#smart manufacturing market Industry

Text

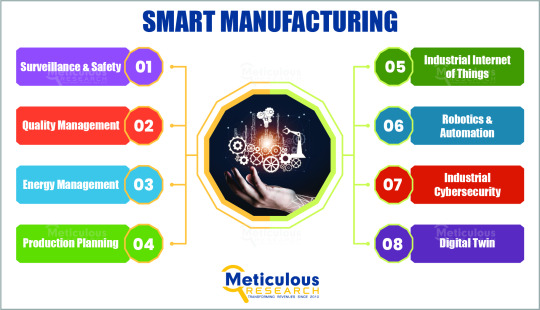

Smart Manufacturing: Market Trends and Growth Insights

The global landscape of manufacturing is undergoing a significant transformation driven by technological advancements and evolving industry needs. The concept of smart manufacturing has emerged as a critical component in this transformation, integrating advanced technologies like the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning (ML) into production processes. According to a recent publication by Meticulous Research®, the smart manufacturing market is expected to reach $733.4 billion by 2031, growing at a robust CAGR of 24.6% from 2024 to 2031. This article delves into the factors driving this market growth, the key technologies involved, and the challenges that industries face in adopting smart manufacturing practices.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5265

The Growth Drivers of the Smart Manufacturing Market

The rise of smart manufacturing is largely driven by the need to optimize production processes, reduce operational costs, and enhance overall efficiency. Several key factors contribute to the growth of the smart manufacturing market:

Predictive Maintenance and Cost Reduction: One of the primary drivers of smart manufacturing is the increasing demand for predictive maintenance. Predictive maintenance leverages data analytics and machine learning to predict equipment failures before they occur, allowing manufacturers to perform maintenance only when necessary. This approach significantly reduces downtime and operational costs, enhancing productivity.

Integration of AI and ML Technologies: The incorporation of AI and ML into manufacturing processes is revolutionizing how industries operate. AI and ML enable manufacturers to analyze vast amounts of data in real time, optimizing production processes and improving decision-making. These technologies also play a crucial role in quality management, resource optimization, and energy management, further driving the adoption of smart manufacturing.

Expansion of 3D Printing and Additive Manufacturing: Additive manufacturing, particularly 3D printing, is another critical component of the smart manufacturing landscape. 3D printing allows for the creation of complex and customized products with reduced waste and shorter lead times. As the technology continues to advance, it is increasingly being integrated into mainstream manufacturing processes, contributing to the market's growth.

Introduction of 5G Connectivity: The rollout of 5G technology is expected to have a profound impact on the smart manufacturing market. 5G offers faster data transmission speeds and lower latency, enabling real-time communication between machines, sensors, and control systems. This enhanced connectivity supports the deployment of advanced applications such as augmented reality (AR), virtual reality (VR), and digital twins in manufacturing environments.

Adoption in Developing Countries: While smart manufacturing has seen significant adoption in developed regions, its expansion into developing countries presents a substantial growth opportunity. Countries in Asia-Pacific, Latin America, and Africa are increasingly investing in smart manufacturing technologies to enhance their industrial capabilities and compete on a global scale. This trend is expected to drive market growth in these regions over the forecast period.

Key Technologies in Smart Manufacturing

Smart manufacturing is an umbrella term that encompasses various advanced technologies aimed at improving the efficiency, flexibility, and sustainability of manufacturing processes. Some of the key technologies driving the smart manufacturing market include:

Industrial Internet of Things (IIoT): The IIoT is a network of interconnected devices, sensors, and machines that communicate with each other and exchange data. In a smart manufacturing environment, IIoT enables real-time monitoring and control of production processes, leading to increased efficiency and reduced waste. IIoT is expected to account for the largest share of the smart manufacturing market, with a significant focus on improving operational visibility and process optimization.

Cloud Computing and Storage: Cloud computing provides manufacturers with the ability to store and process large amounts of data remotely, offering scalability and flexibility. By leveraging cloud-based solutions, manufacturers can access real-time data from multiple locations, streamline operations, and enhance collaboration across different departments.

Robotics and Automation: Robotics and automation are integral to smart manufacturing, enabling manufacturers to automate repetitive tasks and improve precision and speed. The integration of robotics with AI and ML further enhances the capabilities of automated systems, allowing them to perform complex tasks with minimal human intervention.

Industrial Cybersecurity: As manufacturing processes become more interconnected, the need for robust cybersecurity measures becomes increasingly critical. Industrial cybersecurity solutions are designed to protect manufacturing systems from cyber threats, ensuring the integrity and confidentiality of data. With the rising adoption of smart manufacturing technologies, the demand for advanced cybersecurity solutions is expected to grow.

Additive Manufacturing (3D Printing): Additive manufacturing, or 3D printing, allows manufacturers to produce parts and products layer by layer, offering greater design flexibility and reduced material waste. This technology is particularly valuable for producing customized and complex components, making it a key driver of innovation in the smart manufacturing market.

Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are increasingly being used in smart manufacturing for applications such as training, maintenance, and quality control. AR can overlay digital information onto the physical world, helping workers perform tasks more accurately, while VR can simulate real-world environments for training purposes.

