#potato chips packaging equipment sale

Video

youtube

potato chips packing machine price|potato chips packaging equipment sale

Potato chips packaging machine is used for packing granule food easily and quickly. Raw material:all kinds of snacks, potato chips packing machine, french fries packaging machine, puff food packaging machine etc. Capacity:50-500kg/h Wechat/whatsapp:8613213203466

#potato chips packing machine price#potato chips packaging equipment sale#potato chips packaging machine for sale

0 notes

Video

youtube

puff food packaging machine for sale|snacks packaging equipment| potato chips packing machine

Snacks packaging machine is used for packing food quickly. It adopts high quality SUS304 material. Wechat/whatsapp:+86 13213203466.

#puff food packaging machine for sale#snacks packaging equipment#potato chips packing machine#frozen french fries packaging machine#fried french fries packaging equipment for sale

0 notes

Text

Fry and Bake Technologies Pvt. Ltd. is one of the largest food processing equipment manufacturers in India, specializing in potato processing equipment. They offer an extensive range of food processing machinery and equipment for the snack food industry, catering to various culinary requirements, from frozen foods to snacks.

Allow me to provide you with a brief overview of the different fryer types they offer:

Fully Automatic Potato Chips Line: This highly efficient line automates the entire potato chip production process, including steaming, peeling, slicing, frying, seasoning, and packaging. The automatic potato chips line ensures a seamless and consistent production of potato chips.

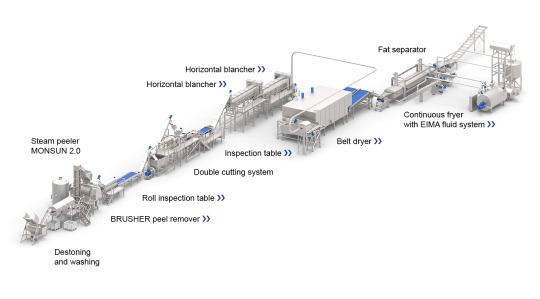

Frozen French Fries Production Line: Fry and Bake Technologies' frozen french fries production line comprises top-of-the-line machinery for washing, peeling, cutting, blanching, drying, frying, freezing, and packaging french fries. This comprehensive line guarantees the production of high-quality frozen french fries.

Fully Automatic Pellets Frying Line: This adaptable line processes and fries pellets made from potato, corn, or rice. The fully automatic pellets frying line ensures efficient processing and frying to meet the demands of various snack production.

Automatic Namkeen Fryer: Fry and Bake Technologies' automatic Namkeen fryer is specifically designed for frying Namkeen, a diverse variety of traditional Indian snacks. This specialized fryer ensures the perfect texture and taste of Namkeen snacks.

All Types of Batch Fryers: These versatile fryers are suitable for frying a wide range of snacks, making them an ideal choice for snack manufacturers with diverse product offerings. The batch fryers enable efficient frying of different snack varieties.

Fry and Bake Technologies places utmost importance on quality and customer satisfaction. They source their potato processing equipment in India from responsible suppliers and implement rigorous quality control measures to deliver exceptional value. Their team of dedicated professionals brings a wealth of knowledge and expertise to their manufacturing facility, constantly striving to improve products and develop innovative solutions.

In addition to their core products, Fry and Bake Technologies offers various value-added services to their customers, including:

Installation and commissioning of equipment.

Training on the operation and maintenance of equipment.

After-sales service and support.

Fry and Bake Technologies is committed to providing the best possible experience to their customers. They understand that the success of their customers is their success, and they are always willing to go the extra mile to ensure customer satisfaction.

To sum up, Fry and Bake Technologies is a leading manufacturer of potato processing equipment in India, offering a wide range of food processing machinery and equipment for the snack food industry. Their expertise, quality products, and dedication to customer satisfaction make them a reliable choice in the market.

#Potato processing equipment in India#automatic potato chips line#Automatic Pellets Frying Line#Automatic Kurkure Frying Line#largest food processing equipment manufacturers#drying equipment in food industry#food processing machinery and equipment#french fries production equipment#food processing instruments

0 notes

Text

Utilising Conveying & Quick Packaging Systems in Potato Production

The world loves potatoes, including India. In the year 2022, India produced 53.58 million metric tonnes of potatoes. A large chunk of these potatoes are used to create various potato-based snack products and the number is only growing. Soon, India will consume packaged potato products as much as fresh potatoes. If you are in the packaged snack business, you cannot afford to lose out on this opportunity to add potato products to your product line-up and earn big profits. Here are some potato products worth considering for your business:

Potato Chips - Possibly the most popular snack of all time, potato chips are always a great seller. Some of the biggest snack producers in the world have potato chips as their highest-selling products. Potato chips are also sold in high volumes on the local level with individual potato chip sellers earning a good profit on this product. Another advantage of potato chips is that you can add flavours and other variations and further increase sales and production. Potato chips are easily the best snack product to have.

