#valve manufacturer

Explore tagged Tumblr posts

Text

#funny#haha#comedy#meme#joyful cheer#joyus whimsy#valve#valve games#steam holiday sale#half life#valve corporation#valve software#black mesa#valve giving up being a developer is the greatest tragedy in video games – reader’s feature#valve manufacturer#hl2#steam#portal#important#half life 2#glados#portal 2#wheatley#half life alyx#valve bundle#tf2#team fortress 2#steam games#steam bundle#team fortress two

28 notes

·

View notes

Text

Best Deals on Ball Valves in India

Introduction

Ball valves are essential components in fluid control systems, offering reliability, durability, and efficient control. Finding the best deals on ball valves in India ensures cost-effectiveness without compromising quality.

Top Suppliers Offering Best Deals

L&T Valves

Known for high-quality and durable ball valves.

Competitive pricing and nationwide availability.

Kirloskar Valves

Offers a wide range of ball valves at affordable prices.

Excellent after-sales service and bulk purchase discounts.

CRI Valves

Provides budget-friendly ball valves without compromising on quality.

Regular promotions and seasonal discounts.

Price Comparison Table

Supplier Price Range (INR)Special Offers L&T Valves 500 - 5000Bulk discounts available Kirloskar Valves 450 - 4800 Free shipping on large orders CRI Valves 400 - 4700 Seasonal sales up to 20% off

Factors to Consider When Buying Ball Valves

Material: Choose between stainless steel, brass, or PVC based on application.

Size: Ensure the valve size matches your piping system.

Pressure Rating: Check for compatibility with your system's pressure requirements.

Supplier Reputation: Opt for well-reviewed suppliers for reliability.

Where to Find Best Deals Online

Amazon India: Regular discounts and wide selection.

TradeIndia: Bulk purchase discounts and verified suppliers.

Justdial: Local suppliers with competitive pricing.

FAQs

Q: Which is the most affordable ball valve brand in India? A: CRI Valves offers budget-friendly options with quality assurance.

Q: Where can I buy bulk ball valves at a discount? A: TradeIndia and Justdial offer excellent bulk purchase discounts.

Q: How to ensure quality when buying ball valves online? A: Check supplier ratings, reviews, and certifications.

3 notes

·

View notes

Text

Gate Valves in the Petrochemical Industry: Key Applications

In the complex and demanding environment of the petrochemical industry, the selection of appropriate valves is critical to ensuring the efficiency and safety of operations. Among the various types of valves used, gate valves play a crucial role due to their unique characteristics and versatility. This article explores the key applications of gate valves in the petrochemical industry and highlights their importance, especially for those seeking reliable suppliers such as a Valve Stockist in the Dubai or renowned Valve Manufacturers globally.

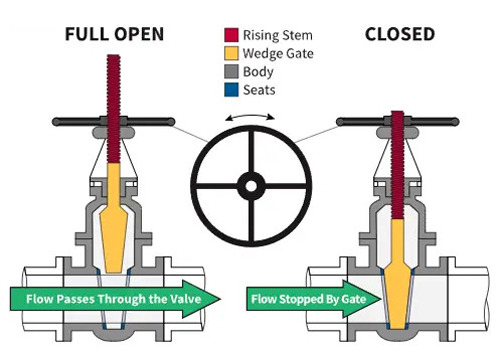

Understanding Gate Valves

Gate valves are primarily used to either completely stop or allow the flow of a fluid through a pipeline. Unlike other valve types, gate valves operate by lifting a gate out of the path of the fluid. This mechanism is ideal for applications that require the valve to be either fully open or fully closed, making them unsuitable for flow regulation but perfect for on-off control.

Key Applications in the Petrochemical Industry

Isolation of Flow:

Gate valves are extensively used for isolating sections of pipelines during maintenance or emergencies. Their ability to provide a tight seal ensures that no leakage occurs, which is vital in handling hazardous fluids. This makes them indispensable in petrochemical plants where safety is paramount.

Handling High-Pressure Fluids:

The petrochemical industry often deals with high-pressure fluids, and gate valves are well-suited to handle such conditions. Their robust design and capability to withstand high pressures make them a preferred choice for critical applications. Valve Manufacturers in Spain are known for producing high-quality gate valves that can operate efficiently under extreme conditions.

