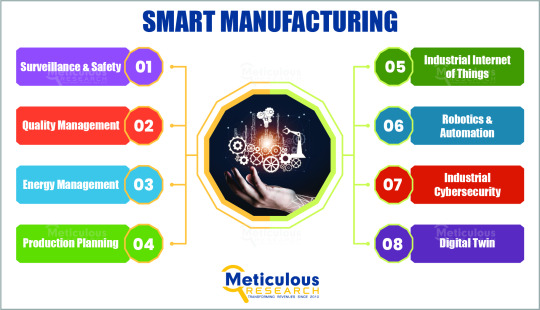

#Smart Manufacturing Industry 4.0

Explore tagged Tumblr posts

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Optimizing Workflows with Lean Manufacturing and Automation

Success in today’s corporate environment is mainly dependent on efficient data management. For reliable data accuracy and easy operations, businesses depend on solid data workflow solutions. Because data is becoming more complicated and abundant, organizations need to enhance their data workflow procedures.

This blog serves as a helpful manual to assist companies in enhancing their company data processing arrangements. In order to make data administration simpler, we shall examine important tactics and industry standards.

How does workflow optimization work?

Workflow optimization refers to the methodical enhancement of a series of jobs and procedures in an establishment with the aim of augmenting production and efficiency. Cutting down on delays and pointless steps entails evaluating current workflows, locating bottlenecks, and optimizing procedures.

Organizations seek to remove manual and repetitive duties through the use of technology and automation, freeing up staff members to concentrate on more strategically important areas of their jobs. Workflow optimization requires effective resource allocation, communication, and quality control procedures. It guarantees efficient use of resources and the completion of tasks with few errors.

In order to satisfy the demands of the organization, workflow optimization is a continual, iterative process that calls for constant evaluation and modification.

There are three different concepts: workflow management, workflow automation, and workflow optimization. Automation streamlines work, management maintains order, and optimization optimizes the entire process for optimal effectiveness. All are essential to a profitable and well-running organization.

Workflow optimization’s advantages

Enhanced effectiveness of operations:

Increasing the operational effectiveness of your business is one of the main benefits of optimizing your procedures. Workflow optimization helps you accelerate your operations and increase team productivity.

Enhanced quality of work:

You may reduce difficulties caused by human mistakes and expedite processes by optimizing your workflow. Every step is made sure to be in the right place through workflow mapping. As a result, there is no uncertainty among team members, which produces consistently excellent results. Superior work enhances the standing of your business and draws in new business.

Easy access to precise information:

The road to current, pertinent data is made hassle-free through workflow optimization. It speeds up work completion and prevents costly errors for your team. Additionally, your organization sets up a standard for data security and integrity, which guarantees that you’re constantly doing things correctly.

Flexible modification:

Your team can respond swiftly to changes thanks to workflow management, which standardized procedures. Consult your process diagram to find appropriate options when new opportunities present themselves. Remain nimble, beat out rivals, make adjustments quickly, and handle any obstacles or hazards.

Increased accountability and transparency:

The increased productivity results from putting performance first. Departments can clearly see who is responsible for what when there is departmental data sharing, which reduces confusion and duplication of effort. This guarantees that everyone is cooperating effectively and staying on the same page.

Essential techniques for streamlining processes:

We’ll look at methods to work smarter, not harder, in this section. We’ll go over everything from making chores simpler to using the newest tools to increase output.

Utilize appropriate tools:

The appropriate tools can make all the difference when it comes to project management. Adding effective project management software to your workflow is a calculated step toward increasing productivity. These solutions have several benefits, including centralized team management, smooth communication, and practical work monitoring.

However, robust project management software goes above and beyond these basics, providing priceless insights via workflow analysis.

Make use of automation:

You can guarantee consistency in task execution, minimize errors, and drastically cut down on manual involvement by implementing automated procedures into your workflow.

Manufacturing Automation solutions allow you to tailor them to your requirements, which simplifies duties and frees up time for critical projects.

Make your workflow visually appealing:

It’s similar to donning glasses for your jobs when you visualize your workflow. Tools that display your work in charts or boards, as opposed to just listing items, provide you with a more comprehensive picture. You can see every step of your assignments using it, which is crucial for improving the quality of your job. What’s functioning and what needs to be fixed are clearly visible.

