#knife gate valve manufacturers

Explore tagged Tumblr posts

Text

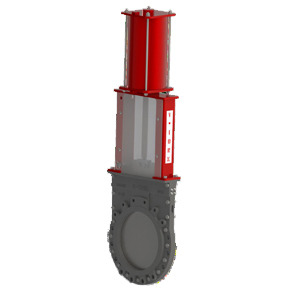

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Top- Rated Knife Edge Gate Valve Gear Box Manufacturer

Viral Industries is a leading knife edge gate valve gear box manufacturer company from India, exporting to USA, Canada, Europe & Gulf. A knife edge gate valve gearbox is a mechanical device used to operate knife edge gate valves, which are designed for controlling the flow of liquids or gases in industrial systems. Connect with us today and share your requirements.

#Knife Edge Gate Valve#Industrial Valve Manufacturer#Valve Gearbox#Valve Actuator#Viral industries#Mechanical Gate Valve

0 notes

Text

#Knife Gate Valve#Knife Gate Valve Manufacturers in India#Knife Gate Valve Suppliers in India#Knife Gate Valve Exporters in India#Knife Gate Valves in India

0 notes

Text

Gate Valve Manufacturers in Ahmedabad | Gate Valve In Ahmedabad - Gold Techno Casting

Gate Valve Manufacturers in Ahmedabad - Gold Techno Casting is a leading Gate Valve Manufacturers in Ahmedabad, Manufacturer Exporter & Supplier of Gate Valves in Ahmedabad, Exporter of Gate Valves in Ahmedabad, Wholesale Gate Valves Supplier in Ahmedabad, Gate Valves Manufacturing Company in Ahmedabad.

Google Map:--> https://maps.app.goo.gl/BRUcNaNQ53yYzrih7

Gate Valve Manufacturers in Ahmedabad, Gate Valve In Ahmedabad, Gate & Sluice Valves in Ahmedabad, Gate & Sluice Valves Price in Ahmedabad, Top Gate Valve Manufacturers in Ahmedabad, Best Sluice Valve Manufacturers Near Me, Best Gate Valve Manufacturer Ahmedabad, Gate Valves Manufacturer, Supplier from Ahmedabad, Gate Valves & Boiler Mountings Manufacturers in Ahmedabad, Knife Gate Valves in Ahmedabad, Top Gate Valve Dealers in Ahmedabad, Valve Manufacturer in Ahmedabad, Ahmedabad, Ahmedabad Gujarat, www.goldtechnocasting.com/gate-valve-manufacturer-in-ahmedabad.php, Gold Techno Casting

#Gate Valve Manufacturers in Ahmedabad#Gate Valve In Ahmedabad#Gate & Sluice Valves in Ahmedabad#Gate & Sluice Valves Price in Ahmedabad#Top Gate Valve Manufacturers in Ahmedabad#Best Sluice Valve Manufacturers Near Me#Best Gate Valve Manufacturer Ahmedabad#Gate Valves Manufacturer#Supplier from Ahmedabad#Gate Valves & Boiler Mountings Manufacturers in Ahmedabad#Knife Gate Valves in Ahmedabad#Top Gate Valve Dealers in Ahmedabad#Valve Manufacturer in Ahmedabad#Ahmedabad#Ahmedabad Gujarat#www.goldtechnocasting.com/gate-valve-manufacturer-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

knife edge gate valve manufacturer

We are leading Knife Edge Gate Valve manufacturer in Ahmedabad, India. sharp-edged gate that can slice through any particulates. This valve is commonly used in industries such as oil and gas, chemical processing and wastewater treatment

#knife edge gate valve#knife edge gate valve manufacurer#knife edge gate valve manufacturer in ahmedabad#knife edge gate valve in india#knife edge gate valve supplier in india#knife edge gate valve in ahmedabad

0 notes

Text

#knife edge gate valve manufacturer#knife edge gate valve manufacturers in Ahmedabad#knife edge gate valves#knife edge gate valve manufacturers in India#mining slurry industry valves in Ahmedabad

0 notes

Text

Best Gate Instrumentation Valve Manufacturer, Supplier & Exporter in India - Mcneil Instruments

Introduction to Gate Instrumentation Valves

In industries requiring precise control and reliable flow management, gate valves are indispensable. Designed for on/off control of fluid flow, gate valves provide a full, unobstructed passage when open and offer secure isolation when closed. Mcneil Instruments, a trusted gate instrumentation valve manufacturer, supplier, and exporter based in India, leads the way in producing top-tier valves for industries such as oil and gas, chemical processing, power generation, and more.