Controlling Corrosive Media:

Petrochemical processes frequently involve corrosive media. Gate valves made from specialized materials, such as stainless steel or alloy, are used to resist corrosion and prolong the valve’s service life. For industries looking for specialized valves, engaging with a reputable Gate Valves Supplier is crucial to ensure durability and reliability.

Steam and Heat Transfer Systems:

In petrochemical plants, steam and heat transfer systems are integral to various processes. Gate valves are employed in these systems to manage the flow of steam and other high-temperature fluids. These valves can handle the thermal expansion and contraction that occur in such systems, making them a vital component of heat management.

Shutdown Systems:

In emergency shutdown systems, gate valves are often used due to their ability to quickly and completely stop the flow of hazardous fluids. This quick response capability is critical in preventing accidents and ensuring the safety of the plant and its personnel.

Sourcing the Right Gate Valves

For businesses in the petrochemical industry, sourcing the right gate valves from reliable suppliers is essential. A Valve Stockist offers a wide range of options, ensuring that industries can find the exact specifications they need. Moreover, working with a Ball valves Supplier, Globe Valves Supplier, or Butterfly valve supplier can provide comprehensive valve solutions for various applications.

Additionally, many industries are turning to international markets for their valve needs. Valve Manufacturers in Spain have earned a reputation for their quality and innovation, providing robust solutions for petrochemical applications. Engaging with such manufacturers ensures access to advanced technology and high-quality products.

Conclusion

Gate valves are indispensable in the petrochemical industry, serving critical functions across various applications. Whether isolating sections of a pipeline, handling high-pressure fluids, or managing corrosive media, these valves provide the reliability and safety that petrochemical plants demand. To ensure optimal performance and safety, it is crucial to source these valves from reputable suppliers, such as a Valve Stockist in UAE or leading Valve Manufacturers globally. Additionally, working with specialized suppliers like a Control valves supplier or Water Valves Supplier can further enhance the efficiency and safety of petrochemical operations

2 notes

·

View notes

Text

Bellow Seal Safety Valve manufacturer

2 notes

·

View notes

Text

Swing Check Valve Manufacturers in india

Speciality Valve is celebrated as the esteemed Swing Check Valve Manufacturers in India. Our advanced manufacturing capabilities enable us to customize valves to your exact specifications, ensuring optimal performance and reliability and type of valve that is designed to prevent backflow in pipelines. It operates automatically without requiring external control.

Working Principle of Swing Check Valve

The Swing Check Valve works through a hinged disc or flap that swings open when the flow direction is correct, allowing fluid to pass through. When the fluid flow reverses or stops, the disc swings back to its closed position, effectively sealing the valve and preventing backflow.

Main Components of Swing Check Valve

Body: The body of the valve is typically made of durable materials like cast iron, stainless steel, or brass to withstand high pressures and resist corrosion.

Hinge and Disc: The disc is attached to a hinge mechanism that allows it to swing open or closed based on the direction of flow.

Seat: The seat provides a surface for the disc to seal against when the valve is closed, preventing leakage.

Bolt: The bolt holds the valve body components together and ensures structural integrity.

Spring (optional): Some designs may include a spring to assist in closing the disc when the flow is stopped.

Benefits of Swing Check Valve

Prevents Backflow: The primary benefit of a Swing Check Valve is its ability to prevent backflow,

Automatic Operation: Swing Check Valves operate automatically, eliminating the need for external control mechanisms.

Low Maintenance: These valves have fewer moving parts and are relatively easy to maintain, reducing downtime.

Durability: High-quality materials used in construction ensure the valve's long service life.

Cost-Effective: it offers affordable solutions for industries, making them a cost-effective choice for preventing backflow.

Speciality valve is the largest Swing Check Valve Manufacturers in India provide guarantees high-quality, durable.

Industries Uses

1.Oil and Gas Industry

2.Chemical and Petrochemical Plants

3.Water Treatment Facilities

4.Power Generation

5.Natural Gas Distribution

its Description

Body Material: Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), WCB, SS304, 316L, Duplex Steel, 904L, Aluminium bronze, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ] Class: 150LB – 2500LB Size: ½” – 40” Ends: butt weld, socket weld, threaded, flanged

Visit now - https://www.specialityvalve.com/product-category/swing-check-valve/

ADDRESS - Satra Plaza, Unit no-126, 1st Floor, 19D, Palm Beach Rd, Phase 2, Sector 14, Vashi , Navi Mumbai, Maharashtra 400703

0 notes

Text

What is A Shut Off Valve: A Guide to Safeguarding Plumbing

A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks). - Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves). - Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges. - Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems. - Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close. – Gate/Globe Valves: Linear motion raises/lowers the gate or disc. – Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves. - Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves. - Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

#ball valve manufacturers in india#ball valve suppliers#china ball valve#china valve manufacturer#valve manufacturer#valve factory#valve price#shut off valve#gate valve#butterfly valve#esdv

1 note

·

View note

Text

Learn about multiple types of industrial valves and their distinct benefits.

