#steel producers and suppliers

Explore tagged Tumblr posts

Text

Since the early stages of Steel Manufacture, the steel factory sector has advanced significantly. Modern steel factories use a variety of cutting-edge technologies and eco-friendly procedures to mass-produce steel goods of the highest quality.

#Steel factory#steel manufacturing#steel manufacturers#steel producers and suppliers#steel production

1 note

·

View note

Text

China Alloy Steel, Alloy Steel, wholesale Alloy Steel, Alloy Steel manufacturers stainless steel manufacturers, stainless steel suppliers, stainless steel factory, China stainless steel price, Chinese suppliers https://superbmaterials.com/

#630 stainless steel#631 stainless steel#stainless steel forging#stainless steel alloys#alloy steel china#carbon steel china#nickel alloys china#stainless steel china#copper producers china#heat resistant alloys#china#united states#Shanghai#Pudong#suppliers#stainless#Alloy Steel#Alloy#Steel#Chinese#factory#manufacturers#kitchen

2 notes

·

View notes

Text

Ganpat Metal Industries is one of the renowned Manufacturer & Exporter, of a qualitative range of High Nickel Alloy SocketWeld Forged Fittings that are being designed as per the national and international standard quality of raw materials.

#carbon steel socketweld fittings manufacturers#high nickel alloy socketweld fittings suppliers#high nickel alloy socketweld fittings stockists#steel#manufacturers#suppliers#producers#exporters

0 notes

Text

Role Of Pig Iron In Steelmaking

Explore the role of pig iron in steelmaking, and reach out to the top pig iron producers in India to access steel grade pig iron in India.

#pig iron suppliers#SG grade pig iron in Eastern India#steel grade pig iron#steel grade pig iron in India#top pig iron producers in India

0 notes

Text

Dealer of Stainless Sheet & Coil I Accurate Steels

Accurate Steel is a team of professionals working hard to provide the best possible service to its customers. We are Jindal-authorized dealers of ss sheets and coils. We have a wide range variety available at our godowns providing express delivery. Our team has been working hard for customer satisfaction. We also keep ready stock of most of the sheets and coils. Contact us for every type of grade sheet.

1 note

·

View note

Text

Shree Mahalaxmi Steel Industries: Pioneering Excellence as an HR Sheet Manufacturer

Introduction:

In the ever-evolving landscape of the steel industry, HR (Hot-Rolled) sheets have emerged as indispensable components, serving as the backbone for diverse applications across various sectors.

As industries demand top-notch quality and versatility, manufacturers like Shree Mahalaxmi Steel Industries play a pivotal role in meeting these requirements. This blog delves into HR Sheet manufacturing, exploring the significance of HR sheets, the part of it, and the broader context of the industry.

Understanding HR Sheets:

HR sheets are a type of steel sheet produced through the hot-rolling process, where metal is passed through rollers at high temperatures. This enhances the material’s strength and formability, making it a preferred choice in construction, automotive, shipbuilding, and various other industries.

The demand for high-quality HR sheets has led to a competitive market, with manufacturers striving to meet the stringent standards of enterprises.

Shree Mahalaxmi Steel Industries: A Beacon of Excellence:

As a leading HR Sheet Manufacturer, it has established itself as a beacon of excellence in the industry. The company’s commitment to quality, innovation, and customer satisfaction sets it apart.

They specialize not only as an HR Sheet Manufacturer but also as a Hot Rolled Sheet Producer and Industrial HR Sheet Supplier. It plays a multifaceted role in shaping the steel landscape in India.

1. Hot Rolled Sheet Producer:

It has emerged as a distinguished Hot Rolled Sheet Producer, offering sheets that meet and exceed international standards. The hot-rolling process employed by the company ensures that the produced sheets possess enhanced strength and malleability, making them suitable for a myriad of applications. Precision and durability emphasize it as a trusted name in Hot Rolled Sheet production.