Digital Twin Technology: A digital twin is a virtual replica of a physical object or system, used to simulate and analyze its performance in real-time. In smart manufacturing, digital twins enable manufacturers to monitor production processes, predict potential issues, and optimize operations. The use of digital twins is expected to grow as manufacturers seek to enhance their operational efficiency and reduce downtime.

Artificial Intelligence (AI): AI is at the core of smart manufacturing, driving innovations in automation, predictive analytics, and process optimization. AI-powered systems can analyze vast amounts of data to identify patterns, predict outcomes, and make informed decisions, helping manufacturers improve their productivity and reduce costs.

Blockchain: Blockchain technology offers a decentralized and secure way to record transactions and track assets in a manufacturing environment. It is particularly valuable for ensuring transparency and traceability in supply chains, reducing the risk of fraud and improving trust among stakeholders.

Applications of Smart Manufacturing

Smart manufacturing technologies are being applied across various industries to enhance efficiency, reduce costs, and improve product quality. Some of the key applications of smart manufacturing include:

Surveillance and Safety: Surveillance and safety are critical components of smart manufacturing, particularly in industries where worker safety is a priority. The integration of smart cameras, motion detection, and facial recognition technologies allows manufacturers to monitor worker behavior, machinery compliance, and safety anomalies in real-time. This not only enhances productivity but also ensures a safer working environment.

Quality Management: Quality management is essential in manufacturing to ensure that products meet the required standards and specifications. Smart manufacturing technologies, such as AI and machine learning, enable manufacturers to monitor and control quality throughout the production process, reducing the risk of defects and improving overall product quality.

Resource Optimization: Resource optimization involves maximizing the efficiency of resources such as materials, energy, and labor. Smart manufacturing technologies, such as IIoT and AI, enable manufacturers to monitor resource usage in real-time, identify inefficiencies, and implement corrective measures to reduce waste and lower costs.

Inventory and Warehouse Management: Effective inventory and warehouse management are crucial for ensuring that materials and products are available when needed. Smart manufacturing technologies, such as robotics and automation, enable manufacturers to streamline inventory management processes, reduce errors, and improve order fulfillment times.

Machine Inspection and Maintenance: Regular machine inspection and maintenance are essential for preventing equipment failures and reducing downtime. Smart manufacturing technologies, such as predictive maintenance and digital twins, enable manufacturers to monitor the condition of machines in real-time, predict potential issues, and perform maintenance only when necessary.

Production Planning: Production planning involves determining the most efficient way to produce products while meeting demand and minimizing costs. Smart manufacturing technologies, such as AI and machine learning, enable manufacturers to optimize production schedules, reduce lead times, and improve overall efficiency.

Energy Management: Energy management is a key consideration for manufacturers looking to reduce their environmental impact and lower operating costs. Smart manufacturing technologies, such as IIoT and AI, enable manufacturers to monitor energy usage in real-time, identify inefficiencies, and implement energy-saving measures.

Challenges in Smart Manufacturing

Despite the many benefits of smart manufacturing, several challenges must be addressed to ensure its successful adoption. Some of the key challenges include:

High Capital and Operating Expenses: Implementing smart manufacturing technologies requires significant capital investment in equipment, software, and infrastructure. Additionally, the ongoing operating costs associated with maintaining and updating these technologies can be substantial. These financial barriers can be a major obstacle for small and medium-sized enterprises (SMEs) looking to adopt smart manufacturing practices.

Need for Skilled Personnel: Smart manufacturing technologies require a workforce with specialized skills in areas such as data analysis, machine learning, and industrial cybersecurity. However, there is a shortage of skilled personnel in these areas, making it difficult for manufacturers to fully leverage the benefits of smart manufacturing.

Privacy and Data Protection Concerns: As manufacturing processes become more interconnected and data-driven, concerns about privacy and data protection have become increasingly important. Manufacturers must ensure that sensitive data is securely stored and transmitted to protect against cyber threats and data breaches.

Integration with Legacy Systems: Many manufacturers still rely on legacy systems that may not be compatible with modern smart manufacturing technologies. Integrating these systems with new technologies can be complex and costly, posing a challenge for manufacturers looking to transition to smart manufacturing.

Conclusion

The smart manufacturing market is poised for significant growth in the coming years, driven by the increasing adoption of advanced technologies such as IIoT, AI, and 3D printing. While there are challenges to overcome, including high costs and the need for skilled personnel, the benefits of smart manufacturing are undeniable. As more industries recognize the value of these technologies in improving efficiency, reducing costs, and enhancing product quality, the smart manufacturing market is expected to continue its upward trajectory, reaching an estimated $733.4 billion by 2031.

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Smart Manufacturing Market#Industrial Internet of Things#Cloud Computing & Storage#Robotics & Automation#Industrial Cybersecurity#Augmented Reality (AR)/Virtual Reality (VR)#Digital Twin#Surveillance & Safety#Inventory & Warehouse Management#Machine Inspection & Maintenance#Production Planning#Resource Optimization

0 notes

Text

IoT in Manufacturing Market is Estimated to Witness High Growth Owing to Need for Streamlining Operations

The IoT in manufacturing market involves connecting and integrating physical devices, sensors, and other smart objects into the manufacturing operations through the use of networking and cloud technologies. It enables the collection of information from various manufacturing equipment and assets and utilizes analytics tools to analyze the collected data to optimize operations. IoT allows manufacturers to drive improvements in equipment performance, reduce downtime, improve quality control, and optimize logistics and inventory management. The advantages of IoT in manufacturing include increased productivity, predictive maintenance, asset monitoring, inventory management, and energy management. The need for streamlined operations, improved asset utilization, and reduced maintenance costs through advanced monitoring and predictive analytics is fueling the demand for IoT in manufacturing.