Using project management software, you may test out many strategies until you find the one that works best for you. For better understanding and improvement at each stage of the process, visualize your projects rather than merely keeping a list of them.

Try utilizing various workflow techniques:

If your existing approaches aren’t working, it could be time for some changes. There isn’t one way that works for everyone, so experimenting with different approaches will help you find the best one for your particular requirements.

Lean:

Although frequently linked to the industrial industry, it can be used in nearly every sector. The key is to maximize value from a few resources by removing waste, removing pointless stages, and cutting down on costs. To expedite the procedure and cut expenses, for example, a hospital might assist with patient admissions.

Agile:

This is an approach that was first employed in programming but is helpful in marketing and sales, incorporating collaboration and ongoing improvement.

Six Sigma:

It’s a technique for lowering performance variability in production. Call centers also employ it to identify areas where customer service is lacking.

To identify the methodology that best suits your workflow, don’t be hesitant to try out a few alternative approaches.

Wrapping Up

Workflow optimization helps your business standardize and enhance its current procedures. Analyzing and recording workflows is the first step in optimization, which aims to identify flaws and enhance workflows. Since even processes that have already been optimized need to be repeatedly adjusted to new conditions, process optimization is a continuous activity rather than an isolated event.

In order to function even more effectively and efficiently over the long run and thus stay up with the competition, optimization should be viewed as the organization’s sustained iterative work. Thus, process thinking and process optimization are essential components of any contemporary management of a business.

#Industry 4.0 in Manufacturing#manufacturing execution system#smart manufacturing industry 4.0#lean six sigma

0 notes

Text

Unlocking the Potential of Industrial Precision with Flow Meters

Flow meters have become indispensable tools in various industries, measuring the movement of liquids and gases with high accuracy. As industrial processes become more complex and demand greater efficiency, the flow meter market is seeing remarkable growth, driven by technological advancements and the need for optimized fluid management.

Overview of Market Growth

In 2024, the global flow meter market is on track to hit approximately USD 9.1 billion, with projections indicating it could grow to USD 12.6 billion by 2029, expanding at a 6.7% compound annual growth rate (CAGR). This growth is largely fueled by industries such as oil & gas, water treatment, chemical processing, and power generation, all of which require precise fluid monitoring for safety, efficiency, and compliance.

Importance Across Industries

Flow meters play a critical role across industries by ensuring accurate measurement of liquid and gas flow. In sectors like oil & gas, the reliability of these meters impacts production quality and safety, preventing costly mishaps such as leaks or inefficient energy use. In the water and wastewater management sectors, flow meters contribute to resource conservation, ensuring systems are running smoothly while complying with environmental regulations.

In industries that are highly regulated, such as pharmaceuticals and food & beverage, the precision provided by flow meters is paramount for maintaining quality control. Flow meters are also key in the renewable energy sector, where they help in monitoring biofuel production and improving energy efficiency.

Technological Advancements and IIoT Integration

The rapid adoption of advanced technologies is reshaping the flow meter market. The advent of digital flow meters, integrated with Industrial Internet of Things (IIoT) technology, has revolutionized how industries monitor and optimize their systems. These devices offer real-time data, predictive analytics, and enhanced diagnostic features. By harnessing IIoT, flow meters provide continuous insights, allowing operators to proactively address potential issues, reduce downtime, and increase operational efficiency.

Furthermore, the growing sophistication of flow meter technologies is reflected in the diversification of product types. Flow meters like Coriolis, ultrasonic, magnetic, and vortex meters are all tailored for specific industrial requirements. Coriolis meters, for example, are known for their accuracy in mass flow measurement, making them ideal for industries such as oil & gas. Meanwhile, ultrasonic and electromagnetic flow meters are extensively used in sectors that deal with conductive fluids, such as wastewater treatment.

Leading Players and Competitive Strategies

Top companies like Emerson Electric Co. and Siemens AG are pushing the boundaries of innovation in the flow meter space. Their products are designed to meet the evolving demands of multiple industries. Siemens AG, for instance, has developed ultrasonic and electromagnetic flow meters that are highly efficient in various industrial applications, while Emerson Electric is recognized for its state-of-the-art Coriolis and magnetic flow meters, which are widely used in hazardous environments.

