#knife edge gate valve supplier in india

Explore tagged Tumblr posts

Text

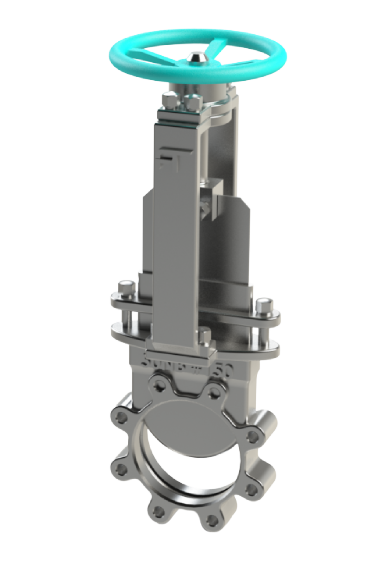

knife edge gate valve manufacturer

We are leading Knife Edge Gate Valve manufacturer in Ahmedabad, India. sharp-edged gate that can slice through any particulates. This valve is commonly used in industries such as oil and gas, chemical processing and wastewater treatment

#knife edge gate valve#knife edge gate valve manufacurer#knife edge gate valve manufacturer in ahmedabad#knife edge gate valve in india#knife edge gate valve supplier in india#knife edge gate valve in ahmedabad

0 notes

Text

Knife Gate Valve Manufacturers, Suppliers, Exporters in India | Knife Gate Valves in Mumbai, Nagpur, Aurangabad, Chennai, Bangalore, Tamil Nadu

#Knife Gate Valve#Knife Gate Valve Manufacturers in India#Knife Gate Valve Suppliers in India#Knife Gate Valve Exporters in India#Knife Gate Valves in India#Pneumatic Cylinder Knife Edge Gate Valve#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in India#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in India#Pneumatic Cylinder Knife Edge Gate Valve Exporters in India#Pneumatic Cylinder Knife Edge Gate Valve in India#Knife Gate Valve Manufacturers in Pune#Knife Gate Valve Suppliers in Pune#Knife Gate Valve Exporters in Pune#Knife Gate Valves in Pune#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Exporters in Pune#Pneumatic Cylinder Knife Edge Gate Valve in Pune

0 notes

Text

Knife Gate Valve vs. Traditional Gate Valve: Which Is Right for You?

In the realm of flow control solutions, gate valves play a pivotal role in regulating the movement of fluids through pipelines. When it comes to selecting the right valve for your application, one common dilemma arises: Knife Gate Valve or Traditional Gate Valve? Each has its unique features and advantages, and choosing the right one can significantly impact the efficiency and reliability of your operations. In this article, we'll explore the differences between these two types of gate valves to help you make an informed decision.

Traditional Gate Valve:

Traditional gate valves, also known as wedge gate valves, are the more conventional choice. They feature a solid wedge-shaped disc that travels perpendicular to the flow direction. When fully open, the gate completely clears the flow path, allowing for minimal pressure drop. Traditional gate valves are known for their tight seal and excellent shut-off capabilities.

Pros of Traditional Gate Valves:

Excellent sealing performance. Minimal pressure drop when fully open. Suitable for a wide range of applications. Long service life with proper maintenance. Cons of Traditional Gate Valves:

Not ideal for handling thick or viscous fluids. Prone to damage from solid particles in the flow. Slower operation compared to Knife Gate Valves. Knife Gate Valve:

Knife gate valves are specifically designed for applications involving thick, abrasive, or viscous media. These valves have a sharp-edged gate that cuts through the flow, providing a reliable seal even in challenging conditions. Knife gate valves are particularly popular in industries such as wastewater treatment, mining, and pulp and paper processing.

Pros of Knife Gate Valves:

Ideal for handling slurry, pulp, and thick media. Resistant to clogging from solids. Quick and easy operation. Space-saving design. Cons of Knife Gate Valves:

May have higher maintenance requirements. Limited to applications with abrasive or viscous fluids. Choosing the Right Valve for Your Application:

The choice between a Knife Gate Valve and a Traditional Gate Valve largely depends on your specific application requirements. Here are some key factors to consider:

Media Type: If you deal with slurry, wastewater, or viscous substances, a Knife Gate Valve is likely the better choice. For general-purpose applications with clean fluids, a Traditional Gate Valve may suffice.

Maintenance: Knife gate valves may require more frequent maintenance, especially in applications with abrasive media. Assess your maintenance capabilities and schedule when making a decision.

