#manufacturing execution system

Explore tagged Tumblr posts

Text

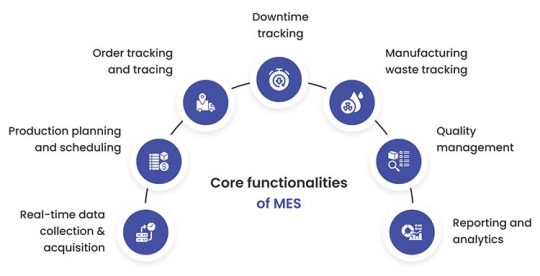

Unlocking Efficiency with Manufacturing Execution Systems (MES)

In today’s fast-paced industrial landscape, a Manufacturing Execution System (MES) is no longer optional—it’s essential. MES bridges the gap between the shop floor and top floor, ensuring real-time visibility, traceability, and operational efficiency across the manufacturing supply chain. It is a critical component of modern supply chain management, enabling seamless operations and improved responsiveness to market demands.

1. Track Genealogy

Traceability is the cornerstone of modern manufacturing. A Manufacturing Execution System enables tracking of raw materials (RM) to intermediate materials (IM) and finished goods (FG), identifying the source of defects and areas for improvement. With FG numbers tagged to RM batch numbers, manufacturers can resolve customer complaints efficiently, enhancing supply chain management visibility and accountability.

2. Shop-floor to Top-floor Integration

MES provides a unified view of operations, offering real-time data on:

- Inventory levels.

- Order progress.

- Production delays and defects.

- Machine stoppages and yield losses.

This visibility empowers leadership to make data-driven decisions and ensures that supply chain management processes remain efficient and responsive.

3. End-to-End (E2E) Integration

A Manufacturing Execution System integrates seamlessly with Level 1 & 2 systems like CNC, HMI, and SCADA, downloading production schedules and parameters. For manual production lines, MES supports manual data capture, ensuring no process is left untracked. This level of integration is vital for improving efficiency in supply chain management.

4. Machine Control

Through MES, manufacturers can generate Production Data Instructions (PDI) that sequence tasks and define process instructions for equipment. By streamlining operations, MES improves overall production efficiency, which directly impacts the broader supply chain management.

5. Quality Management

MES enhances quality control by:

- Capturing and validating specifications, recipes, and test results.

- Providing real-time trends and notifications to ensure quality standards are met.

- Generating test certificates and quality documentation to streamline compliance processes.

Quality assurance is a key component of effective supply chain management, ensuring that products meet customer expectations and regulatory standards.

6. Intelligence for Real-time Decisions

A Manufacturing Execution System incorporates intelligence to auto-allocate and divert tasks, optimizing shop-floor decisions in real time. By analyzing operational parameters, it helps reduce failures and ensures the smooth flow of operations within the supply chain management framework.

7. FG and WIP Inventory Management

MES tracks work-in-progress (WIP) at every production stage and computes real-time inventory levels. Using bills of materials (BOM), MES calculates material consumption and updates inventory records dynamically. This ensures efficient inventory management, a critical factor in effective supply chain management.

8. Raw Material (RM) Inventory Management

Efficient RM management is critical for meeting production goals. MES supports:

- Generate MRP using pending orders, current inventory levels, and procurement details.

- Tracking RM at production lines and managing material returns for quality issues or sequence changes.

- Setting min and max levels for RM and automating reorder processes.

A Manufacturing Execution System ensures that raw material usage aligns with production schedules, enabling better synchronization with supply chain management needs.

A well-implemented Manufacturing Execution System transforms manufacturing operations by enhancing visibility, ensuring quality, and optimizing resource utilization. It not only aligns production with supply chain management needs but also sets the foundation for Industry 4.0. Embracing MES is a step toward a smarter, more agile, and efficient manufacturing ecosystem.

0 notes

Text

MES System

Explore our comprehensive MES system, designed to streamline manufacturing processes and enhance production efficiency. Our MES courses cover key aspects of this essential Manufacturing Execution System, providing in-depth knowledge and practical skills for a competitive edge in your industry. Enroll today to master MES.

Get more details at: www.companysconnects.com/manufaturing-execution-system-mes

#pharmacovigilance courses#drug regulatory affairs certification#CSV Certification#Manufacturing Execution System

0 notes

Text

Jump into the teamwork of IoT and Manufacturing Execution Software. See how they make business better by improving real-time traceability, enhance operational efficiency & More.

