#automatic potato chips making machine

Explore tagged Tumblr posts

Text

Exploring Types of Potato Chips Machines

If you’re considering starting or expanding your potato chips business, choosing the right machinery is critical. As an India-based manufacturer with years of industry experience, we understand the unique needs of snack producers. In this guide, we explore the different types of potato chips machine available—from small scale options perfect for startups to industrial production lines for high-volume operations. We’ll also help you understand the benefits of commercial potato chips machines, ensuring your production is both efficient and high-quality.

#potato chips machine#potato chips making machine#potato wafer machine#automatic potato chips making machine#chips production machine#aloo chips machine#aloo chips making machine#manufacturer#supplier#exporter#Supplier#Ahmedabad#Gujarat#India#commercial potato chips machine#bulk chips maker machine

0 notes

Text

Armind Industries in Patna offers a potato chips making machine designed for efficiency and quality. The machine features an automated slicing, frying, and seasoning system, allowing for continuous production with minimal manual intervention. It is made from high-quality stainless steel, ensuring durability and easy cleaning.

0 notes

Text

Helpful Household Items: Air Fryer

To use the meme format: "I've only had my air fryer for a week and a half, but if anything happened to it, I would kill everyone in this room and then myself". I mean, not literally, but largely because I'm not in that place in my life anymore and live alone, but you get what I mean. I had some gift voucher and it was about enough to get myself a small air fryer - only two litre capacity. It seemed a good compromise; I didn't have to spend any money, I could see how an air fryer could or could not change my life, and I could get a new, bigger one if it worked out.

...Okay, I mostly got an air fryer so I could try this quasi-recipe that Jordan Howlett tripped over, so here's your recipe for the post:

youtube

I haven't tried that yet, but I will tell you this much: it has absolutely changed my life, and honestly, I think every spoonie should own one. Here's a few examples of why:

It's great for when the physical spoons are lacking. I'm not just talking about bad pain days, either. My experience with fibromyalgia has involved a fair few days where my grip strength is hit and miss, or when I have spasms so my motor control is equally hit and miss. But as long as you're keeping things in a single layer, you hardly even have to turn anything in an air fryer (though I grant it sometimes helps). No bending to put things into or pull things out the oven, no shoving things around a skillet, nothing like that. Just put a thing in the drawer, set it to the right parameters, and withdraw the drawer when done.

To add to that - little to no cleaning. You're using little to no oil, so all it takes is lining it with parchment and a quick wipe-down when done. Washing a skillet is hell on bad days, especially if your skillet is a good heavy one.

It's also great when mental spoons are lacking. My personal experience with a combination of ADHD and brain fog is that sometimes I forget when something's in the oven, mostly when I'm doing oven chips or something. Or I get a little unsure as to exactly how long a piece of meat should be in the oven for the level of done-ness I want. Or both. Either way, I could go to the rigamarole of getting an egg timer and setting it and the like ... or I could have a nice little machine that not only automatically beeps like the microwave when it's done, it also turns itself off like the microwave when it's done. So if I, say, got involved in something I couldn't easily pause because I didn't realise my food would be ready in two minutes, I don't have to worry about it burning.

There's an economic benefit as well. I'm single. I live alone. Even if I got (when I get) a larger air fryer, running one of those to cook a chicken leg quarter or a a salmon fillet has to be easier on the electric bill than doing it in a full-sized oven. Because of the size, it also pre-heats faster than a full-sized oven, just because there's less space to heat.

Seriously, I used it to cook salmon for dinner tonight. Done perfectly with little to no effort. Mine is small, but the basket is the perfect size for a serving of fish or a chicken leg quarter or just the right number of tater tots. Mostly I want a bigger one for when I have company or when I want to do chicken nuggets and tater tots. Also to make a decent-sized batch of potato chips, or frozen fries where I don't have to stop midway through to shake up the contents of the container because their shape doesn't lend well to a single layer in a basket that small. I worried about the space it took up until I learned that an air fryer can also serve as a dehydrator. So I could get rid of my dehydrator, put a good-sized air fryer in its place, and ... I dunno, keep the little one around for emergencies?

No, not for emergencies - for small batches of the above recipe so I don't end up becoming 80% sugar by volume.