Aloo Bhujia - Another snack that is always growing in popularity is aloo bhujia. Made from a mixture of potato flour, chickpea flour (besan), spices, and salt, aloo bhujia has become the go-to daily snack for many Indians who like to munch on something crispy and spicy. One of the biggest advantages of this snack is that it is quite affordable, and is made from inexpensive ingredients, thus increasing the chances of making high profits.

Potato Sev & Chiwda - Tasty and crispy, potato sev and chiwda are a snack for many occasions. Be it guests at your home or an evening of chit and chat and partying with your friends, potato sev and chiwda is a lip-smacking treat many Indians love. So, adding these amazing snacks to your products will ensure your products are in every home.

Packaging & Conveyor Systems

If you want these potato products and more to your product line-up, you will need the best packaging and conveyor equipment that will help move products quickly and meet high demand. Saurabh Flexipack is one of the biggest suppliers of packaging and conveyor equipment in India and counts many national and international clients amongst its clientele. Here are some of our products that you can use for your business:

Contibag - With an impressive speed of 130 packs per minute, the Contibag is India’s foremost and best packaging machine that operates in continuous motion. It is a machine of international standards and can take on attachments like multihead weigh filler, bucket elevator, etc. to become even more efficient and help you package your potato based snacks and other products.

To know more about our products in snacks packaging machines, visit our website and click on the get a quote button!

0 notes

Text

snack food making machine-Fry And Bake Technology Pvt. Ltd.

Fry and Bake Technologies Pvt. Ltd company founded in 2012 and based in Gujarat, India. As a world leader in the manufacture of process lines for the Snacks processing industry, we focus on product development, continuous improvement, innovation, sustainable technology and co-operation to ensure, we give added value to every customer. We respect our team, our customers, and the environment.

With a team of qualified personnel we innovate, design, manufacture and install advanced processing lines worldwide. We specialize in lines to process into French fries, potato chips, pellet snacks, Namkeen snacks, and Bakery products.

OUR QUALITY

We will never be compromised with the quality. We specialize in lines to process into French fries, potato chips, pellet snacks, Namkeen snacks, that is made in high quality of raw materials and latest technology. Our team of expert quality auditors keeps close eye on the production tasks as well as check the manufactured range of equipment for any kind of defects.

OUR MISSION

Our Mission is to satisfy the needs of our customers. We have specialized team for fulfilling the requirements of our customers and to give them appropriate service whenever the need.

OUR INFRASTRUCTURE

We uphold a state-of-the-art infrastructure base which conforms to the standards of international level in terms of various kinds of facilities. Our manufacturing unit is spread over a total plot area of 110 ft X 130 ft, with optimum installed capacity that is sufficient to prove our capacity in terms of robust infrastructure. We have equipped this spacious unit with necessary machines and equipment that facilitate flawless production of our wide range of food processing machines.

RESEARCH & DEVELOPMENT

The Company has an extremely experienced Research, Development & Design department staffed by personnel from both food equipment as well as snack food industry. It is well equipped with latest equipment and facilities to keep abreast of latest trends in technology.

AFTER SALES SERVICE

After sales service plays an important role in customer satisfaction and customer retention. It generates loyal customers. And we provide best service to our loyal customers.

OUR VISSION

now, we want to become the largest and innovative player in developing food machines to automate all processes in the most economical price in India

OUR STRENGTH

Fry And Bake strength is to deliver total solutions in Snacks processing from the infeed of product to the packaging line resulting in a high quality end product. Our success is achieved by working in total co-operation with our customers to achieve their specific requirements, We aim to get the best out of the product and the customers process line.

WHY US

International quality range

Well equipped manufacturing|

Competitive prices

Team of experts

Total quality management

Training & service support

0 notes

Text

Fully Automatic Potato Chips Making Machine Price

Potato chips have gained widespread popularity as a snack food worldwide, resulting in a surge in demand. Potato chips manufacturers have responded to this by incorporating an affordable fully potato chips machine price. This modern line of equipment enables the efficient and high-quality production of potato chips on a large scale.

