#positive material identification equipment

Explore tagged Tumblr posts

Text

Reliable Positive Material Inspection in Pune | PMI Services & XRF PMI Technology

Positive Material Identification (PMI) is a crucial process in industries where the integrity and composition of materials are of utmost importance. At Integrated NDE Solutions, we specialize in providing comprehensive PMI services in Pune, ensuring that your materials meet the required specifications and standards.

What is Positive Material Identification (PMI)?

Positive Material Identification (PMI) is a non-destructive testing (NDT) technique used to verify the chemical composition of materials, particularly metals. PMI is essential in industries such as oil and gas, aerospace, manufacturing, and construction, where material mix-ups can lead to severe consequences, including safety risks and costly failures.

Our PMI Services in Pune

At Integrated NDE Solutions, we offer a range of PMI services to meet the diverse needs of our clients:

XRF PMI Equipment: We utilize advanced X-Ray Fluorescence (XRF) PMI equipment to provide accurate and reliable material identification. XRF PMI technology allows us to perform on-site inspections quickly, ensuring minimal disruption to your operations.

PMI Inspection: Our PMI inspections are conducted by experienced technicians who are trained to identify the composition of various materials, including alloys, stainless steel, and carbon steel. This is particularly important for industries where precise material identification is critical.

PMI Material Identification: Our PMI material identification services are designed to confirm the exact composition of materials used in your projects. This helps prevent material mix-ups and ensures compliance with industry standards.

Positive Material Identification for Carbon Steel: Carbon steel is widely used in many industries, and its proper identification is crucial. Our PMI services for carbon steel ensure that the correct material is used, preventing potential failures and ensuring the safety and reliability of your structures and products.

PMI Chemical Analysis: Our PMI chemical analysis services provide detailed information about the chemical composition of materials, helping you make informed decisions about material selection and usage.

Positive Material Inspection: Regular positive material inspections are essential for maintaining the integrity of your materials and ensuring they meet the required specifications. Our team conducts thorough inspections to verify the composition of your materials, reducing the risk of costly errors.

Why Choose Integrated NDE Solutions for PMI in Pune?

Expertise: Our team of skilled technicians has extensive experience in PMI material analysis, identification, and inspection. We understand the critical importance of accurate material identification and are committed to delivering reliable results.

Advanced Technology: We use state-of-the-art PMI equipment, including XRF technology, to ensure precise and efficient material identification. Our technology allows us to perform inspections quickly and accurately, minimizing downtime.

Comprehensive Services: Whether you need PMI for a single material or a comprehensive inspection of an entire project, we offer tailored services to meet your specific needs.

Compliance: We ensure that all PMI services comply with industry standards and regulations, giving you peace of mind that your materials meet the necessary requirements.

Conclusion

Positive Material Identification (PMI) is an essential process in ensuring the safety, reliability, and compliance of materials used in various industries. At Integrated NDE Solutions, we are dedicated to providing top-quality PMI services in Pune, using advanced technology and expertise to deliver accurate results. Whether you require PMI for carbon steel, chemical analysis, or regular inspections, our team is here to support your needs. Contact us today to learn more about our PMI services and how we can help you ensure the integrity of your materials.

#positive material identification#pmi#pmi positive material identification#xrf pmi#pmi inspection#material identification#positive material#positive material inspection#pmi material identification#pmi material#positive materials identification#pmi material inspection#positive material identification for carbon steel#positive material identification equipment#identification of pmi#pmi chemical analysis#pmis#pmi identification#pmi material analysis#positive material identification standard

0 notes

Photo

Battle of Gazala

The Battle of Gazala in Libya in May-June 1942 was a decisive victory for German and Italian forces led by General Erwin Rommel (1891-1944) against British, Commonwealth, and Free French forces during the Western Desert Campaigns (Jun 1940 to Jan 1943) of the Second World War (1939-1945). As a consequence of the defeat and breaking up of the British defensive line at Gazala, the Allies were obliged to surrender the key fortress port of Tobruk and give Rommel his finest victory.

General Rommel, Western Desert

Imperial War Museums (CC BY-NC-SA)

Desert Warfare

Into the second year of WWII, the Allies, then principally British and Commonwealth forces, were keen to protect the Suez Canal from falling into enemy hands, that is into the control of the Axis powers of Germany and Italy. North Africa was also strategically important to both sides' wish to control and protect vital Mediterranean shipping routes. The island of Malta was also crucial in this role and holding the island fortress (then in British hands) was another reason to control potential airfields in the North African desert. Finally, North Africa was the only place where Britain could fight a land war against Germany and Italy and so hopefully gain much-needed victories that would encourage the British people after the debacle of the Dunkirk Evacuation and the horrors of the London Blitz.

For all of the above reasons, a series of desert battles ensued, which are collectively known as the Western Desert Campaigns. At first, the British Army faced poorly equipped Italian forces, but these were soon considerably boosted by German troops with superior armour, weapons, and training.

North Africa proved a difficult theatre of war with its small ports, poor (or often non-existent) roads, and harsh desert environment. For both sides, battling local conditions and overcoming frequent shortfalls in logistics became just as important as bettering the enemy's military forces. As Rommel once reflected: "The battle is fought and decided by the quartermasters before the shooting begins" (Mitchellhill-Green, 264).

One thing the desert had was space, and battles could range over many miles as territorial gains became much less important than inflicting material damage on the enemy compared to other theatres of the war. Other peculiarities of desert warfare included the general absence of any civilian involvement and the fact that both sides frequently used captured equipment, a phenomenon that often made positive identification of exactly who was approaching across the far horizon in clouds of dust and sand extremely difficult. These same dust clouds, and the speed of armoured engagements, also meant that both the Axis and Allied air forces could only play a limited role in battles and so were largely reduced to targeting supply lines or fixed defensive positions.

General Erwin Rommel

Bundesarchiv, Bild 146-1977-018-13A / Otto (CC BY-SA)

Continue reading...

24 notes

·

View notes

Text

Herein lies a contradiction typical of extreme mainstream culture in film, which cannot but be ambitious (the amount of money invested in it requires it) but has to contain (in both senses of “checking” and “enclosing”) the potential it is forced to make use of. In Red Dragon this happens by means of the utterly impoverishing psychological proto-narrative involving the main evil character, a boy, we are shown, who was raised by a domineering grandmother and whose memories still haunt him. But if this subtext fails to completely mediate an abused childhood with the posthuman Red Dragon, it serves the purpose of inserting the family space as both the origin of the problem and the realm of its possible solution. Reba McClane, a blind woman who works with Dolarhyde, is not shocked by his looks and eccentric behavior; she represents an equal, someone who also has a “disability” but who manages to function well in society. She is a source of hope inasmuch as with her the Red Dragon’s evil could be tamed by the formation of a nuclear family. If only Dolarhyde had not misrepresented the relationship between Reba and Ralph Mandy, another coworker, so the film makes us wonder, then there would be a way out for him, a passage from the dark and dangerous world of writing/reading to that of the lack of ambiguity in the conflict-free home.

Mediating between the hero and villain is the third pivotal element of the film: the police and the FBI. It is Crawford himself who takes Graham away from what we are led to see as paradise, and it is the FBI and the police who provide the material support needed for him to read and reconstitute what passes through Dolarhyde’s mind. What they obviously represent is a social apparatus of repression, one which, again, evinces the most astounding development from the stone-age computers in Manhunter to the up-to-date digitalized network of identification and decoding. It would be tempting to posit an en abîme structure in this case, whereby the technological development undergone by the police would be a miniature of, and would stand for, the film itself in relation to its precursor. But whether or not one relies on this clue, the parallels between the police and mainstream film are worth paying attention to, for both are socially prominent and aspire to be ubiquitous. (The camera indeed has come to perform both roles of universal instrument of surveillance and fundamental means of representation, as the verb “to shoot” and its derivatives attest.)