0 notes

Text

Discover how connecting IoT with Manufacturing Execution Software changes the game. Make your manufacturing better by improving efficiency and staying connected for excellence.

0 notes

Text

Optimizing Workflows with Lean Manufacturing and Automation

Success in today’s corporate environment is mainly dependent on efficient data management. For reliable data accuracy and easy operations, businesses depend on solid data workflow solutions. Because data is becoming more complicated and abundant, organizations need to enhance their data workflow procedures.

This blog serves as a helpful manual to assist companies in enhancing their company data processing arrangements. In order to make data administration simpler, we shall examine important tactics and industry standards.

How does workflow optimization work?

Workflow optimization refers to the methodical enhancement of a series of jobs and procedures in an establishment with the aim of augmenting production and efficiency. Cutting down on delays and pointless steps entails evaluating current workflows, locating bottlenecks, and optimizing procedures.

Organizations seek to remove manual and repetitive duties through the use of technology and automation, freeing up staff members to concentrate on more strategically important areas of their jobs. Workflow optimization requires effective resource allocation, communication, and quality control procedures. It guarantees efficient use of resources and the completion of tasks with few errors.

In order to satisfy the demands of the organization, workflow optimization is a continual, iterative process that calls for constant evaluation and modification.

There are three different concepts: workflow management, workflow automation, and workflow optimization. Automation streamlines work, management maintains order, and optimization optimizes the entire process for optimal effectiveness. All are essential to a profitable and well-running organization.

Workflow optimization’s advantages

Enhanced effectiveness of operations:

Increasing the operational effectiveness of your business is one of the main benefits of optimizing your procedures. Workflow optimization helps you accelerate your operations and increase team productivity.

Enhanced quality of work:

You may reduce difficulties caused by human mistakes and expedite processes by optimizing your workflow. Every step is made sure to be in the right place through workflow mapping. As a result, there is no uncertainty among team members, which produces consistently excellent results. Superior work enhances the standing of your business and draws in new business.

Easy access to precise information:

The road to current, pertinent data is made hassle-free through workflow optimization. It speeds up work completion and prevents costly errors for your team. Additionally, your organization sets up a standard for data security and integrity, which guarantees that you’re constantly doing things correctly.

Flexible modification:

Your team can respond swiftly to changes thanks to workflow management, which standardized procedures. Consult your process diagram to find appropriate options when new opportunities present themselves. Remain nimble, beat out rivals, make adjustments quickly, and handle any obstacles or hazards.

Increased accountability and transparency:

The increased productivity results from putting performance first. Departments can clearly see who is responsible for what when there is departmental data sharing, which reduces confusion and duplication of effort. This guarantees that everyone is cooperating effectively and staying on the same page.

Essential techniques for streamlining processes:

We’ll look at methods to work smarter, not harder, in this section. We’ll go over everything from making chores simpler to using the newest tools to increase output.

Utilize appropriate tools:

The appropriate tools can make all the difference when it comes to project management. Adding effective project management software to your workflow is a calculated step toward increasing productivity. These solutions have several benefits, including centralized team management, smooth communication, and practical work monitoring.

However, robust project management software goes above and beyond these basics, providing priceless insights via workflow analysis.

Make use of automation:

You can guarantee consistency in task execution, minimize errors, and drastically cut down on manual involvement by implementing automated procedures into your workflow.

Manufacturing Automation solutions allow you to tailor them to your requirements, which simplifies duties and frees up time for critical projects.

Make your workflow visually appealing:

It’s similar to donning glasses for your jobs when you visualize your workflow. Tools that display your work in charts or boards, as opposed to just listing items, provide you with a more comprehensive picture. You can see every step of your assignments using it, which is crucial for improving the quality of your job. What’s functioning and what needs to be fixed are clearly visible.

Using project management software, you may test out many strategies until you find the one that works best for you. For better understanding and improvement at each stage of the process, visualize your projects rather than merely keeping a list of them.

Try utilizing various workflow techniques:

If your existing approaches aren’t working, it could be time for some changes. There isn’t one way that works for everyone, so experimenting with different approaches will help you find the best one for your particular requirements.

Lean:

Although frequently linked to the industrial industry, it can be used in nearly every sector. The key is to maximize value from a few resources by removing waste, removing pointless stages, and cutting down on costs. To expedite the procedure and cut expenses, for example, a hospital might assist with patient admissions.

Agile:

This is an approach that was first employed in programming but is helpful in marketing and sales, incorporating collaboration and ongoing improvement.