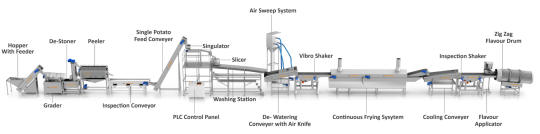

A fully automatic potato chips line comprises a range of machines that perform different functions throughout the manufacturing process. These machines include a potato slicer, potato washing machine, potato blanching machine, potato frying machine, potato de-oiling machine, seasoning machine, and packaging machine. These parts come within a budget for chips making machine price.

The semi-automatic potato chips making machine price is determined by various factors, including machine capacity, quality, and brand. However, the high production output and efficiency of the line usually offset the potato chips making machine price.

In a nutshell, the fully automatic potato chips line has brought about a significant change in the potato chips manufacturing industry by streamlining the production process on a large scale. If you’re planning to launch a potato chips manufacturing company, investing in Economode’s fully automatic potato chips line is a wise decision. Despite the high initial expense, the benefits of this technology will become evident in the long run.

How fully automatic potato chips machine benefit potato chips manufacturers?

Potato chips are a highly popular snack food that has seen a significant increase in demand globally. However, manufacturers face the challenge of keeping up with this demand while maintaining high-quality products. The solution to this challenge is Economode’s affordable potato chips frying machine price, which offers various benefits to manufacturers.

Increased Production Capacity

One significant benefit of this budget-friendly potato chips machine price is its increased production capacity. This is achieved through the use of high-speed machines that can perform various tasks such as slicing, washing, blanching, frying, seasoning, and packaging in a short period. The machines are also designed to operate continuously, which reduces downtime and increases productivity.

Improved Quality Control

Another benefit of that comes with affordable semi-automatic potato chips making machine price is the improved quality control it provides. The affordable chips making machine price is equipped with sensors that monitor the production process to ensure that the potato chips meet the required quality standards. This helps to detect any defects, allowing for immediate corrective action, which leads to better products, higher customer satisfaction, and increased sales.

Reduced Labor Costs

The potato chips line also significantly reduces labor costs. Since the machines perform most of the tasks that would otherwise require human labor, this leads to significant savings for manufacturers. Additionally, the potato chips making machine price is competitive & can operate 24/7 without fatigue or the need for breaks, reducing the need for additional staff and increasing productivity.

Consistent Product Quality

Consistent product quality is another benefit of the affordable fully automatic potato chips making machine price. The machines are programmed to perform tasks precisely, which ensures that the potato chips have uniform thickness, texture, and flavor. This consistency in quality is essential in maintaining customer loyalty and increasing sales.

Reduced Energy Consumption

Compared to traditional manufacturing methods, the fully automatic potato chips line also reduces energy consumption. The machines are designed to operate efficiently, using minimal energy to perform tasks. Additionally, the machines use modern technology such as heat exchangers and automatic temperature control, which reduces energy waste and costs.

Increased Profit Margins

Investing in a budget friendly potato chips frying machine price can increase profit margins for manufacturers. The increased production capacity, improved quality control, and reduced labor and energy costs translate to higher profits. Moreover, the consistent product quality and customer satisfaction lead to repeat business and increased sales.

Competitive Advantage

The potato chips machine price is affordable & also provides a competitive advantage to manufacturers in the market. It enables manufacturers to produce high-quality potato chips at a lower cost, which translates to lower prices for consumers. This advantage leads to increased market share and a stronger brand image.

In conclusion, investing in a affordable chips making machine price is a valuable investment for potato chips manufacturers. Though the cost varies depending on the capacity and quality of the machines, the benefits far outweigh the initial investment. If you are a potato chips manufacturer looking to improve your production process, the fully automatic potato chips line is the way to go.

Fully automatic potato chips line capacity

A semi-automatic potato chips making machine price is competitive and also is an advanced manufacturing system that handles the entire process of potato chip production from raw potatoes to packaged chips with minimal human intervention. These production lines are equipped with high-tech machines and sensors that perform various tasks like slicing, washing, blanching, frying, seasoning, and packaging the chips. The potato chips making machine’s price is affordable and its production depends on the size and quality of the machines used in the line.

Smaller lines can produce 50-100 kg of chips per hour, while larger lines can produce up to 500 kg or more per hour. However, the production capacity can be influenced by factors like the type of potato used, chip thickness, and seasoning requirements.

Investing in our affordable fully automatic potato chips making machine price can offer several benefits such as increased production capacity, reduced labor costs, and improved product quality. The potato chips frying machine price depends on the capacity and quality of the machines, but the benefits outweigh the initial investment. Here at Economode, we consider the production needs and goals when choosing a fully automatic potato chips line that meets your specific business requirements.

