#pmi material inspection

Explore tagged Tumblr posts

Text

Reliable Positive Material Inspection in Pune | PMI Services & XRF PMI Technology

Positive Material Identification (PMI) is a crucial process in industries where the integrity and composition of materials are of utmost importance. At Integrated NDE Solutions, we specialize in providing comprehensive PMI services in Pune, ensuring that your materials meet the required specifications and standards.

What is Positive Material Identification (PMI)?

Positive Material Identification (PMI) is a non-destructive testing (NDT) technique used to verify the chemical composition of materials, particularly metals. PMI is essential in industries such as oil and gas, aerospace, manufacturing, and construction, where material mix-ups can lead to severe consequences, including safety risks and costly failures.

Our PMI Services in Pune

At Integrated NDE Solutions, we offer a range of PMI services to meet the diverse needs of our clients:

XRF PMI Equipment: We utilize advanced X-Ray Fluorescence (XRF) PMI equipment to provide accurate and reliable material identification. XRF PMI technology allows us to perform on-site inspections quickly, ensuring minimal disruption to your operations.

PMI Inspection: Our PMI inspections are conducted by experienced technicians who are trained to identify the composition of various materials, including alloys, stainless steel, and carbon steel. This is particularly important for industries where precise material identification is critical.

PMI Material Identification: Our PMI material identification services are designed to confirm the exact composition of materials used in your projects. This helps prevent material mix-ups and ensures compliance with industry standards.

Positive Material Identification for Carbon Steel: Carbon steel is widely used in many industries, and its proper identification is crucial. Our PMI services for carbon steel ensure that the correct material is used, preventing potential failures and ensuring the safety and reliability of your structures and products.

PMI Chemical Analysis: Our PMI chemical analysis services provide detailed information about the chemical composition of materials, helping you make informed decisions about material selection and usage.

Positive Material Inspection: Regular positive material inspections are essential for maintaining the integrity of your materials and ensuring they meet the required specifications. Our team conducts thorough inspections to verify the composition of your materials, reducing the risk of costly errors.

Why Choose Integrated NDE Solutions for PMI in Pune?

Expertise: Our team of skilled technicians has extensive experience in PMI material analysis, identification, and inspection. We understand the critical importance of accurate material identification and are committed to delivering reliable results.

Advanced Technology: We use state-of-the-art PMI equipment, including XRF technology, to ensure precise and efficient material identification. Our technology allows us to perform inspections quickly and accurately, minimizing downtime.

Comprehensive Services: Whether you need PMI for a single material or a comprehensive inspection of an entire project, we offer tailored services to meet your specific needs.

Compliance: We ensure that all PMI services comply with industry standards and regulations, giving you peace of mind that your materials meet the necessary requirements.

Conclusion

Positive Material Identification (PMI) is an essential process in ensuring the safety, reliability, and compliance of materials used in various industries. At Integrated NDE Solutions, we are dedicated to providing top-quality PMI services in Pune, using advanced technology and expertise to deliver accurate results. Whether you require PMI for carbon steel, chemical analysis, or regular inspections, our team is here to support your needs. Contact us today to learn more about our PMI services and how we can help you ensure the integrity of your materials.

#positive material identification#pmi#pmi positive material identification#xrf pmi#pmi inspection#material identification#positive material#positive material inspection#pmi material identification#pmi material#positive materials identification#pmi material inspection#positive material identification for carbon steel#positive material identification equipment#identification of pmi#pmi chemical analysis#pmis#pmi identification#pmi material analysis#positive material identification standard

0 notes

Text

Drive with confidence, choose VICC.com's vehicle inspection service

When it comes to your vehicle, safety and reliability are paramount. That's why you need VICC.com's vehicle inspection service. Our team of expert technicians will meticulously inspect your vehicle from top to bottom, ensuring that it meets the highest standards of quality and performance. Visit us:

Drive with confidence, choose VICC.com's vehicle inspection service

#Pre-Shipment Inspection#quality control services#quality inspection service#third party inspection#supplier audit service#factory audit service#China Pre-Shipment Inspection#Container loading inspection#loading inspection service#FAT inspection service#sorting service#lab testing services#chemical analysis services#material lab testing#PMI service#china equipment inspection company#industrial inspection services#excavator inspection service#vehicle inspection service#truck inspection#machinery inspection#equipment inspection#mechanical parts inspection#pipe pre-shipment inspection#generator inspection#steel plate inspection#china inspection company#china best inspection company#china third party inspection

0 notes

Text

DNV GL Approved Elbow

Arvind Pipes Fittings Industries, Came into existence in the year 1982 well known as Arvind Metal Syndicate. The genesis of ARVIND's birth & growth is "ACCEPTING CHALLENGES."

We will serve you for all your piping requirements under one roof such as high quality pipe Fittings, Butt-weld and Socket- weld Fittings, Flanges & End-Connection in Alloy steel, Carbon steel, Stainless Steel, Nickel alloys.

Our quality management system confirm to ISO 9001-2008. and PED certificated by TUV Rheinland.

Due to modern manufacturing process, equipments and inspection tools practised by us in producing the products and putting them through strict Quality Control Procedure, Our products meet the requirements of International and National standards.

Our product undergo various strict inspection & testing stages at the corporate in-house facilities, such as Chemical, Mechanical, Hydrostatic, Corrosion test, PMI Test, Non-Destructive test etc. before they are despatched to the customers. This assures high value quality of products.

As a testimony to our relentless efforts in satisfying the client's need, we have been retained by various clients across industries like Refineries & Petrochemicals, Oil & Gas, Chemicals & Fertilizers, Cement, Engineering, Construction, Sugar, Nuclear & Thermal, Paper & Pulp etc. We have founded wide acceptance with reputed Engineering consultants under third party Inspection agencies Like Lloyd, BVQ, SGS, H&G, PDIL, CEIL, DNV, TUV etc.

We are supported by some of the most qualified and technically sound professionals, who are well aware about different techniques required to manufacture products. Our team members hold vast industry experience, which help them in sourcing quality raw material from reputed vendors.

We are looking forward for a positive response from your side about your requirement, so that we can provide you with best quality products at the very competitive rate.

#dnv gl approved pipe fittings#buttweld fittings#flanges#elbow manufactuers#stockist & exporetrs in india#reducer#socketweld fittings

0 notes

Text

Stainless Steel 316 Seamless Tubes Stockists In Mumbai

Metinox Overseas: Premier Stainless Steel 316/316L Seamless Tubing Manufacturer, Supplier, Stockist, and Exporter in Mumbai, India

Metinox Overseas stands out as a leading manufacturer, supplier, stockist, and exporter of Stainless Steel 316/316L Seamless Tubing in Mumbai, India. Our commitment to excellence ensures that each tube is meticulously tested and inspected by industrial experts, guaranteeing the highest quality standards, free from creases or damages, before reaching our esteemed clients.

Comprehensive Testing for Superior Quality

At Metinox Overseas, we prioritize quality through rigorous testing procedures for our Stainless Steel 316L Seamless Tubes. Our comprehensive array of tests includes:

Eddy Current Testing

Hydrostatic Testing or Ultrasonic Examination

Non-Destructive Testing (NDT)

Chemical and Physical Property Inspections

Additionally, we perform:

Chemical Analysis

Mechanical Tests

Rockwell Hardness Tests

Intergranular Corrosion Tests

Positive Material Identification (PMI)

Flattening and Flaring Tests

Third-Party Inspections

Exceptional Features and Applications

The inclusion of molybdenum in our alloys enhances corrosion resistance, making our Stainless Steel 316 Seamless Tubes ideal for various demanding applications. The austenitic structure of these tubes ensures exceptional toughness, while nickel and molybdenum significantly improve their strength and resistance to corrosion. These grades also exhibit excellent weldability, both with and without filler metal, offering versatility and ease of use in numerous applications.