These key players are not only focused on product innovation but are also strategically expanding their market presence through acquisitions and collaborations. Such strategies enable them to diversify their product offerings and expand into new markets, particularly in regions with growing industrial infrastructure, such as Asia-Pacific and the Middle East.

Future Trends in the Flow Meter Market

Looking ahead, the flow meter market is expected to continue evolving in response to both technological and regulatory pressures. Sustainability is becoming a crucial focus across industries, with governments worldwide implementing stricter regulations around energy efficiency and environmental conservation. Flow meters will play a vital role in helping industries meet these regulatory requirements by providing accurate measurements of water, air, and energy usage, thereby minimizing waste and emissions.

The push towards smart manufacturing and the implementation of Industry 4.0 will further accelerate the demand for advanced flow meters. As more industries transition to fully automated and interconnected production systems, the ability to remotely monitor and control processes via IIoT-enabled devices will be essential. This integration will lead to smarter, more sustainable operations, with flow meters at the heart of process optimization.

Download PDF Brochure :

Flow meters are becoming increasingly important in driving operational efficiency and ensuring industrial safety across multiple sectors. The market’s growth trajectory, supported by ongoing technological advancements and the increasing need for precision, positions it for continued expansion in the coming years. Companies like Emerson Electric and Siemens AG are at the forefront of this evolution, constantly innovating to meet the diverse needs of global industries. With trends like IIoT, sustainability, and smart manufacturing leading the way, flow meters are set to remain a cornerstone of industrial progress well into the future.

#flow meters#IIoT#smart manufacturing#sustainability#energy efficiency#industrial automation#Industry 4.0

0 notes

Text

0 notes

Text

Digital Twin in Smart Manufacturing: Unlocking Efficiency and Innovation

In today’s rapidly evolving manufacturing landscape, the integration of digital twin technology has emerged as a game-changer. By creating virtual replicas of physical assets and processes, manufacturers can unlock unprecedented levels of efficiency and innovation. Companies like Web Synergies are at the forefront of this transformation, offering comprehensive solutions that enable businesses to harness the power of digital twins in their operations.

What is a Digital Twin?

A digital twin is a real-time digital replica of a physical object or system, created through the integration of Internet of Things (IoT) sensors, data analytics, and simulation technologies. It allows manufacturers to monitor, analyze, and optimize their production processes remotely. This dynamic representation provides valuable insights that drive data-informed decisions, leading to enhanced operational efficiency and reduced costs.

The Role of Digital Twins in Smart Manufacturing

Streamlining Operations

Digital twins are instrumental in streamlining operations by providing a detailed view of manufacturing processes. With Web Synergies’ Connected Manufacturing solutions, manufacturers can establish a cohesive ecosystem where every component is interconnected. This connectivity facilitates real-time monitoring and analysis, enabling manufacturers to identify bottlenecks and inefficiencies swiftly.

Enhancing Predictive Maintenance

One of the most significant advantages of digital twin technology is its ability to enhance predictive maintenance. By leveraging Intelligent Asset Management solutions from Web Synergies, manufacturers can predict equipment failures before they occur. This proactive approach not only minimizes downtime but also extends the lifespan of machinery, ultimately resulting in substantial cost savings.

Improving Quality Control

Quality control is paramount in manufacturing, and digital twins significantly enhance this aspect. With Web Synergies’ Data and Analytics services, manufacturers can perform simulations and analyses that allow them to fine-tune their production processes. By monitoring performance in real-time, manufacturers can quickly identify defects and implement corrective measures, ensuring that quality standards are consistently met.

Web Synergies’ Digital Twin Solutions

Web Synergies offers a suite of digital twin solutions designed to empower manufacturers on their journey toward Industry 4.0. By leveraging Cloud Services and Data Transformation, Web Synergies ensures that manufacturers have access to the latest technology and insights necessary for optimizing their operations. Their comprehensive approach guarantees seamless integration of digital twin technology into existing manufacturing processes.