The global IoT in manufacturing market size was valued at US$ 198.8 billion in 2022 and is anticipated to witness a compound annual growth rate (CAGR) of 18.4% from 2023 to 2030.

Key Takeaways

Key players operating in the IoT in Manufacturing are EnableX.io (VCLOUDX PTE. LTD), Twilio Inc., Infobip Ltd., Vonage Holdings Corp, M800 Limited, MessageBird BV, Iotum Inc., Plivo Inc., Voxbone SA, Snich AB, Telestax, Voximplant (Zingaya Inc.), Mitel Networks Corporation, 8x8 Inc., AT&T Inc., Voxvalley Technologies, Avaya Inc., Bandwidth Inc. (Bandwidth.com), Wazo Communication Inc., and IntelePeer Cloud Communications. These players are focusing on developing advanced IoT solutions and services for manufacturing applications.

The key opportunities in the Iot In Manufacturing Market Forecast include predictive maintenance through condition monitoring of equipment, remote asset management through sensors and connectivity, improving supply chain visibility, and optimizing energy consumption. Adoption of advanced analytics is also opening up new revenue streams through data monetization.

North America is expected to continue dominating the global IoT in manufacturing market during the forecast period owing to the presence of many global players and early adoption. However, Asia Pacific is expected to witness the highest growth attributed to increasing investments by governments and manufacturers in smart factory initiatives to drive industry 4.0. Countries like China, India, Japan, and South Korea are emerging as global manufacturing hubs and rapidly adopting IoT technologies.

Market drivers

The key driver fueling the growth of IoT in manufacturing is the need for streamlining operations through real-time data collection, monitoring, and analytics. IoT allows connecting all manufacturing assets and enables data-driven decision making for predictive maintenance, quality control, inventory management, and production planning. This helps reduce downtime, save costs, improve overall equipment effectiveness, and enhance operational efficiency. IoT also enables remote asset management and driving energy efficiency initiatives through connected smart systems and remote asset performance monitoring.

PEST Analysis

Political: IoT in manufacturing market is affected by government regulations around data privacy and security. Stricter privacy laws make it challenging for businesses to collect and use customer data. On the other hand, regulations supporting industry digitization creates opportunities for IoT solutions.

Economic: Factors like global economic growth, industrial production levels, and investment in automation impact demand for IoT systems in manufacturing. During recessionary periods, organizations may delay IoT deployments to control costs.

Social: Younger workforce is more receptive to new technologies. Skill gaps challenge wider IoT adoption. Awareness programs help promote social acceptance of advanced manufacturing technologies.

Technological: Emerging technologies like AI, 5G, edge computing, and blockchain offer new possibilities for optimizing manufacturing processes. However, integrating legacy systems with advanced IoT platforms poses technological challenges. Security also remains a key concern with expanding network connectivity.

The geographical regions where the IoT in manufacturing market is concentrated in terms of value are North America and Europe. North America accounts for the largest share mainly due to early adoption of Industry 4.0 technologies by US factories.

The Asia Pacific region is projected to be the fastest growing market during the forecast period. This is because key developing economies like China and India are making heavy investments to automate their manufacturing industries using industrial IoT solutions. China's "Made in China 2025" initiative advocates implementation of IoT, robotics, and other innovative technologies across manufacturing sectors.

Get more insights on Iot In Manufacturing Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Coherent Market Insights#Iot In Manufacturing Market#Iot In Manufacturing#Smart Manufacturing#Industry 4.0#Digital Transformation#Automation#Industrial Iot#Iiot#Connected Devices#Sensors

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Smart Manufacturing Market Outlook On The Basis Of Component, Technology, End-Use, Region And Forecast To 2030: Grand View Research Inc.

San Francisco, 21 Dec 2023: The Report Smart Manufacturing Market Size, Share & Trends Analysis Report By Component, By Technology (Product Lifecycle Management, 3D Printing, Enterprise Resource Planning), By End-use, By Region, And Segment Forecasts, 2023 – 2030

The global smart manufacturing market size is predicted to hit USD 787.54 billion by 2030, according to a new study by Grand View…

View On WordPress

#Smart Manufacturing Industry#Smart Manufacturing Market#Smart Manufacturing Market 2023#Smart Manufacturing Market 2030#Smart Manufacturing Market Revenue#Smart Manufacturing Market Share#Smart Manufacturing Market Size

0 notes

Text

Smart Manufacturing Market to see huge growth by 2031

According to a new report published by Allied Market Research, titled, “Smart Manufacturing Market, by Component (Hardware, Software, Services), by Application (Machine Execution System, Programmable Logic Controller, Enterprise Resource Planning, SCADA, Discrete Control Systems, Human Machine Interface, Machine Vision, 3D Printing, Product Lifecycle Management, Plant Asset Management, Others), by End-User (Automotive, Aerospace and Defense, Chemicals and Materials, Healthcare, Industrial Equipment, Electronics, Food and Agriculture, Oil and Gas, Others): Global Opportunity Analysis and Industry Forecast, 2022–2031” The smart manufacturing market size was valued at $249.50 billion in 2021, and is estimated to reach $860 billion by 2031, growing at a CAGR of 13.7% from 2022 to 2031.