Industrial valves play an essential role in regulating the flow of liquids, gases, and other substances within various systems. These valves are critical components in industries such as oil and gas, water treatment, manufacturing, and chemical processing, among others. Understanding the different types of industrial valves and their specific functions is crucial for choosing the right valve for your system. In this article, we will explore the most common types of industrial valves, their unique benefits, and the general purpose and function of a valve manufacturer.

The General Purpose and Function of Industrial Valves

Industrial valves are mechanical devices used to control the flow of fluids within a pipeline or system. The primary purpose of a valve is to regulate, direct, or control the flow of fluids, whether it’s by stopping, starting, or throttling the flow. These valves can be operated manually, automatically, or remotely, depending on the specific requirements of the application.

A valve manufacturer designs and manufactures these essential components, ensuring that they meet the required standards and specifications. The role of a valve manufacturer is critical because they are responsible for producing reliable, durable, and safe valves that can handle extreme conditions like high pressures, temperatures, and corrosive environments. When looking for a valve manufacturer, it's important to consider factors like the company's experience, product range, and commitment to quality.

Cair Euro is one such leading valve manufacturer and supplier. With years of experience, Cair Euro provides high-quality valves that cater to a variety of industrial applications. Their products include a wide range of valve types, each designed to meet specific operational needs.

1. Gate Valves

Gate valves are one of the most commonly used types of industrial valves. These valves are primarily used to control the flow of liquids and gases in a pipeline. The gate valve consists of a wedge-shaped gate that moves up and down to open or close the flow path. When fully open, gate valves have minimal pressure drop, making them ideal for applications where the flow needs to be fully stopped or fully opened.

Benefits of Gate Valves:

Full Flow Capability: When fully opened, gate valves allow the flow to pass with minimal resistance.

High Durability: Made from high-quality materials, gate valves are highly durable and can withstand harsh conditions.

Reliable Performance: Gate valves are known for their long service life and low maintenance needs.

2. Ball Valves

Ball valves are widely used for their ability to start, stop, and regulate the flow of a variety of fluids. These valves feature a spherical ball with a hole in the middle, which rotates to allow or stop the flow. When the ball is aligned with the pipeline, the valve is open, and when it is turned 90 degrees, the flow is stopped.

Benefits of Ball Valves:

Quick Operation: Ball valves can be quickly opened or closed with a simple quarter-turn.

Leakage Prevention: The design of the ball valve ensures tight sealing, reducing the chances of leakage.

Versatility: Ball valves can be used for both high and low-pressure applications, making them versatile for various industrial processes.

3. Globe Valves

Globe valves are commonly used for regulating or throttling the flow of fluids. Unlike gate valves, which are designed for on/off control, globe valves are used to adjust the flow rate by regulating the position of the valve plug inside the valve body. They are often used in systems where flow needs to be carefully controlled.

Benefits of Globe Valves:

Precise Flow Control: Globe valves provide better control over flow rates than gate valves.

Compact Design: They are more compact than other valve types, making them suitable for applications where space is limited.

Stable Performance: Globe valves offer stable and reliable performance, even in challenging conditions.

4. Butterfly Valves

Butterfly valves are a popular choice in systems that require a lightweight and compact valve. These valves consist of a disc that rotates to regulate the flow. Butterfly valves are especially suitable for large pipes and systems where a fast shutoff is needed. They are often used in industries like water treatment, food processing, and HVAC.

Benefits of Butterfly Valves:

Space-Efficient Design: Due to their compact size, butterfly valves are ideal for systems where space is limited.

Cost-Effective: These valves are generally more affordable compared to other valve types, making them cost-effective for large systems.

Quick Operation: Butterfly valves can be opened or closed quickly, providing fast control over fluid flow.