Furthermore, there is something revealing in the kind of opulence at stake here, not only in the habitually exorbitant Hollywood film budget (by now an important part of any mainstream film advertisement campaign) but also in the amount of resources available to repressive apparatuses. Perhaps one has to live in a Third World country, as I do, to be able to recuperate something of the amazement coming from the disproportionality between that one individual, Dolarhyde, and the State’s inextinguishable resources. From the point of view of its employees (state policemen, FBI agents, all sorts of technicians), an interesting dialectics takes place, whereby the agents of repression renounce the division between their private lives and their work in order to guarantee that this division remain absolute. As for material resources, their total deployment of means is redolent of the purest totalitarian fantasy: in a film where realism seems only to be left aside in the murderer’s pathological, delirious transgression, one might very well ask if this apparently infinite availability—of helicopters, 24-hour personnel, computers, and so forth—is not somehow fanciful, even in the case of a famous serial killer deserving abundant news coverage. The suspicion may very well arise, that is, that in this perfect working of the repressive machine (no one on vacation here, no single computer breakdown, no one using any equipment when it is not needed, no space for a lazy “let’s-do-it-tomorrow” attitude) a social truth is manifested: that writing/reading is dangerous and that to combat it there are no limits to the State apparatuses of counter-reading.

—Fabio Akcelrud Durão, "A Short Circuit of Reading: Red Dragon as Anti-Theory," 2004. Emphasis mine.

#fabio akcelrud durão#red dragon#thomas harris#manhunter 1986#red dragon 2002#literary theory#heat 2 midrash

11 notes

·

View notes

Text

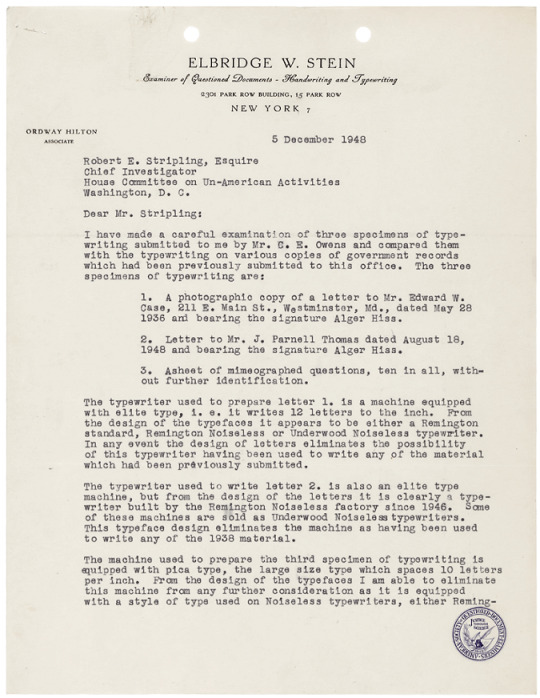

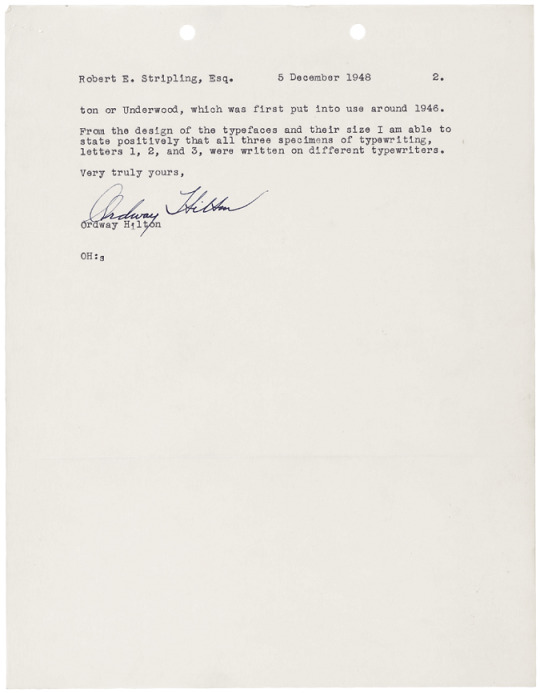

Letter from Ordway Hilton to Robert Stripling Regarding Alger Hiss

Record Group 233: Records of the U.S. House of RepresentativesSeries: Investigative Name Files

[letterhead] Elbridge W. Stein Examiner of Questioned Documents - Handwriting and Typewriting 2301 Park Row Building, 15 Park Row New York 7 5 December 1948 Robert E. Strping, Esquire Chief Investigator House Committee on Un-American Activities Washington, D.C. Dear Mr. Stripling: I have made a careful examination of three specimens of typewriting submitted to me by Mr. C.E. Owens and compared them with the typewriting on various copies of government records which had been previously submitted to this office. The three specimens of typewriting are: 1. A photographic copy of a letter to Mr. Edward W. Case, 211 E. Main St., Westminster, Md., dated May 28 1936 and bearing the signature Alger Hiss. 2. Letter to Mr. J. Parnell Thomas dated August 18, 1948 and bearing the signature Alger Hiss. 3. A sheet of mimeographed questions, ten in all, without further identification. The typewriter used to prepare letter 1. is a machine equipped with elite type, i.e. it writes 12 letters to the inch. From the design of the typefaces it appears to be either a Remington standard, Remington Noiseless or Underwood Noiseless typewriter. In any event the design of letters eliminates the possibility of this typewriter having been used to write any of the material which had been previously submitted. The typewriter used to write letter 2. is also an elite type machine, but from the design of the letters it is clearly a typewriter built by the Remington Noiseless factory since 1946. Some of these machine are sold as Underwood Noiseless typewriters. This typeface design eliminates the machine as having been used to write any of the 1938 material. The machine used to prepared the third specimen of typewriting is equipped with pica type, the large size type which spaces 10 letters per inch. From the design of the typefaces I am able to eliminate this machine from any further consideration as it is equipped with a style of type used on Noiseless typewriters, either Remington Robert E. Stripling, Esq. 5 December 1948 2. Remington or Underwood, which was first put into use around 1946. From the design of the typefaces and their size I am able to state positively that all three specimens of typewriting, letters 1, 2, and 3, were written on different typewriters. Very truly yours, [handwritten signature] Ordway Hilton [typed signature] Ordway Hilton OH:3

#archivesgov#December 30#1948#1940s#huac#house committee on unamerican activities#alger hiss#red scare#mccarthyism

11 notes

·

View notes

Text

Cost estimation

Cost estimation plays a crucial role in various aspects of business and project management. Some of the key benefits of cost estimation include:

Budget Planning: Cost estimation helps in planning and allocating budgets for projects or business operations. By accurately estimating costs, organizations can ensure that they have sufficient funds to complete the project without exceeding the budget.

Resource Allocation: It enables effective allocation of resources such as manpower, materials, equipment, and time. With a clear understanding of the costs involved, organizations can allocate resources efficiently to maximize productivity and minimize waste.

Risk Management: Cost estimation allows for better identification and mitigation of risks associated with a project. By anticipating potential cost overruns or budget constraints, organizations can implement risk management strategies to address these issues proactively.

Decision Making: Accurate cost estimation provides decision-makers with valuable insights for making informed decisions. It helps in evaluating the feasibility of projects, comparing alternative options, and selecting the most cost-effective solutions.

Contract Negotiation: In business transactions, cost estimation serves as a basis for negotiating contracts with suppliers, vendors, and clients. It helps in setting fair prices, establishing payment terms, and ensuring that both parties agree on the financial aspects of the agreement.

Performance Measurement: Cost estimation provides a benchmark for evaluating the performance of projects or business activities. By comparing estimated costs with actual costs, organizations can assess their financial performance, identify areas for improvement, and implement corrective actions if necessary.

Customer Satisfaction: Accurate cost estimation contributes to customer satisfaction by ensuring that projects are completed within budget and delivered on time. It helps in building trust and credibility with clients, which can lead to repeat business and positive referrals.

Legal and Regulatory Compliance: Cost estimation is often required for regulatory compliance and legal purposes. It helps organizations ensure that they meet financial reporting requirements, adhere to industry standards, and comply with relevant laws and regulations.

Overall, cost estimation is essential for effective financial management, project planning, and decision-making in both business and project management contexts. It helps organizations optimize resources, minimize risks, and achieve their objectives in a cost-efficient manner.