Versatility of Stainless Steel 316/316L Grades

Stainless Steel 316/316L grades are highly sought after for their superior mechanical and corrosion properties. The straight 316 grade is suitable for pressure or structural applications, while the 316L grade, with its lower maximum carbon limit, is ideal for projects requiring long-term durability and sustainability. Notably, 316L is 100% recyclable, underscoring its environmental benefits. Our SS 316L Seamless Tubing is extensively used in process engineering, control lines, and heat exchangers, especially in aggressive environments where corrosion resistance is crucial.

Commitment to Excellence

At Metinox Overseas, our dedication to excellence goes beyond manufacturing top-quality products. We strive to provide our customers with informative, engaging, and optimized content for search engines. This ensures that when you choose Metinox Overseas, you're receiving not only premium-grade Stainless Steel 316 Seamless Tubes but also a wealth of valuable information.

Specifications of Stainless Steel 316 Tubes

Specifications: ASTM A213 / ASME SA213

Outside Diameter: 1/8″ OD to 2″OD, 3mm OD to 38mm OD

Thickness: 1mm to 3mm, 0.028 to 0.156 inches, SCH 5, SCH 10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size: 1/2″ NB – 24″ NB

Type: Seamless / Capillary Tubes

Form: Round Tubes, Square Tubes, Rectangular Tubes

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, Threaded

Finish: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Equivalent Grades of Stainless Steel 316 Tubes

STANDARD: UNS S30403, WERKSTOFF NR. 1.4301, AFNOR Z7CN18‐09, EN X5CrNi18-10, JIS SUS 304, BS 304S31, GOST 08Х18Н10

Chemical Composition and Mechanical Properties

Chemical Composition: C: 0.08, Mn: 2.0, Si: 0.75, P: 0.045, S: 0.030, Cr: 18.0-20.0, Mo: –, Ni: 8.0-10.5, N: 0.10

Mechanical Properties: Tensile Strength (MPa) min 515, Yield Strength 0.2% Proof (MPa) min 205, Elongation (% in 50mm) min 40, Hardness Rockwell B (HR B) max 92, Brinell (HB) max 201

Contact Us

For the best in Stainless Steel 316 Seamless Tubes, trust Metinox Overseas for quality and reliability. Contact us at:

Phone: +91-98199 80997 / +91-70212 61928

Metinox Overseas is dedicated to maintaining its reputation for excellence in manufacturing, supplying, stocking, and exporting top-quality stainless steel seamless tubing. Trust Metinox Overseas for all your stainless steel tubing needs, where quality and reliability are guaranteed.

0 notes

Text

An Insight Into Jolly Clamps’s Quality Control in Clamp Manufacturing

At Jolly Clamps, we take pride in delivering top-notch products that meet and exceed our customers’ expectations. Our commitment to quality goes far beyond the visible aspects of our products. We understand that true quality lies in the meticulous testing and scrutiny of every component and material used in our clamp manufacturing process. In this blog post, we will take you on a journey inside Jolly Clamps, shedding light on the rigorous quality control measures we implement to ensure the excellence of our clamp products.

At Jolly Clamps we follow inspection right from Raw material to Finished Goods. Below are the stages and type of inspections that are carried out:

The Foundation of Excellence — Raw Material: The foundation of a high-quality clamp lies in the quality of the raw materials used. At Jolly Clamps, we source materials from trusted suppliers and conduct thorough inspections upon arrival. Our quality control team examines the raw materials to ensure they meet our stringent standards for strength, durability, and corrosion resistance. Our inhouse facility allows us for mechanical and chemical testing of raw material on machines likes Spectro, PMI and UTM. Along with inhouse testing, 3rd party lab testing is conducted on the received Raw Material.

2. The Perfect Fit Test — Dimensional Accuracy Checks: Dimensional accuracy is non-negotiable in clamp manufacturing. Our quality control team conducts checks at various stages of the production process starting from First piece approval, in-process inspection, and Last piece inspection for each process. This ensures that each clamp aligns with the specified measurements, guaranteeing a perfect fit and functionality in diverse applications.

3. The Tough Test- Strength and Load Showdown: Jolly Clamps are designed to withstand extreme conditions and heavy loads. To validate the strength and load-bearing capacity of our products, we subject them to rigorous testing protocols. Our advanced in-house testing facilities simulate real-world scenarios, allowing us to confidently assure, our customers of the reliability and durability of our clamps.