Advancements in technology, particularly in areas such as the Internet of Things (IoT), cloud computing, and big data analytics, are driving the growth of the smart manufacturing industry. These technologies enable manufacturers to collect and analyze large amounts of data in real-time, providing valuable insights and improving decision-making. The Internet of Things (IoT) involves the use of sensors and connected devices to gather data from machines, equipment, and products. This data can then be used to optimize production processes, predict maintenance needs, and improve quality control. Cloud computing allows this data to be stored and processed in a scalable and cost-effective way, enabling real-time monitoring and analysis. Big data analytics allows manufacturers to analyze large amounts of data to identify patterns and insights that can assist decision-making. This can help manufacturers to optimize production, reduce waste, and improve quality control. Machine learning and artificial intelligence can also be used to automate decision-making and improve production efficiency. Advancements in technology are also driving the development of new products and services, such as predictive maintenance and remote monitoring solutions. These solutions can help manufacturers to improve uptime, reduce downtime, and optimize maintenance schedules.

However, high costs associated with implementing smart manufacturing solutions, lack of standardization among suppliers of equipment and protocols, constant need for software updates, and limited use of technologies due to technical issues are among the major factors that will limit market growth The adoption of this technology may be significantly hampered by the substantial initial expenditure needed to deploy smart manufacturing, particularly for small and medium-sized businesses (SMEs). Smart manufacturing technology like cutting-edge sensors, robots, artificial intelligence, and machine learning algorithms can be expensive to purchase and integrate.

Smart manufacturing is revolutionizing the industrial sector by integrating cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning. By identifying and fixing errors in real-time, guaranteeing uniform quality across production lines, and cutting waste, these technologies assist producers in raising the caliber of their goods. Smart Manufacturing may give manufacturers real-time insights into the manufacturing process through the use of AI and IoT, helping them to swiftly identify and fix quality concerns. In addition to boosting customer happiness by ensuring that products meet or exceed their expectations, this can result in significant cost savings by lowering the need for manual inspection and rework.

The global smart manufacturing market share is segmented based on component, application, and end-user, and region. By component, it is classified into hardware, software, and services. By application, it is classified into machine execution system, programmable logic controller, enterprise resource planning, Scada, discrete control systems, human machine interface, machine vision, 3D printing, product lifecycle management, plant asset management and others. By end-user, it is classified into automotive, aerospace & defense, chemicals & materials, healthcare, industrial equipment, electronics, food and agriculture, oil & gas, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The key players profiled in the smart manufacturing market analysis report include ABB Ltd., Siemens, General Electric, Rockwell Automation Inc., Schneider Electric, Honeywell International Inc., Emerson Electric Co., Fanuc UK Limited, Fujitsu Global, and IBM.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/75089

The report offers a comprehensive analysis of the global smart manufacturing market trends by thoroughly studying different aspects of the market including major segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working towards the growth of the market. The report also sheds light on the present scenario and upcoming trends & developments that are contributing to the growth of the market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the market.

Impact of Covid-19 on the Global Smart Manufacturing Industry

COVID-19 pandemic disrupted global supply chains, leading to shortages of raw materials and components, and delays in production and delivery. This affected the ability of manufacturers to meet demand and led to increased costs.

The pandemic created significant uncertainty for businesses, as it is difficult to predict how long the pandemic will last and what the long-term impacts will be. This has made it difficult for businesses to plan for the future and make strategic decisions.

The outbreak led to a reduction in investment in many industries, including smart manufacturing. This has led to a slowdown in innovation and development of new technologies.

Key Findings of the Study

Based on component, the hardware sub-segment emerged as the global leader in 2021 and software sub-segment is anticipated to be the fastest growing sub-segment during the forecast period.

Based on application, the product lifecycle management sub-segment emerged as the global leader in 2021 and is predicted to show the fastest growth in the upcoming years.

Based on end-user, the automotive sub-segment emerged as the global leader in 2021 and is predicted to show the fastest growth in the upcoming years.

Based on region, the North America market registered the highest market share in 2021 and is projected to maintain the position during the smart manufacturing market forecast period.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports Insights” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

0 notes

Text

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

The automotive industry is undergoing a major transformation. India has witnessed a massive change and growth in this segment. The Indian auto parts industry is witnessing a massive growth, it marked a 23% growth in 2023 and is contributing 2.3% to India’s GDP.

Everything from smart manufacturing to sustainable practices will strongly impact how the automotive industry will function in the future. One of the key technologies that is pivotal in redefining the auto industry’s efficiency is the vision inspection system.

Stringent quality practices are a must for automotive part manufacturers. The visual inspection system has become integral for smart manufacturing processes. It enables the manufacturer to achieve unparalleled reliability, efficiency and productivity. This blog will unfold the details of how a vision inspection system can enhance the automotive industry.