7 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] ROMINO Multifunctional Vegetable Cutter Chopper for Kitchen, Mandoline Slicer, Potato Chips Cutter, Spring Slicer, Onion Chopper with Stainless Steel Blades and Safety Holder, 650 ml (Multi) Manual Vegetable Shredder Grater Salad Maker Dicer With 30+ Adjustments 3 Different Cuts And Pusher Heavy Duty Safe To Cut 5 In 1 Easy Hand Veg Press Handheld With Adjustable German Blade Pusher This Vegetable Cutter Comes with 3 cutting options and 30 thickness options ranging between 1 mm and 8 mm. Safe Multi-Purpose vegetable chopper: Our vegetable cutter for the kitchen lets you slice, strip, dice, and julienne your vegetables safely in seconds,40+ different cuts do not need to change blades, this mandoline slicer is perfect for cutting potatoes, tomatoes, cucumbers, cabbage cutter ,carrots and more. EASY TO USE AND CLEAN: This slicer kitchen is a 5-in-1 slicer without a changing blade. The shredder is easy to clean under water or a dishwasher machine Detachable & Easy to Clean: One-click disassembly multifunctional vegetable slicer, BPA dishwasher safe, easy to clean, folded size just 13.5” L x 5.5” H x 2” W, takes up less space in the cabinet, once for all vegetable slicer cutterPORTABLE & EASY TO STORE - Our slicer for kitchen has a collapsible design. You can fold and tuck it away into your cabinet or drawer after use. This also makes it easier to bring anywhere. The vegetable slicer for kitchen can be used to julienne, cube, quarter, or cut vegetables in any way you Want. Sturdy ABS plastic and 100% BPA-free materials make the romino multifunctional vegetable chopper durable and safe for regular use. Upgraded mandoline chopper, Fruit Cutter: The upgraded vegetable chopper kitchen's handle is automatic rebound after pressing is more labor-saving, larger feeding port & container chopping machine more food at once, built-in rust-resistant stainless steel blade making faster-cutting speed, quick preparation of Vegetable salads, French fries, onion cutter for kitchen and more. Read the Manual Carefully: Please read the instruction manual of the hand chopper vegetable cutter closely before use. If you have any questions or issues regarding the multipurpose vegetable slicer please do not hesitate to send the seller a message through Amazon and we will respond within 24 hours. PORTABLE & EASY TO STORE - Our slicer for kitchen has a collapsible design. You can fold and tuck it away into your cabinet or drawer after use. This also makes it easier to bring anywhere. Package Contents: 1 multipurpose slicer/ dicer/ grater with pusher, chute, and container [ad_2]

0 notes

Text

Choosing the Right Chips Packing Machine A Comprehensive Buyer’s Guide

In the snack food industry, the efficiency and effectiveness of your production line can significantly impact your bottom line. A key player in this process is the chips packing machine. Selecting the right machine is crucial for optimizing your operations, ensuring product quality, and meeting consumer demands. This comprehensive buyer’s guide will help you navigate the various factors to consider when choosing a chips packing machine.

Understanding Your Needs

Before diving into the specifications of different chips packing machines, it's essential to understand your specific needs. Consider the following factors:

Production Volume: Assess your daily or hourly production volume. Machines come in various sizes and speeds, so identifying your output requirements will help you select a machine that meets your needs without over- or under-investing.

Product Type: Different types of chips—potato, tortilla, or vegetable—may require different packaging approaches. Ensure that the machine you choose can handle the specific type of chips you produce.

Packaging Format: Consider the types of packaging you want to use. Options include bags, pouches, or cartons. Some machines are designed for specific formats, while others offer versatility.

Key Features to Look For

When choosing a chips packing machine, keep an eye on these critical features:

Automation Level: Fully automated machines can significantly reduce labor costs and increase efficiency. However, semi-automatic options may be more suitable for smaller operations or businesses just starting. Consider your budget and production goals when deciding on the level of automation.

Speed and Efficiency: Look for machines that can achieve high output rates while maintaining product quality. Check the machine's specifications for speed (bags per minute) and any available options for quick changeovers between different packaging formats.

Durability and Maintenance: Choose a machine constructed from high-quality materials that can withstand the demands of a production environment. Additionally, consider the maintenance requirements—machines that are easy to clean and service can save you time and money in the long run.