5. Check Valves

Check valves are designed to prevent backflow in a piping system. These valves allow fluid to flow in one direction only and automatically close if the flow reverses. Check valves are crucial in preventing damage to pumps and other equipment caused by backflow, which can lead to operational failures.

Benefits of Check Valves:

Prevents Backflow: The primary function of check valves is to prevent backflow, protecting the integrity of the system.

Automatic Operation: These valves automatically close when the flow reverses, requiring no manual intervention.

Versatility: Check valves can be used in a wide range of applications, including water systems, oil pipelines, and chemical plants.

6. Pressure Relief Valves

Pressure relief valves are safety valves designed to protect systems from overpressure conditions. These valves open automatically when the pressure within the system exceeds a set limit, allowing excess pressure to be released. This prevents equipment from being damaged due to high pressure.

Benefits of Pressure Relief Valves:

Safety: Pressure relief valves are essential for protecting systems from dangerous overpressure conditions.

Prevent Damage: By releasing excess pressure, these valves prevent damage to pipes, pumps, and other components.

Reliable Performance: Pressure relief valves are designed to open and close quickly, providing fast protection when needed.

Conclusion

Industrial valves are critical components in the smooth operation of many industries. Whether you need to control flow, prevent backflow, or protect against overpressure, there’s a valve type specifically designed to meet your needs. From gate valves and ball valves to check valves and pressure relief valves, each valve type offers distinct advantages depending on the application.

Choosing the right valve manufacturer is equally important, as the quality of the valve can significantly impact the performance of the entire system. Cair Euro stands out as a leading valve manufacturer, offering high-quality valves for a wide range of industrial applications. With a reputation for reliability and innovation, Cair Euro provides the expertise and solutions you need to ensure your systems run smoothly and efficiently.

By understanding the different types of valves and their benefits, you can make informed decisions that will enhance the performance and safety of your industrial operations.

1 note

·

View note

Text

Double Flanged Butterfly Valve Manufacturers in India

Speciality valve is the leading Double Flanged Butterfly Valve Manufacturers in India. A double flanged butterfly valve is a valve. It is used for the control of liquids or gases that flow through pipelines. In fact, it differs from other valves because of the design. It has flanges on both ends, so this valve can be installed in between two pipe flanges with bolts and gaskets to create a secure seal. Inside, there is a disc that turns to control the flow. This valve is especially effective in larger pipelines where a fast and sure flow of control is needed.

What is a Double Flanged Butterfly Valve?

A double flanged butterfly valve is a flanged valve that has both ends flanged, thereby allowing it to be inserted directly into the pipeline. Because of the ability to either permit or deny the fluid, this disc type of valve is excellent for various applications where the regulation and isolation of flow is important in industries. "Double flanged" construction allows for strong piping connection with a double seal; it can thus be applied in high pressure piping. This valve is inexpensive and compact but highly reliable for operation in challenging conditions.

Double Flanged Butterfly Valve with Actuator

The inclusion of an actuator to a double flanged butterfly valve helps it become an automatic system. An actuator is those which provide the needed torque to be applied to rotate the valve disc and may be electrically, pneumatically, or hydraulically operated besides being manually operated. These are useful for applications where operation has to be made without the aid of human power and also at places where it needs automation in flow control. In fact:

Electric actuators are very useful for remote and automatic operation.

Pneumatic and hydraulic actuators are particularly ideal for applications where speed of response and torque demand is required.

Manual actuators are utilized when small systems are needed in manual control.

Double Flanged Butterfly Valve vs. Lug Type Butterfly Valve

Though double flanged butterfly valves and lug type butterfly valves are utilized in applications in regulating flow, both designs have different approaches towards structural intensity and installation.

Double Flanged Butterfly Valve:

Design: This valve has flanges at both ends for secure installation between two pipe flanges.

Application: Best suited for larger pipelines and high pressure systems, where a strong and reliable connection is required.

Strength: Offers more durability and structural strength, especially in more demanding applications.

Installation: Requires flanged pipe connections at both ends.

Lug Type Butterfly Valve:

Design: Lug type valve has threaded lugs on both sides and is bolted into place.

Application: Commonly used in applications where one side of the pipeline can be isolated, such as deadened applications.

Strength: Used for lower pressure systems compared to double flanged valves.

Installation: Easier to install and remove, making it ideal for certain maintenance scenarios.