Six Sigma:

It’s a technique for lowering performance variability in production. Call centers also employ it to identify areas where customer service is lacking.

To identify the methodology that best suits your workflow, don’t be hesitant to try out a few alternative approaches.

Wrapping Up

Workflow optimization helps your business standardize and enhance its current procedures. Analyzing and recording workflows is the first step in optimization, which aims to identify flaws and enhance workflows. Since even processes that have already been optimized need to be repeatedly adjusted to new conditions, process optimization is a continuous activity rather than an isolated event.

In order to function even more effectively and efficiently over the long run and thus stay up with the competition, optimization should be viewed as the organization’s sustained iterative work. Thus, process thinking and process optimization are essential components of any contemporary management of a business.

#Industry 4.0 in Manufacturing#manufacturing execution system#smart manufacturing industry 4.0#lean six sigma

0 notes

Text

Manufacturing Software (MES) for Metal Fabrication, Millwork and Furniture

HitechDigital provides manufacturing software MES solutions that help streamline production process for metal Fabrication, millwork and furniture manufacturers.

0 notes

Text

Analytics in manufacturing execution systems

Analytics plays a crucial role in Manufacturing Execution Systems (MES) by helping organizations gain valuable insights from the vast amount of data generated on the shop floor. To leverage analytics effectively in MES, it’s essential to have a data strategy in place, including data collection, storage, and integration with other systems (e.g., ERP, CRM). Additionally, organizations should invest…

View On WordPress

0 notes

Text

#Electronic logbooks#equipment log book#machine log book#equipment life cycle management#manufacturing execution system#online logbook software#electronic equipment log book

0 notes

Text

Best Auditorium Chair Manufacturers in Chennai

Are you looking for high quality Auditorium Chair from top Auditorium Chair Manufacturers in Chennai? Then you can look at VR office. You can obtain any kind of chairs that are theatre Chair, Visitor Chair, Office Chair, College Auditorium Chairs, you can check out @ https://www.vrofficeneeds.com/

#Modular furniture Manufacturers in Chennai#Auditorium Chair Manufacturers in Chennai#College Auditorium Chairs in chennai#Modular Workstation Manufacturers in Chennai#Modular Office Workstation Manufacturers in Chennai#Modular Office Workstation in Chennai#Office Workstation in Chennai#Modular Workstation in Chennai#Modular Cluster Workstation Manufacturers in Chennai#Linear Workstation Manufacturers in Chennai#Seating Systems in Chennai#Executive Chair Manufacturers In Chennai#Office Chair Manufacturers in Chennai#Visitor Chair Manufacturers in Chennai#Lounge Furniture Manufacturers in Chennai#Sofa Manufacturers in Chennai#Office Furniture Manufacturers in Chennai#Office Furniture And Table Manufacturers In Chennai#Reception Table Manufacturers In Chennai#Conference Table Manufacturers in Chennai#Steel Table Manufacturers in Chennai#Wooden Furniture Manufacturers in Chennai#Filing Cabinet Manufacturers in Chennai#Storage Rack Manufacturers in chennai#Steel Storage Rack Manufacturers in chennai#Wooden Rack Manufacturers in Chennai#School furniture Manufacturers in Chennai#Educational Furniture Manufacturers in Chennai#Library Furniture Manufacturers in Chennai#Computer Furniture Manufacturers in Chennai

2 notes

·

View notes

Text

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

Manufacturing Execution Systems will be the most important part of smart manufacturing In 2025

Manufacturing Execution Systems (MES) have become the most important part of smart manufacturing in today's industries, which are changing very quickly. MES solutions are a key part of connecting production processes with real-time data analytics as businesses around the world move toward digital change. Not only are these systems useful for making operations more efficient, they are also the main force behind the fourth industrial revolution, which is making it possible for companies to reach new levels of quality, productivity, and sustainability.

What is a Manufacturing Execution Systems

A Manufacturing Execution System (MES) is a computer system that helps companies constantly monitor, manage, and improve their production processes. It makes sure that communication and data flow smoothly between enterprise resource planning (ERP) tools and operations on the shop floor. By combining data from machines, people, and materials, MES gives manufacturers useful information that they can use to make better decisions, cut down on waste, and raise the overall efficiency of their equipment (OEE) 14.