Integration with Existing Systems: If you already have equipment in your production line, ensure that the new chips packing machine can integrate smoothly with your existing systems. Compatibility with other machines will help streamline your operations.

Technology and Smart Features: Modern chips packing machines come equipped with advanced technology, including IoT capabilities and real-time monitoring systems. These features can enhance operational efficiency by providing valuable data and insights for better decision-making.

Assessing Quality Control

Quality control is vital in the snack food industry, where product consistency and safety are paramount. Look for features that enhance quality assurance:

Inspection Systems: Many machines now come with built-in inspection systems that use cameras and sensors to detect defects, such as incorrect fill levels or foreign objects. These systems can significantly reduce the risk of faulty products reaching the market.

Sealing Technology: Proper sealing is crucial for maintaining freshness and extending shelf life. Investigate the sealing methods used by the machine—options include heat sealing, vacuum sealing, or nitrogen flushing. Choose a method that aligns with your product's requirements.

User-Friendly Interfaces: A machine with an intuitive control panel will reduce training time for your staff and minimize the risk of operator errors. Look for machines that offer easy navigation and clear displays for monitoring production processes.

Budget Considerations

Investing in a chips packing machine is a significant decision, and budget considerations are essential:

Initial Cost vs. Long-Term Value: While it may be tempting to opt for the cheapest option, consider the long-term value. A more expensive machine may offer better efficiency, durability, and features that could save you money over time.

Operating Costs: Analyze the operating costs associated with the machine, including energy consumption, maintenance expenses, and labor costs. Machines that offer energy efficiency and lower maintenance needs can contribute to overall savings.

Financing Options: Explore financing options that can help spread the cost over time. Many suppliers offer leasing or financing plans that make acquiring a new chips packing machine more manageable.

Supplier Reputation and Support

The supplier you choose can significantly impact your experience with the chips packing machine. Consider the following:

Reputation: Research the supplier's reputation in the industry. Look for customer reviews, case studies, and testimonials to gauge their reliability and the quality of their machines.

Customer Support: Ensure that the supplier offers robust customer support, including installation assistance, training, and ongoing maintenance. A responsive support team can be invaluable in minimizing downtime and resolving issues quickly.

Warranty and Service Agreements: Review the warranty and service agreements offered by the supplier. A good warranty can provide peace of mind, while a service agreement can ensure that your machine remains in optimal condition throughout its lifespan.

Conclusion

Choosing the right chips packing machine is a critical decision that can affect your production efficiency, product quality, and overall success in the snack food industry. By understanding your needs, evaluating key features, and considering budgetary factors, you can make an informed choice that aligns with your business goals. Remember to research suppliers carefully and seek those who offer reliable support and high-quality machines. With the right chips packing machine, you’ll be well-equipped to meet consumer demands and stay competitive in this dynamic market.

0 notes

Text

Nichrome: Packaging Taste and Safety into Every Bite with Integrated Food Packaging Solutions

The demand for packaged food has skyrocketed over the last decade, driven by consumers seeking convenience, hygiene, and ready-to-eat options. With changing lifestyles, rising incomes, and increasing mobility, more people are opting for packaged goods like edible oils, food grains, milk, snacks, and mithai over traditional loose products. The modern consumer is not just looking for taste but also for safety, quality, and portability, while manufacturers focus on maximizing production, minimizing downtime, and reaching new markets with international standards.

Smart Packaging for a Fast-Paced World

For food manufacturers, packaging is no longer just about wrapping a product — it’s about ensuring efficiency, safety, and convenience. A packaging partner that can deliver an integrated line, from primary to secondary and even tertiary packaging, can revolutionize a manufacturer’s operations. This is where Nichrome steps in, offering comprehensive solutions that not only streamline operations but also ensure that every element of packaging works seamlessly together.

A turnkey supplier like Nichrome takes the headache out of packaging by managing everything from design to installation, so manufacturers can focus on what they do best: producing great food.

Finding the Right Fit: How to Choose Your Packaging Machine

Choosing the right packaging machine can be overwhelming, but there are a few key factors to consider:

Size and Weight: Make sure the machine fits your floor space.

Ease of Operation: A user-friendly machine keeps your line moving.

Cost Efficiency: Consider not just the upfront cost, but the long-term savings on maintenance and operations.

Flexibility: Look for machines that can adapt to different product lines.

Reliability: Trust in the manufacturer’s expertise and after-sales support.