What is a Vision Inspection System?

Before delving deeper into how vision inspection systems can enhance smart manufacturing processes, let’s examine what makes this technology crucial for the automotive sector. Vision Inspection System, or Machine Vision, is a technology that uses cameras and image processing software to inspect and measure objects in real-time.

It works on similar principles as the human visual system but with better efficiency and precision. It helps identify defects, inconsistencies, or deviations from the desired specifications. One of the unique propositions of this technology is that it is highly versatile and is not just limited to the automotive industry. There are several other applications of the same.

Implementing Vision Inspection System Ensures:

Quality products

Increased production efficiency

It helps in reducing the cost

Compliance with the safety standards

Types Of Vision Inspection Systems Used In the Auto Industry

1. Laser Marking Inspection

This helps mark identification codes, logos, and labels on automotive components. It ensures accuracy by verifying its position and quality.

2. Barcode Scanning

Another type includes the scanning of barcodes. It is used for tracking and tracing of the automotive parts. Also, it ensures effective inventory management and reduces the probability of errors.

3. Pattern Matching Inspection

As the name indicates, this method identifies specific patterns and shapes of the automotive components. It is integral for the quality control and ensures that each component fits perfectly. This ensures seamless functioning of the manufacturing process.

4. Bearing Inspection

Bearings are critical components in vehicles; their integrity is essential for safety and performance. Vision Inspection Systems can detect even minor defects in bearings, such as cracks or irregularities, ensuring that only high-quality components make it into the assembly line.

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

1. Improved Quality Control and Defect Detection

One of the key reasons companies rely on vision inspection system is because it ensures precise quality control. The vision inspection system canteen even the minutest of errors or flaws otherwise invisible to the human eye. Identifying the defence early in manufacturing can help overcome the issues and reduce the probability of faulty products. This also helps in maintaining the brand quality and ensures better customer satisfaction.

2. Enhanced Efficiency and Production Speed

With the growing demand in the automotive sector, automotive companies are always on their toes to address these demands. With modern technologies like vision inspection systems, companies can ensure real-time inspection. With effective quality control, they can overcome the delay of manual quality checks and also reduce the labour cost. This overall increases productivity and helps in maintaining consistency. This further increases the product efficiency.

3. Real-time Monitoring and Data Analysis

In the case of smart manufacturing, the company heavily relies on the data. This data will give them an analysis of the production process, allowing the manufacturers to gain valuable insight. By analysing the data generated during the inspection process, the companies can identify trends, pinpoint areas of improvement and make data-driven decisions, which can help gain a competitive edge.

4. Cost Reduction and Resource Optimization

By reducing the occurrence of defects and minimizing rework, Vision Inspection Systems contribute to cost reduction. Additionally, the efficiency gains achieved through automation and real-time monitoring lead to resource optimization. Manufacturers can allocate their workforce and resources more effectively, making their operations leaner and more cost-efficient. This, in turn, allows for competitive pricing while maintaining profit margins.

5. Compliance with Industry Regulations

For an automotive company to gain a competitive edge, it must adhere to the quality and comply with the safety regulations. The vision inspection system makes it easier to ensure complete consistency and accuracy while inspecting the components and products. Thus, the manufacturers can demonstrate their commitment to quality standards, reducing the risk of regulatory penalties.

Trends in Vision Inspection Technology

Technological implementation is pivotal for any organisation to stay ahead of the curve. The vision inspection system can further be improvised with the integration of modern technologies like:

Artificial Intelligence and Machine Learning

We cannot separate AI and machine learning when discussing technological revolution. Technologies like artificial intelligence and machine learning drive the modern-day revolution. With these technologies, it becomes easier to analyse the trends in the past and adapt new methods that can help improve the vision inspection process. AI-powered vision systems are becoming more sophisticated and capable of handling complex inspection tasks.

Enhanced Connectivity and Industry 4.0

The vision inspection system has become crucial for automotive companies. It is an integral part of Industry 4.0 initiatives. The data exchange is playing a pivotal role in this. These systems are increasingly integrated into the broader manufacturing ecosystem, allowing seamless communication between machines, robots, and other equipment. This interconnectedness enables real-time decision-making and the optimization of the entire production process.

Miniaturization and Portability

Advancements in camera technology and miniaturization have made it possible to deploy Vision Inspection Systems in smaller, more challenging spaces. Portable vision systems can be used for on-site inspections and maintenance, enhancing efficiency and flexibility.

Conclusion

As the technology continues to evolve, its applications will transform the industry and the process. Vision inspection system has become an indispensable tool for the automotive industry. Its ability to deliver consistent quality control, enhance production efficiency and real-time insights helps the automotive company comply with the quality standards, keeping them ahead of the curve.

SOURCE: https://optopixel.com/how-vision-inspection-enhances-auto-industry-in-smart-manufacturing/

0 notes

Text

#industrial#industry trends#automotive industry#small business#power tool equipment#business and industry sectors#control#distributor#supplier#manufacturer#market trends#components#controller#sensor#switches#smart devices

0 notes

Text

The global aircraft tire market is a dynamic and rapidly evolving sector within the aviation industry. Aircraft tires play a crucial role in ensuring the safe and efficient operation of aircraft. These tires are specially designed to withstand the extreme conditions of take-off, landing, and taxiing, while also offering optimal performance, durability, and reliability.