What is a Gate Valve?

Gate valves operate by raising or lowering a wedge-like gate within the valve body, allowing for full flow when open and complete shut-off when closed. Unlike other valves, gate valves are not suited for throttling or fine control but are highly effective for full open/close applications. Their design results in minimal pressure drop across the valve, providing efficient flow with limited resistance.

Key Features of Gate Valves:Minimal Pressure Drop: When open, gate valves allow fluid to pass freely with minimal obstruction.

Effective Shut-Off: Ideal for applications where a secure shut-off is essential.Straight-Line Flow: Supports a clear, unobstructed flow, minimizing turbulence and erosion.

Types of Forged Gate Valves by Mcneil Instruments

As a premier manufacturer, supplier, and exporter of gate instrumentation valves, Mcneil Instruments offers a diverse selection of forged gate valves, each tailored to specific industrial requirements:

1. Forged Steel Gate Valve: Known for durability and resilience, this valve is ideal for high-pressure applications in heavy industries, where it withstands intense conditions without compromising performance.

2. Threaded Gate Valve: With a compact design, the threaded gate valve is optimal for tight spaces, allowing for easy installation without sacrificing functionality or efficiency.

3. Bellow Sealed Gate Valve: Engineered for zero leakage, this valve is essential for handling hazardous materials safely, providing a containment solution critical for safety-sensitive applications.

4. Resilient Forged Gate Valve: This general-purpose valve delivers reliable sealing, making it a cost-effective and versatile choice for standard industrial operations.

5. Expanding Gate Valve: Equipped with enhanced sealing capabilities, the expanding gate valve is suitable for high-pressure systems requiring robust flow isolation.

6. Knife Gate Valve: With its sharp-edged design, the knife gate valve effectively handles thick fluids and slurries, ensuring smooth operation in challenging applications such as wastewater treatment and mining.

7. Parallel Slide Gate Valve: Designed to avoid binding, this valve is suited for high-pressure conditions where consistent performance is essential.

8. Slab Gate Valve: Offering a strong seal, the slab gate valve is perfect for oil and gas pipelines, where it delivers reliable isolation and supports efficient flow management.

Why Choose Mcneil Instruments for Gate Valves?

Mcneil Instruments is a globally recognized manufacturer, supplier, and exporter of gate valves, committed to meeting the highest industry standards and ensuring long-lasting performance. Here’s why industries choose Mcneil Instruments:

1. Quality & Durability: Each valve is meticulously crafted from high-grade materials, engineered to endure demanding industrial environments.

2. Industry Compliance: Mcneil Instruments’ valves comply with stringent industry standards, including ANSI, ASME, and API, ensuring reliable performance across applications.

3. Trusted Exporter: Known worldwide, Mcneil Instruments has established a reputation for delivering quality valves that meet the specific needs of industries globally, ensuring precision, durability, and efficiency in every product.

Conclusion

For industries seeking dependable flow control solutions, Mcneil Instruments offers an unmatched selection of forged gate instrumentation valves. As a leading gate valve manufacturer, supplier, and exporter in India, Mcneil Instruments combines expertise, innovation, and quality to deliver valves that exceed performance expectations.

Whether you need a valve for high-pressure applications, corrosive environments, or general-purpose use, Mcneil Instruments provides reliable solutions that enhance efficiency and safety in your operations.Explore our range of gate valves to find the ideal solution for your industrial requirements.