2. Industrial HR Sheet Supplier:

Beyond manufacturing, it operates as an Industrial HR Sheet Supplier, facilitating the seamless flow of materials from production facilities to end-users. The company’s extensive network allows it to cater to the diverse needs of industries across India. It plays a crucial role in sustaining the manufacturing processes of various sectors by ensuring a timely and reliable supply of HR sheets.

3. HR Sheet Manufacturers in India:

As one of India’s prominent HR Sheet Manufacturers, it contributes significantly to its position in the global steel market. The company’s products are not only tailored to meet domestic demands but also to compete on the international stage. The prowess of Indian HR Sheet manufacturers, exemplified by companies like it, is crucial in establishing India as a critical player in the global steel industry.

4. Cold-Rolled Steel Sheet Manufacturer:

While Hot-Rolled Sheets dominate specific applications, Cold-Rolled Sheets cater to industries where a smoother surface finish and precise dimensions are critical. It extends its influence into this domain, showcasing versatility as a Cold-Rolled Steel Sheet Manufacturer. This diversification allows the company to meet the nuanced needs of industries such as automotive manufacturing and electrical appliances.

Significance of HR Sheets in Industries:

Construction Sector:

HR sheets find widespread use in the construction sector, contributing to structural components, roofing, and cladding. It ensures that its HR sheets align with the demanding standards of construction projects, providing materials known for their high strength and durability.

Automotive Manufacturing:

The automotive industry relies on the malleability and strength of HR sheets, using them to fabricate chassis, body panels, and structural reinforcements. It plays a crucial role in this sector, producing top-quality HR sheets and contributing to vehicle safety and performance.

Shipbuilding Industry:

Hot-rolled steel Sheets have become integral in the shipbuilding industry, where materials must withstand the harsh marine environment. The company’s commitment to quality ensures that these sheets offer the necessary strength and corrosion resistance, contributing to the longevity of vessels.

Manufacturing of Industrial Equipment:

HR sheets are indispensable in manufacturing industrial equipment, from heavy machinery to specialized components. It provides versatile offerings that contribute to the customization of these components, meeting specific performance and safety standards in various industrial applications.

The Competitive Landscape and Shree Mahalaxmi Steel Industries’ Approach:

The Indian market for HR sheets is marked by intense competition, with manufacturers striving to distinguish themselves in quality, innovation, and customer satisfaction. It rises to this challenge by consistently upgrading its production facilities, adopting eco-friendly practices, and investing in research and development. This approach ensures that the company remains at the forefront of the industry, delivering products that meet and exceed the expectations of its diverse clientele.

Challenges and Opportunities:

India’s HR Sheet manufacturing industry faces challenges such as fluctuating raw material prices, stringent environmental regulations, and the need for continuous technological advancements. However, It views these challenges as opportunities to innovate, optimize processes, and explore sustainable practices. By doing so, the company ensures a resilient and future-ready approach to HR Sheet manufacturing, positioning itself as a leader in the industry.

Conclusion:

In conclusion, It is a cornerstone in HR Sheet manufacturing. The company’s multifaceted role as an HR Sheet Manufacturer, Hot Rolled Sheet Producer, and Industrial HR Sheet Supplier underscores its versatility and commitment to excellence. As industries evolve, the demand for high-quality HR sheets remains unabated.

It is meeting this demand and setting new standards for quality, innovation, and reliability. The synergy between manufacturers, suppliers, and end-users, exemplified by it, forms the backbone of a robust HR Sheet ecosystem, ensuring India remains a formidable force in the global steel industry.

#HR Sheet Manufacturer#Hot Rolled Sheet Producer#Steel Sheet Manufacturer#Hot-Rolled Steel Sheet Manufacturer#Worker Locker Manufacturer#storage locker#industrial office#staff locker#industrial locker#HR Coil Manufacturer#Hot Rolled Coil Producer#hot rolled coil#hot rolled#Industrial HR Coil Supplier#Industrial HR Sheet Supplier#hot rolled sheet#CR Coil Manufacturer