Key Trends That Will Shape MES in 2025

1. AI-Powered MES: Changing the Way Manufacturing Intelligence WorksThanks to artificial intelligence (AI), MES is becoming a dynamic, self-optimizing system. AI-powered algorithms make predictive repair, real-time production scheduling, and automated decision-making possible. AI can, for example, tell when equipment will break down before it does, which cuts down on downtime and boosts productivity. Over half of manufacturers will likely use AI-powered quality control and predictive repair systems by 2025. This will save them a lot of money and make their operations run more smoothly 15.

2. Edge computing: processing data in real-time at the source Source Edge computing is changing MES by bringing data processing closer to the factory floor. Edge computing cuts down on latency and makes sure that processes don't stop when the network goes down, unlike cloud computing, which uses remote servers. This technology is especially helpful in fields like medical devices and cars, where real-time tracking and finding problems are very important 17.

3. MES as a Service (MESaaS): The power to grow and change On the rise are cloud-based MES systems, also known as MES as a Service (MESaaS). MESaaS gives producers more ways to grow, lower start-up costs, and constant access to software updates. Most manufacturers will likely use cloud-based MES by 2025 to make their operations more flexible and speed up the digital revolution. 13.

4. IIoT Integration: Making Factories Smart When MES is combined with the Industrial Internet of Things (IIoT), plants become smarter and more linked. IIoT devices, like sensors and machines that are connected to the internet, send data to MES systems in real time that they use to track and improve production. This integration gives makers more information, lets them automate tasks, and sets up condition-based monitoring, which makes sure that everything always works at its best 17.

5. Sustainability: Making manufacturing more eco-friendly Manufacturers are putting sustainability at the top of their list of priorities, and MES systems are a big part of how they can reach these goals. Modern MES systems have tools for tracking carbon footprints, keeping an eye on energy efficiency, and cutting down on waste. Manufacturers can meet government rules, lessen their effect on the environment, and meet customer demands for greener production methods by using these tools 111.

What MES Does for Modern Manufacturing

Improving the efficiency of operations MES systems make production more efficient by giving real-time information about how machines are working, how resources are being used, and output schedules. This helps manufacturers find slow spots, improve workflows, and cut down on downtime, which leads to higher total efficiency 48.

Making sure of quality and compliance A very important part of MES is quality control. MES systems make sure that the quality of all products is always the same by keeping an eye on production in real time and finding problems early. MES also helps manufacturers follow industry rules and standards by keeping detailed records of all production actions 410.

Making it possible to trace and see MES systems help manufacturers to keep track of products from the raw materials they use to the finished goods they make. In fields like drugs and food and beverage, where product safety and compliance are very important 48, this ability is a must.

Problems with Putting MES in Place: Integration and Complexity Putting in place a MES system can be hard because it needs to be connected to other business systems like ERP, SCADA, and others. A big problem 46 is making sure that data is consistent and works on all of these systems.

Adapting the Workforce When MES is used, processes and job roles often need to be changed, which means that full training programs are needed. Manufacturers need to spend money to improve the skills of their employees so that implementation and management go smoothly 46.

Concerns about cybersecurity Cyber threats can get into MES systems because they handle private work data. To keep their operations safe, manufacturers must put strong cybersecurity measures like advanced encryption and multiple layers of defense at the top of their list of priorities 111.

A Way to Get to Industry 5.0 with MES in the Future MES systems will change to support human-centered manufacturing as we move toward Industry 5.0. In this type of manufacturing, AI and robots will work together with humans to improve efficiency and creativity. In 2025, MES will be a key part of this change that will help factories become more flexible, environmentally friendly, and competitive 711.

Manufacturing Execution Systems (MES) are no longer a have; companies that want to do well in the digital age need them. MES is changing the way things are made and leading the way for smart manufacturing in the future by using AI, edge computing, IIoT, and environmental tools. As businesses change, using cutting-edge MES systems is going to be important for long-term success and operational excellence. Original Reference - https://bipjacksonville.com/manufacturing-execution-systems-will-be-the-most-important-part-of-smart-manufacturing-in-2025

0 notes

Text

Manufacturing Execution System Software in pune | India

The MES is not only responsible for providing technical advice but also for carrying out the assigned responsibilities. Planning, constructing, and maintaining all works, buildings, airfields, dock installations, and other structures is the responsibility of the Military Engineering Services.

#MES Manufacturing Execution System Pune#System Software India#Solutions for OEMs and Machine Builders Pune#Conveyors India#PLC Automation Pune#PLC and SCADA Service Provider India#Automators Industrial Projects#Let’s Get in Touch#Company

0 notes

Text

Manufacturing Automation: A Deep Dive

Automation is becoming increasingly essential for manufacturers each year. Manufacturing stands out as one of the most prevalent and pivotal industries for applying automation technology.