Suggestions for cost estimation company

Jamie Thompson

EXCABILER ESTIMATING LTD

Company Number: 15153674

Address: 30 Riverhead Close, London.

www(.)exacabilerestimating(.)co(.)uk

also for USA

Jamie Thompson

Cost Masters Inc

2316 Short Street Austin Texas, TX 78741, WWW(.)costmasters (.)us

#COST ESTIMATION#COST#ESTIMATION#CONTRACTOR#construction#renovation#modern architecture#steel structure#architectural design#Contractore#takkup#accurate#100% accurate#home builders#home extension

3 notes

·

View notes

Text

Peiyuan Sun's Internship Highlights

Hi, I am Peiyuan Sun (锫瑗 孙). I am a graduate student at the Conservation Center, Institute of Fine Arts, NYU. I have been working as a Conservation Fellow under the supervision of Preventive Conservator Jessica Pace at the Barbara Goldsmith Preservation & Conservation Department of NYU Libraries since September 2022. Upon completion of my internship in June, I will graduate with an M.A. in Art History and M.S. in Conservation of Historic and Artistic Works. In other words, by the time you see this Tumblr post, I will have finished my four-year-long studies and work! I am really grateful for working in the Department. In this Tumblr post, I will review the highlights of the past 9 months and 22 days.

Setting up a polarizing light microscope

My first mission was to build a LEICA polarizing light microscope from parts and modules. I was a little surprised at first. I had used microscopes but I had never had to build one worth thousands of dollars. And there were two manuals because the microscope would be made with parts from two different models: the stage and illuminator were from DM750 P, and the reflected light unit was DM750 M. It turned out to be straightforward and only took me and Jessica a morning to put everything together (fig. 1).

Figure 1. Me and the microscope.

The next challenge was to write instructions for beginner microscopists because both LEICA manuals assumed that their users are microscopists. To make sure that the instructions are clear to beginners in microscopy, I compiled my notes into 29 pages of step-by-step instructions with many color illustrations. The manual was printed and kept with the microscope in a binder. Not a professional microscopist myself, I found this exercise inspiring, pointing me to the large body of knowledge in microscopy that was still waiting for me to explore.

The microscope can be used in the material identification of fibers, pigments, and other particles. While other recent developments in analytical technologies made polarized light microscopy seem so primitive, a polarizing light microscope is still a beloved, simple, and powerful tool for conservators. Sometimes identification dictates how people should handle an object. For example, blue asbestos fibers are characterized by their needle-like appearance and pale blue birefringence color under transmitted cross-polarized light (fig. 2). While asbestos is an obsolete fill material with health hazard issues, they can surprisingly show up in a collection. If the fibers are loose on an object, the people handling it should take extra precautions to prevent inhaling the fibers (wearing personal protection equipment such as gloves, mask, goggles, and lab coat).

Figure 2. Blue asbestos fibers under transmitted crossed-polarized light.

Kathe Burkhard’s “Gold Fan”

The first object to treat was a painted and gilded paper folding fan made by Kathe Burkhard (1958–), an American painter, writer, and art critic. The fan is covered in gold-colored metal leaves and thick layers of transparent resin which hardened and froze the fan in its open position. Burkhard transformed a cheap paper fan into a gold fan glimmering in thick coatings that look like honey-colored amber. She wrote in white paint “truths” on the one side, and “Lies” on the other side (fig. 3).

Figure 3. The “Gold Fan” before treatment.

The fan had several issues when it came to the care of the Department. The fan’s paper leaves were torn and its gold-colored metal leaves were peeling off the paper (fig. 4). The surface was also covered with dust and grime that darkened colors.

Figure 4. Details of the torn paper fan before treatment.

With the goal to stabilize the fan and improve its appearance, we decided to close the fractures, put down the lifted metal leaves, and reduce the surface dust and grime. I used wheat starch paste to adhere to the torn edges, and I used small strong magnets to press the joints together while the starch paste dried and cured. Adhering a small part each time, I worked along each fracture, and back and forth between the two sides to make sure things align correctly. There was one tear that went along a fold line of the fan. The two sides of the tear had little overlap for adhesion, like the two halves of a malfunctioned lifted bridge. I used a strip of Japanese paper coated with starch paste and a synthetic adhesive called methylcellulose to mend this tear––now I put an extra bridge over the broken one to hold the two sides together.

I introduced gelatin solution as an adhesive to reattach the leaves to the paper. And after the leaves were secured, I used dry pre-washed cosmetic sponges to clean the surface. I cut my sponges into tiny wedges so that I can maneuver a small piece between and over fragile metal leaves. After the treatment, the fan’s paper structure was more stable, and its surface recovered some of its past glitter (fig. 5 & 6).

Figure 5. Details of the torn area after treatment.

Figure 6. The “Gold Fan” after treatment.

Rehousing objects from the David Wojnarowicz Papers MSS.092

Organizing objects crowded in a box can give conservators headaches. When I opened “box 139”, I did not know how many objects were there. It was only after taking a documenting photograph, I realized that 28 objects were crammed into one archival box (fig. 7). They are made of various materials, including metal, plastic, fabric, stone, and glass. These random things were collected by American artist David Wojnarowicz (1954–1992). Some were used as props for his photographs. For example, I noticed that a clock face, “object 092.2.0492”, with Roman numbers might be featured in his 1988 photo Untitled (Time/Money) in the Ant Series (fig. 8).

My mission is to identify the plastic objects and separate them from the rest of the objects. Apart from visual observation, I used Fourier-transform infrared spectroscopy (FTIR) to analyze materials that are suspected to be plastic. This analysis can be used as a non-destructive method. The object’s material of interest could be clamped down against the analysis window on the stage to gain data (fig. 9). Yet not all objects could be fitted onto the stage. Because the machine was intended for industrial use, where samples are usually in powder (such as drugs), the space between the stage and the built-in clamp is limited. The analysis also requires that the surface of the object be pressed against the window on the stage. The pressure can also leave tiny impression marks on some objects due to the clamping. So while the analysis may be non-destructive, it might damage the object.

Though identifying plastics with FTIR was fun, the most interesting part for me was driving a polyester encapsulation system with an ultrasonic generator and motor control. The instrument allowed me to create 35 small Mylar pockets custom-made for the objects. “Object 092.2.0504” consists of small charms (34 metal pendants and 1 feather). Before rehousing, they were stuffed in a small bag made of bubble wrap and brown pressure-sensitive tapes. After rehousing, each charm was snuggly fitted in its pocket (fig. 10). A visitor can easily see both sides of the charms by handling the Mylar sleeves.

Figure 7. Objects from the David Wojnarowicz Papers.

Figure 8. David Wojnarowicz. 1988. Untitled (Time + Money). Photographs. Gelatin silver print on paper.

Figure 9. FTIR analysis of a scarecrow candy container manufactured by the E. Rosen Company at Rosbro Plastics in the 1950s. The cardboard was added to support bigger objects on the stage.

Figure 10. Charms rehoused in Mylar pockets.

Conservation of Balinese Shadow Puppets in the Mabou Mines Archive MSS 133.

I first knew about the project of the shadow puppets from my supervisor Jessica on September 23rd, 2022. I thought it would be another rehousing project. I did not know that I would study, research, and work on the puppets till the last day of my internship. The project included research, artist interviews, treatment, and rehousing.

The 40 shadow puppets (133.2.0023 through 133.2.0053) were mostly made for MahabharANTa, written by Lee Breuer and performed in 1992 in the United States. The story is a battle between the animals and insects on the White House lawn. The puppets are flat shapes attached to wooden and bamboo handles. 6 puppets were made of paper materials, and the rest were made of painted rawhide. Balinese shadow puppet master (dalang in Balinese) I Wayan Wija made all the rawhide puppets in Bali. The puppets have fragile paints that needed consolidation. They also needed rehousing because they were originally sandwiched in flimsy paper folders and piled in two boxes.

If you are interested to learn more about his project, a recording of my presentation on the project is available through this link. Here, I want to tell you some things that are not in the treatment reports or my presentation.