Conclusion: Embracing Innovation with Digital Twins

As the manufacturing sector continues to evolve, embracing digital twin technology is no longer an option but a necessity for staying competitive. Companies like Web Synergies are leading the charge, providing innovative solutions that unlock efficiency and drive continuous improvement. By adopting digital twins, manufacturers can not only enhance operational performance but also foster a culture of innovation that propels them into the future.

For more insights into how digital twin technology can transform your manufacturing processes, visit Web Synergies’ blog on smart manufacturing.

#Digital Twin Technology#Smart Manufacturing#Industry 4.0#Connected Manufacturing#Intelligent Asset Management#Data Analytics#Web Synergies

0 notes

Text

An Industry 4.0 consulting company helps you assess current systems, select appropriate technologies, and develop a strategic implementation roadmap. They guide you through pilot testing, full-scale deployment, and continuous optimization, ensuring smooth transitions and ongoing support.

#Industry 4.0 Strategy Consulting Services#Industry 4.0 consulting company#Industry 4.0 experts#Smart Manufacturing consulting services

0 notes

Text

IIoT Platform Market Share, Key Market Players, Trends & Forecast, 2024–2030

The IIoT Platform Market was valued at USD 9.0 billion in 2023 and will surpass USD 21.7 billion by 2030; growing at a CAGR of 13.4% during 2024 - 2030. IIoT platforms act as the backbone of this revolution, offering the essential infrastructure for integrating diverse devices, systems, and processes within industrial environments. The IIoT platform market is experiencing rapid growth, driven by the need for increased efficiency, predictive maintenance, and smarter manufacturing processes. In this blog, we explore the current state of the IIoT platform market, key trends shaping its development, and the challenges and opportunities that lie ahead.

IIoT platforms are comprehensive software solutions designed to manage and analyze data from industrial devices and systems. These platforms enable real-time monitoring, predictive maintenance, and data-driven decision-making, which are critical in industries such as manufacturing, energy, and transportation. By providing a unified interface for integrating sensors, machines, and IT systems, IIoT platforms help businesses optimize operations, reduce downtime, and enhance overall productivity.

Get a Sample Report: https://intentmarketresearch.com/request-sample/iiot-platform-market-3652.html

Key Trends Driving the IIoT Platform Market

Edge Computing and Analytics: One of the most significant trends in the IIoT market is the shift towards edge computing. By processing data closer to the source—at the edge of the network—businesses can reduce latency, enhance data security, and improve real-time decision-making. Edge analytics allows companies to analyze data locally, providing immediate insights without the need for constant cloud connectivity.

Artificial Intelligence and Machine Learning Integration: AI and ML are becoming integral components of IIoT platforms, enabling predictive maintenance, anomaly detection, and automated decision-making. These technologies allow platforms to learn from historical data, identify patterns, and predict potential issues before they lead to costly downtime.

Interoperability and Open Standards: As the IIoT ecosystem expands, the need for interoperability between different devices, systems, and platforms has become crucial. Open standards and protocols, such as OPC UA and MQTT, are gaining traction, allowing seamless communication and data exchange across diverse industrial environments.

Cybersecurity Focus: With the increasing connectivity of industrial systems, cybersecurity has become a paramount concern. IIoT platforms are evolving to include robust security features, such as encryption, identity management, and anomaly detection, to protect against cyber threats and ensure the integrity of industrial operations.

Cloud-Native Platforms: The adoption of cloud-native architectures is accelerating in the IIoT space. Cloud-native platforms offer scalability, flexibility, and ease of integration, making it easier for businesses to deploy and manage IIoT solutions. The combination of cloud computing and IIoT enables enterprises to leverage vast amounts of data for advanced analytics and decision-making.

Challenges in the IIoT Platform Market

Despite the promising growth, the IIoT platform market faces several challenges:

Complexity of Integration: Integrating IIoT platforms with existing legacy systems and infrastructure can be complex and costly. Companies often need to invest in new hardware, software, and training to ensure a smooth transition.

Data Management and Privacy: The vast amount of data generated by IIoT devices raises concerns about data management, privacy, and ownership. Companies need to establish clear policies for data governance to ensure compliance with regulations and protect sensitive information.

Scalability Issues: As IIoT deployments scale, managing and processing data from thousands of devices becomes increasingly challenging. Ensuring that IIoT platforms can handle large-scale deployments without compromising performance is a key concern for businesses.