4. Surface Finish and Coating Test: Aesthetics matter, and so does the longevity of our products. Our quality control team pays

meticulous attention to the surface finish and coating of each clamp. This is done by carrying out plating thickness testing and salt spray testing. This not only ensures the visual appeal, but also confirms the clamps life against corrosion and environmental factors, ensuring a longer lifespan for our products.

5. Non-Destructive Testing (NDT): NDT methods, such as liquid penetrant testing allow for the evaluation of materials and components without causing damage. These techniques, along with visual inspection, have proven beneficial to us for identifying any surface defects in our RM as well as finished parts.

6. Final Quality Assurance: Before a Clamp leaves our manufacturing facility, it undergoes a final comprehensive quality assurance check. This includes a final inspection of all components, a review of documentation, and a confirmation that each clamp adheres to our quality standards. Only products that pass this rigorous evaluation are deemed ready for shipment to our customers.

In addition to inspection stages, the manufacturing industry employs a variety of other tools and methods for quality control. Here are some notable ones:

1. Super Tools for Super Quality — Application of 7 QC Tools: Jolly Clamps employs the renowned 7 Quality Control (QC) tools as a cornerstone of our quality assurance strategy. These tools, including Pareto Analysis, Ishikawa Diagrams, and Control Charts, allow us to systematically identify, analyse, and address potential issues in our manufacturing process. By leveraging these tools, we continuously refine our processes to achieve optimal efficiency and eliminate defects.

2. Fool proofing the Game — Poka Yoke Techniques: To enhance our error-proofing mechanisms, we have integrated Poka Yoke (mistake-proofing) techniques into our manufacturing processes. These techniques involve designing foolproof systems and mechanisms that prevent errors before they occur and monitoring the sustenance. This not only reduces the likelihood of defects but also streamlines our operations, contributing to the overall efficiency and reliability of our clamps.

3. Handling the Risky Factors: Failure Mode and Effects Analysis (FMEA): At Jolly Clamps we have implemented FMEAs and are committed to following a risk based approach for all the processes. Throughout our journey, FMEA has been a very helpful tool to identify and eliminate the issues even before the occur, which helps us to keep our rejection percentage at par minimum level. It helps us prioritize areas for improvement based on the severity, occurrence, and detectability of potential failures.

4. Master Plan of Jolly Clamps — Control Plans: A robust quality control framework necessitates planning and execution. At Jolly Clamps, we implement detailed Control Plans that outline every critical step in the manufacturing process. These plans specify key parameters, inspection points, and control measures to ensure consistency and adherence to quality standards. By adhering to these control plans, we guarantee the uniformity and precision of our clamp products.

5. Statistical Process Control (SPC): SPC involves monitoring and controlling production processes through statistical methods. Control charts, histograms, and process capability analysis are common SPC tools used to detect variations and maintain process stability. Capability indices assess the capability of a process to produce products within specification limits. Cp measures the potential capability, while Cpk measures the actual capability, accounting for any deviations from the target.

6. We have got eyes everywhere — Visual Inspection: Visual inspection is a major part of our inspection process. It involves manually checking products for defects, irregularities, or deviations from specifications. Along with the previous “Lesson Learned”, “Quality Alerts” and “Defect Displays” as each production and inspection stage, visual inspection helps each and every operator to identify and prevent any defective product from passing to the next process.

7. Measurement System Analysis: Conducting MSA assesses the reliability and consistency of measurement systems at our facility, ensuring that our equipment and operators provide accurate and repeatable results may it be variable of attribute characteristic.

8. Continuous Improvements, Kaizen: At Jolly Clamps, improvements are proposed, implemented and appreciated from our operators as well as our staff. These incremental improvements in our processes have been helping us to optimize and improve them. It involves the entire workforce and fosters a culture of continuous learning and enhancement. We take pride in announcing our IATF 16949 and EMS certifications, reflecting our dedication to meeting the highest standards in automotive quality management and environmental responsibility.