#potato chips machine#potato chips making machine#potato chips machine price#chips making machine#potato chips making machine price#potato chips making small machine#potato chips making machine for small business#potato slicer machine#potato chips#automatic potato chips making machine#potato chips machine rajkot#potato chips making machine price in india#potato chips machine online#sweet potato chips making machine#potato chips making machine automatic

0 notes

Video

youtube

automatic candy packing machine for sale|candy packaging equipment|candy packing machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc.

Capacity:50kg/h-500kg/h

https://www.cnyazhong.com/products/Snacks-packaging-machine.html

Wechat/whatsapp:8613213203466

#automatic dry fruits packing machine

#automatic seed packing machine

#automatic dal packing machine

#automatic vegetable packing machine

#automatic snacks packing machine

#food packing machine automatic

#automatic food packaging machine

#automatic candy wrapping machine

#automatic popcorn packing machine

#candy packaging machine#candy packing machine#candy packaging machine for sale#lolipop packaging machine

0 notes

Text

Utilising Conveying & Quick Packaging Systems in Potato Production

The world loves potatoes, including India. In the year 2022, India produced 53.58 million metric tonnes of potatoes. A large chunk of these potatoes are used to create various potato-based snack products and the number is only growing. Soon, India will consume packaged potato products as much as fresh potatoes. If you are in the packaged snack business, you cannot afford to lose out on this opportunity to add potato products to your product line-up and earn big profits. Here are some potato products worth considering for your business:

Potato Chips - Possibly the most popular snack of all time, potato chips are always a great seller. Some of the biggest snack producers in the world have potato chips as their highest-selling products. Potato chips are also sold in high volumes on the local level with individual potato chip sellers earning a good profit on this product. Another advantage of potato chips is that you can add flavours and other variations and further increase sales and production. Potato chips are easily the best snack product to have.

Aloo Bhujia - Another snack that is always growing in popularity is aloo bhujia. Made from a mixture of potato flour, chickpea flour (besan), spices, and salt, aloo bhujia has become the go-to daily snack for many Indians who like to munch on something crispy and spicy. One of the biggest advantages of this snack is that it is quite affordable, and is made from inexpensive ingredients, thus increasing the chances of making high profits.

Potato Sev & Chiwda - Tasty and crispy, potato sev and chiwda are a snack for many occasions. Be it guests at your home or an evening of chit and chat and partying with your friends, potato sev and chiwda is a lip-smacking treat many Indians love. So, adding these amazing snacks to your products will ensure your products are in every home.

Packaging & Conveyor Systems

If you want these potato products and more to your product line-up, you will need the best packaging and conveyor equipment that will help move products quickly and meet high demand. Saurabh Flexipack is one of the biggest suppliers of packaging and conveyor equipment in India and counts many national and international clients amongst its clientele. Here are some of our products that you can use for your business:

Contibag - With an impressive speed of 130 packs per minute, the Contibag is India’s foremost and best packaging machine that operates in continuous motion. It is a machine of international standards and can take on attachments like multihead weigh filler, bucket elevator, etcto become even more efficient and help you package your potato based snacks and other products.

To know more about our products in snacks packaging machines, visit our website and click on the get a quote button!

#Snacks packaging machine in India#packaging automation companies in India#product bagging machine in India#rice packing machine price in India#packaging machinery companies in India#packing machine for food products in India#machines for packaging in India#packaging machine suppliers in India#best packaging machine in India#packing machines manufacturers in India#packaging machine manufacturers in India#food product packaging machine in India#pouch packing machine price in India#Best packaging machine manufacturers in India

0 notes

Text

7 Easy Ways To Make Nutrition Faster

Who doesn't like saving more cash? If you've recently gotten thinking about the raw food lifestyle and diet and are attempting to find more ways to economize performing it, listed here is a number of money-saving tips for you. Finding a way to choose this diet sustainable for you personally as well as your wallet might be the most key elements to make it work in your case. The other two factors are you must ensure it is fun and healthy/balanced!

1. Invest in a dehydrator and earn your chips, crackers, cookies, dehydrated nuts, etc. A good idea is usually to copy down the ingredients of packaged raw food snacks and make your version of which in your own home. It can be more enjoyable by doing this and you will make enough for some friends too.

2. Borrow raw food and also other health/spiritual books from your library as opposed to buying them and reading them once from the bookstore or online. You'd be surprised at how many raw food books the library system has. Most library websites have a very request function that may transfer the book(s) you would like to any local branch and notify you if it's ready to pick up.

3. Additional book options: You can organize a novel exchange by incorporating other health-conscious friends. Or you are able to buy those books you already know you would like for your collection from a web based bookstore like.