Nichrome: Pioneers of Food Packaging in India

Nichrome has been at the forefront of food packaging innovation for over 40 years. From creating India’s first indigenous milk pouch packaging machine to providing advanced automated systems today, Nichrome continues to lead the charge in delivering versatile, efficient packaging solutions. Whether you need machines for potato chips, edible oil, ketchup, sugar, or any other food product, Nichrome’s machines are designed for high efficiency with minimal downtime.

Nichrome’s Versatile Food Packaging Solutions

Nichrome’s strength lies in its ability to provide single-source convenience, offering end-to-end solutions that cover everything from product handling to warehousing. Nichrome’s solutions are highly adaptable, with many machines capable of serving multiple applications through simple changes in the filling system.

Primary Packaging Solutions: Including bottle filling, jar filling, tin filling, bulk bag filling, and Blow Fill Seal (BFS) lines.

Secondary Packaging Solutions: These can be integrated for seamless operations, such as vertical and horizontal cartoners, auto case packers, and flexiwrap systems.

End-of-Line Systems: From automatic pallet dispensing to robotic palletizers, Nichrome provides complete integration to ensure your entire packaging process is optimized.

Why Nichrome?

As a trusted name in food packaging, Nichrome’s expertise spans the packaging of everything from grains, pulses, and powders to liquids, viscous foods, and ready-to-eat products. With over four decades of experience and more than 10,000 installations in 45 countries, Nichrome offers unmatched solutions that maximize space, efficiency, and resource utilization.

Conclusion: The Complete Packaging Solution with Nichrome

Whatever your packaging needs — whether it’s tin packing, bottle filling, case packing, or flow wrap — Nichrome is your go-to partner for integrated solutions that not only meet your needs but exceed your expectations. With Nichrome’s tailored approach and extensive experience, you can be confident that your packaging operations will run smoothly, efficiently, and cost-effectively.

So, why settle for less when you can pack perfection with Nichrome? Step into the world of advanced packaging and discover how Nichrome’s solutions can propel your business to new heights!

#TinFillingMachine#AutomaticBottleFillingMachine#PackagingSolutions#NichromePackaging#IntegratedPackaging#SafeFoodPackaging

0 notes

Text

Crunching the Numbers: How to Choose the Perfect Snack Packaging Machine

Crunching the Numbers: How to Choose the Perfect Snack Packaging Machine

In today’s snacking world, keeping your munchies fresh, safe, and irresistible is more crucial than ever. That’s where snack packaging machines come into play—transforming your snack game from homemade to high-tech. But with so many options out there, how do you choose the right machine for your business?

Enter Nichrome’s snack packaging solutions—your ultimate ally in the snack world! Our Vertical Form Fill Seal (VFFS) range, including the Wing 200 E-Line Snack Pack and Sprint 250, delivers exceptional performance. With advanced features like PLC controls, touch screen interfaces, and servo motor-driven sealing systems, Nichrome’s machines are designed to handle diverse snacks efficiently. With over ten thousand successful installations worldwide, Nichrome ensures you get the perfect machine to meet your needs and future-proof your snack packaging operations.

Here’s how Nichrome does it –

Size Matters: Machine Capacity Before you start dreaming of snack-filled success, consider the capacity of your packaging machine. Whether you’re a small-scale snack artisan or a major player in the snack industry, your machine needs to keep up with your production volume. Think of it as your snack machine’s superpower—will it need to churn out hundreds or thousands of packs per hour? Choose wisely to avoid any hiccups in your snack-tastic journey!

Flexibility Is Key: Intended Use Are you packaging a variety of snacks or focusing on a specific type? Your snack packaging machine should be as versatile as your snack lineup. From crispy chips to savory namkeen, your machine should be adaptable enough to handle different products without a hitch. Look for machines that offer flexibility and easy adjustments to cater to diverse snack needs.

Feature-Fest: Machine Options When it comes to snack packaging, one size doesn’t fit all. Compare features across different machines to find the one that suits your needs best. Automatic, semi-automatic, or manual—what’s your pick? Additionally, if your lineup includes powdery substances or liquid snacks, make sure your machine can handle these special cases with ease. It’s all about finding the perfect fit for your snack-tastic operations!