Read More: https://cmi-reports.blogspot.com/2023/06/global-aircraft-tire-market-industry.html

#Coherent Market Insights#Aerospace and Defense Industry#Global Aircraft Tire Market#Commercial aircraft tires#Aviation tire market#Tire manufacturers#Smart tire technologies#Re-treading solutions

0 notes

Text

Smart Augmented Reality (AR) Glasses Market Key Manufacturers and Global Industry Analysis by 2032

The market for smart augmented reality (AR) glasses has been experiencing significant growth in recent years. AR glasses, also known as smart glasses, are wearable devices that overlay digital information, graphics, and virtual objects onto the real world, enhancing the user's perception and interaction with their surroundings. They offer various applications across industries such as gaming, entertainment, healthcare, manufacturing, and more.

The augmented Reality Glasses Market is to reach a valuation of US$ 74384.1 Million by 2032, likely to surge at a vigorous 20.3% CAGR from 2022 to 2032.

Market Growth and Trends:

The smart AR glasses market has been witnessing steady growth due to advancements in technology and increasing demand across various industries. Key factors driving the market include:

Enterprise Adoption: AR glasses are finding applications in various industries, including healthcare, manufacturing, logistics, and retail. They offer benefits such as hands-free operation, remote assistance, improved productivity, and enhanced training and maintenance capabilities.

Consumer Applications: AR glasses are also gaining popularity in consumer markets, particularly in gaming, entertainment, and immersive experiences. They enable users to interact with digital content in real-world environments, opening up new possibilities for entertainment and social experiences.

Advancements in Technology: Technological advancements in areas such as optics, display systems, sensors, and battery life are improving the performance and usability of AR glasses. Smaller form factors, improved field of view, and enhanced graphics contribute to a better user experience.

Integration with AI and IoT: Integration of AR glasses with artificial intelligence (AI) and the Internet of Things (IoT) is enabling advanced functionalities. AI-powered computer vision can enhance object recognition and tracking, while IoT connectivity enables seamless integration with other devices and data sources.

Cost Reduction: As the technology matures and economies of scale kick in, the cost of AR glasses is expected to decrease, making them more accessible to a wider consumer base.

Challenges:

Despite the promising growth prospects, the smart AR glasses market faces several challenges:

Design and Usability: AR glasses need to strike a balance between functionality and user comfort. Overcoming design challenges such as size, weight, and ergonomics is crucial for widespread adoption.

Privacy and Social Acceptance: AR glasses raise concerns related to privacy, data security, and social acceptance. Striking a balance between user convenience and respecting privacy norms is essential for market growth.

Limited Field of View: Current AR glasses often have a limited field of view, restricting the immersive experience. Improving the field of view without compromising the form factor and usability remains a challenge.

Battery Life: AR glasses require sufficient battery life to support extended usage. Enhancements in battery technology are necessary to address this challenge.

Regulatory and Legal Hurdles: The introduction of AR glasses raises regulatory and legal challenges

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/smart-augmented-reality-(ar)-glasses-market/952/

Market Segmentations:

Global Smart Augmented Reality (AR) Glasses Market: By Company

• Atheer

• Epson

• Google

• Microsoft

• ODg

• Recon

• Sony

• Vuzix

Global Smart Augmented Reality (AR) Glasses Market: By Type

• Simple Assisted Reality Glasses

• MR Holographic Displays

• Smart Helmets

Global Smart Augmented Reality (AR) Glasses Market: By Application

• Individual Consumer

• Enterprises

Global Smart Augmented Reality (AR) Glasses Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Smart Augmented Reality (AR) Glasses market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/smart-augmented-reality-(ar)-glasses-market/952/

Reasons to Purchase Smart Augmented Reality (AR) Glasses Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/smart-augmented-reality-(ar)-glasses-market/952/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

0 notes

Link

New York, US, Nov. 08, 2022 (GLOBE NEWSWIRE) -- According to a comprehensive research report by Market Research Future (MRFR), “Process Automation &...

#market research future#process automation#industrial manufacturing marke#smart manufacturing market#total station market

0 notes

Text

#Robotics and job market impact#Automation and employment effects#Robotics and job displacement#Impact of robots on labor market#Robotics and future of work#Automation and job opportunitiesRobotics and career prospects#Robotics and career prospects#Impact of automation on workforce#Robotics and job security#Robotics and employment trends#Robotics 2023#Future of Robotics#"Robotics and AI 2023#Robotics Industry 2023#Smart Robotics 2023#Autonomous Robotics 2023#Robotics in manufacturing 2023#IoT and Robotics 2023#Robotics and automation 2023#Industry 4.0 and Robotics 2023

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

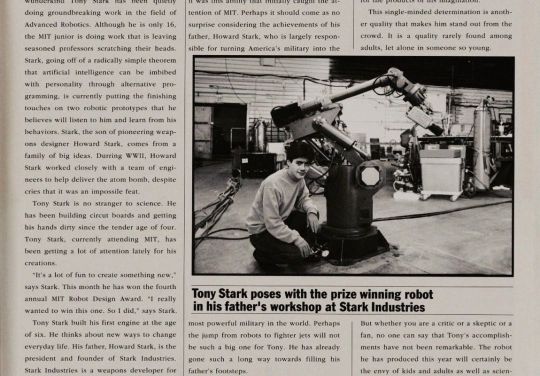

Tony is not a businessman

Crazy opinion, some might say. But I know what I'm talking about. Let me show you.