4. Buy your supplements on the internet and preferably in bulk, if possible.

youtube

5. If you don't need or want very much product, create co-ops along with your friends, buy large quantities, and split the shipping.

6. Make your cosmetics from the foods you have inside your kitchen.

7. Make and exchange food with friends to try out new recipes and reduce money and time: Either make raw food recipes in big batches and share among friends or organize your potluck and invite some friends. To allow it to be easy on them, it is possible to give them some easy recipes to select from or direct them among the numerous raw food recipe websites online.

8. Buy used kitchen equipment: Check online, at local nutrition stores for the notice board, or ask your family and friends if they have a blender, blender, or juicer they just don't use you could borrow.

9. Join a wholesale club and save big on family-sized bags and boxes of vegatables and fruits. You will probably undergo these just you'd like children would! You can find avocados, dates, organic spinach, raw nuts, some frozen fruit, and select organic berry at these stores.

10. Create your own individual raw food recipe books with all of your favorite or most appealing recipes by copying and pasting all of your preferred recipes posted online onto a thing processing document. You can use the find function in the same way you'd the index of the ebook.

11. Always search for several websites online for top possible price before choosing online (especially supplements). It's usually a similar product online versus in a raw food restaurant or local health store.

12 Make your own Rejuvelac and/or Kombucha if you can. Search online for ingredients and instructions. It's very easy and economical to perform. It could help you save money on Probiotic supplements as well.

13 Sprout your sprouts. Each tray of sprouts is only going to run you about .20-.30 cents each and 4-5 dollars at a shop.

14 Shop the location where the organic meals is most inexpensive first: Buy whatever good organic food is offered at the farmers' market or smaller produce stores before heading to the big chain natural food store. Then determine your menu or recipe ideas for your week, according to whatever you have to work inside your fridge.

15 Buy all your spices and nuts, seeds, grain, and dried fruit inside bulk area of your big chain natural grocery store. Because you are not investing in the packaging, it's really a lot less expensive.

16 If available, buy mint, basil, rosemary as well as other fresh herbs inside the bulk section in the natural foods grocery store for substantial savings.

17 If it is possible to't afford to buy all organic produce (some are very challenging to even find organic), exchange signal of buying conventional product for the people fruit and veggies carrying the least amount of pesticides when grown conventionally: broccoli, eggplant, cabbage, banana, kiwi, asparagus, sweet peas, mango, pineapple, sweet corn, avocado, onion. Buy only organic for that "dirty dozen," produce found to carry the best level of pesticides when grown conventionally: peaches, apples, sweet bell peppers, celery, nectarines, strawberries, cherries, lettuce, imported grapes, pears, spinach, and potatoes.

18 Love your sea veggies? Avoid acquiring the $5 to $6 bags unless you are tinkering with new ones. Buying online large quantities (2-4 lbs at the time) is most economical. You could also split an order with another man to talk about the cost with the shipping and handling.

19 Forage totally free wild foods for super nutrition (e.g. dandelion, clover, purslane, stinging nettles, etc.). Use some of these greens with your salads, smoothies, and juices and save money inside the store.

20 Sign around receive newsletters from raw food online stores for announcements on special sales and promotions. Be notified and make use when you need to restock on supplies!

21 Get involved in a loyalty marketing business such as Elements for Life and get access to superfoods and supplements at the discount. OR get started inside your own in the home business to start out earning profits so you can afford to spend more on sensible food and superfoods. Get free education on raw foods and superfoods with these varieties of companies also!

22 Don't forget to everyone of these other locations you're saving in since you're living a greater portion of a raw vegan lifestyle: gas bills, doctor and hospital visits, prescription medicine, OTC medicine, coffee, soda, candy, (and other unhealthy food,) expensive cooked food restaurants (not really that you may not check out these again but you won't be ordering $35 entrees and appetizers and desserts there).

1 note

·

View note

Video

youtube

puff food packaging machine for sale|snacks packaging equipment|potato chips packaging machine

Snacks packaging machine is used for packing food quickly. It adopts high quality SUS304 material. Wechat/whatsapp:+86 13213203466.

#puff food packaging machine for sale#snacks packaging equipment|#potato chips packaging machine#forzen french fries packing equipment#fried french fries packaging machine cost

0 notes

Video

youtube

520 bean sprout packaging machine Joyshine 2021

It adopts electronic scale to pack food, like vegetables, snacks, fruit. if you need, please contact me as soon as possible. wechat/whatsapp: 0086 132 1320 3466 [email protected] https://www.hnjoyshine.com

#bean sprout packaging machine for sale#snacks packaging machine for sale#potato chips production line#french fries production line#candy packaging equipment

0 notes

Link

JiangXi ACME Packaging Co., Ltd.