An episode before everything began was taking the documentation photos of the puppets, some of which measure 26 to 28 inches long, and some have multiple moveable arms, jaws, and even antennae. Photographing colorful objects could be hard for the background color must be right. I first opted for black, the default color of the background paper already set up in the photo room. I soon realized that many puppets have black parts and all of them have dark outlines, which happily blended in with the black background. Then I tried neutral grey, a color that conservators love. The issue was that a similar grey was used on the puppets. The grey areas can be mistaken for hollow places (fig. 11). Finally, I decided to use white as my background. There was no white background paper in the photo room. Fortunately, there are plenty of white things in a book and paper conservation lab. I used a large piece of Artcare foam core as my white background (fig. 12). I regretted that I did not try different colors against just one puppet at the beginning, but caused extra handling of all puppets. Bits of paint did come off when I moved puppets around. This was a lesson learned hard.

Figure 11. Before treatment photo of the “chariot” shadow puppet against neutral grey.

Figure 12. Before treatment photo of the “chariot” shadow puppet against white.

Though I started on the project in 2022, I did not treat the rawhide puppets until 2023. Jessica and I did research into the puppets because the finding aid provided inadequate information, missing the artist and date, and whether the paper and rawhide puppets were made for the same performance. So in 2022, I treated and rehoused the paper puppets while learning about Balinese shadow puppets. Jessica and I did archival research in the Mabou Mines archives, and we found that the puppets were all made for the same performance. Two names came up as the designers of the puppets, Larry Reed and I Wayan Wija. We contact Larry Reed who told us that I Wayan Wija made all the puppets. Pak Wija lives in Bali. Our first few emails ended with no responses. When we were thinking that we would never find him, I found, on the website of the Smithsonian National Museum of Asian Art, an article on Balinese shadow puppet theater by Professor Lisa Gold. She met with Pak Wija and featured him in her article. I emailed her and she provided me with Pak Wija’s contact information. In February, Jessica and I interviewed Pak Wija on Whatsapp.

While the research slowed down the progress, we were grateful that we did not skip it. We learned that the Balinese puppets have sacred entities beyond their physical materials. Balinese puppets were alive in performances, needed to be fed and paid respect, and have the healing power to help people in return.

As conservators, we had limited power beyond taking care of the physical materials; Not a Balinese shadow master, or dalang, I could not take care of the spiritual parts of these puppets that I could not see or touch. According to Balinese traditions, untrained hands were not even allowed to handle sacred puppets. But Jessica and I were proud of our work. I think what we tried to do was to restore the connection between objects and people, giving back the puppets their identities and meanings. I think getting to know them is a starting point for paying the puppets the respect that is overdue so that others can do better in the future. The bond between the puppets and the people would have been lost in time and the dark storage rooms if we did not bring the puppets to Conservation.

The greatest challenge was the consolidation. To stabilize the paints, I fed an isinglass solution into detached paints to stick them back down and to hold tiny flaked paint pieces together. I chose to treat the “chariot” puppet as a trial. It took me a month to finish it. At that time, I had less than 5 months left and 29 puppets to treat and rehouse. Plus, the old stock of isinglass was running out, and I had to extract a new batch to carry on.

So finally I told Jessica, “I don’t think I can treat all the puppets.”

But the puppets might not have the chance to be treated again with enough space, time, and budget. Jessica and my colleagues said I should give it a try. The whole book and paper lab helped in making the new batch of isinglass. Jessica and I agreed that I would treat the most unstable ones as our priority. So that even if I could not treat every single puppet, the ones left would be relatively stable.

I used a Leica microscope to guide the consolidation. Examining the parts that need treatment under powerful magnification allows me to grasp the microstructures of unstable paints and find out a strategy for approaching each situation. Some look like colorful tents, volcanoes, cliffs, and archipelagoes. I found myself diminishing in size, taking a walk in these landscapes. Strangely, with the pressing deadlines, I did not feel like a desperate traveler in a hurry to get to a destination, but more like an explorer on a joyful journey.

When the final month approached, Jessica and I decided to rehouse all puppets and finish their reports before I carry out more treatment. I cut archival blue boards and cut them into the sizes of the boxes. And I attached soft Volara foam blocks as bumpers to hold the puppets in place. And Ethafoam blocks were added to the board so trays could be stacked in a box without pressing on the puppets.

Before we wrap up, Jessica and I met with Weatherly Stephan (Head of Archival Collections management) and Nicholas Martin (Curator for the Arts and Humanities) to share my research findings so that information regarding the maker, date, and correct names of the puppets can be incorporated into the finding aid. For the housing information to be updated and to facilitate clarifying “what went where”, I created a Google document with an illustrated rehousing scheme for reference. Jessica will also keep the research information, including the artists’ contacts, for future reference.

I ended with all the puppets rehoused with their own reports. Of the 37 treated puppets, 30 were consolidated. There are 3 puppets left to treat, but the amount of work required should be minimum.

Ending

I am grateful for working with so many kind and professional people during the past months. I want to give my special thanks to my supervisor Jessica Pace. Jessica helped me better understand the priorities of different tasks. This project is in debt to her patient guidance, communication, and foresight. You can also find out more about the people at NYU Libraries through the staff directory.

I want to thank any patient Tumblr reader who read thus far. If you are eager for getting into Conservation, please find out more at the Emerging Conservation Professionals Network. You are also welcome to contact me via email [email protected]. I am happy to talk about my experience and projects, or just discuss random nerdy things in Conservation.

14 notes

·

View notes

Text

Russia used Zircon hypersonic missile to attack Kiev

Fernando Valduga

Ukrainian analysts say there is clear forensic evidence suggesting that during the missile attack on February 7, 2024, Russian forces used a 3M22 Zircon missile to hit a target in Ukraine's capital, Kiev.

The Kiev Institute of Forensic Expertise Scientific Research confirmed the use of a 3M22 Zircon hypersonic missile during the missile attack from Russia on the capital of Ukraine, based on photos of the wreckage found in Kiev, indicating that this was probably the first operational firing of the zircon hypersonic cruise missile in sea-to-ground mode.

Oleksandr Ruvin, Director of the Institute of Scientific Research of Forensic Expertise in Kiev, said: "According to preliminary information, there is in fact evidence of the use of a 3M22 Zircon missile. This is evidenced by the markings on parts and debris, identification of components and parts and characteristics of a relevant type of weapon".

youtube

Experts said that in Russian missiles there are parts that can be used in several types at the same time, but others are used only for specific models. In this case, specific elements of the 3M22 Zircon missile were found. Specific markings contain parts and fragments of the jet engine and control surfaces.

Other markings on the missile wreckage indicate the date of production of its components - end of 2023-2024. This means that the missile was recently assembled.

Experts note that microelectronics is poorly preserved and is almost impossible to analyze due to physical damage.

Currently, the Institute is taking measures to determine the composition of the metal from fragments of the missile body and thermal insulation materials.

Zircon is a hypersonic cruise missile developed by the Association of Scientific Production of Machine Construction (NPO Mashinostroyeniya). It uses a solid thruster and a SCRAMJET engine, with a maximum range of 1,000 km and a warhead weighing approximately 300 kg. Zircon's cruising speed is Mach 8 at an altitude of 30 to 35 km. Guidance regarding terrestrial targets is probably achieved through GNSS and INS positioning systems.

Tags: weaponsMilitary AviationhypersonicZirconWar Zones - Russia/Ukraine

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

Canada commits $46 million to support Ukraine's future F-16 fleet

15/02/2024 - 09:30

INCIDENTS

USMC F-35C landing gear incident inside the hangar

15/02/2024 - 08:52

BRAZIL

Air Force Commander talks about a new batch of Gripen or F-16 fighters for FAB? We explain

14/02/2024 - 21:16

EMBRAER

Embraer takes KC-390 to Nigeria for demonstration flights

14/02/2024 - 19:25

MILITARY

IMAGES: Czech Air Force performs first Gripen REVO with Airbus A330 MRTT

14/02/2024 - 18:21

MILITARY

Iran simulates attack with ballistic missiles against Israeli F-35 hangars in office on National Guard Day

3 notes

·

View notes

Text

High Purity Pipefitting Training: Ensuring Precision and Safety

High purity pipefitting is an essential discipline in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and food and beverage processing. These industries require ultra-clean piping systems to transport gases, liquids, and chemicals without contamination. To maintain the integrity of these systems, professionals must undergo specialized high purity pipefitting training. This article explores the importance of such training, the skills it imparts, and its benefits to individuals and organizations.