0 notes

Text

Knife Edge Gate Valve Manufacturer & Supplier in Nashik, Maharashtra, India

Yashshree Enterprises is the Best Knife Edge Gate Valve Manufacturer & Supplier in Nashik, Maharashtra. We are also the Top Manufacturer & Supplier in India

Knife Edge Gate Valve

Price: ₹ 1,000/ Piece

Size14inchMaterialCast IronUsage/ApplicationPipe FittingTypeKnife EdgeIs It Rust ProofYesHardness55 HRC

Inquiry Now

SS Pressure Gauge

Price: ₹ 1,000/ Piece

Dial Size1.5 inch / 40 mmPressure Range4barUseGasDisplay TypeAnalogPressure TypeGauge PressureConnection TypeNPTConnection Size1/2inchDial TypeDryMaterial of casingStainless Steel

Inquiry Now

Engine Timing Belt

Price: ₹ 750/ Piece

MaterialRubberTypeSingle SidedThickness1.52mmUsage/ApplicationMachinery IndustryColorBlackWidth4inch

Inquiry Now

91-7020144157, 9226136327

0 notes

Text

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Best Knife Edge Gate Valve Gear Box Manufacturer

Viral Industries is a well-known knife edge gate valve gear box manufacturer & supplier in the USA, Europe, Canada, and the Gulf. We are renowned for our high-quality knife edge gate valve gearboxes, which are designed according to the specific requirements of various businesses and applications. Get in touch with us today!

For more information: Call us: +91 98250 58387 Reach us: https://www.viralindustriesindia.com/knife-edge-gate-valve-gearbox-manufacturer/

0 notes

Text

Ribbon Blender Machine Supplier in Madhya Pradesh

Amma En-fab Is a leading Supplier of Ribbon Blender Machine in Madhya Pradesh, India.

Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India.

The Ribbon Blender we offer is globally appreciated for its superior technology and competitive price range. It is widely used for mixing dry powder, typically free-flowing solid substances. Our ribbon blender, fabricated in well-equipped infrastructure, is a worthwhile investment for industries.

These blenders are proven agitator construction-based systems that provide triple mixing action, ensuring efficient blending.

Designed for effective linear and radial motion, they blend materials homogeneously. We offer ribbon blenders in different configurations and can customize them based on specific preferences.

We offer Ribbon Blenders in small laboratory batch sizes (2.0 Kg) to large production capacities (up to 10,000 Kg batch).

Features: Special shaft seals Heating & cooling jackets Wear resistance Corrosive resistance Vacuum filling and discharge arrangements Manually operated knife gate discharge valve Ribbon agitator for center discharge Designed for atmospheric operation Safety limit switches to prevent operation when covers are raised Stuffing boxes with easily disassembled split housing

How does a Ribbon Blender work? A Ribbon Blender operates by using two interwoven ribbon-like blades that rotate inside a cylindrical drum. The ribbons move materials in opposite directions, creating a shearing action that mixes powders, granules, or pastes uniformly.

What are the advantages of a Ribbon Blender over other types of mixers? Compared to other mixers like paddle blenders or planetary mixers, Ribbon Blenders offer superior efficiency, gentle blending action, and uniformity in mixing, especially for dry powders or granular substances.

Amma En-fab Is a leading Ribbon Blender Machine Supplier in Madhya Pradesh, India Including Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar.

If you have any questions or need more information, feel free to reach out to us.

0 notes

Text

Knife Edge Gate Valves: Design, Function, and Industry Applications

These suppliers cater to a variety of sectors, offering durable, high-performance valves that are designed to handle the toughest applications. If you are looking for a knife edge gate valve supplier in Ahmedabad, it's important to choose one with a reputation for quality and reliability.

0 notes

Text

Knife Gate Valve Manufacturers, Suppliers, Exporters in India | Knife Gate Valves in Mumbai, Nagpur, Aurangabad, Chennai, Bangalore, Tamil Nadu

#Knife Gate Valve#Knife Gate Valve Manufacturers in India#Knife Gate Valve Suppliers in India#Knife Gate Valve Exporters in India#Knife Gate Valves in India#Pneumatic Cylinder Knife Edge Gate Valve#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in India#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in India#Pneumatic Cylinder Knife Edge Gate Valve Exporters in India#Pneumatic Cylinder Knife Edge Gate Valve in India#Knife Gate Valve Manufacturers in Pune#Knife Gate Valve Suppliers in Pune#Knife Gate Valve Exporters in Pune#Knife Gate Valves in Pune#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Exporters in Pune#Pneumatic Cylinder Knife Edge Gate Valve in Pune

0 notes

Text

Gate Valve Manufacturers Ahmedabad - Gold Techno Casting

Gate Valve Manufacturers in Ahmedabad – Gold Techno Casting is a leading manufacturer of high-quality gate valves and sluice valves in Ahmedabad, Gujarat. We offer a wide range of gate valves for various industrial applications at competitive prices. Contact us today for your valve requirements.