Maintenance Matters: Machine Upkeep No one likes a high-maintenance diva, and your snack packaging machine is no exception. Regular maintenance is key to keeping your machine in tip-top shape. Look for machines that are easy to clean and maintain, and check the availability of replacement parts. This will ensure your machine stays reliable and your snacks stay fresh, without breaking the bank.

Plan for the Future: Growth Potential Is your business ready to expand? Make sure your snack packaging machine can grow with you. Opt for machines that can be upgraded or adapted as your business evolves. A future-proof machine will save you from costly replacements and keep your snack game strong as you scale up.

Speed and Efficiency: Packaging Speed Speed thrills, especially when it comes to packaging. Consider how fast you need your snack packaging machine to be. Efficient machinery means quicker turnaround times and less manual labor, so your snacks hit the shelves faster. If speed is the name of the game, investing in top-notch snack packaging machinery will be a game-changer.

Durability: Built to Last Snack packaging machines are a substantial investment, so durability is crucial. Look for machines designed for long-term use, with features that ensure easy and inexpensive upgrades. Your machine should stand the test of time and market demands, providing reliable service well into the future.

Versatility: Snack Variety From dry fruits to potato chips, your machine should handle a variety of snacks with ease. A versatile machine can package everything from candies and pasta to cereals and grains. This adaptability will help you keep up with changing market trends and customer preferences.

Conclusion

Choosing the right snack packaging machine is essential for keeping your business fresh and competitive. With Nichrome’s cutting-edge solutions, you’ll have the perfect partner to ensure your snacks are packaged with precision and flair. Whether you’re a snack newbie or a seasoned pro, Nichrome is here to make your packaging process a breeze. Ready to elevate your snack game? Let’s get packing! Learn More:

0 notes

Text

potato chips making machine | buy aloo chips making machine in Varanasi

Introduction

Are you tired of outdated methods of making potato chips and want to upgrade to a more efficient machine? Contact Laghu Udyog, a renowned manufacturer and supplier in Varanasi, brings you cutting-edge potato chips making machine that will revolutionize your snack production line. Let's explore the benefits of using their potato wafers making machine and how it can take your business to the next level.

Why Choose Laghu Udyog Potato Chips Making Machine?

With years of experience in the industry, Laghu Udyog has established itself as a trusted name in the market for providing top-quality machines for potato chips production. Their chips making machine in Varanasi is designed with precision and innovation, ensuring high efficiency and excellent output.

Key Features of Laghu Udyog Potato Chips Making Machine:

Automatic Operation: Say goodbye to manual labor and streamline your production process with the automatic operation of Laghu Udyog machine.

High Capacity: Increase your output with the high-capacity production capabilities of the potato chips making machine.

Customization Options: Tailor the machine to suit your specific production needs with customizable features offered by Laghu Udyog.

Easy Maintenance: Keep your machine running smoothly with easy maintenance procedures that ensure longevity and reliability.

Experience Unmatched Quality with Laghu Udyog

When you invest in Laghu Udyog potato chips making machine, you can rest assured that you are getting a product of unparalleled quality. Their machines are built to last, with sturdy construction and high-grade materials that ensure durability and performance.

What Sets Laghu Udyog Apart:

Expertise: With years of experience in the industry, Laghu Udyog brings expertise and knowledge to the table, delivering top-notch machines that meet the highest standards.

Innovation: Stay ahead of the competition with Laghu Udyog innovative solutions that are designed to optimize your production process and maximize efficiency.

Reliability: Count on Laghu Udyog for reliable products that deliver consistent results, keeping your snack production running smoothly day in and day out.

Elevate Your Snack Production with Laghu Udyog Potato Chips Making Machine

Say goodbye to traditional methods of making potato chips and embrace the future of snack production with Laghu Udyog cutting-edge machines. Visit their website at laghuudyogindia.com to explore their range of potato chips making machines and revolutionize your production line today!

Meta Description: Elevate your snack production with Laghu Udyog potato chips making machine in Varanasi. Visit their website for top-quality machines and maximize efficiency.

Conclusion

Investing in a high-quality potato chips making machine is essential for any budding entrepreneur looking to enter the snack industry in Varanasi. With Laghu Udyog as your partner, you can trust that you are getting reliable equipment that will help you create delicious potato chips for your customers. Visit their website today to explore their range of products and kick start your potato chips business with confidence.