0 notes

Text

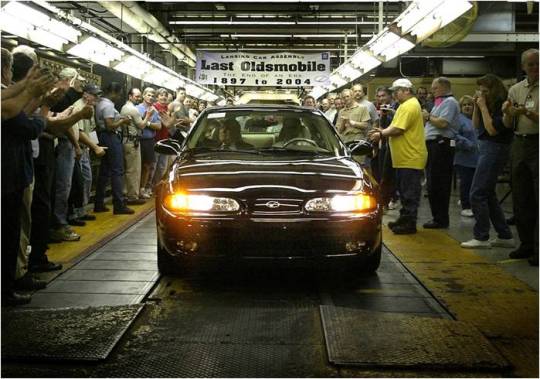

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

94 notes

·

View notes

Text

In Eastern Europe, for instance, the number of people living in cities declined by almost one-third during the seventeenth century, as the region became an agrarian serf-economy exporting cheap grain and timber to Western Europe. At the same time, Spanish and Portuguese colonizers were transforming the American continents into suppliers of precious metals and agricultural goods, with urban manufacturing suppressed by the state. When the capitalist world-system expanded into Africa in the eighteenth and nineteenth centuries, imports of British cloth and steel destroyed Indigenous textile production and iron smelting, while Africans were instead made to specialize in palm oil, peanuts, and other cheap cash crops produced with enslaved labor. India—once the great manufacturing hub of the world—suffered a similar fate after colonization by Britain in 1757. By 1840, British colonizers boasted that they had “succeeded in converting India from a manufacturing country into a country exporting raw produce.” Much the same story unfolded in China after it was forced to open its domestic economy to capitalist trade during the British invasion of 1839–42. According to historians, the influx of European textiles, soap, and other manufactured goods “destroyed rural handicraft industries in the villages, causing unemployment and hardship for the Chinese peasantry.”

Jason Hickel and Dylan Sullivan, Capitalism, Global Poverty, and the Case for Democratic Socialism

104 notes

·

View notes

Text

Excerpt from this story from RMI:

As new clean technologies grow up S-curves, the incumbent technologies get pushed out in inverse S-curves.This creates an X pattern that is standard in technology history; we saw this for example in the shift from cast iron to steel and from horses to cars.

The energy transition can be summarized in three Xs: renewables, electrification, and efficiency.

Solar and wind push out fossil-fueled electricity Solar and wind are the new superior energy sources: they are cheap and getting cheaper, available everywhere, and captured locally. They eliminate combustion and pollution from electricity generation. They are rapidly taking over electricity supply. In 2000, solar and wind produced just 0.2 percent of global electricity. By 2010, this figure had increased to 2 percent, and by 2023, it had reached 13 percent. By 2030, they will be producing over a third of global electricity generation.

Obedient electrons push out fiery molecules Electricity is the newly dominant energy carrier, transcending the inefficiencies and pollution resulting from setting fossil molecules on fire. Over the past century, electricity has quietly risen to become the largest supplier of useful energy. According to Rystad Energy, in 1965 electricity accounted for 10 percent of useful energy, rising to 30 percent in 2022. This century-long trend is about to accelerate as renewables make electricity cleaner, cheaper, more secure, and more efficient. By 2050, electricity is likely to supply around 70 percent of useful energy.

Efficiency pushes out waste The efficiency of the energy system is set to structurally rise in the decades ahead, enabling more wealth creation per unit of energy. Old fossil energy is incredibly inefficient: about two-thirds of primary energy goes up in smoke as it is converted to useful purposes. But renewable electrification removes combustion from the energy chain, meaning we lose much less energy to unused heat. Further considering design and digitalization can give us more energy services from far less primary energy. And greater efficiency means the supply-side takeover of renewables and electricity happens even faster.

10 notes

·

View notes

Text

Industry Insights: Where We Supply Tool Steel - Virat Special Steels

Virat Special Steels stands tall as India’s largest stockiest, importer, and supplier of HSS Steel, Hot Work Steel, Cold Work Steel & Plastic Mould Steel. Representing top manufacturers of special steels worldwide, we enjoy global recognition for our unwavering commitment to quality.

Serving Industries: 🔧 Forging Industry: Shaping metal using compressive forces with a hammer or press, classified into cold forging, warm forging, or hot forging.