Vendor Lock-In: With a multitude of IIoT platforms available, companies may face the risk of vendor lock-in, where they become dependent on a single vendor's ecosystem. This can limit flexibility and increase long-term costs. Companies must carefully evaluate platforms to avoid being tied to proprietary solutions.

Get an insights of Customization: https://intentmarketresearch.com/ask-for-customization/iiot-platform-market-3652.html

Opportunities Ahead

The IIoT platform market presents significant opportunities for innovation and growth:

Vertical-Specific Solutions: Developing IIoT platforms tailored to specific industries—such as automotive, healthcare, or agriculture—can offer more targeted functionalities and improve adoption rates.

Partnerships and Ecosystem Development: Collaborations between IIoT platform providers, hardware manufacturers, and industry players can foster innovation and create more comprehensive solutions. Building a robust ecosystem around IIoT platforms can drive market growth and provide added value to customers.

Sustainability and Energy Efficiency: As industries increasingly focus on sustainability, IIoT platforms can play a crucial role in optimizing energy use and reducing carbon footprints. Platforms that offer energy management and environmental monitoring features will be in high demand.

Expansion into Emerging Markets: The adoption of IIoT platforms in emerging markets offers significant growth potential. As industries in these regions modernize, there will be a growing demand for IIoT solutions that can enhance productivity and competitiveness.

Conclusion

The IIoT platform market is poised for continued expansion as industries embrace digital transformation and seek to optimize their operations. While challenges such as integration complexity and data management persist, the opportunities for innovation and growth are vast.

#Industrial IoT platform#Smart manufacturing platform#Industrial Internet platform#Industry 4.0#IoT for manufacturing

0 notes

Text

Smart Factories: The Future of Manufacturing

Discover how smart factories are revolutionizing the manufacturing industry. Explore the cutting-edge technologies that are driving efficiency, productivity, and innovation. Learn about the benefits of automation, data analytics, and connected systems in creating smarter, more sustainable manufacturing processes.

0 notes

Text

#industrial iot#technology#iot app development#iot development company#smart manufacturing#industrial IoT#smart factories#manufacturing technology#digital transformation#Industry 4.0#IoT in manufacturing

0 notes

Text

IIM Sirmaur Launches PG Programme on Leadership in Smart Manufacturing

The Indian Institute of Management (IIM) Sirmaur is excited to announce the introduction of its new post-graduate programme for executives, focusing on Leadership in Smart Manufacturing (LSM). This one-year, full-time, fully residential programme is set to begin in January 2025 and is designed to prepare senior professionals for leadership roles in the rapidly evolving landscape of Industry 4.0.

Programme Overview

The Leadership in Smart Manufacturing programme is developed in collaboration with RWTH Aachen University in Germany, bringing a global perspective to the curriculum. This advanced course aims to provide executives with cutting-edge skills and knowledge essential for leading in the era of smart manufacturing.

What to Expect

The PG LSM programme combines rigorous academic coursework with practical insights from industry experts. It covers the latest advancements in smart manufacturing, including automation, digital transformation, artificial intelligence (AI), the Internet of Things (IoT), and sustainable manufacturing practices.

One of the highlights of the programme is the opportunity for participants to attend a module at RWTH Aachen University. This international module will offer valuable exposure to advanced manufacturing facilities and best practices in Germany.

Application and Details

Interested candidates are encouraged to visit the IIM Sirmaur website for detailed information on eligibility criteria, application deadlines, and other essential details. The programme is tailored to experienced engineers and senior professionals aiming to enhance their leadership skills in the field of smart manufacturing.

With its blend of academic rigor and practical experience, the PG LSM programme at IIM Sirmaur is poised to equip future leaders with the expertise needed to drive innovation and success in the evolving manufacturing sector.

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Manufacturing Automation: A Deep Dive

Automation is becoming increasingly essential for manufacturers each year. Manufacturing stands out as one of the most prevalent and pivotal industries for applying automation technology.