#potato chips making machine#business#manufacturer#chips making machine in Varanasi#potato wafers making machine

1 note

·

View note

Text

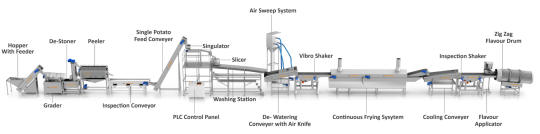

Full automatic Baked Potato Chips Production Line

Full Automatic Baked Potato Chips production Line ( baked potato chips making machine ) is our company's latest developed non-fried equipment based on the technology of the compound potato chips production line and biscuit production line. The potato chips making machine equipment can produce healthy and non-fried new type potato chips by the process of sheeting, baking, flavoring. This equipment has the characteristics of high automation, easy operation, stable running, etc, and widely accepted by our customers.

Capacity and Utilities: HG Food Machinery manufacturer can provide machinery capacity 250kg/h and 500kg/h Workshop requirements length 70m and width 20m Power : 130-140kw Gas consumption : 25kg/h-50kg/h Compressed air consumption :25-30 m3/h

Advantages : 1)Complete potato chips production line with smart PLC controlling system. 2)Wide range of food application, high standard biscuit is also available in this line 3)Safe and energy-saving tunnel oven; 4)Full stainless steel 304 contacted with food

• 0086-21-57458832 • Mob: 0086-15800718880

• 0086-21-57456127 • Website: www.hg-machine.com

• [email protected] • Skype: hamasakiyumi

0 notes

Video

youtube

potato chips production line|automatic potato chips making machine|potato chips machine for sale

Fully automatic potato chips production line is used for making potato chips quickly with high quality. Capacity:50-2000kg/h Wechat/whatsapp:+8613213203466

#potato chips production line#automatic potato chips making machine#potato chips machine for sale#Fully automatic potato chips production line#potato chips packaging machine price

0 notes

Text

Selecting a High-Capacity Potato Chips Machine for Large-Scale Production

Selecting the right potato chips frying machine is crucial if you want to produce crispy, delicious chips consistently. Whether you’re a small-scale snack producer or operating a large production line, the right fryer can elevate the quality of your product while boosting efficiency. In this guide, we explore key considerations and expert tips to help you choose the best potato chips machine that meets your specific production needs.

https://frymode.com/how-to-choose-the-best-potato-chips-fryer-machine/

#potato chips making machine#High Capacity Potato Chips Machine#Potato Chips Machine#Automatic Potato Chips Machine#Manufacturer#Exporter#Supplier#Ahmedabad#Gujarat#India

0 notes

Text

0 notes

Text

Fully Automatic Potato Chips Making Machine Price

Potato chips have gained widespread popularity as a snack food worldwide, resulting in a surge in demand. Potato chips manufacturers have responded to this by incorporating an affordable fully potato chips machine price. This modern line of equipment enables the efficient and high-quality production of potato chips on a large scale.

A fully automatic potato chips line comprises a range of machines that perform different functions throughout the manufacturing process. These machines include a potato slicer, potato washing machine, potato blanching machine, potato frying machine, potato de-oiling machine, seasoning machine, and packaging machine. These parts come within a budget for chips making machine price.

The semi-automatic potato chips making machine price is determined by various factors, including machine capacity, quality, and brand. However, the high production output and efficiency of the line usually offset the potato chips making machine price.

In a nutshell, the fully automatic potato chips line has brought about a significant change in the potato chips manufacturing industry by streamlining the production process on a large scale. If you’re planning to launch a potato chips manufacturing company, investing in Economode’s fully automatic potato chips line is a wise decision. Despite the high initial expense, the benefits of this technology will become evident in the long run.

How fully automatic potato chips machine benefit potato chips manufacturers?

Potato chips are a highly popular snack food that has seen a significant increase in demand globally. However, manufacturers face the challenge of keeping up with this demand while maintaining high-quality products. The solution to this challenge is Economode’s affordable potato chips frying machine price, which offers various benefits to manufacturers.

Increased Production Capacity

One significant benefit of this budget-friendly potato chips machine price is its increased production capacity. This is achieved through the use of high-speed machines that can perform various tasks such as slicing, washing, blanching, frying, seasoning, and packaging in a short period. The machines are also designed to operate continuously, which reduces downtime and increases productivity.