9. Integrated Quality Control Measures: The IATF 16949, ISO 14001 and ISO 45001 certifications seamlessly integrate with our existing quality control measures, creating a harmonized approach to excellence. Every step of our manufacturing process, from raw material inspection to final product testing, aligns with the principles of these certifications. By following strict guidelines and protocols, we ensure that Jolly Clamps not only meet the standards but sets new benchmarks for quality and sustainability in the industry.

10. Traceability and Accountability The IATF 16949 certification emphasizes the importance of traceability throughout the supply chain. At Jolly Clamps, we have implemented robust traceability systems that allow us to track and verify the origin and journey of every component used in our clamps. This not only ensures compliance with certification requirements but also enables us to quickly respond to any quality-related concerns, further enhancing customer satisfaction.

Choose Jolly, Choose Excellence : Jolly Clamps is synonymous with quality, and our in-house laboratory, equipped with advanced technologies is a testament to our dedication. Our commitment to quality extends beyond the manufacturing floor and is deeply embedded in our comprehensive quality control measures. Every step in our manufacturing process is meticulously planned and executed, guided by a relentless pursuit of excellence. When you choose Jolly Clamps, you’re not just getting a product; you’re getting a guarantee of excellence backed by rigorous testing and quality control measures, you’re choosing a product that embodies precision, reliability, and performance backed by a robust quality control framework.

0 notes

Text

Stainless Steel 304L Pipes & Tubes Exporters In Mumbai

Nascent Pipe & Tubes is the fundamental manufacturers of the SS 304/304L/304H Pipes & Tubes. In any case, we are giving and exchanging the Pipes & Tubes and loads to the clients open beginning with one side of the world then onto the following. We are nearly considered among the momentous stockist and specialist of the wide levels of Pipes & Tubes. The Pipes & Tubes are open in different subtleties as per the requests for the clients. Choices like surface fulfillment, end finish, focuses, shapes, sizes, length, and strength are there.

Pipes & Tubes open are almost used in current applications. The best way that the endeavors are spreading fluids among the applications is with the help of the changed piece of the Pipes & Tubes. This is dumbfounding for supply the gas and the fluids which are fitting. The line is the unfilled portions which are used in the applications with the round cross-region that convey the things easily. The fixations and the broadness of the line are noted by the application in which it is used.

Abutting this, the chambers are the strain hardware that is utilized in current applications. The chambers and Pipes & Tubes are open in many shapes and sizes. A piece of the shapes where the Pipes & Tubes and loads are open are shot, square, square shape that is having the unfilled pieces. Also, the essential contrast among the Pipes & Tubes comes in the wall thickness, material, end affiliations, and others.

The SS 304 Alloy steel is utilized in the improvement of the line. Notwithstanding, the Alloy is involved chromium and nickel contents which are giving the Pipes & Tubes different properties. Thusly, the SS 304L is the low carbon content than the 304 Alloy steel. This is the means by which it is shocking at having the intergranular utilize hindrance cutoff. Essentially, the SS 304H is the high-temperature application utilized blend which is there with the high-temperature strength and the capacity to work in the raised temperatures.

The Alloy is the explanation that the SS 304/304L/304H Pipes & Tubes and Cylinders are having various properties. A piece of the properties which the Pipes & Tubes are having are breaking down obstruction, grand flexibility, strength, power in the raised temperatures, and fundamental force.

Specification Of Stainless Steel 304/304L/304H Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size :1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Visit Website:

Email: [email protected]

#Stainless Steel 304/304L/304H Pipes & Tubes#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers#Stainless Steel 304/304L/304H Pipes & Tubes Stockists#Stainless Steel 304/304L/304H Pipes & Tubes Exporters#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers In India#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers In India#Stainless Steel 304/304L/304H Pipes & Tubes Stockists In India#Stainless Steel 304/304L/304H Pipes & Tubes Exporters In India#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Stockists in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Exporters in Mumbai

0 notes

Text

Sanicro 28 Pipe Fittings Manufacturers in India

We, the Deep Steel Centre, are a central Manufacturers and Stockists of the whole ever-changing development of blends, chambers, pipes, and Sanicro 28 Unsurprising and Welded Pipes and Tubes. Our start and end are made with the assistance of the remarkable thought of the raw substance, generally speaking. These pipes and chambers are open in different sorts and plans. We even approach the re-attempted kind of thing, as shown by the direction of the client and sellers.