Understanding High Purity Piping Systems

High purity piping systems differ significantly from conventional plumbing or industrial piping. They must meet strict standards for cleanliness, material integrity, and contamination control. These systems often utilize stainless steel, PFA, PTFE, or other specialized materials that prevent corrosion and leaching.

Contaminants such as particulates, microorganisms, and chemical residues can compromise product quality, lead to equipment failures, and even pose health risks. Therefore, professionals working in these environments must have an in-depth understanding of:

Material selection and compatibility

Welding and joining techniques (orbital welding, tube bending, etc.)

Proper handling and installation of high purity components

Cleaning, passivation, and sterilization techniques

Compliance with industry standards such as ASME BPE, ISO, and cGMP

The Need for Specialized Training

Given the stringent requirements in high purity environments, on-the-job training alone is insufficient. Formal high purity pipefitting training is essential to:

Ensure Compliance with Industry Standards Regulatory agencies such as the FDA, EPA, and ISO require strict adherence to quality and safety standards. Trained professionals understand how to comply with these regulations, ensuring that piping systems meet all necessary certifications.

Improve Installation Accuracy and Efficiency Mistakes in high purity piping can lead to costly failures, contamination, or system downtime. Training equips professionals with precision skills, reducing errors and improving efficiency in installation and maintenance.

Enhance Safety and Risk Mitigation Working with hazardous chemicals and gases requires expertise in safety protocols. Training covers hazard identification, proper handling procedures, and emergency response, reducing the risk of accidents and exposure.

Master Advanced Techniques High purity pipefitting involves advanced orbital welding techniques, which requires specialized training and certification. Proper training ensures that professionals can execute these tasks flawlessly, maintaining system integrity.

Increase Employability and Career Growth The demand for skilled high purity pipefitters is rising across industries. Obtaining formal training and certifications enhances job prospects, opening doors to higher-paying positions and career advancement opportunities.

Key Components of High Purity Pipefitting Training

A comprehensive high purity pipefitting training program typically covers:

Material Science: Understanding properties of stainless steel, plastics, and other high purity materials.

Fabrication Techniques: Training in cutting, bending, welding, and joining high purity pipes.

Orbital Welding Training: Hands-on practice with orbital welding machines to achieve precise, repeatable welds.

Cleanroom Protocols: Training on contamination control, proper gowning, and cleanroom behavior.

Testing and Inspection: Leak detection, pressure testing, and visual inspections to ensure system integrity.

Regulatory Compliance: Familiarization with ASME BPE, FDA, ISO, and cGMP requirements.

Benefits for Employers and Organizations

Investing in high purity pipefitting training benefits organizations by:

Reducing Equipment Failures and Downtime: Properly trained personnel minimize installation errors, reducing maintenance costs and downtime.

Ensuring Product Quality and Safety: Contamination-free piping systems prevent product recalls and regulatory violations.

Enhancing Operational Efficiency: Skilled workers complete projects faster and more accurately, increasing overall productivity.

Meeting Industry Regulations: Compliance with stringent standards avoids legal penalties and enhances the company’s reputation.

Conclusion

High purity pipefitting training is crucial for maintaining contamination-free environments in critical industries. It ensures compliance with industry regulations, enhances safety, improves efficiency, and boosts career opportunities. Whether you are an aspiring professional or an employer looking to enhance workforce competency, investing in high purity pipefitting training is a strategic move that ensures long-term success.

0 notes

Text

Next-Gen Interior Illumination: Laser-Enhanced Rocker Switch

The technology of interior illumination control has seen a significant advancement with the laser rocker switch. Combining traditional rocker switch functionality with laser technology offers enhanced durability, visibility, and aesthetic appeal. These switches are suitable for various applications, from automotive interiors to marine environments and industrial control panels.

Key Features and Benefits

Enhanced Visibility: Laser etching allows for highly visible and customizable symbols and labels on the switch. This ensures clear identification of the switch function, even in low-light conditions.

Durability: Laser-etched markings are resistant to wear and tear, ensuring longevity compared to traditional printing methods. The switches are designed to withstand harsh conditions, making them suitable for demanding applications.

Customization: Laser technology enables the creation of intricate and precise designs, allowing for a high degree of customization. Manufacturers can easily incorporate specific symbols, logos, or text to meet unique requirements.

Waterproof: Many laser rocker switches are designed to be waterproof, making them ideal for marine and outdoor applications.

High Capacity Switching: Some rocker switches offer high-capacity switching solutions for reliable power control.

Types of Rocker Switches

Standard Rocker Switches: Provide basic on/off functionality.

Rocker Switches with Reset Function: Include a reset feature for added control.

Remote Reset Rocker Switches: Feature a delay-off function and can be controlled remotely.

Miniature Rocker Switches: Designed for high-capacity switching in a compact size.

Power Rocker Switches: Prioritize safety in power control applications.

Applications

Automotive: Interior lighting control, accessory switches.

Marine: Control panels for boats and other marine vessels.

Industrial: Control panels for machinery and equipment.

Consumer Electronics: Power switches for various electronic devices.

Manufacturing and Technology

Switch Design: Engineers design the switch to meet specific functional and aesthetic requirements.

Material Selection: High-quality materials are chosen to ensure durability and longevity.

Laser Etching: Laser technology is used to create precise markings and symbols on the switch surface.

Assembly: The switch components are assembled to create a functional unit.

Testing: Rigorous testing is conducted to ensure the switch meets quality and performance standards.

Future Trends

Integration with Smart Systems: Incorporation of smart technology for remote control and monitoring.

Improved Customization: Enhanced laser etching techniques for even more intricate designs.

Enhanced Durability: Use of advanced materials to further extend switch lifespan.

Miniaturization: Development of smaller, more compact switches for space-constrained applications.

In summary, the laser rocker switch represents a significant leap forward in switch technology, offering superior visibility, durability, and customization options compared to traditional alternatives. Its diverse applications across automotive, marine, industrial, and consumer electronics sectors underscore its versatility and value. With ongoing advancements in smart integration, enhanced durability, and miniaturization, the future of the laser rocker switch looks promising, solidifying its position as a key component in modern control systems.

#rocker switch#laser rocker switch#off road accessories las vegas#off road parts and accessories#motorsports

0 notes

Text

Mastering Phlebotomy Skills: Essential Techniques Every Technician Should Know

Mastering phlebotomy Skills: Essential Techniques Every Technician should No

Phlebotomy is a vital practice in the healthcare field, playing a key role in patient diagnosis and treatment. As a phlebotomy technician, mastering essential techniques can considerably influence patient safety, comfort, and overall care. In this extensive article, we explore crucial phlebotomy skills every technician should know, along wiht tips and real-life case studies to enhance your practice. Let’s dive in!

Understanding the Importance of Phlebotomy

Phlebotomy involves the process of drawing blood for tests, transfusions, research, or donation.Effective phlebotomy is essential for accurate test results, making it an indispensable skill across various healthcare settings. Here are some key reasons why mastering phlebotomy skills is critical:

Accurate Diagnosis: Blood tests are often pivotal in diagnosing medical conditions.

Patient Trust: Proper techniques reduce discomfort and build patient rapport.

Infection Control: Adequate skills ensure minimal risk of infection during blood draws.

Essential Phlebotomy Techniques Every Technician Should Know

To excel in phlebotomy, it’s crucial to be familiar with various techniques. Below are some of the fundamental skills required:

1. Proper Venipuncture Techniques

Venipuncture is the process of puncturing a vein to collect blood. Here’s how to perform it correctly:

Identify the appropriate Vein: Common veins include the median cubital vein, cephalic vein, and basilic vein.

Position the Patient: Ensure the patient is seated comfortably with their arm extended.

Clean the Site: Use an antiseptic wipe to clean the area and allow it to dry.

Insert the Needle: Hold the needle at a 15-30 degree angle and insert it into the vein smoothly.

Collect the blood: Use the vacutainer system to collect required blood samples.