86-1332-0154810 13320154810

Village West, Fanjia Community, Shangzhuang St., Yichun, Jiangxi, China

Jiangxi ACME Packaging Co., Ltd. is an Enterprise specializing in the production of Food Grade metal covers. Our factory focuses on the production, research and development of Easy Peel Open Ends ( POE ). The main products are aluminum foil Easy Open Lids series, which are suitable for different types, different designs and different sizes of covers. Products are widely used in Leisure food, Potato chips, Protein powder, Candy, Coffee, Tea, Medicine, Chemical Industry, Wine, Leisure Food, Dried Fruit, Food Powder, Cosmetics, Crafts, Gifts and other industries.Its Advanced Equipment and Innovative Technology, Research and Development of Low-carbon Environmental Protection. Packaging food in a Healthy & Environmentally Friendly way. ACME has a professional and reliable sales team and a complete and scientific quality management system. The integrity, strength and product quality of Jiangxi ACME Packaging Co., Ltd. have been recognized by the industry. Welcome to visit, guide and business negotiation.

0 notes

Text

Utilising Conveying & Quick Packaging Systems in

The world loves potatoes, including India. In the year 2022, India produced 53.58 million metric tonnes of potatoes. A large chunk of these potatoes are used to create various potato-based snack products and the number is only growing. Soon, India will consume packaged potato products as much as fresh potatoes. If you are in the packaged snack business, you cannot afford to lose out on this opportunity to add potato products to your product line-up and earn big profits. Here are some potato products worth considering for your business:

Potato Chips - Possibly the most popular snack of all time, potato chips are always a great seller. Some of the biggest snack producers in the world have potato chips as their highest-selling products. Potato chips are also sold in high volumes on the local level with individual potato chip sellers earning a good profit on this product. Another advantage of potato chips is that you can add flavours and other variations and further increase sales and production. Potato chips are easily the best snack product to have.

Aloo Bhujia - Another snack that is always growing in popularity is aloo bhujia. Made from a mixture of potato flour, chickpea flour (besan), spices, and salt, aloo bhujia has become the go-to daily snack for many Indians who like to munch on something crispy and spicy. One of the biggest advantages of this snack is that it is quite affordable, and is made from inexpensive ingredients, thus increasing the chances of making high profits.

Potato Sev & Chiwda - Tasty and crispy, potato sev and chiwda are a snack for many occasions. Be it guests at your home or an evening of chit and chat and partying with your friends, potato sev and chiwda is a lip-smacking treat many Indians love. So, adding these amazing snacks to your products will ensure your products are in every home.

Packaging & Conveyor Systems

If you want these potato products and more to your product line-up, you will need the best packaging and conveyor equipment that will help move products quickly and meet high demand. Saurabh Flexipack is one of the biggest suppliers of packaging and conveyor equipment in India and counts many national and international clients amongst its clientele. Here are some of our products that you can use for your business:

Contibag - With an impressive speed of 130 packs per minute, the Contibag is India’s foremost and best packaging machine that operates in continuous motion. It is a machine of international standards and can take on attachments like multihead weigh filler, bucket elevator, etc. to become even more efficient and help you package your potato based snacks and other products.

To know more about our products in snacks packaging machines, visit our website and click on the get a quote button!

Potato Production

0 notes

Text

G&G, Sundial and Interstate Chips

Close to my home on Saratoga Lake is the Washington County Fairgrounds. During the summer, it is the locale of a few antiques festivals. At a recent one, I was drawn to the Gordon Potato Chips sign in a booth of Bill Hodges Antiques. Bill has been in the antiques business for half a century. While discussing the sign with Bill, he mentioned that his grandfather owned a potato chip company and generously invited me to his place of business to view the memorabilia and discuss his family's legacy. We finally got together.

Bill's grandfather, Alexander P. Grega, of Austrian and Russian descent, had owned a small Mom and Pop grocery store in Cohoes, NY, which is a suburb of Albany, NY. He also owned a small farm where he grew fruits and vegetables including potatoes. A large man, Alexander was a jack of all trades including being a carpenter and mason. Alexander sold the grocery store and started a potato chip company named G&G Potato Chips Co, Inc. in 1923.

Both G’s stood for Grega as Alexander was joined in the company by his son Peter. At first Alexander used the potatoes he grew on his farm to make the chips. They were cooked in huge copper kettles that were scrapped in the 1960s.