🏗️ Pressure Die Casting: Forcing molten metal under high pressure into a mold cavity, made using two hardened tool steel dies.

🚗 Aluminum Extrusions: Material pushed through a die to the desired cross-section, creating complex parts with excellent surface finishes.

🚙 Automotive Industry: Involved in manufacturing, design, and development of motor vehicles.

⛽ Oil & Gas Industry: Supplying more than 60% of our nation’s energy, including natural gas for electricity.

🧩 Plastic Industry: Manufacturing polymer materials for aerospace, construction, electronics, packaging, and transportation.

🍶 Glass Industry: Involves float glass process and glassblowing, producing sheet glass and containers.

🚲 Cycle Parts: Manufacturing components like bearings, chains, chain sets & cranks, handlebars, forks.

🚉 Railways: Manufacturing railway components such as gear holders, bogie cast parts, axles, pins, ground lever frames, adjustable cranks, compressor pistons, and bearings.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is your trusted partner, supplying premium tool steels to diverse industries in India and globally.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#h13diesteel#h13steel#h13steelbarexporter#h11steel#din 2714#din 2344#din2343#din2738#d2steel#m2steels#m35#p20ni

3 notes

·

View notes

Text

Stronger, Safer, Better: Discover the Best TMT Steel Bars !

As the No.1 TMT steel bars manufacturer, we pride ourselves on producing high-quality TMT bars that adhere to the most stringent industry standards. Our state-of-the-art manufacturing process ensures the production of durable, corrosion-resistant, and highly flexible TMT steel bars, suitable for all types of construction projects. Whether you’re building a residential, commercial, or industrial structure, our TMT bars offer unmatched strength and reliability. Choose us for the best quality and dependable steel reinforcement.

When it comes to selecting the best TMT bars in Palakkad, Kerala, our product range stands out for its unparalleled strength, flexibility, and long-lasting performance. Manufactured using advanced technology, our TMT steel bars ensure superior resistance to seismic forces and corrosion, making them the ideal choice for construction in Kerala's diverse climate. Choose our high-quality TMT bars for your building and infrastructure projects, and experience the difference in performance and durability.

As leading TMT bar manufacturers in Palakkad, Kerala, we specialize in producing high-quality TMT steel bars that offer the perfect balance of strength, durability, and flexibility. Our TMT bars are manufactured using the latest technology, ensuring that they meet international quality standards. We are committed to providing our clients with steel reinforcement solutions that are both cost-effective and reliable. Whether you’re working on residential or large-scale commercial projects, our TMT bars are designed to provide maximum safety and strength.

Best TMT Bar for House Construction

For house construction, the best TMT bars provide the ultimate combination of strength, ductility, and corrosion resistance. Our TMT bars are designed to withstand the stress of building structures in different climatic conditions, ensuring long-lasting durability. With the latest technology in steel manufacturing, we offer TMT bars that offer enhanced safety and structural integrity, making them the perfect choice for residential construction. Trust our high-quality TMT steel bars to build your dream home with strength and security.

As the supplier of the best TMT steel bars in Palakkad, Kerala, we ensure that our products meet the highest quality standards for safety and durability. Manufactured using the latest technology, our TMT bars are highly flexible and resistant to corrosion, making them ideal for use in construction across diverse conditions. Whether you’re involved in residential, commercial, or industrial construction projects, our TMT steel bars will provide the necessary strength and reliability for your building needs.

We are one of the leading TMT steel suppliers in Palakkad, Kerala, offering premium-quality steel products for all types of construction projects. With a focus on excellence, we supply TMT steel bars that are strong, flexible, and durable, meeting the highest standards of quality and performance. Whether you need steel for residential buildings, bridges, or large-scale infrastructure projects, we have the right TMT steel bars for your specific requirements. Count on us for timely delivery and competitive prices.