2. Patient Identification

Before any procedure,it’s crucial to confirm the patient’s identity. Follow these steps:

Ask for the patient’s full name, date of birth, and any ID if possible.

Verify the information against the laboratory requisition form.

Always double-check before proceeding with the blood draw.

3. hemolysis Prevention Techniques

Hemolysis can invalidate blood test results. Here’s how to avoid it:

Handle blood containers gently to prevent rupture of red blood cells.

Ensure proper mixing of anticoagulant tubes by gentle inversion, not shaking.

use the correct gauge needles to minimize damage during the draw.

4. Safety and Infection Control Practices

Adopting safety measures and infection control practices is vital. Follow these guidelines:

Always wear gloves and use appropriate personal protective equipment (PPE).

Dispose of all needles and biohazard materials properly.

Maintain cleanliness in the work area to prevent contamination.

Benefits of Mastering Phlebotomy Skills

Mastering these phlebotomy skills brings numerous benefits to technicians, patients, and healthcare systems alike:

Benefit

Description

Enhanced Patient Safety

Reduce the risk of complications and improve overall patient outcomes.

Improved Efficiency

Streamline procedures, leading to better workflow and productivity.

Stronger Patient Relationships

Build trust and rapport by demonstrating professionalism and care.

Practical Tips for Aspiring Phlebotomy Technicians

Here are several practical tips to enhance your phlebotomy skills:

Practice,Practice,Practice: Use simulation and shadow experienced technicians to hone your skills.

seek Feedback: regularly ask for feedback from peers and supervisors to identify areas for improvement.

Stay Updated: Attend workshops and courses to learn about the latest techniques and regulations in phlebotomy.

Case Studies: Real-Life Phlebotomy Experiences

Let’s explore a few case studies to understand the impact of effective phlebotomy practices:

Case Study 1: Reducing Patient Anxiety

A clinic implemented an initiative to train technicians in patient communication.Technicians learned to explain the procedure, leading to a 30% decrease in patient anxiety levels, shown through follow-up surveys.

Case Study 2: Infection Control Improvement

After intensive training on infection control, a hospital reported a significant reduction in post-phlebotomy infections from 2% to 0.5% within six months, citing improved technique adherence.

Conclusion

Mastering phlebotomy skills is an ongoing process crucial for every technician in the healthcare field. by understanding essential techniques, adopting best practices, and learning from real-life experiences, you can enhance your competency, ensure patient safety, and improve care quality. Remember, your skills directly impact patient outcomes—strive for excellence!

youtube

https://phlebotomyclassesonline.net/mastering-phlebotomy-skills-essential-techniques-every-technician-should-know/

0 notes

Text

Ensuring Safety with PMI Material Identification and Positive Material Inspection in Pune

Positive Material Identification (PMI) Services by Integrated NDE

Positive Material Identification (PMI) is a critical aspect of quality control and assurance in various industries, ensuring that the materials used in manufacturing and construction meet specified requirements. Integrated NDE offers comprehensive PMI services that cater to the stringent demands of industries such as oil and gas, petrochemicals, power generation, pharmaceuticals, and more.

The Importance of Positive Material Identification

In industrial applications, using the correct material is paramount to maintaining safety, performance, and regulatory compliance. PMI helps prevent material mix-ups, which can lead to catastrophic failures, costly repairs, and safety hazards. By implementing PMI, companies can verify the material composition and ensure that they are using the appropriate alloys for their specific applications.

Advanced Techniques in PMI

Integrated NDE utilizes state-of-the-art techniques and equipment to provide accurate PMI results. Among these techniques are X-ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES), which are highly effective for material identification.

XRF PMI

XRF PMI is a non-destructive testing method that determines the elemental composition of materials. It is particularly useful for analyzing metals and alloys, offering quick and accurate results. XRF PMI is ideal for identifying various elements such as chromium, nickel, molybdenum, and other alloying elements.

OES PMI

OES PMI involves using an optical emission spectrometer to analyze the light emitted by a sample when it is excited by an energy source. This technique is highly sensitive and can detect low levels of elements, making it suitable for detailed chemical analysis and positive material inspection.

Comprehensive PMI Services

Integrated NDE provides a wide range of PMI services tailored to meet the needs of different industries. These services include:

PMI Material Identification

Our PMI material identification services ensure that the materials used in your processes are correctly identified and compliant with industry standards. We help you verify the composition of metals and alloys, providing detailed reports on their chemical makeup.

Positive Material Inspection

Our positive material inspection services are designed to prevent material mix-ups and ensure the integrity of your products. By conducting thorough inspections, we help you maintain quality control and avoid potential issues related to material discrepancies.

Positive Material Identification for Carbon Steel

Carbon steel is widely used in various industries due to its strength and durability. Our PMI services for carbon steel ensure that the material meets the required specifications, preventing failures and ensuring optimal performance.

State-of-the-Art Equipment

Integrated NDE uses advanced PMI equipment to deliver accurate and reliable results. Our tools are calibrated and maintained to the highest standards, ensuring precise measurements and consistent performance. The use of cutting-edge technology allows us to provide quick and efficient PMI inspections, minimizing downtime and maximizing productivity.

Benefits of PMI Services

Implementing PMI services offers several advantages, including:

Safety Compliance: Ensuring that materials meet safety standards and regulations.

Quality Assurance: Verifying the composition and quality of materials to maintain product integrity.

Cost Savings: Preventing costly repairs and downtime caused by material failures.

Regulatory Compliance: Meeting industry-specific requirements and avoiding penalties.

PMI Chemical Analysis

PMI chemical analysis is a crucial part of our services, providing detailed information about the elemental composition of materials. This analysis helps in identifying potential issues and ensuring that the materials used in your processes are suitable for their intended applications.

Identification of PMI

Our identification of PMI services includes detailed reporting and documentation, providing you with the necessary information to make informed decisions about material usage. We offer comprehensive reports that include elemental analysis, material composition, and compliance verification.

Industries We Serve

Integrated NDE serves a wide range of industries, including:

Oil and Gas: Ensuring the integrity of pipelines, refineries, and other critical infrastructure.

Petrochemicals: Verifying the composition of materials used in chemical processing plants.

Power Generation: Ensuring the reliability and safety of materials used in power plants.

Pharmaceuticals: Maintaining the quality and purity of materials used in drug manufacturing.

Why Choose Integrated NDE?

Integrated NDE is a trusted provider of PMI services, offering expert knowledge and advanced technology to meet your material identification needs. Our team of experienced professionals is dedicated to delivering accurate and reliable results, helping you maintain quality control and ensure the safety of your operations.

For more information about our positive material identification services and how we can assist you, visit our Positive Material Identification page.

#positive material identification#pmi#pmi positive material identification#xrf pmi#pmi inspection#material identification#positive material#positive material inspection#pmi material identification#pmi material#positive materials identification#pmi material inspection#positive material identification for carbon steel#positive material identification equipment#identification of pmi#pmi chemical analysis#pmis#pmi identification#pmi material analysis#positive material ide

0 notes

Photo

Operation Compass

Operation Compass (9 Dec 1940 to 7 Feb 1941) was an Allied offensive in North Africa, which pushed Italian forces out of Egypt and then Cyrenaica (Eastern Libya). The Allied Western Desert Force, led by Lieutenant-General Richard O'Connor (1889-1981), inflicted numerous heavy defeats on the Italian army commanded by Marshal Rodolfo Graziani (1882-1955).

The Italian army was poorly trained and equipped with their troops often so eager to surrender that the Allies captured an incredible 138,000 prisoners. Operation Compass thus gained the Allies control of the Western Desert. The Axis powers would fight back, but Compass was a much-needed victory for the Allies after enduring nothing but defeats so far in the war.

The Importance of North Africa

After WWII broke out in Europe in September 1939, the Allies, then principally British and Commonwealth forces, were particularly keen to protect the Suez Canal from falling into the control of the Axis powers of Germany and Italy. The loss of the canal would have effectively cut the British Empire in half. North Africa was also strategically important to both sides' wish to control and protect vital Mediterranean shipping routes. The island of Malta was also crucial in this role and holding the island fortress (then in British hands) was another reason to control potential airfields in the North African desert. Finally, North Africa was the only place where Britain could fight a land war against Germany and Italy and so hopefully gain much-needed victories that would encourage the British people after the debacle of the Dunkirk Evacuation and the horrors of the London Blitz. For all of the above reasons, a series of desert battles ensued, which are collectively known as the Western Desert Campaigns (June 1940 to January 1943).