Space Constraints: If space is limited, knife gate valves have a compact design that can be advantageous.

Pressure Drop: Consider the pressure drop tolerance of your system. Traditional gate valves typically offer lower pressure drop when fully open.

In the choice between a Knife Gate Valve and a Traditional Gate Valve, there is no one-size-fits-all answer. It's crucial to evaluate your specific application, fluid characteristics, maintenance capabilities, and space constraints. Both types of valves have their merits, and making an informed decision will ensure optimal performance and reliability in your fluid control system. Consult with valve experts, like Feature Techno, to select the valve that best suits your needs and enjoy efficient flow control in your operations.

0 notes

Text

Knife Edge Gate Valve: Optimizing Flow Control in Harsh Conditions

Precise control of liquids and gases is crucial in industries operating under demanding conditions. In such scenarios, the knife edge gate valve emerges as a dependable choice, delivering exceptional performance even in harsh environments. Allied Valves India, a trusted knife edge gate valve supplier in Ahmedabad, offers premium-quality valves designed for durability, efficiency, and smooth operation.

What is a Knife Edge Gate Valve?

A knife edge gate valve is a specialized valve designed for applications requiring a robust sealing mechanism in tough, abrasive conditions. Its defining feature is the sharp-edged gate, which effectively cuts through sludges, thick liquids, and slurries. This innovative design prevents material buildup around the sealing area, making it ideal for industries such as mining, wastewater treatment, and chemical processing.

Key Benefits of Knife Edge Gate Valve

Enhanced Durability in Harsh Environments

The knife edge gate valve is built to withstand high pressures and extreme temperatures, making it suitable for industries handling abrasive materials or harsh conditions. Whether managing corrosive fluids in a chemical plant or coarse materials in a mining operation, this valve ensures reliable performance.

Accurate Flow Control

The sharp-edged design of the knife edge gate valve provides precise flow control, ensuring smooth operation even with thick and abrasive substances. This precision minimizes wear and tear, extending the valve's lifespan and ensuring consistent performance.

Low Maintenance Design

The knife edge gate valve is designed to prevent clogging, reducing the need for frequent maintenance. Its sharp edge maintains a clean sealing surface, resulting in longer service intervals and lower overall maintenance costs.

Versatile Applications

The knife edge gate valve is widely used across industries such as mining, pulp and paper, and wastewater management. It handles a variety of media, including slurries, oils, chemicals, and other viscous materials, making it a reliable choice for diverse industrial needs.

Why Choose Allied Valves India?

As a leading knife edge gate valve supplier in Ahmedabad, Allied Valves India provides high-quality products tailored to meet the rigorous demands of various industries. Here’s what sets us apart:

Quality You Can Trust

Our knife edge gate valve is manufactured using premium materials and adheres to international quality standards. This ensures reliable performance, even in the most challenging conditions.

Customized Solutions

We understand that every industrial requirement is unique. Allied Valves India provides customized valve solutions to meet specific application needs, ensuring optimal performance in every situation.

Expertise in Challenging Applications

With extensive experience, we specialize in designing knife edge gate valve solutions that perform seamlessly in harsh environments. Our expertise guarantees solutions that meet your industry’s most demanding challenges.

On-Time Delivery

We recognize the importance of minimizing downtime in operations. Our efficient manufacturing and delivery process ensures that your valves arrive on schedule, keeping your processes running smoothly.

Applications of Knife Edge Gate Valve

Knife edge gate valve from Allied Valves India is trusted across various demanding applications:

Mining and Mineral Processing: Efficiently manage slurries and abrasive materials.

Wastewater and Sewage Treatment: Control flow in abrasive and corrosive environments.

Pulp and Paper Industry: Handle the flow of thick liquids and sludges.

Chemical Processing: Regulate the flow of chemicals and other dense fluids.

Conclusion

The knife edge gate valve is essential for industries requiring superior durability, effective flow control, and resistance to abrasive and corrosive substances. Allied Valves India, a trusted knife edge gate valve supplier in Ahmedabad, delivers reliable, high-quality products for demanding industrial applications.

If you’re seeking a dependable knife edge gate valve supplier in Ahmedabad, contact Allied Valves India today to experience excellence in performance and quality.