As one of the top TMT bar manufacturers in Palakkad, Kerala, we take pride in providing our customers with high-performance steel bars that are suitable for all types of construction applications. Our TMT bars are engineered with advanced technology to ensure superior strength, ductility, and corrosion resistance. With a reputation for excellence and a commitment to customer satisfaction, we are the preferred choice for contractors and builders across Kerala. Choose our TMT bars for reliable reinforcement solutions that stand the test of time.

#commercial#interior design#sales#type#manufacturing company#manufacturing#manufacturer#fiber art#tmt steel bars#steel structure#steel manufacturer#steelers#steeldoors#product#wall#artists on tumblr#tmt bars#tmt steel#tmt steels#steelsolutions#steelsupplier#suppliers#services#kerala#palakkad#no. 1#business#development

3 notes

·

View notes

Text

MS ERW B/Weld Reducer Eccentric at Best Price in India

In the dynamic world of industrial piping, efficiency and reliability are paramount. The MS ERW (Electric Resistance Welded) Butt Weld Eccentric Reducer plays a crucial role in connecting pipes of different diameters while ensuring optimal fluid flow. If you're in search of the best prices for MS ERW B/Weld Eccentric Reducers in India, look no further than Udhhyog, your trusted supplier.

What is an MS ERW B/Weld Eccentric Reducer?

An MS ERW B/Weld Eccentric Reducer is a specialized fitting designed to connect pipes of varying sizes. Unlike concentric reducers, which maintain a circular profile, eccentric reducers feature a flat edge on one side. This design is essential for preventing sedimentation in applications where solids may accumulate, making them ideal for use in wastewater systems and other similar setups. The robust construction and butt-welded design provide a secure, leak-proof connection suitable for high-pressure environments.

Key Features of MS ERW B/Weld Eccentric Reducers

Efficient Fluid Flow: The eccentric design minimizes turbulence and ensures a smooth transition between pipe sizes, facilitating better flow rates.

Durable Material: Crafted from high-quality mild steel, these reducers are built to withstand harsh operating conditions, including high pressures and temperatures.

Leak-Proof Connections: The butt weld design ensures a secure joint that significantly reduces the likelihood of leaks.

Versatile Applications: Suitable for a range of industries, including oil and gas, water treatment, and chemical processing.

Cost-Effective Solution: Offering exceptional quality at competitive prices, these reducers are an economical choice for industrial applications.

Applications of MS ERW B/Weld Eccentric Reducers

Wastewater Management: Eccentric reducers are particularly useful in wastewater applications, where preventing sediment buildup is crucial for maintaining system efficiency.

Oil and Gas Pipelines: These fittings provide seamless transitions in pipelines, ensuring pressure integrity and fluid management.

Chemical Processing: In chemical plants, they help maintain efficient fluid transitions, facilitating various processes with minimal disruption.

HVAC Systems: Eccentric reducers are often used in HVAC systems to ensure balanced airflow and effective pressure control.

Why Choose Udhhyog for MS ERW B/Weld Eccentric Reducers?

At Udhhyog, we pride ourselves on being a leading supplier of MS ERW B/Weld Eccentric Reducers at the best prices in India. Here’s why you should partner with us:

Quality Manufacturing: Our reducers are produced under strict quality control measures to meet industry standards, ensuring you receive top-tier products.

Affordable Pricing: We are committed to providing high-quality products without breaking your budget, making us the go-to supplier for industrial fittings.

Prompt Delivery: Located in Delhi, we offer timely delivery services across India, ensuring your projects remain on schedule.

Extensive Product Range: Beyond eccentric reducers, we offer a wide selection of industrial fittings, flanges, and valves to cater to all your piping needs.

Dedicated Customer Support: Our team is focused on understanding your specific requirements and delivering tailored solutions to enhance your operational efficiency.

Order Your MS ERW B/Weld Eccentric Reducers Today

Choosing Udhhyog as your supplier for MS ERW B/Weld Eccentric Reducers means gaining access to high-quality products at the best prices in India. Whether you're involved in large-scale industrial projects or specific applications, we are here to support your needs with reliable and effective solutions.