The desert war involved battles that could range over many miles as, relative to other theatres of the war, territorial gains became much less important than inflicting material damage on the enemy. Other peculiarities of desert warfare included the general absence of any civilian involvement and the fact that both sides frequently used captured equipment, a phenomenon that often made positive identification of exactly who was who difficult. Allied and Axis air forces could only play a limited role in mobile tank battles and so were largely reduced to targeting supply lines or fixed defensive positions.

Continue reading...

13 notes

·

View notes

Text

Effortless Office Relocation Services for a Smooth Transition

Relocating an office can be a daunting task, requiring meticulous planning, coordination, and execution to ensure a seamless transition. Whether you are moving a small office or an entire corporate setup, professional office relocation services can simplify the process, minimize downtime, and ensure business continuity.

Why Choose Professional Office Relocation Services?

Expert Planning and Management Professional relocation teams bring expertise to plan every aspect of your move. From packing office equipment to setting up your new workspace, they create a step-by-step plan tailored to your needs.

Minimized Downtime Relocation experts understand the importance of minimizing disruption to your business. They work efficiently to ensure that your operations resume in the new location without delays.

Safety and Security Office equipment, documents, and furniture are valuable assets. Professional movers use specialized packing materials and techniques to safeguard these items during transit, reducing the risk of damage.

Cost-Effective Solutions Hiring an office relocation service may seem like an additional expense, but it can save you money in the long run. Avoiding damage, loss, or delays ensures a smooth and cost-efficient move.

Services Offered by Office Relocation Experts

Pre-Move Consultation Relocation services begin with a consultation to understand your specific requirements. This includes analyzing the size of the move, inventory, and deadlines.

Packing and Labeling Professional movers handle packing with precision, using high-quality materials to protect your assets. Clear labeling ensures easy identification and organized unpacking.

Transport and Logistics Relocation companies offer well-maintained vehicles and trained drivers to transport your belongings safely. They handle logistics, ensuring timely delivery to the new location.

Unpacking and Setup Upon reaching your destination, the team unpacks, arranges furniture, and sets up workstations, helping your team get back to work quickly.

IT Infrastructure Handling Experts manage the disconnection, safe transport, and reconnection of computers, servers, and other IT equipment, ensuring seamless integration in the new office.

Tips for a Successful Office Relocation

Plan Early: Start preparations well in advance to avoid last-minute rushes.

Communicate with Employees: Keep your team informed about the relocation timeline and their roles.

Hire Professionals: Choose a reliable office relocation service with positive reviews and experience.

Back-Up Data: Ensure all critical data is backed up before the move to prevent losses.

Conclusion

Moving your workplace has never been more straightforward! Sri Balaji Packers and Movers expert office relocation solutions guarantee a hassle-free change with least disturbance to your company operations. From careful furniture and equipment packing to safe transportation and quick unpacking at your new place, we take care of every element. Our staff is quite skilled in carefully managing IT systems, delicate papers, and heavy machines. We are one of the best Packers and Movers in Sholinganallur, first concern is prompt delivery, hence we provide tailored solutions to satisfy your particular needs. Trust us to make your workplace move seamless and stress-free whether you are moving locally or across the nation. Get in touch right now to create a customized moving schedule!

Visit Our Website : https://sribalajipackersmovers.com/sholinganallur-chennai.html

0 notes

Text

Mastering Phlebotomy: Essential Techniques and Best Practices for Effective Blood Collection

# Mastering Phlebotomy: Essential Techniques and best Practices for Effective Blood Collection

**Meta title:** Mastering Phlebotomy: Effective Blood Collection Techniques and Best Practices **Meta Description:** Discover essential phlebotomy techniques, best practices, and tips for effective blood collection. Learn more about teh benefits and real-world applications of phlebotomy.

—

In the medical field, phlebotomy plays a crucial role in diagnosis and treatment. Mastering blood collection techniques is essential for healthcare professionals, ensuring they can perform procedures safely and effectively. this complete guide will cover essential phlebotomy techniques, best practices, and tips to enhance your skills and confidence.

## what is Phlebotomy?

Phlebotomy is the process of collecting blood samples from patients for various medical purposes, including diagnostic tests, blood donations, and treatment. Phlebotomists are trained professionals equipped with the knowledge and skills to perform this essential task while minimizing discomfort and ensuring the safety of patients.

## Importance of Effective Blood Collection

effective blood collection techniques are vital to ensure accurate test results, improve patient experiences, and maintain safety standards. Proper phlebotomy techniques reduce the risk of complications,such as hematomas or infections,and make the process more comfortable for patients.

### key Benefits of Mastering Phlebotomy Techniques:

1. **Improved Accuracy:** Effective blood collection techniques ensure high-quality samples, leading to reliable test results. 2. **Enhanced Safety:** proper methods reduce the risk of complications for both patients and healthcare providers. 3. **Patient Satisfaction:** A skilled phlebotomist minimizes discomfort and anxiety, leading to a more positive experience. 4. **Professional Growth:** Mastering phlebotomy can open doors to advanced medical positions and specializations.

## Essential Phlebotomy Techniques

To excel in phlebotomy,it’s essential to understand the fundamental techniques involved in effective blood collection. Below are some critical techniques and best practices to keep in mind.

### 1. Understanding Venipuncture

**Definition:** Venipuncture is the process of puncturing a vein with a needle to collect blood.

#### Steps for a Prosperous Venipuncture:

– **Planning:** Gather all necessary supplies (needles, tubes, alcohol wipes, bandages) and ensure a clean workspace. – **Patient Identification:** Confirm the patient’s identity using two identifiers, such as name and date of birth. – **Positioning:** ensure the patient is comfortably seated or lying down with their arm extended. – **Site Selection:** Identify a suitable vein (typically the median cubital vein) by palpating the area. – **Sanitization:** Clean the puncture site with an alcohol pad in a circular motion and allow it to dry. – **Needle Insertion:** Hold the needle at a 15-30 degree angle and insert it swiftly and smoothly into the vein. – **Blood Collection:** Attach the blood collection tube while the needle is still in the vein. Fill the tube to the appropriate level. – **Post-Collection Care:** Withdraw the needle, apply pressure to the site, and place a bandage after bleeding stops.

### 2. The Art of Capillary Collection

**Definition:** capillary collection involves obtaining blood from a fingertip or heel, commonly used for infants or when veins are inaccessible.

#### Key Steps:

– **Preparation:** Ensure all materials (lancets, microcontainers) are ready. – **Site Selection:** Choose the appropriate site (usually the side of the fingertip or heel for infants) and clean with an alcohol wipe. – **Incision:** Use a sterile lancet to make a swift puncture. – **Collection:** Allow a drop of blood to form and collect it with a microcontainer. Avoid squeezing the site excessively.

### 3. Proper Use of Equipment

Understanding and using the right equipment is crucial in phlebotomy:

– **Needles:** Choose the right gauge; larger gauges (e.g., 21) for blood collection, smaller gauges for fragile veins. - **Collection Tubes:** Use color-coded tubes based on the additive requirements for specific tests. – **Tourniquets:** Apply to promote venous filling, but do not leave it on for more than one minute.

### 4. Managing Patient Anxiety

patient anxiety can affect blood collection outcomes. here are some strategies to help ease fears:

– **Establish Rapport:** Take the time to talk and connect with the patient, explaining the procedure. – **Use Distractions:** Engage patients in conversation or encourage them to focus on their breathing. – **Provide Comfort:** Offer a warm blanket or a soothing voice to alleviate anxiety.

## Practical Tips for Effective Blood Collection

1. **Maintain Sterile Technique:** Always use new and sterile equipment to prevent infections. 2. **Correct order of Draw:** Follow the order of draw for collection tubes to avoid contamination. 3. ��**Assess Patient Conditions:** Be aware of patient conditions (obesity, medications) that may affect blood collection. 4. **Document Everything:** Maintain accurate records of the procedure and any complications.