A couple of years later, half the company was purchased by John H. Guba. Since his last name started with a "G", there was no need to change the name. The business was located at 92 Oneida Street., and moved to 74 Oneida St. in 1929. By 1931 the business had outgrown the space on Oneida St. and moved to 91 Saratoga St. (on the corner of Ontario) where it remained until it was dissolved in 1951. Alexander's wife Anna Grega and their three daughters, Mary Mulcahy, Olga Hodges (Bill's mother) and Dora Mudry, all worked for the company.

John Guba later exited the company, purchased chip manufacturing equipment at auction and formed his own company, Super Crisp.

G&G not only sold potato chips, but also pure egg noodles, chopsticks (potato sticks) and cheese corn as shown in the Invoice form. Bill says that horse radish was also sold, but he hasn't found any signs or memorabilia regarding the horse radish. The minutes of a a 1930 meeting states that the company also sold "kokonut macaroons." The chips were sold in bags, cartons and bulk. In addition to marketing under the G&G brand, it also manufactured under the Sundial brand. See the sign. Bill explained that some of these Sundial signs were used to insulate his grandfather's home that his parents later inherited. The home was torn down in 1965 to widen Rt. 9. It was located near to what is now Guptile's Roller Skating Rink.

Alexander's son, Peter, was in charge of sales and marketing and later moved to New Jersey. He opened a small office in the Bronx, NY under the Interstate Biscuit Co.l brand. They were packaged in vintage cellophane potato chip bags- each marked 1 cent Interstate Biscuit Co. Bronx NY. "Before Eating", there is a frowning face, but when you are done eating and turn the bag upside down, "After Eating", there is a smiling face.

Enjoy Dick Van Dyke and Janet Leigh in Bye Bye Birdie perform "Put On a Happy Face."

youtube

Enjoy Louis Prima sing "When You're Smiling."

youtube

Wrestler and actor Mike Mazerki worked as a driver for a year. You can read his New York Times obituary. https://www.nytimes.com/1990/12/12/obituaries/mike-mazurki-actor-82.html.

Like Alexander, he was born in Austria and also lived in Cohoes. https://www.imdb.com/name/nm0563417/bio.

Mazerki was one of cinema's first serial thugs and specialized in playing strongarm men, gangsters and bullies for over 50 years on screen.

Alexander was one of the founders of St. Nicholas Russian Orthodox Church in Cohoes. Prior to the construction of the current brick church structure, the congregation met in the potato chip factory between 1923 and 1926 after the old wooden structure had been torn down.

Bill generously shared many items of memorabilia. included are a wage slip from 1941 showing that his mother, Olga's weekly wages were $11.54. There is also a shipping tag used for bulk orders, letterhead stationery, invoices, statements, a share certificate, See the photos of the company name and logo stamps, advertising mechanical and regular pencils, a calendar and pages from a 1933 business ledger. Expense categories include boxes/bags, potatoes, cooking oil, bakery supplies, advertising, Repairs, Insurance, commissions, office supplies, and Express and Cartage.

In 1951 the company was liquidated. Alexander sold the Saratoga St. site to the Orthodox Christian Association (O.C.A). The group converted the building to a private club, adding a bar, restaurant, and upstairs banquet hall. The facility was opened to the public after a few years. Today this building is home to Awards by Walsh, a business that provides trophies, awards, and promotional items. Alexander kept the formula and then sold it to Wise in 1954 or 1955 for $1000.

Thanks to the Cohoes Town Historian Steve Lackmann for providing an excerpt from an article published in the Winter 2001 issue of the Spindle City Historic Society newsletter. Also thanks to former City Historian Walter Lipka and Walter Cherniak of the Spindle City Historic Society.

The Toga Chip Guy

1 note

·

View note

Text

How to choose your perfect food marketing agency | fmtmagazine

Trying to choose a food marketing agency to develop your brand or deliver creative work can be a daunting task.

Food coating is love expressed for food, visible to us. Foods contain basic flavour, but coating can serve to improve the taste, texture and flavour of food products. Coating is an industrial process which involves the application of liquids and powders on the surface of food products. (Food Marketing Agency) This is a complex process; food products are sensitive in nature and, thus, need mild treatment and proper processing as deterioration in the form of water loss and enzymatic action due to physical, chemical and other biological reasons can easily take place.