0 notes

Text

Best Gate Instrumentation Valve Manufacturer, Supplier & Exporter in India - Mcneil Instruments

Introduction to Gate Instrumentation Valves

In industries requiring precise control and reliable flow management, gate valves are indispensable. Designed for on/off control of fluid flow, gate valves provide a full, unobstructed passage when open and offer secure isolation when closed. Mcneil Instruments, a trusted gate instrumentation valve manufacturer, supplier, and exporter based in India, leads the way in producing top-tier valves for industries such as oil and gas, chemical processing, power generation, and more.

What is a Gate Valve?

Gate valves operate by raising or lowering a wedge-like gate within the valve body, allowing for full flow when open and complete shut-off when closed. Unlike other valves, gate valves are not suited for throttling or fine control but are highly effective for full open/close applications. Their design results in minimal pressure drop across the valve, providing efficient flow with limited resistance.

Key Features of Gate Valves:Minimal Pressure Drop: When open, gate valves allow fluid to pass freely with minimal obstruction.

Effective Shut-Off: Ideal for applications where a secure shut-off is essential.Straight-Line Flow: Supports a clear, unobstructed flow, minimizing turbulence and erosion.

Types of Forged Gate Valves by Mcneil Instruments

As a premier manufacturer, supplier, and exporter of gate instrumentation valves, Mcneil Instruments offers a diverse selection of forged gate valves, each tailored to specific industrial requirements:

1. Forged Steel Gate Valve: Known for durability and resilience, this valve is ideal for high-pressure applications in heavy industries, where it withstands intense conditions without compromising performance.

2. Threaded Gate Valve: With a compact design, the threaded gate valve is optimal for tight spaces, allowing for easy installation without sacrificing functionality or efficiency.

3. Bellow Sealed Gate Valve: Engineered for zero leakage, this valve is essential for handling hazardous materials safely, providing a containment solution critical for safety-sensitive applications.

4. Resilient Forged Gate Valve: This general-purpose valve delivers reliable sealing, making it a cost-effective and versatile choice for standard industrial operations.

5. Expanding Gate Valve: Equipped with enhanced sealing capabilities, the expanding gate valve is suitable for high-pressure systems requiring robust flow isolation.

6. Knife Gate Valve: With its sharp-edged design, the knife gate valve effectively handles thick fluids and slurries, ensuring smooth operation in challenging applications such as wastewater treatment and mining.

7. Parallel Slide Gate Valve: Designed to avoid binding, this valve is suited for high-pressure conditions where consistent performance is essential.

8. Slab Gate Valve: Offering a strong seal, the slab gate valve is perfect for oil and gas pipelines, where it delivers reliable isolation and supports efficient flow management.

Why Choose Mcneil Instruments for Gate Valves?

Mcneil Instruments is a globally recognized manufacturer, supplier, and exporter of gate valves, committed to meeting the highest industry standards and ensuring long-lasting performance. Here’s why industries choose Mcneil Instruments:

1. Quality & Durability: Each valve is meticulously crafted from high-grade materials, engineered to endure demanding industrial environments.

2. Industry Compliance: Mcneil Instruments’ valves comply with stringent industry standards, including ANSI, ASME, and API, ensuring reliable performance across applications.

3. Trusted Exporter: Known worldwide, Mcneil Instruments has established a reputation for delivering quality valves that meet the specific needs of industries globally, ensuring precision, durability, and efficiency in every product.

Conclusion

For industries seeking dependable flow control solutions, Mcneil Instruments offers an unmatched selection of forged gate instrumentation valves. As a leading gate valve manufacturer, supplier, and exporter in India, Mcneil Instruments combines expertise, innovation, and quality to deliver valves that exceed performance expectations.

Whether you need a valve for high-pressure applications, corrosive environments, or general-purpose use, Mcneil Instruments provides reliable solutions that enhance efficiency and safety in your operations.Explore our range of gate valves to find the ideal solution for your industrial requirements.

0 notes

Text

Knife Edge Gate Valve Manufacturer & Supplier in Nashik, Maharashtra, India

Yashshree Enterprises is the Best Knife Edge Gate Valve Manufacturer & Supplier in Nashik, Maharashtra. We are also the Top Manufacturer & Supplier in India

Knife Edge Gate Valve

Price: ₹ 1,000/ Piece

Size14inchMaterialCast IronUsage/ApplicationPipe FittingTypeKnife EdgeIs It Rust ProofYesHardness55 HRC