#manufacturing execution system#smart manufacturing industry 4.0#manufacturing operations management

0 notes

Text

IoT in Manufacturing Market is Estimated to Witness High Growth Owing to Need for Streamlining Operations

The IoT in manufacturing market involves connecting and integrating physical devices, sensors, and other smart objects into the manufacturing operations through the use of networking and cloud technologies. It enables the collection of information from various manufacturing equipment and assets and utilizes analytics tools to analyze the collected data to optimize operations. IoT allows manufacturers to drive improvements in equipment performance, reduce downtime, improve quality control, and optimize logistics and inventory management. The advantages of IoT in manufacturing include increased productivity, predictive maintenance, asset monitoring, inventory management, and energy management. The need for streamlined operations, improved asset utilization, and reduced maintenance costs through advanced monitoring and predictive analytics is fueling the demand for IoT in manufacturing. The global IoT in manufacturing market size was valued at US$ 198.8 billion in 2022 and is anticipated to witness a compound annual growth rate (CAGR) of 18.4% from 2023 to 2030. Key Takeaways Key players operating in the IoT in Manufacturing are EnableX.io (VCLOUDX PTE. LTD), Twilio Inc., Infobip Ltd., Vonage Holdings Corp, M800 Limited, MessageBird BV, Iotum Inc., Plivo Inc., Voxbone SA, Snich AB, Telestax, Voximplant (Zingaya Inc.), Mitel Networks Corporation, 8x8 Inc., AT&T Inc., Voxvalley Technologies, Avaya Inc., Bandwidth Inc. (Bandwidth.com), Wazo Communication Inc., and IntelePeer Cloud Communications. These players are focusing on developing advanced IoT solutions and services for manufacturing applications. The key opportunities in the Iot In Manufacturing Market Forecast include predictive maintenance through condition monitoring of equipment, remote asset management through sensors and connectivity, improving supply chain visibility, and optimizing energy consumption. Adoption of advanced analytics is also opening up new revenue streams through data monetization. North America is expected to continue dominating the global IoT in manufacturing market during the forecast period owing to the presence of many global players and early adoption. However, Asia Pacific is expected to witness the highest growth attributed to increasing investments by governments and manufacturers in smart factory initiatives to drive industry 4.0. Countries like China, India, Japan, and South Korea are emerging as global manufacturing hubs and rapidly adopting IoT technologies. Market drivers The key driver fueling the growth of IoT in manufacturing is the need for streamlining operations through real-time data collection, monitoring, and analytics. IoT allows connecting all manufacturing assets and enables data-driven decision making for predictive maintenance, quality control, inventory management, and production planning. This helps reduce downtime, save costs, improve overall equipment effectiveness, and enhance operational efficiency. IoT also enables remote asset management and driving energy efficiency initiatives through connected smart systems and remote asset performance monitoring.

PEST Analysis Political: IoT in manufacturing market is affected by government regulations around data privacy and security. Stricter privacy laws make it challenging for businesses to collect and use customer data. On the other hand, regulations supporting industry digitization creates opportunities for IoT solutions. Economic: Factors like global economic growth, industrial production levels, and investment in automation impact demand for IoT systems in manufacturing. During recessionary periods, organizations may delay IoT deployments to control costs. Social: Younger workforce is more receptive to new technologies. Skill gaps challenge wider IoT adoption. Awareness programs help promote social acceptance of advanced manufacturing technologies. Technological: Emerging technologies like AI, 5G, edge computing, and blockchain offer new possibilities for optimizing manufacturing processes. However, integrating legacy systems with advanced IoT platforms poses technological challenges. Security also remains a key concern with expanding network connectivity. The geographical regions where the IoT in manufacturing market is concentrated in terms of value are North America and Europe. North America accounts for the largest share mainly due to early adoption of Industry 4.0 technologies by US factories. The Asia Pacific region is projected to be the fastest growing market during the forecast period. This is because key developing economies like China and India are making heavy investments to automate their manufacturing industries using industrial IoT solutions. China's "Made in China 2025" initiative advocates implementation of IoT, robotics, and other innovative technologies across manufacturing sectors.

Get more insights on Iot In Manufacturing Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Coherent Market Insights#Iot In Manufacturing Market#Iot In Manufacturing#Smart Manufacturing#Industry 4.0#Digital Transformation#Automation#Industrial Iot#Iiot#Connected Devices#Sensors

0 notes

Text

0 notes

Text

A Guide to Implementing Industry 4.0 and Smart Manufacturing

.