Here's a hypothesis: Tony was never interested in becoming CEO of SI or any other company. Never wanted to do business for life. Was not interested in what's going on in his company before Afghanistan. And never even learned how to run it.

Let's check the facts we have:

Before becoming CEO, Tony spent his entire life as a student. He had degrees in science and engineering. Nothing close to business. No MBA, no economics, no management. His interest was focused on robotics and AI. Before his parents died, he had no experience running a company or working in business. I'm sure his father gave him some business training. Including, of course, how to behave in public so as not to be eaten by sharks. But that's it. He never showed or mentioned any interest in business.

He was not interested in expanding his company or making more money. He stopped at $10-20 billion. Never earned more, but could. Reminder from this post about the net worth of real billionaires: Elon Musk - $210 billions, Jeff Bezos - $195 billions, Bill Gates - $129 billions. Huge difference. And they are not even as brilliant as he is.

He also didn't try to buy and take over other companies.

He didn't really care about money. He stopped weapon manufacturing after returning from Afghanistan. He knew that SI could go bankrupt. Easily. But he did it anyway. He could have made a lot of enemies. Including politicians and military. He did it anyway.

He instructed Pepper not to do business with other companies working on anything that could be used as a weapon.

And this means fewer projects and contracts, less profit and influence on the market and many industries.

Have you ever seen him actually run SI independently? In IM1, he showed Jericho to officers in Afghanistan and reported back to Stane on how it went.

He wasn't even aware of the Board meeting.

He appointed Pepper as CEO. Yes, he thought he was going to die soon. But he never took it back. This gave him more freedom to do what he was most interested in and enjoyed doing - science and saving the world.

When he was appointing her in IM2, he said:

He thought. He didn't even know how the company's processes worked. Because he was not interested, and because Stane was doing business for him.

And Tony simply trusted him and the board of directors because they promised him they wouldn't do dirty business. That was the only thing that interested him back then.

That's why he had zero awareness of all the under-the-table deals Stane made behind his back. Because Tony never looked back. He trusted them. This trait will again hurt him greatly in the future.

We never saw him in his office (only when it became Pepper's office). He was always at home in his lab.

Every time Pepper or other people came to Tony with business matters, Tony tried to get rid of them (the matters and the people). To postpone, to ignore, to be late, intentionally or not. It was boring. He didn't like the people in business. He didn't respect them because he knew who they were. He didn't care about their recognition. He was making more room in his busy schedule to spend time at home, doing science and tinkering.

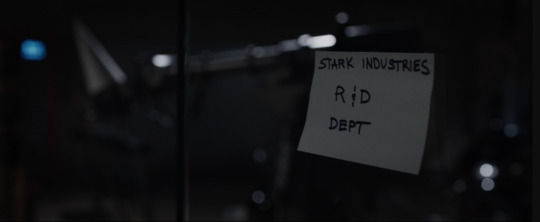

Conclusion: Tony was never really the CEO of SI. He was its R&D Department.

He was never a businessman, but had to pretend to be one. He was not a businessman not because he was incapable or lazy. He was smart enough to do the job. It just wasn't his thing. He was glad to get rid of this obligation as soon as possible. After 20 years of living a life he never wanted, it certainly felt great being someone closer to himself.

P.S. Happy non-CEO 1602 Tony says Hi from his science barn (he also knows the local Robin Hood, but shh...).

#marvel#mcu#tony stark#iron man#the avengers#iron man 3#iron man 2#pepper potts#obadiah stane#business#stark industries#what if

51 notes

·

View notes

Text

Related to my monopoly+pricing post, Astral Codex Ten recently wrote about off-label Ozempic from compounding pharmacies that shows this little logic flaw in action:

How much does is cost?

HenryMeds is $297/month, Eden is $296, Mochi is $254 - compared to the $1,300/month you’d pay for the official product. This isn’t covered by insurance, so it’s still not affordable for lots of people. But it’s more affordable than the $1,300/month version. Also, there’s not a shortage of it.

Why doesn’t it cost even less?

This is still a mystery to me. The compounding pharmacies are circumventing the patent, so they don’t need to pay back investment. And there’s a lot of competition between various compounders and telemedicine startups - even 23andMe is getting in on the deal now! And some Harvard doctors recently published a paper saying that the unit cost to the manufacturer is only about $5/month.

Maybe the bottleneck is FDA-approved factories, or high-capacity compounding pharmacies. Or maybe Harvard doctors with no skin in the game are assuming too many things away, and $250 is the best we’ll get for now.