Google Map:--> https://maps.app.goo.gl/MkGb56Jaso8mu3qC8

Gate Valve Manufacturers in Ahmedabad, Gate & Sluice Valves in Ahmedabad, Popular Gate Valve Manufacturers in Ahmedabad, Manufacturers of Industrial Gate Valves in Ahmedabad, Top Gate Valve Manufacturers in Ahmedabad, Gate Valve In Ahmedabad, Top 10 Gate Valve Manufacturers In Ahmedabad, Top 5 Gate Valve Manufacturers In Ahmedabad, No Gate Valve Manufacturers In Ahmedabad, Flanged Gate Valve Manufacturers in Ahmedabad, Gate Valves Manufacturer, Supplier from Ahmedabad, Knife Edge Gate Valve manufacturer in Ahmedabad, Top Gate Valve Dealers in Ahmedabad, Ahmedabad, www.goldtechnocasting.com/gate-valve-manufacturer-in-ahmedabad.php, Gold Techno Casting

#Gate Valve Manufacturers in Ahmedabad#Gate & Sluice Valves in Ahmedabad#Popular Gate Valve Manufacturers in Ahmedabad#Manufacturers of Industrial Gate Valves in Ahmedabad#Top Gate Valve Manufacturers in Ahmedabad#Gate Valve In Ahmedabad#Top 10 Gate Valve Manufacturers In Ahmedabad#Top 5 Gate Valve Manufacturers In Ahmedabad#No Gate Valve Manufacturers In Ahmedabad#Flanged Gate Valve Manufacturers in Ahmedabad#Gate Valves Manufacturer#Supplier from Ahmedabad#Knife Edge Gate Valve manufacturer in Ahmedabad#Top Gate Valve Dealers in Ahmedabad#Ahmedabad#www.goldtechnocasting.com/gate-valve-manufacturer-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

How To Operate Concrete Batching Plant

The operation of a concrete batching plant is a complex process involving several steps and details, which can be mainly divided into the preparation stage, the charging stage, the mixing stage, the transportation stage and the unloading stage. The following is a detailed description of these stages: 1. Preparation stage - System energization and inspection: After the automatic control system of the concrete mixer is energized, it enters into the operation page. Carry out a series of inspections, including no foreign matter stuck in the mixing cylinder and the transmission and movement parts of each supporting mechanism as well as the bin door, bucket door and track, etc., the oil level of each lubricating oil tank is in accordance with the regulations, as well as each electrical device can effectively control the mechanical action. - Reset and recipe settings: The system software carries out the reset solution, which mainly includes the setting of formula standard, concrete grade, caving degree, and production and manufacturing square volume.

2. Charging stage - Raw material weighing and measurement: Based on the weighing of the hopper, measurement to carry out inspection, export empty or full of material data signal, prompting the operating staff to run the mixing management program. Run the sand, stone drive belt drum motor into the pre-materials to the measurement hopper, open the coal ash, cement silo disc valve, run the screw machine motor to transport coal ash, cement to the measurement and verification hopper. Open the regulator valve of the water and concrete admixture tank to allow water and concrete admixture to be injected into the metering and checking hopper. - Open the feeding port: Open the door of metering and checking hopper after the measurement reaches the setting regulations, and the ingredients enter into the already running mixer. 3. Mixing stage Inside the concrete mixer, the raw materials are mixed with water, and fully mixed and crushed through the high-speed rotating mixing blades to make the concrete uniform and consistent. During the mixing process, it is necessary to pay attention to whether there are people in the mixer and on the conveyor belt, and when there are people, operation is prohibited. 4. Transportation stage While mixing, the concrete mixer conveys the mixed concrete into the concrete transportation truck so that the concrete can be transported to the site. 5. Unloading Stage After transporting the concrete transporter to the construction site, the concrete is discharged from the vehicle through the hydraulic discharging system. 6. Shutdown and cleaning Before the concrete mixer stops, it should be unloaded first, and then close the switches and pipelines of each ministry in order. All the cement in the spiral pipe should be conveyed out, and no material should be left in the pipe. After operation, the mixing cylinder, discharge door and discharge hopper should be cleaned and flushed with water, and the additives and their supply system should be flushed at the same time. The knife seat and knife edge of the weighing system should be cleaned and the weighing accuracy should be ensured. 7. Precautions - Safe operation: After starting the machinery, carefully check the operation of the machinery and check whether the rotation direction of each rotating part is consistent with the direction of the marked arrow. No repair, maintenance, lubrication, fastening and other operations can be carried out during the operation of the machinery. It is prohibited to put hands and feet near the gate, mixing drum, spiral pipe, etc. - Troubleshooting: No shutdown is allowed when mixing with full load, when fault or power failure occurs, immediately cut off the power supply, lock the switch box, remove the concrete in the mixing drum, and then troubleshoot or wait for the power supply to be restored. - Training and examination: The mixer operator shall undergo study and training to understand the structure and performance of the mixing system and operation work procedure of the unit, familiarize with the safety operation and technical specifications, familiarize with the basic operation of the computer, and basically understand the quality requirements of concrete and the main properties, specifications and roles of the raw materials, and shall only be allowed to operate after passing the actual examination of the parent company. Through the above steps and precautions, you can ensure the safe and efficient operation of the concrete batching plant.