Learn about the importance of Smart Manufacturing and Industry 4.0 Implementation and how it can help your business optimize its operations.

Architect Consultant in Gujarat

Industry 4.0 and smart manufacturing are rapidly emerging as transformative forces in the fast-paced field of industrial evolution, in which innovation plays a significant role in maintaining a competitive advantage.

VMS Consultants provides the expertise and experience needed to make sure you are up to date with the latest trends and implement the right strategies for Smart Manufacturing and Industry 4.0 in Ahmedabad, Gujarat.

Our aim in this article is to simplify and explain these trending concepts, as well as to illustrate their impact on industrial processes.

.

Top industrial Architect in India

What is Smart Manufacturing?

A smart manufacturing process combines traditional manufacturing processes with cutting-edge technology. At its core, it's about leveraging real-time data and advanced analytics to improve efficiency, quality, and overall productivity.

The integration of Smart Manufacturing technologies brings forth a paradigm shift in how industries approach production.

.

3 Pillars of Smart Manufacturing

1. IoT Integration: The Internet of Things (IoT) forms the foundation of Smart Manufacturing, connecting devices, sensors, and machines. As a result of this interconnected ecosystem, data exchange and communication become seamless.

2. Data Analytics: Smart Manufacturing relies heavily on data analytics to extract meaningful insights from massive amounts of data. To optimize decision-making processes, predictive analytics, machine learning, and artificial intelligence are used.

Automation and Robotics: Robots perform repetitive tasks and automate complicated processes in Smart Manufacturing. It improves efficiency and ensures accuracy and consistency.

.

Civil Consultant in Vadodara

What is Industry 4.0?

Smart Manufacturing lays the foundation for Industry 4.0, resulting in the Fourth Industrial Revolution. In addition to the factory floor, it encompasses the entire value chain and blurs the boundaries between the physical and digital worlds.

.

Industry 4.0 is characterized by:

1. Cyber-Physical Systems: Interconnected and intelligent systems created by integrating physical systems with digital technologies.

2. Big Data and Analytics: Analyzing and making real-time decisions based on big data, enabling continuous improvement.

3. Horizontal and Vertical Integration: Efforts to integrate processes horizontally along the value chain and vertically from shop floor to management.

.

Industrial infrastructure in Gujarat

Benefits of Smart Manufacturing and Industry 4.0 Integration

1. Enhanced Efficiency: Real-time monitoring and optimization lead to increased operational efficiency.

2. Improved Quality: Data-driven insights enable proactive quality control, reducing defects and enhancing product quality.

3. Agile Response: The ability to adapt quickly to market changes and evolving customer demands.

4. Resource Optimization: Smart Manufacturing and Industry 4.0 facilitate better resource utilization, reducing waste and costs.

.

Project Management Consultant in Gujarat

Intelligence Will Drive The Industry of The Future

In conclusion, Smart Manufacturing and Industry 4.0 are not just concepts; they are the future of industrial processes. The integration of intelligence into manufacturing paves the way for unprecedented efficiency, agility, and innovation.

Collaboration with industry experts like VMS Consultants, leading engineering consultants in Gujarat, becomes the roadmap that helps industries take part in this journey.

Ready to unlock the potential of Smart Manufacturing and Industry 4.0 for your business? Consult with VMS Consultants today and get started on a journey towards a future where your industry thrives on intelligence and innovation.

Your path to the future starts with VMS Consultants.

CONTACT US

Address: Chitrakoot Flats, Ground floor, Behind Time of India, Off Ashram Road, Ahmedabad, Gujarat, India. 380009

.

Call: +91 88661 36236, 79 40236236

Email: [email protected]

Website: https://www.vmsconsultants.com/

0 notes

Text

Industry 4.0 consultants specialize in IoT, AI, and robotics to upgrade manufacturing, providing tailored tech solutions for efficiency. They create strategic plans for digital transformation, ensuring regulatory alignment and competitive edge.

#Industry 4.0 Strategy Consulting Services#Industry 4.0 consulting company#Industry 4.0 experts#Smart Manufacturing consulting services

0 notes