Inquiry Now

SS Pressure Gauge

Price: ₹ 1,000/ Piece

Dial Size1.5 inch / 40 mmPressure Range4barUseGasDisplay TypeAnalogPressure TypeGauge PressureConnection TypeNPTConnection Size1/2inchDial TypeDryMaterial of casingStainless Steel

Inquiry Now

Engine Timing Belt

Price: ₹ 750/ Piece

MaterialRubberTypeSingle SidedThickness1.52mmUsage/ApplicationMachinery IndustryColorBlackWidth4inch

Inquiry Now

91-7020144157, 9226136327

0 notes

Text

Knife Edge Gate Valve Supplier in India

Speciality Valve proudly leads as the foremost Knife Edge Gate Valve Supplier in India, with our products reaching global destinations including Canada, France, Australia, and Mexico.

Description:

Available Materials: SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

Ends: Flanged, Wafer, Lug

Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA

Explore our range of Valves on our website: https://www.specialityvalve.com/product-category/unidirectional-knife-gate-valve/

0 notes

Text

Buy Knife-Edge Gate Valve Gearbox at Best Price

Look to buy Knife edge gate valve gearbox for industrial purpose? Viral Industries is a top notch knife edge gate valve gearbox manufacturer and supplier in India. Visit here to know more about the knife edge gate valve gearbox.

#valvegearbox#knife edge gate valve#gear box valve manufacturer#gearbox manufacturer#knife edge gate valve gear box

1 note

·

View note

Link

Our Knife Edge Gate Valves are made using premium quality raw materials and available as per customer requirement at best market price.

1 note

·

View note

Text

Advantages of Slurry Knife Gate Valves in Industries

Introduction:

Typically, slurry knife gate valve manufacturers usually design the valve in such a way that it isolates the slurry flow even in one of the most challenging processing conditions. The bi-directional flow of the valve tolerates the backflow while the sleeves made of elastomer present on the both sides of the gate provide a tighter shut off mechanism.

The slurry knife gate valve manufacturers follows the concept of the ease of maintenance since the body of the valve is casted in a single piece which usually eliminates the need for sealing in between the halves of valve body. The distribution of the load in ring is integrated into these valve sleeves which contain only two service parts; secondary seal and the ring sleeves.

Valve Design:

A heavy-duty knife gate valve should be specially designed to offer a superior performance while giving a low downtime for heavy-duty usage, high pressure loads, higher solid concentration materials, corrosive slurry applications that are erosive-abrasive that are generally seen in the tailing lines of the concentrate slurry transport pipelines and the mineral ore concentration plants.

A single casting designed valve body contains a two field-replaceable elastomer sleeves as mentioned earlier which would be a full port bi-directional knife gate valve offering bubble tight working which is suitable for working under heavy pressures of up to a 20 bar. They also withstand a slurry temperature of up to 80ºC. The sleeve present on either side of the blade which are removable provide the actual bi-directional bubble tight sealing, with eliminating contact of the parts with the slurry.

Valve Working:

Generally, the rubber ring sleeves are matched with the stiffener ring by placing in the valve housing in order to seal them against each other when the slurry valve is in the open position so that this tighter fitting contains all the high internal line pressure thus providing a bi-directional flow and shut off. Going with the industrial specific scenario a wide-body slurry knife gate valve is an ideal choice for low as well as medium pressure heavy duty slurry applications.

A Slurry knife gate valve, whilst being designed for heavy-duty conditions, is equally ideal for usage in the high-pressure application requirements of the specific industrial sector like mining & mineral processing, power generation, waste water treatment etc.

Some of the Major Advantages are:

Replacing of the sleeves is a lot easier.

Has a bi-directional flow.

The slurry knife-gate when open fully is usually withdrawn from the flow.

No downstream leakage since there is a bubble tight shutoff.

There is no clogging of the bonnet so as to impede the flow.

Lower maintenance conditions.

Very well suited either for wet or dry service or for both.

Easier way of handling due to light weight design.

Conclusion:

Thanks to our wider experience in the designing and manufacturing of specialist slurry knife gate valves, we at V-tork are adept in designing to suit the specific application requirements.

Here at V-tork leading knife gate valve manufacturers and knife gate valve suppliers in India, we have used our extensive experience in valve design and manufacturing for the industry specific application to offer a comprehensive range of slurry knife gate valves by offering an edge over other valve designs in the industry by using different materials for fabricating the valves as required by the customer.