#MSErwEccentricReducer#PipeFittings#IndustrialPiping#Udhhyog#EccentricReducerIndia#BestPriceIndia#DelhiSupplier#SteelPipeFittings#CostEffectiveSolutions#MSPipeFittings

2 notes

·

View notes

Text

SS 316 Blind Flange Manufacturer

Overview: As a leading SS 316 Blind Flange manufacturer, we specialize in producing high-quality, corrosion-resistant flanges designed to meet the needs of various industrial applications. Our commitment to quality and precision engineering sets us apart in the market.

Key Features:

Premium Material: Our SS 316 Blind Flanges are crafted from top-grade stainless steel 316, ensuring superior resistance to corrosion, high temperatures, and oxidation.

Custom Manufacturing: We offer custom sizes and specifications to cater to the unique requirements of your projects.

High Precision: Manufactured using advanced technology and strict quality control measures to ensure perfect dimensions and fit.

Versatile Applications: Ideal for use in chemical processing, pharmaceuticals, oil and gas, and other industries requiring robust sealing solutions.

Why Choose Us?

Experienced Manufacturer: With years of expertise in the industry, we guarantee reliable products that meet international standards.

Competitive Pricing: We provide the best prices without compromising on quality, making us a preferred supplier for many clients.

Timely Delivery: We understand the importance of deadlines and ensure that your orders are delivered on time.

5 notes

·

View notes

Text

Gate Valves in the Petrochemical Industry: Key Applications

In the complex and demanding environment of the petrochemical industry, the selection of appropriate valves is critical to ensuring the efficiency and safety of operations. Among the various types of valves used, gate valves play a crucial role due to their unique characteristics and versatility. This article explores the key applications of gate valves in the petrochemical industry and highlights their importance, especially for those seeking reliable suppliers such as a Valve Stockist in the Dubai or renowned Valve Manufacturers globally.

Understanding Gate Valves

Gate valves are primarily used to either completely stop or allow the flow of a fluid through a pipeline. Unlike other valve types, gate valves operate by lifting a gate out of the path of the fluid. This mechanism is ideal for applications that require the valve to be either fully open or fully closed, making them unsuitable for flow regulation but perfect for on-off control.

Key Applications in the Petrochemical Industry

Isolation of Flow:

Gate valves are extensively used for isolating sections of pipelines during maintenance or emergencies. Their ability to provide a tight seal ensures that no leakage occurs, which is vital in handling hazardous fluids. This makes them indispensable in petrochemical plants where safety is paramount.

Handling High-Pressure Fluids:

The petrochemical industry often deals with high-pressure fluids, and gate valves are well-suited to handle such conditions. Their robust design and capability to withstand high pressures make them a preferred choice for critical applications. Valve Manufacturers in Spain are known for producing high-quality gate valves that can operate efficiently under extreme conditions.

Controlling Corrosive Media:

Petrochemical processes frequently involve corrosive media. Gate valves made from specialized materials, such as stainless steel or alloy, are used to resist corrosion and prolong the valve’s service life. For industries looking for specialized valves, engaging with a reputable Gate Valves Supplier is crucial to ensure durability and reliability.

Steam and Heat Transfer Systems:

In petrochemical plants, steam and heat transfer systems are integral to various processes. Gate valves are employed in these systems to manage the flow of steam and other high-temperature fluids. These valves can handle the thermal expansion and contraction that occur in such systems, making them a vital component of heat management.

Shutdown Systems:

In emergency shutdown systems, gate valves are often used due to their ability to quickly and completely stop the flow of hazardous fluids. This quick response capability is critical in preventing accidents and ensuring the safety of the plant and its personnel.

Sourcing the Right Gate Valves

For businesses in the petrochemical industry, sourcing the right gate valves from reliable suppliers is essential. A Valve Stockist offers a wide range of options, ensuring that industries can find the exact specifications they need. Moreover, working with a Ball valves Supplier, Globe Valves Supplier, or Butterfly valve supplier can provide comprehensive valve solutions for various applications.

Additionally, many industries are turning to international markets for their valve needs. Valve Manufacturers in Spain have earned a reputation for their quality and innovation, providing robust solutions for petrochemical applications. Engaging with such manufacturers ensures access to advanced technology and high-quality products.