Double flanged butterfly valves are more robust and designed for applications involving higher pressures, while lugtype valves are more appropriate for simpler applications and for maintenance where isolation of one side of the pipeline is necessary.

Advantages of Double Flanged Butterfly Valves

1. Strong and Durable:

The double flanged design makes the valve highly resistant to high pressures and mechanical stress, thus making it reliable for tough environments.

2. Space Saving and Light Weighted:

These valves are spacesaving, and despite their robust design, they are ideal for use in installations where space is limited.

3. CostEffective:

Double flanged butterfly valves are moderately priced compared to gate or globe valves, thus a safe and cheap flow control.

4. Easy Installation:

The flanged valve is easier to mount in the pipelines, especially when it comes to a large diameter.

5. Flow Control Efficiency:

A rotating disc ensures that there is a fine control of flow, which makes it good for throttling and consistent flow rates.

6. Low Maintenance Requirement:

Since there are fewer moving parts than in other valve types, double flanged butterfly valves have less maintenance and are known to have a longer lifespan.

7. Versatility:

These valves can handle fluids ranging from water to chemicals and can be used in most industries.

Industries That Use Double Flanged Butterfly Valves

1. Oil and Gas:

Double flanged butterfly valves are primarily used in pipelines carrying oil, gas, and other fluids, especially in a highpressure closed environment for tight shutoff.

2. Water and Wastewater Treatment:

Used in water treatment plants to control the passage of water through filtration, treatment, and distribution systems.

3. Chemical Processing:

In chemical plants, they control the flow of chemicals; hence, offering safe and efficient handling of dangerous materials.

4. Power Generation:

Double flanged butterfly valves, are typically installed within steam and water regulating equipment in a power plant, that ensures correct generation of the energy.

5. HVAC Systems:

Double flanged butterfly valves have been majorly employed to use their functioning on the biggest heating, ventilation, as well as airconditioning units.

6. Mining:

Double flanged butterfly valves are used in mining activities to regulate slurry and other materials.

7. Pulp and Paper:

In pulp and paper industries, these valves are used to regulate liquid and slurry flows as part of the manufacturing process.

Conclusion

This double flanged butterfly valve is known for its strength, reliability, and costeffectiveness, making it perfect for highpressure flow control applications. Its compact design makes installation easy, and it's widely used in industries like oil and gas, water treatment, chemical processing, and power generation. Whether automated with an actuator or operated manually, this valve ensures effective flow regulation. Speciality Valve, one of the top manufacturers of Double Flanged Butterfly Valve Manufacturers in India, offers solution driven products for various industries.

Description: 1.Available Materials: Cast Iron, Ductile Iron, WCB, WC6, LCC, LCB, WCC, SS304, SS316, Aluminium Bronze 2.Class: 150 to 1500 3.Nominal Pressure: PN6 to PN250 4.Size: 2” to 48” 5.Ends: Wafer, Lug, Flanged

0 notes

Text

API 6D Valves: Key Specifications and Industry Applications

API 6D valves are crucial in pipeline as well as the facility management offering efficient operation, safety and reliability in flow control. These valves are developed to meet the industry specifications so that high pressure, high temperature applications are not a problem.

Used widely in oil and gas, refining, and chemical processing industries, API 6D valves provide features that improve operating safety and productivity. All these API 6D valve manufacturers and most other valve manufacturers borrow these specifications and guidelines in their production to meet the client’s needs of different industries including Ghatge Patil Industries (GPI).

Key Specifications of API 6D Valves

1) Design and Construction Standards

API 6D valves are produced based on specific design and manufacturing requirements set by the API. These valves come as performance-type valves, they are strong construction values for use in high-performance environments due to their ability to last longer without wearing out.

API 6D specification provides design stresses for various load conditions, minimum manufacturing standards for materials for pressure containment, and protection against fire.

2) Valve Types

API 6D comprises various valves that are used with different functions in the operation field. Some examples include; gate valves, ball valves, check valves, and plug valves. All are designed for particular services including flow separation, backflow protection, or direction, and each delivers dependable service in any situation.

3) Material Requirements

API 6D valve is constructed to a high specification that is suitable for use in harsh environments. Carbon steel, stainless steel, and other alloys are chosen depending on the pressure exerted, temperature, and the kind of material in the system. These material specifications make the valve robust and immune to corrosion overview that is important when dealing with chemical or abrasive material.