Food coating has taken on a whole new meaning in the age of globalisation and social media. Food around the world is getting trendier day by day, as people are demanding adventure and novelty in their food choices much like the rest of their life. An increasing number of people are now experimenting with different flavour profiles when it comes to their food. In this fast-paced world where people are unable to find time to stay fit and eat healthily, food coating has provided an easy way to make food healthy without sacrificing on flavour. Food Marketing Agency

Food coating allows for a product to be coated with ingredients or materials which render it more palatable whilst retaining the inherent health benefits of the product. For example, otherwise ordinary tasting salads when coated with flavourful dressing turn into appetizing, new dishes. Similarly, a boring vegetable sandwich when coated with flavoured herbs or mayonnaise sauce becomes delicious whilst still remaining a healthy meal option.

Food coating as a technique and process has, among its many benefits, also made it easier for mothers to feed their toddlers. Toppings and add-ons are some of the types of food coating which are hugely popular with consumers. Food Marketing Agency Food items like pizza, wafers, soups, and even fruit and meat products all require additional flavours and coatings. Despite providing tasty and flavourful comfort food, KFC, Subway, Dunkin Donuts and other fast-food chains still offer customers a variety of toppings to coat their food with.

The food packaging industry has also adapted to this growing trend, introducing new kinds of packaging which ensure that the coated products remain fresh and tasty inside the package. The development of Modifies Atmospheric Packaging (MAP) packaging and Ready-to-Eat & Ready-t0-Serve (RTE & RTS) packs was a direct result of this major shift toward food coating in the food product industry.

While it may sound simple enough, the process of food coating is actually heavily technique-based. The process entails the use of a variety of machinery and equipment like mixers, rollers, hoppers, blenders, etc. to prepare and coat the food product. Scientific processes and phenomena including adhesion, surface tension, friction, velocity and crystallization form the core foundation of the entire process in its myriad variations. Food Marketing Agency

The human tendency to snack has been a major factor which has contributed to the growth and development of the idea of coating. The more flavourful a product is, the more one will snack on it. With a highly competitive food product market, coating has become an industry standard as companies vie to make their products more palatable and boost consumer sales. An example of the above is provided by the flavoured chips market, one of the most consumed type of snack the world over.

Flavoured chips have also been the most experimented on snack item in terms of flavour and coatings. Initially, regular potato chips when consumed tasted bland. Flavours and seasoning were developed as additions to regular chips in an attempt to do away with the greasy taste of oil most associated with chips. Factors considered while seasoning chips include the overall shape and size of the chip; a different coating is applied on thin- and thick-layered slices of chips. The flavour imparted to the product will vary according to the thickness and surface area of the chips.

Today, one can find a variety of snacking chips in the market such as tortillas, corn chips, extruded chips, potato chips with chocolate coating, etc. The major objective of coating the chips is to enhance the organoleptic properties of the chips. Seasoning is a key part of the product formulation process; the most common method to season products is using a drum tumbler. Selection of ingredients for food coating is also integral to the entire process. Food Marketing Agency

This should be done wisely, ensuring that ingredients are of good quality. A proper ingredient selection will determine the final taste as well as cost of the product. Usually, seasoning is added to the product in the dry form. However, methods like spray drying and encapsulation can be used to coat products in liquid form. A new ‘slurry’ concept of coating is used with water as a carrier instead of fats or oils. This method is used to produce starch-based snacks where water is removed during the final stage through the process of drying.

As research and development has progressed in this field, edible films for coatings which protect the food surface from damage have emerged on to the scene. Functional additives like protein based hydrocolloids, lipids, polysaccharides, anti-oxidants, nutraceuticle compounds, antimicrobials, etc., have been developed in recent times. These serve to not only protect the food but also increase the nutrition of the product.

Another point of note is that coating requires the successful adhesion of ingredient to the product. More sophisticated coating processes employ the method of spray-drying or encapsulation of the product to ensure proper adhesion. Products made using these methods last longer than those prepared with seasoning simply sprinkled on top. Food Marketing Agency

Coating is an easy process, but it is crucial to employ the right technique in the process. Maintaining optimum temperature conditions as well as timing are key to the successful completion of the process. Further, selecting the right ingredients is also important. Increasing the shelf-life of a product remains a primary concern in the food industry. Thus, methods developed to make chips or snacks last longer can prove to be extremely crucial for stakeholders within the industry.

Indians have been snacking for centuries, but with the advent of new technology in the last ten years, the food product sector in the country has witnessed tremendous growth. Food Marketing Agency In recent years, nachos and other types of snacks normally found abroad have been introduced in the Indian market; garlic salt and peri-peri seasoning are also now popularly used throughout the country.

In the coming years, more experiments with flavours and coatings are likely to take place as people become more adventurous in their eating habits. This shows that while the market for food products might be slow in growth, it will remain a dynamic industry in terms of product creation and development for years to come.

0 notes