Improved Quality Control

Another benefit of that comes with affordable semi-automatic potato chips making machine price is the improved quality control it provides. The affordable chips making machine price is equipped with sensors that monitor the production process to ensure that the potato chips meet the required quality standards. This helps to detect any defects, allowing for immediate corrective action, which leads to better products, higher customer satisfaction, and increased sales.

Reduced Labor Costs

The potato chips line also significantly reduces labor costs. Since the machines perform most of the tasks that would otherwise require human labor, this leads to significant savings for manufacturers. Additionally, the potato chips making machine price is competitive & can operate 24/7 without fatigue or the need for breaks, reducing the need for additional staff and increasing productivity.

Consistent Product Quality

Consistent product quality is another benefit of the affordable fully automatic potato chips making machine price. The machines are programmed to perform tasks precisely, which ensures that the potato chips have uniform thickness, texture, and flavor. This consistency in quality is essential in maintaining customer loyalty and increasing sales.

Reduced Energy Consumption

Compared to traditional manufacturing methods, the fully automatic potato chips line also reduces energy consumption. The machines are designed to operate efficiently, using minimal energy to perform tasks. Additionally, the machines use modern technology such as heat exchangers and automatic temperature control, which reduces energy waste and costs.

Increased Profit Margins

Investing in a budget friendly potato chips frying machine price can increase profit margins for manufacturers. The increased production capacity, improved quality control, and reduced labor and energy costs translate to higher profits. Moreover, the consistent product quality and customer satisfaction lead to repeat business and increased sales.

Competitive Advantage

The potato chips machine price is affordable & also provides a competitive advantage to manufacturers in the market. It enables manufacturers to produce high-quality potato chips at a lower cost, which translates to lower prices for consumers. This advantage leads to increased market share and a stronger brand image.

In conclusion, investing in a affordable chips making machine price is a valuable investment for potato chips manufacturers. Though the cost varies depending on the capacity and quality of the machines, the benefits far outweigh the initial investment. If you are a potato chips manufacturer looking to improve your production process, the fully automatic potato chips line is the way to go.

Fully automatic potato chips line capacity

A semi-automatic potato chips making machine price is competitive and also is an advanced manufacturing system that handles the entire process of potato chip production from raw potatoes to packaged chips with minimal human intervention. These production lines are equipped with high-tech machines and sensors that perform various tasks like slicing, washing, blanching, frying, seasoning, and packaging the chips. The potato chips making machine’s price is affordable and its production depends on the size and quality of the machines used in the line.

Smaller lines can produce 50-100 kg of chips per hour, while larger lines can produce up to 500 kg or more per hour. However, the production capacity can be influenced by factors like the type of potato used, chip thickness, and seasoning requirements.

Investing in our affordable fully automatic potato chips making machine price can offer several benefits such as increased production capacity, reduced labor costs, and improved product quality. The potato chips frying machine price depends on the capacity and quality of the machines, but the benefits outweigh the initial investment. Here at Economode, we consider the production needs and goals when choosing a fully automatic potato chips line that meets your specific business requirements.

#potato chips machine#potato chips making machine#potato chips machine price#chips making machine#potato chips making machine price#potato chips making small machine#potato chips making machine for small business#potato slicer machine#potato chips#automatic potato chips making machine#potato chips machine rajkot#potato chips making machine price in india#potato chips machine online#sweet potato chips making machine#potato chips making machine automatic

0 notes

Link

Verma Food Processing System is the best Automatic Potato Chips Making Machine Manufacturers. Our automatic potato chips making machines are fully automatic machines. We are supplying automatic potato chips making machines at the best industry prices.

2 notes

·

View notes

Link

Get info of a Leading Manufacturers, Suppliers of Potato Chips Plant, Banana/Potato Chips Making Machine, Fully Automatic Chips Frying Line/Fryer, Batch Type Banana Chips Line&Pellet Frying Line.

1 note

·

View note

Video

youtube

potato chips production line|automatic potato chips making machine price|potato chips machine for sale

Fully automatic potato chips production line is used for making potato chips quickly with high quality. Capacity:50-2000kg/h Wechat/whatsapp:+8613213203466

#potato chips production line#automatic potato chips making machine price#potato chips machine for sale#potato prccessing machine#banana chips production line

0 notes