API 6D valves supplying companies like Ghatge Patil Industries (GPI) have valves that are manufactured using materials that meet these rigid standards.

4) Testing Protocols

API 6D valves are subjected to further examination to conform to the laid down performance levels. These tests include a hydrostatic test, seat leakage test, and operational test to confirm the pressure-retaining capability of the valve, freedom from leakage, and its performance during operation.

Test procedures are important for purposes of quality assurance since they fulfill the actual test of each valve to function appropriately under high pressure.

5) Quality Specification Levels (QSL)

API 6D has QSL that outlines the quality that is expected of the valve depending on its pressure range rating, its material type, and design among the other two qualities of the valve are QSL 1 and QSL 2. Higher QSL levels mean that higher quality checks are needed and may be necessary for the application types.

Industry Applications of API 6D Valves

1) Oil and Gas Transportation

API 6D valves are crucial in the oil field where crude oil, natural gas, and other end products have to be transported via pipeline systems. These valves regulate flow and afford shut-off when required for pip streamline structure and security.

API 6D valves are necessary to successively bear high operating pressure and have leakage-tight advantages, which are very important for transporting inflammable medium. Ghatge Patil Industries (GPI) manufactures API 6D valves which are of premium standard for the oil and gas transportation industry.

2) Refining Processes

API 6D valves on the other hand are used commonly in the refining steps flowing crude oil and other related products during the refining and processing activity. These valves are designed to achieve efficient flow control and operate at high-risk operative refineries. API 6D valves offer value for services in refining plants due to the enhanced features of their robust structure to withstand high-pressure and high-temperature conditions.

GPI provides API 6D valves, which comply with different industries to ensure the effective refining process for the company.

3) LNG Facilities

An LNG facility requires API 6d valves for flow control of natural gas and other hydrocarbon products. Treatment of 'LNG' entails stringent measures in terms of both operational temperature and pressure. LNG valves fabricated using cryogenic ratings are strong and do not allow leakage in the pipeline used in handling the dangerous material.

Some suppliers, including the Ghatge Patil Industries (GPI), source API 6D valves to match the requirements of LNG facilities, which helped to prevent operation disruptions.

4) Chemical Processing

API 6D valves are also utilized in the chemical processing industry as they come into contact with chemicals and work at high temperatures. Chemically, they offer superior strength and do not react vigorously with the media they control; therefore, they should be used in regulating the flow of several chemicals.

API 6D valves are fashioned to meet specifications of high shut off and control to deter leakages and risk to human life and property. API 6D actuators for valves are made by using material that is chemically erode-resistant which makes GPI suitable for this business.

5) Water and Wastewater management

In water treatment and wastewater systems, the API 6D valves are used for flow control and for on/off as well as modulating functions. These valves are for the application of clean water and waste and can provide shut-off and minimize the probability of leakages. Due to their durability and flexibility in use API 6D valves are used in water treatment facilities and sewage systems.

API 6D valves are used in a wide variety of applications in various process industries including transportation of oil and gas along with the water treatment sector. Due to its highly durable construction, strict quality control, and versatility to change conditions in a system, it has great usage in environments where a steady efficient, and stable valve is needed most.

Leading API 6D valve suppliers, such as Ghatge Patil Industries (GPI), adhere to API standards, providing high-performance valves that meet the demanding needs of various sectors. As industries continue to prioritize safety and efficiency, API 6D valves will remain essential for maintaining safe and reliable operations.

1 note

·

View note

Text

V-TORK CONTROLS is a trusted name in India in the manufacturing of high-performance Knife Gate Valves, Butterfly Valves, Ball Valves, and Custom-Designed Valves. V-TORK caters to industries such as Power, Metal & Mining, Water Treatment, Paper & Pulp, Cement, Sugar, Oil & Gas, and Chemicals. The company is driven by a commitment to excellence, innovation, and customer satisfaction, supported by a skilled team and a robust quality management system certified to ISO 9001-2015. With a focus on engineered valve solutions, V-TORK offers cutting-edge product features, efficient after-sales support, and third-party inspections to ensure quality. Their advanced research and development, along with strict quality checks, make them a trusted partner for industries worldwide.