This resource is from http://www.haomeibatchplant.com/news/how-to-operate-concrete-batching-plant.html Should you be interested in, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Top Knife Gate Valves in Delhi: Best & Lowest Prices from Udhhyog

Udhhyog, a leading manufacturer and supplier based in Delhi, India, offers a wide range of knife gate valves at the lowest prices and best prices in the market. Our high-quality valves are designed for precision and durability, ensuring reliable performance in various industrial applications. Whether you need valves for high-pressure systems or general use, our selection guarantees excellent functionality and value.

Explore our knife gate valves here: Knife Gate Valve

Why Choose Udhhyog’s Knife Gate Valves?

Udhhyog provides knife gate valves known for their exceptional quality and performance. Here’s why our valves are the preferred choice:

Durability: Our valves are built to withstand demanding industrial environments.

Cost-Effectiveness: We offer the lowest price and best price without compromising on quality.

Reliable Performance: Designed for efficient flow control and durability.

Variety: We have a wide range of options to suit different application needs.

Featured Knife Gate Valves

1. Atam Investment Casting Stainless Steel (CF-8) Gate Valve Screwed PN-16 This stainless steel gate valve offers high resistance to corrosion and is ideal for high-pressure applications. The screwed PN-16 design ensures a secure and leak-proof connection.

Explore this valve here: Atam Investment Casting Stainless Steel (CF-8) Gate Valve Screwed PN-16

2. Atam Cast Iron Gate Valve Flanged PN-16 Our cast iron gate valve with flanged PN-16 connections is known for its durability and cost-effectiveness. Perfect for high-pressure systems, it offers reliable performance and ease of installation.

Find out more here: Atam Cast Iron Gate Valve Flanged PN-16

3. Atam Cast Iron Gate Valve Flanged PN-10 Ideal for applications requiring a lower pressure rating, the cast iron gate valve with flanged PN-10 provides the same high-quality performance as the PN-16 version but is designed for lower pressure systems.

Check out this valve here: Atam Cast Iron Gate Valve Flanged PN-10

Selecting the Right Knife Gate Valve

When choosing a knife gate valve, consider the following:

Material: Stainless steel for corrosion resistance or cast iron for durability.

Pressure Rating: Ensure the valve meets the pressure requirements of your application.

Size and Connection Type: Match the valve size and connection type to your piping system.

Udhhyog provides a comprehensive selection of knife gate valves to meet your specific needs. With our competitive pricing and high-quality products, you can trust us for your valve procurement needs.

Why Udhhyog?

At Udhhyog, we are committed to simplifying industrial procurement for MSMEs across India. Our focus on delivering high-quality products at the best prices makes us a leading choice for industrial valves and other components.

For more information and to view our full range of knife gate valves, visit Udhhyog today.

#KnifeGateValves#IndustrialValves#ValveManufacturer#BestPriceValves#LowestPriceValves#DelhiIndustry#ValveSupplier#StainlessSteelValves#CastIronValves#FlowControlValves

1 note

·

View note