses of Wrought Fittings?

For the construction of buildings, the wrought iron plate girder evolved as a basic device. There were many decorative uses for wrought iron in historical times, including fences, gates, railings, balconies, porches, canopies, roof crestings, lamps, grilles, hardware, nails, cramps, and structural members in tension (I, H, etc.).

What is Forged Fittings?

Forged Fittings is a material produced by alloying iron and carbon under extreme pressure. The surface porosity of forged steel is lower, its grain structure is finer, it has a greater tensile and fatigue strength, and its ductility is significantly higher than steel that has been processed by other means.

What are uses of Forged Fittings?

It is common for forged fitting components to be used in automotive and truck applications, for manufacturing valves, fittings, hand tools and hardware, as well as in manufacturing industrial, heavy construction and mining equipment. The components are made of steel, and these components include the powertrain, axle beams, shafts, wheel spindles and kingpins.

What are the types of forged Fittings?

In order to keep things simple, we divide steel forging into three categories based on the temperature at which it is forged.

Hot forged steel

As the temperature reaches 950°C, the forging process is carried out between 950°C and 1250°C, which is over the temperature of recrystallization. Steel that has been hot forged has good formability and requires a low level of force to shape, which is why it is so popular.

Hardened steel forging

As a general rule, the forging temperature is between 750°C and 950°C. There are limitations in the ductility of this material as well as higher forming forces required than forging at a hot temperature. Besides its great advantages, it can also be considered a middle ground between hot and cold forging, which makes it more versatile than either one alone.

Cold forged steel

This process is carried out under ‘room conditions,’ that is, under temperatures as high as 150 degrees Celsius. The forging process is characterized by the low formability of the material, which demands high forces during the forming process. As a result, it is of great advantage for the conservation of material and for the smoothness of the surface that is achieved with this method.

Here are some comparisons between wrought steel products and forged steel products:

It is important to keep in mind that the major difference between wrought steel and forged steel is their strength. There is no doubt that forged steel is much more durable than wrought steel, since forged steel becomes a casting that is then forged, which adds to its durability even further.

Tap here to read more about:

2 notes

·

View notes

Text

Empathy, 2018 - Paul Villinski

#paul villinski#butterfly art#butterflies#found aluminum cans#copper leaf#wire#art gallery#contemporary art#art#artwork#recycled art#jonathan ferrara gallery

3 notes

·

View notes

Text

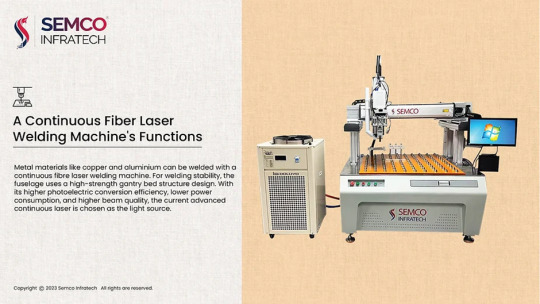

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

More Disco Turkeys (Peacocks). Made for the staff at my dentists office. 18 gauge copper wire base, with blue, brass, purple, silver, and light pink aluminum wire for accents.

0 notes