#valve manufacturer#ball valve ball manufacturer#valve manufacturers in india#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#ball valve suppliers#valve manufacturers in australia

0 notes

Text

High-Quality Valve Manufacturer | Husteel Industry Group

Discover high-quality Valve Manufacturers from Husteel Industry Group. We are a reliable manufacturer offering a diverse array of valve solutions specifically designed to fulfill your unique requirements. Contact us for more information @ 0086-731-88787781.

0 notes

Text

Top Butterfly Valve Suppliers in India

Introduction

Brief overview of butterfly valves, their industrial importance, and demand in India.

Top Butterfly Valve Suppliers

L&T Valves Ltd – Known for high-quality industrial valves.

Kirloskar Brothers Ltd – Offers durable and reliable butterfly valves.

Hawa Valves – Exporters and suppliers of industrial-grade valves.

Hyper Valves – Provides cost-effective butterfly valves.

Key Features to Look for in Butterfly Valve Suppliers

Quality Assurance

ISO Certification

After-Sales Service

Butterfly Valve Applications

Water Treatment Plants

Oil and Gas Industry

Chemical Processing

FAQs

Q: Which is the top butterfly valve brand in India? A: L&T Valves is highly trusted in the industry.

Q: How to buy butterfly valves in bulk? A: Platforms like TradeIndia and Justdial have numerous suppliers.

2 notes

·

View notes

Text

Top Ball Valves Manufacturers in Pune

Pune, Maharashtra’s industrial hub, is home to top manufacturers in many industries. One of the most trusted names in the industry is Parth Valves and Hoses LLP. Parth Valves, known for their quality and innovation, manufactures and services a comprehensive range of Ball Valves for various industrial needs.

What Are Ball Valves?

Industries that need precise liquid and gas control use ball valves. Quarter-turn valves control material flow via a hollow, perforated, revolving ball. Oil and gas, medicines, water treatment, and manufacturing employ ball valves for their effective sealing.

Ball valves are indispensable for many applications due to their great pressure and temperature tolerance.

Ball Valves

Why Ball Valves Manufacturing Is Popular in Pune

Pune’s industrial ecosystem, facilities, and qualified people make it suitable for ball valve manufacture. The city’s manufacturers value innovation, quality, and durability.

Parth Valves and Hoses LLP, a Pune-based ball valve manufacturer, sets standards with their cutting-edge facilities and customer service. They have years of experience making durable, high-performance ball valves for many sectors.

Ball Valves Trusted Name Parth Valves and Hoses LLP

1. Wide Selection of Ball Valves Parth Valves offers a wide range of ball valves for various industrial applications. There are standard ball valves and sophisticated high-performance models:

Two- and three-piece ball valves are modular and easy to maintain. Flanged Ball Valves: High-pressure friendly. Full-Port and Reduced-Port Ball Valves: Flexible flow control for various applications.

Uncompromising Quality Parth Valves manufactures with quality in mind. Each valve is rigorously tested to meet ISO, ASTM, and ASME standards. Their ball valves work reliably in the harshest situations due to their thorough approach.3. Unique Needs Customization Since every sector has unique needs, Parth Valves excels in tailored solutions. Their professionals work with clients to design and build ball valves to exact specifications for optimal efficiency and lifetime.4. Innovation Focus Innovation also distinguishes Parth Valves. Their valve development team uses cutting-edge technology to improve performance and durability.Applications of Ball Valves Parth Valves ball valves are versatile and appropriate for many applications:Oil and Gas: Pipeline high-pressure fluid and gas management. Pharmaceutical Industry: Hygienic flow regulation in delicate situations. Purification plant water flow regulation. Manufacturing Units: Supporting production line efficiency.

Why Choose Parth Valves and Hoses LLP for Ball Valves?

Ball valve manufacturers should be chosen based on quality, reliability, and customer service. Parth Valves and Hoses LLP excels in these areas:

Their engineers and technicians have decades of experience and provide unmatched expertise. Timely Delivery: They deliver on time to keep projects on track. They offer high-quality valves at competitive prices.

Improvement in Ball Valves Manufacturing

Parth Valves and Hoses LLP provides precision, dependability, and durability in ball valves for industries. Their dedication to quality has made them Pune’s top ball valve producers.

Contact Parth Valves Now

Contact Parth Valves and Hoses LLP for durable ball valves. Industries in Pune and beyond choose them for their experience and customer-first approach.

With Parth Valves, you’re buying a heritage of quality that guarantees your industrial operations run smoothly. Enjoy the greatest ball valves with Parth Valves and Hoses LLP.