He is puzzled about why the price isn't cheaper, why aren't they racing to the bottom? And I am no expert in this industry, maybe there are barriers and that $250 really is the floor, I am just using this as a logic example. But really, consider instead that pharmacists - running their own business - are smart and trying to maximize their own revenue. If they can sell their supply at $250, and enough customers are willing to pay, why wouldn't they do that? Why would one of them "try to undercut" and, what, maybe steal some orders until the others notice and then match and now they all make less? Why instead wouldn't they all feel around for the "market maximizing price" for them collectively? I would bet their supply is not infinite, and while they could lower the price to sell more they can't sell *so* much more of it that it would make up for the loss. And they can all figure that our independently and experimentally raise and lower prices, watching each other, till they are at equilibrium.

And again this isn't some like radical economics take, in actual economics practice we have dozens of models for firm behavior for different contexts. The 101 model is a tool in the toolbox, but raw is just quite rare in the world.

27 notes

·

View notes

Text

Exploring The History And Success Of A Canadian Car Company

Buckle up, gearheads! Today, we are revving our engines and taking a thrilling ride through the fascinating history and remarkable success of a Canadian car company that has left an indelible mark on the automotive industry. From its humble beginnings to conquering international markets, this company's journey is awe-inspiring. So, fasten your seatbelts as we dive into the exhilarating world of innovation, challenges, triumphs, and everything in between!

Impact On The Canadian Automotive Industry

Established decades ago, the Canadian car company has played a pivotal role in shaping and driving the automotive landscape within Canada. Its presence has bolstered the economy and fostered a sense of national pride in producing quality vehicles on home soil. The company's commitment to innovation and excellence has set new standards for the industry, inspiring others to push boundaries and strive for greatness.

This company has become an integral part of Canada's automotive sector by providing jobs, investing in research and development, and supporting local suppliers. Its impact ripples through various communities across the country, creating opportunities for growth and advancement. As a beacon of success in a competitive market, this Canadian car company continues to pave the way for future automakers to follow suit.

Expansion Into International Markets

The Canadian Car Company's expansion into international markets marked a significant milestone in its history. It opened up new opportunities for growth and global recognition, and by venturing beyond national borders, the company showcased its ability to compete globally.

With a strategic approach, the Canadian Car Company penetrated various international markets, adapting to different cultural preferences and regulations. This adaptability was crucial in establishing a strong presence in diverse regions worldwide.

The Canadian Car Company successfully introduced its vehicles to consumers worldwide through partnerships and collaborations with local distributors and dealerships. This approach not only boosted sales but also solidified the brand's reputation on an international level.

Expanding into international markets allowed the Canadian Car Company to showcase its commitment to innovation and quality across borders. The company's dedication to excellence resonated with customers globally, increasing demand for its vehicles.

Key Innovations And Technological Advancements

One key factor contributing to the success of this Canadian car company is its continuous focus on innovations and technological advancements. From the early days of manufacturing vehicles, they have strived to stay ahead of the curve by integrating cutting-edge technology into their designs. This commitment has allowed them to meet evolving consumer demands and set new industry standards.

The company's investment in research and development has led to breakthroughs in fuel efficiency, safety features, and overall performance. By harnessing the power of innovation, they have created cars that are not only reliable but also environmentally friendly. These advancements have positioned them as a leader in sustainable transportation solutions.

Moreover, this Canadian car company has incorporated advanced software and connectivity options into its vehicles through strategic partnerships with tech companies and suppliers. This forward-thinking approach has created smart cars that offer customers a seamless driving experience.

By staying at the forefront of technological progress, this Canadian car company continues to push boundaries and shape the future of automotive engineering.

Success Stories And Notable Achievements

One of the most renowned success stories in Canadian Car Company's history is its groundbreaking introduction of electric vehicles to the market. This bold move not only revolutionized the industry but also solidified the company's position as a forward-thinking and environmentally conscious automaker.

In addition, the company's commitment to innovation has led to numerous accolades and awards for its cutting-edge designs and advanced technology integration. Its dedication to pushing boundaries and setting new standards has earned it a loyal customer base around the globe.

Furthermore, their strategic partnerships with key players in the automotive sector have paved the way for collaborative projects that have further enhanced their brand reputation. These successful collaborations have resulted in mutually beneficial outcomes for all parties involved, showcasing Canadian Car Company's ability to thrive in competitive environments.

These notable achievements are testaments to the Canadian Car Company's unwavering commitment to excellence and continuous growth in the automotive industry.

Challenges faced by the company

Navigating the competitive landscape of the automotive industry, the Canadian Car Company has faced its fair share of challenges. From economic downturns to shifts in consumer preferences, staying ahead of the curve requires continuous innovation and adaptability.

One significant challenge has been balancing sustainability with performance in an environmentally conscious market. As regulations tighten, the company continues to address the delicate balance between investing in eco-friendly technologies and maintaining high-quality standards.

Moreover, global supply chain disruptions and fluctuating raw material costs have posed logistical hurdles for production and distribution. Finding efficient solutions to minimize delays and optimize operations remains a top priority for sustained growth.

Despite these obstacles, the Canadian Car Company's commitment to excellence and resilience has propelled it forward. By embracing change, fostering creativity, and prioritizing customer satisfaction, this iconic brand continues to make waves domestically and internationally.

As we reflect on its journey through history filled with achievements, innovations, and challenges, overcome, one thing is clear - the legacy of this Canadian car company will undoubtedly continue shaping the future of automotive excellence for years to come.

40 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles:

The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing:

As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity:

AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

19 notes

·

View notes