## Common Challenges in Phlebotomy

Even experienced phlebotomists may face several challenges during blood collection.

### Table 1: Common Challenges and Solutions in Phlebotomy

| **Challenge** | **Solution** | |——————————-|————————————————–| | Difficult Venous Access | Use ultrasound guidance or select choice sites | | Patient Movement | Encourage relaxation and proper positioning | | Blood Contamination | Follow sterile techniques and proper tube handling | | Hematoma Formation | Apply pressure for an adequate time after withdrawal |

## Case Studies: Real-World Examples

### Case Study 1: Overcoming Difficult Collections

A phlebotomist faced challenges when trying to collect blood from a patient with small veins. By employing a warming technique and palpation skills, they successfully identified a suitable vein, ultimately leading to a successful blood draw.

### Case Study 2: Handling Patient Anxiety

in another instance, a nervous patient was hesitant about the blood draw. The phlebotomist took time to explain the process, which eased the patient’s anxiety and enabled successful collection.

## First-Hand Experience: A Phlebotomist’s Journey

“As a phlebotomist, every day presents new challenges and learning opportunities. I remember my first blood draw—my hands shook, and I was worried about hurting the patient. However, after numerous practice sessions and mentorship, I gained confidence. The key to success is understanding the techniques, communicating well with patients, and continually learning from each experience.” – Jane Doe, Certified Phlebotomist

## Conclusion

Mastering phlebotomy is not only about learning techniques; it’s about providing quality care and building trust with patients. By following the essential techniques and best practices highlighted in this article, healthcare professionals can enhance their phlebotomy skills, ultimately improving patient outcomes and satisfaction. regular practice, continuous education, and a patient-centered approach will pave the way for success in the field of phlebotomy.

—

By incorporating these strategies into your practice, you will not only enhance your phlebotomy skills but also make a positive impact in the healthcare field. Happy drawing!

youtube

https://phlebotomytechnicianprogram.org/mastering-phlebotomy-essential-techniques-and-best-practices-for-effective-blood-collection/

0 notes

Text

Whatever You Need to Know About the National Phlebotomy Exam: A Comprehensive Guide for Success

Everything you Need to Know About the National Phlebotomy Exam: A Thorough Guide for success

Are you ready to take the next step in your healthcare career? The National Phlebotomy Exam is a crucial milestone for aspiring phlebotomists. This comprehensive guide will equip you with everything you need to know about the exam, from readiness strategies to benefits and practical tips for success.

What is the National Phlebotomy Exam?

The National Phlebotomy Exam is a standardized test designed to assess the knowledge and skills necessary for phlebotomists to perform their duties effectively. Administered by various certifying bodies, passing this exam is often a requirement for obtaining your certification and securing a job in the healthcare field.

why Take the National Phlebotomy Exam?

Obtaining certification through the National Phlebotomy exam comes with numerous benefits, including:

Increased Job Opportunities: Many employers prefer or require certification for phlebotomists, making this exam essential for career advancement.

Higher Earning Potential: Certified phlebotomists often earn higher wages compared to their non-certified counterparts.

Professional Credibility: Certification demonstrates your knowledge and commitment to the field, enhancing your professional reputation.

Exam Overview

The National Phlebotomy Exam typically covers the following key areas:

Topic

Description

Blood Collection Procedures

Techniques for drawing blood correctly and safely.

Patient Care

Understanding patient needs before, during, and after procedures.

Laboratory Operations

Knowledge of lab safety, standards, and equipment used.

Sample Handling

Best practices for collecting, processing, and transporting samples.

How to Prepare for the National Phlebotomy Exam

Preparation is key to success in your phlebotomy career. Here are some effective strategies to ensure you are ready:

1.Understand the Exam Format

Familiarize yourself with the exam structure, including the number of questions, types of questions (multiple choice, etc.),and the time allowed. This will help you manage your time effectively on test day.

2. Take a Phlebotomy Course

Enroll in a reputable phlebotomy training program. Many of these programs offer preparation for the National Phlebotomy Exam, including hands-on practice and mentorship.

3. Utilize Study Materials

Invest in quality study guides, flashcards, and online resources specifically created for the National Phlebotomy Exam. Here are some recommended resources:

Phlebotomy Certification Exam Study Guide

Online Practice Tests

Phlebotomy Textbooks

4. Join a Study Group

Collaborating with peers can enhance your understanding of the material. Join a study group or find a study partner to share insights and quiz each other.

5. Practice Hands-On Skills

Practice your blood collection and patient interaction skills in a clinical setting. This not only builds your confidence but also prepares you for real-world scenarios.

Tips for Exam Day Success

On exam day, follow these tips to ensure a positive experience:

Get Plenty of Sleep: A good night’s rest before the exam will help you stay focused.

Arrive Early: Plan to arrive at least 30 minutes early to allow time for any unforeseen delays.

Bring Required Materials: Ensure you have all necessary items such as identification and any required documentation.

Stay Calm: Use breathing techniques or positive affirmations to calm any nerves before you begin.

Insights From Phlebotomy Professionals

Hearing from those who have successfully passed the National Phlebotomy Exam can provide motivation and insight. Here’s what some professionals say:

“The preparation was intense but worth it.The exam challenges you, but knowing I coudl make a difference in patients’ lives pushed me through.” – Jane Doe, Certified Phlebotomist

“Studying in a group helped me grasp concepts I initially struggled with.It’s a great way to learn!” – John Smith,Certified Phlebotomist

Conclusion

Preparing for and passing the National Phlebotomy Exam is a crucial step in achieving your career goals as a phlebotomist.With the right preparation, practice, and mindset, you can succeed in earning your certification. Remember, certification not only enhances your resume but also opens doors to greater job opportunities and professional growth.start preparing today to secure your future in this rewarding field!

youtube

https://phlebotomytrainingcenter.net/whatever-you-need-to-know-about-the-national-phlebotomy-exam-a-comprehensive-guide-for-success/

0 notes

Text

Mastering Phlebotomy: Your Complete Guide to NHA Certification Success

Mastering Phlebotomy: Your Complete Guide to NHA Certification Success

Phlebotomy is an essential skill in the healthcare field, playing a crucial role in patient care and diagnostics.If you’re considering becoming a certified phlebotomist, this extensive guide will help you navigate the path toward National Healthcareer Association (NHA) certification success. With practical tips, benefits, insights from industry experts, and case studies, you’ll be well-equipped to master phlebotomy.

What is Phlebotomy?

Phlebotomy involves drawing blood for various medical purposes,including tests,transfusions,donations,or research. Phlebotomists are trained professionals who ensure the safety and comfort of patients while performing blood draws. The NHA certification is an increasingly valuable credential that showcases your expertise in this field.

Why Pursue NHA Certification in Phlebotomy?

Career Advancement: Certification enhances your resume and opens doors for better job opportunities.

Professional Credibility: NHA certification indicates a standard of knowledge and competency that employers value.

Increased Earning Potential: Certified phlebotomists often earn higher wages compared to non-certified counterparts.

Comprehensive Training: NHA certification programs equip you with essential skills and knowledge for success in phlebotomy.

Steps to Achieve NHA Certification

To become NHA certified, follow these crucial steps:

1. Complete a Phlebotomy Program

Enroll in an accredited phlebotomy training program that offers both theoretical knowledge and practical experience.Look for programs that prepare you for the NHA exam.

2. Gain Hands-On Experience

Most certification programs require you to complete a certain number of blood draws. Pursuing internships or volunteer opportunities in a clinical setting can provide valuable experience.

3. Prepare for the NHA Exam

Study the material covered in your program and utilize exam planning resources. Consider joining study groups or forums to discuss challenging topics with peers.

4. Register for the NHA Certification Exam

Visit the NHA website to register for the certification exam. Be sure to review the exam requirements and fees before registration.

5. Take the Exam

On exam day,make sure to arrive early,bring necessary identification,and follow the guidelines set by the NHA. The exam will test your knowledge of blood collection, safety procedures, and patient care.

6. Maintain Your Certification