Website- https://parthvalve.com/

Email id – [email protected]

Call On- (+91)8600034431

0 notes

Text

Common Industrial Valves and Features

Valves are an unavoidable topic when it comes to plumbing. We often hear all kinds of confusing valve names, especially when we recently compiled this Chinese-English comparison table. Due to the lack of understanding of valves, we had no idea where to start, so we decided to sort out some common valve types, and friends who are interested can learn about them together.

Ball Valve

●Working principle:

● Features:

Good sealing performance, easy operation, small fluid resistance, simple structure, suitable for rapid opening and closing.

● Application scenarios:

Widely used in water treatment, petrochemical, natural gas pipelines and other fields, suitable for automatic control.

Gate Valve

● Working principle:

● Features:

The gate valve has good sealing performance, but due to the long switching time, frequent operation is inconvenient.

● Application scenario:

It is mainly used for large-diameter, high-pressure pipelines that need to completely cut off the fluid, such as water, steam, oil, natural gas, etc.

Butterfly Valve

● Working principle:

● Features:

Quick opening and closing, but relatively poor sealing.

● Application scenarios:

Applicable to large-diameter, low-pressure pipeline systems, such as water supply and drainage, cooling water circulation, etc.

Globe Valve

●Working principle:

● Features:

Good sealing, fast opening and closing speed, but large fluid resistance, relatively complex structure, and high pressure loss.

● Application scenario:

Mostly used in working conditions that require flow regulation, such as boilers, HVAC, steam systems, etc.

Check Valve

● Working principle:

The valve that prevents the backflow of the medium automatically opens and closes based on the pressure of the medium flow.

● Features:

Usually used to prevent backflow in the pipeline, no manual operation is required, and the structure is simple.

● Application scenarios:

Widely used in pipelines such as water pump outlets and drainage systems that need to prevent backflow.

Safety Valve

● Working principle:

When the system pressure exceeds the set value, the valve automatically opens to release the pressure, and automatically closes after the pressure is restored to protect the equipment and system from overpressure damage.

● Features:

The safety valve has high sensitivity and automatically responds to pressure changes to prevent system overpressure and protect equipment safety.

● Application scenarios:

Used for overpressure protection of equipment such as boilers, pressure vessels, and pipeline systems.

Needle Valve

● Working principle:

● Features:

Precisely control the flow, good sealing, suitable for high-pressure and small-flow systems, and slow opening and closing speed.

● Application scenarios:

Widely used in laboratory equipment, gas or liquid regulation systems, high-pressure and small-flow control and other occasions.

Plug Valve

● Working principle:

● Features:

Simple structure, fast opening and closing, suitable for frequent operation.

● Application scenario:

Widely used for opening and closing control of natural gas, petroleum and chemical pipeline systems.

Angle Valve

● Working principle:

Manually rotate the valve stem to move the valve core up and down to control the on and off of the water flow.

● Features:

Compact design, easy installation, used for local water flow control, suitable for 90-degree pipe connection.

● Application scenario:

Water flow control in household water systems, such as faucets, toilets, etc.

0 notes

Text

Leading Breather Valve Manufacturer in China - Luofu Valve Group

As one of China's prominent manufacturers of breather valves, Luofu Valve Group focuses on making breather valves for application in a broad industrial field. At our state-of-the-art manufacturing facilities, fully supported by an expert team, we manufacture high-quality breather valves to always ensure we are the preferred Breather valve manufacturer in china for the most reliable and durable solutions. Our breather valves are intended for safety and operating efficiency in protection of the equipment against exposure to overpressure and vacuum conditions.

0 notes

Text

Best Instrumentation Valves Manufacturers - Avlok

Avlok is a leading Instrumentation Valves manufacturer & supplier. Our top quality valves are designed for use predominantly in a process line along with measuring tools like gauges and transmitters. Options available include ball, needle, check valves & manifold valves.

Our valves are meeting the ASME standards and API 6A requirements and hence each and every one of them are radically tested. Become one of our valued customers today and choose Avlok for all your valve needs. Check out our offerings now.

For more details:

Product: Instrument Valves

Website: avlok.com

#Instrumentation Valves Manufacturers#Instrument Valves Manufacturers#Instrumentation Valve#plumbing#valve manufacturer

0 notes