#slurry knife gate valve manufacturers#knife gate valve suppliers in India#knife gate valve manufacturers

1 note

·

View note

Link

Fiksar Valve Mfg - Our wide range of Ball Valve, Plug Valve, Butterfly Valve, Knife Edge Gate Valve, Non Return Valve, Steam Trap, Ball Valve, Ball Valve API 6D, Plug Valve Teflon Sleeve, PTFE Lined Plug Valve, FEP Lined Plug Valve, PFA Lined Plug Valve, Ball Valve BS5351, SMS Ball Valve Manufacturer, Supplier, Gujarat, India

1 note

·

View note

Text

Knife Gate Valve - Knife Gate Valve Manufacturer in Ahmedabad, India

https://knifegatevalve.co.in/

We are confinement benefits in systems with high content of deferred things and initially calculated for use in the crush and paper industry. Knife gate valves is engaged with manufacturer, exporter and supplier of knife edge gate valves, cast iron, ductile iron, carbon steel, stainless steel, duplex stainless stee, electric actuated, pneumatic cylinder operated, motorised, ptfe seated, soft seated, resilient seated, ahmedabad, india.

0 notes

Link

The Knife Gate Valves are offered in an extensive range of Material where as its Knife edged Plate is made of from Stainless Steel Plates of different grades irrespective of the Body material, Hard Faced Plates to suit the application.

#knifegatevalvemanufacturers#knifegatevalve#knifevalvemanufacturer#knifegatevalvemanufacturersgujarat

0 notes

Text

0 notes

Link

conactpneumatics is one of the leading manufacturers, Supplier and exporters of high quality of Pneumatic Cylinder Barrel.We make reliable and advance pneumatic cylinder knife edge gate valve in India

0 notes

Text

How to Select Knife Gate Valve for Waste Water Treatment

To begin understanding how the waste water treatment valves process let us take a look in to these water treatment stations structures. The waste water treatment stations are designed in to a wet well or a wet and dry well design here the dry well usually contains the pumps and its related equipment. The valves that are deployed in a lift station are located in the basin of the wastewater, in a separate valve vault or in a dry well. The four main types of valves typically found in the lift stations include shutoff valves, check valves, air valves and knife gate valves.

The function of shutoff valves is the isolation when repair or maintenance is needed. The work of the check valve is preventing the reverse flow when the pump is turned off. Air valves are used to expel the air present in the pump column and the forces main to provide efficient flow to minimize the surges. Knife gate valves are used for their ability to cut through the sludge’s since they have flow resistance whereas in other valves are having blunt seating which will not cut the media and leads to operation failure.

Selecting valves for a wastewater plant is similar to that of selection of the pumps where the consideration must be given to the contents of solid medium of the flow media. The water treatment valves of these wastewater treatment plants must be selected to operate safely and consistently with higher efficiency so as to avoid unwanted maintenance situations that are costlier.

The main criteria that should always be considered while selecting valves are:

Purpose: Isolation

Parameters: Essential Flow, pressure and temperature.

Requirements: Frequency of operation, admissible rate of leakage, space available, level of cleanliness

Compatibility: Percentage of concentration, percentage of solids, media, and their density.

Generally, the Knife gate valves are similar to the typical gate valves; however, these knife-edge of a gate valve can cut through solids that has accumulated in the seat area. The knife gate valves are mainly used in the wastewater treatment systems for handling sludge’s of abrasive, corrosive nature. They are available in standard cast configurations which are as small as 50 mm to 3000 mm. In some cases the knife gate valve manufacturers intending the valves for using in sludge applications should specify them with a bi-directional pressure rating so as to make them precisely suitable for unplugging of the pipelines in both directions.

These knife gate valves as mentioned prior can cut through the scales, slurries, and build-ups of the surface. Since they do not have an obstruction in their flow path, they always provide a higher flow capacity. Since they have smaller dimension face-to-face, they specially assist with a reduction of the valve weight and facilitates the piping designing.

Conclusion:

Choosing the right valve for the water treatment plant is of prime importance since it is a very sensitive process on the whole. A right advice from manufacturer or supplier can ensure the longevity and proper functioning of the valves. We V-Tork being one of the leading knife gate valve manufacturers and knife gate valve suppliers in India, have ensured that our customers are assisted in selecting the right valves for their industrial applications. We also manufacture waste water valves & also valves for mining operations. Our expertise application team understand the requirement in detail so that they are provided with the right choice of valve design to the clients.

#knife gate valve manufacturers#knife gate valve suppliers in India#water treatment valves#waste water valves

0 notes