#manufacturing execution system#smart manufacturing industry 4.0#manufacturing operations management

0 notes

Text

ERP vs. MES - Understanding Key Differences

MES and ERP - the two prominent data and operations management systems in the manufacturing industry are so interconnected that they are often interchangeable.

1 note

·

View note

Text

The Importance of Manufacturing Execution System in Industry 4.0

Industry 4.0 marks a transformative era in manufacturing, defined by the integration of digital technologies to create smart factories. Central to this transformation is the Manufacturing Execution System (MES), which connects machines, systems, and humans in real-time. MES is pivotal in enhancing manufacturing processes, ensuring high standards in production, and enabling lean manufacturing principles.

Quality Management and Manufacturing Execution System

Quality management within Manufacturing Execution System is crucial for maintaining high production standards. MES captures and validates essential data such as results, comments, specifications, recipes, and procedural documents. This real-time data monitoring enables manufacturers to control quality effectively, providing insights through trends, statistics, and notifications to preempt potential issues. Additionally, MES generates test certificates and quality documentation, ensuring compliance with industry standards and customer requirements. By tracing quality issues back to their origin, MES fosters accountability and maintains customer trust.

MES Intelligence for Operational Efficiency

The intelligence component of MES significantly enhances decision-making on the shop floor. Manufacturing Execution System supports intelligent auto allocation and diversion, enabling optimal, real-time decisions. By continuously analyzing operating parameters, MES helps reduce failures and improve efficiency. This intelligence-driven approach minimizes waste, ensures effective resource utilization, and promotes a culture of continuous improvement in manufacturing.

Operational Flexibility and Security

MES enhances operational flexibility and security, crucial elements in the Industry 4.0 landscape. It allows manufacturers to adapt quickly to changing production demands and conditions, ensuring agility and competitiveness. Enhanced security measures within MES protect critical data and systems from potential threats, safeguarding the integrity of manufacturing operations.

Lean Manufacturing and MES

Lean manufacturing focuses on minimizing waste while maximizing productivity. MES plays a critical role in implementing lean principles by providing real-time data and insights that identify inefficiencies and streamline production processes. End-to-End (E2E) integration within Manufacturing Execution System connects various shop floor systems, such as CNC machines, Human-Machine Interfaces (HMI), and Supervisory Control and Data Acquisition (SCADA) systems. This integration ensures seamless production schedule downloads and parameter alignment, reducing errors and inefficiencies.

Machine Control and MES

Machine control within Manufacturing Execution System involves generating Process Data Interface (PDI) instructions that guide equipment operations. This precise control enhances consistency and quality, reducing variability and improving overall product standards. By maintaining stringent control over the manufacturing process, MES supports lean manufacturing goals of reducing waste and improving efficiency.

Real-Time Monitoring and Issue Response

MES enables real-time monitoring of production, allowing manufacturers to respond quickly to defects or delays. This proactive approach minimizes downtime and optimizes resource allocation, fundamental to lean manufacturing principles.

FG and WIP Inventory Management

MES tracks Work-in-Progress (WIP) at each production stage, generating real-time finished goods (FG) and WIP inventory records. By computing input material consumption using the Bill of Materials (BOM), Manufacturing Execution System updates WIP and raw materials (RM) inventory accurately. This real-time tracking reduces waste, avoids overproduction, and helps maintain optimal inventory levels.

RM Inventory Management

MES manages Material Requirements Planning (MRP) based on pending orders, available inventory, and existing purchase requisitions (PR) and orders (PO). It ensures RM is consumed in alignment with FG and WIP production at each stage. Manufacturing Execution System also facilitates the transfer of materials from stores to lines and tracks RM usage, ensuring efficient inventory management.

RM Inventory Control

Manufacturing Execution System defines minimum and maximum RM thresholds, generating orders to prevent overstocking and stockouts. This ensures uninterrupted production, maintaining a smooth manufacturing process.

As manufacturing evolves, the role of Manufacturing Execution System is becoming increasingly critical. It is no longer just a tracking tool but a comprehensive solution for managing the entire manufacturing lifecycle. With advancements in AI, cloud computing, IoT, and sustainability, MES drives innovation, growth, and adaptability. Manufacturers that leverage MES effectively will be better positioned to succeed in the evolving industrial landscape, achieving higher efficiency, quality, and agility.

0 notes