Conclusion

Gate valves are indispensable in the petrochemical industry, serving critical functions across various applications. Whether isolating sections of a pipeline, handling high-pressure fluids, or managing corrosive media, these valves provide the reliability and safety that petrochemical plants demand. To ensure optimal performance and safety, it is crucial to source these valves from reputable suppliers, such as a Valve Stockist in UAE or leading Valve Manufacturers globally. Additionally, working with specialized suppliers like a Control valves supplier or Water Valves Supplier can further enhance the efficiency and safety of petrochemical operations

2 notes

·

View notes

Text

Drive Your Corvette to Work Day

Many Corvette owners own other cars as well, and often only drive their Corvettes on special occasions. Corvettes are regularly driven on beautiful days or are taken to car shows, but usually aren’t used as commuter cars for work. But, today is different—today is Drive Your Corvette to Work Day. Sponsored by Mid America Motorworks, a supplier of aftermarket Corvette parts and accessories, the day has taken place since 2001. The goal is to get as many Corvette owners as possible around the world to drive their car, in order to show how popular the car is. It takes place on the Friday closest to June 30, the day in 1953 when the first Corvette came off the General Motors assembly line.

Harley J. Earl was no stranger to designing cars. He redesigned the LaSalle in the late 1920s, designed the Buick Y-Job—which is seen as being the first concept car, and also designed the GM Le Sabre. He then began working on “Project Opel,” which would turn into the Corvette. In its design, he took inspiration from the Jaguar XK120. On January 17, 1953, the Corvette was introduced at GM’s traveling Motorama display, at the Waldorf Astoria Hotel in New York City.

Later that year, on June 30, the first Corvette for consumers came off the assembly line at the GM plant in Flint, Michigan. Tony Kleiber, a worker at the plant, drove the first car off the line. The Corvette had been named by Myron Scott, a photographer for Chevrolet. After looking in the dictionary for a word that started with a “C,” in order to give the make and model phrase an alliterative effect, he found “corvette,” the name for a small warship that was fast and easy to maneuver.

At a time when most cars were built out of steel, the Corvette was the first sports car with a body made completely of fiberglass. There were only 300 built the first year, all of which were white convertibles with red interiors and black canvas tops. They otherwise used standard Chevrolet parts, such as the “Blue Flame” six-cylinder engine, and the two-speed Powerglide automatic transmission. Still, they could go from the speed of 0-60 in 11 seconds and could reach a speed of 110 mph. They had no exterior door handles, and no windows as well, just plastic curtains. They had a sticker price of $3,513, which is $32,979 in 2018 dollars. All were equipped with a $91 heater and $145 AM radio, which was added to the sticker price. 1953 models are worth much more now: the third Corvette produced was sold for 1.06 million dollars in 2006.

As of 2018, there have been seven generations of Corvettes (C1-C7). V8 engines were an option beginning in 1955, and 9 out of 10 buyers selected the option that year; all Corvettes have since been equipped with V8s. By the 1960s, the Corvette was known as America’s favorite sports car. The second generation (C2) of the car was produced from 1963-1967 and was known as the Sting Ray. One of the most popular Corvettes of all time is the 1963 model, which is unique for having a split rear window.

Corvettes have been produced in Flint, Michigan, St. Louis, Missouri, and since 1981, in Bowling Green, Kentucky, where the National Corvette Museum also is also located. There were issues when making the 4th generation of the car, thus only one 1983 model exists, and production was continued with the 1984 models. The lone 1983 model can be seen at the Corvette Museum. Years after the first Corvette rolled off the assembly line, they still are towards the top of the pack for speed and acceleration. They have also been continually produced longer than any sports car or passenger car in the world.

Drive Your Corvette to Work Day is being observed today! It has been observed the closest Friday to June 30th since 2001.

Source

#Drive Your Corvette to Work Day#DriveYourCorvettetoWorkDay#28 June 2024#Friday that's closest to June 30#National Corvette Museum#Bowling Green#Kentucky#USA#summer 2016#original photography#car#vacation#travel#engineering#Chevrolet Corvette#'Vette#sports car#tourist attraction#interior#Corvette Stingray#landmark#architecture#technology

6 notes

·

View notes

Text

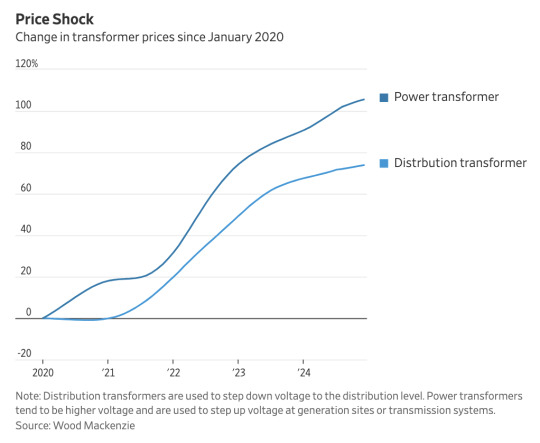

How Tariffs Could Shock America’s Power System. (Wall Street Journal)

Excerpt from this Wall Street Journal story:

America’s power grid is due for some big investments. Tariffs could now make that much costlier.

As surging power demand from places such as data centers is set to strain the system, transformers, the nuts and bolts of the power system, look particularly vulnerable. These are devices that step up or down voltages as electricity moves from power plants to homes and factories. New ones are also required every time a new source of electricity—whether wind, solar or natural gas—connects to the grid. The lack of these components can therefore hold up more power from being brought online.

The power industry has already been experiencing a shortage of transformers, for which demand is expected to jump even more in the coming years. Suppliers have been reluctant to invest large sums of capital to expand production capacity because such investments have long break-even timelines, according to a report from Wood Mackenzie.

The National Renewable Energy Laboratory estimates that about 55% of in-service distribution transformer units are older than 33 years and approaching their end of life. Distribution transformer capacity might need to increase 160% to 260% by 2050 compared with 2021 levels to meet demand, according to the NREL.

So far, the Trump administration has imposed 25% tariffs on steel and aluminum, as well as a 10% across-the-board tariff on China. But more could come: The one-month pause on Trump’s proposed 25% tariffs on Canada and Mexico is set to expire in early March. Meanwhile, Trump has ordered federal agencies to explore reciprocal tariffs on trading partners around the world. He has also floated tariffs on copper.

Transformers could become a chokepoint. Only about 20% of transformer demand can be met by the domestic supply chain, according to Wood Mackenzie, which also estimated that transformer prices have already risen 70% to 100% since January 2020 because of inflation for raw materials such as electrical steel and copper. Steel is also an essential component of transformers, and notably, Cleveland-Cliffs is the only domestic producer of grain-oriented electrical steel for them. Assuming that Trump moves ahead with 25% tariffs on Canada and Mexico, and imposes tariffs on copper as well, Wood Mackenzie estimates that transformer prices could increase by an additional 8% to 9%.

Mexico, Canada and China are important sources of electrical equipment to the U.S. In 2024, China accounted for over 32% of U.S. low-voltage transformer equipment imports and Mexico accounted for 36% of high-voltage transformer imports, according to Wood Mackenzie. Canada accounted for about 16% of U.S. imports of high-voltage switchgear and 100% of imported utility poles. Utilities typically go through a lengthy process to test the reliability of transformers they are purchasing and tend to require custom specifications, so it isn’t an easy process to switch to a new supplier, notes Chris Seiple, Wood Mackenzie vice chairman.

Worth watching is whether tariffs become a tailwind for U.S. manufacturers. GE Vernova said at a conference Wednesday that it is too early to determine what the tariffs’ financial implications are for the company. It does seem less exposed for now: Chief Executive Scott Strazik said Canada, Mexico and China account for less than 5% of its imports into the U.S. The company has transformer factories in the U.S. and Europe. It also announced in January that it would invest nearly $600 million in U.S. factories and facilities over the next two years, including for gas turbines, transformers and switchgears.

3 notes

·

View notes