Sanicro 28 Dependable Pipe Fittings are made with the assistance of the different arranged substances, which are essential for the hardness and high strength of these things. These materials include carbon, copper, silicon, chromium, nickel, sulphur, manganese, and phosphorous as well. These chambers and pipes are even made with various decisions for the best layered precision and suitable fitting for state-of-the-art purposes. These decisions are like sorts, structures, grade, rules, plan, size, shape, length, width, thickness, surface, finish, and end of the chambers and pipes.

Sanicro 28 Welded Pipes and Tubes are genuine for their utilization in a colossal number of undertakings and general works, for example, oil and gas pipe, compound industries, plumbing warming, water supply structures, power plants, food management industries, paper and pound industries, and chief pipes.

Specification : ASTM B668 / ASME SB668; EN 10216-5; SEW 400 (Feb 1991); SS 14 25 84; NFA 49-217 Sanicro 28 Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes. Sanicro 28 Tube Size : 1/2" OD to 8" OD. Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS Type : Seamless / ERW / Welded / Fabricated Pipes Form : Round, Square, Rectangular, Oval, Hydraulic Etc Length : Single Random, Double Random & Required Length End : Plain End, Beveled End, Treaded End Protection : Plastic Caps Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests Specials : Sizes and Specifications other than above can be manufactured on request.

For More Information

Visit Website: https://www.deepsteelalloys.com/sanicro-28-seamless-welded-pipes-fittings-manufacturer-exporter.html

Email: [email protected]

#Sanicro 28 Pipes and Fittings Manufacturers#Sanicro 28 Pipes and Fittings Suppliers#Sanicro 28 Pipes and Fittings Stockists#Sanicro 28 Pipes and Fittings Exporters#Sanicro 28 Pipes and Fittings Manufacturers in India#Sanicro 28 Pipes and Fittings Suppliers in India#Sanicro 28 Pipes and Fittings Stockists in India#Sanicro 28 Pipes and Fittings Exporters in India#Sanicro 28 Pipes and Fittings Manufacturers in Mumbai#Sanicro 28 Pipes and Fittings Suppliers in Mumbai#Sanicro 28 Pipes and Fittings Stockists in Mumbai#Sanicro 28 Pipes and Fittings Exporters in Mumbai

0 notes

Text

500 BHN Steel Plate Manufacturers

What is 500 BHN Steel Plate?

Chhajed Steel & Alloy Pvt Ltd. are featuring in offering the optimum quality of 500BHN PLATES. The industry is providing a comprehensive range of plates that are varying differently in specifications, sizes, thickness, and grades. They are offering the product in the different range is easily able to meet the variety of needs and requirements of the buyers. The product to the global and international buyer is supplied at reasonable rates only. The fabrication of the 500BHN – NSSMC, ESSAR PLATES are actually done only by making effective utilization of very good quality of raw materials. The material is collected from reputable market vendors. Apart from that fabrication is done by keeping in mind industry set up norms or policies and production guidelines. The industry is considering several national and international product quality standards for better fabrication only. Use of latest technology and modern tools are assuring the manufacturers in making the perfect quality of plates.

The industry has appointed the team of professional experts that is holding desirable skills, knowledge and years of working experience in the same sector. They are guiding the manufacturers in making the error-free product so that it can be used easily in different applications. The quality control team is working harder there so that all offered product ranges are well maintained in terms of quality and no impurity is found in it. This is thus making it suitable for formability and welding.

The product is having various good features that are greatly responsible for making it an ideal choice for different applications. The features are high tensile strength, easy to use, low maintenance, good dimensional accuracy, fine surface finishes, longevity, durability, flexibility, and ability to withstand heavy loads. The product is having other good attributes to offer like corrosion resistance, pitting resistance, stress corrosion cracking and crevice corrosion cracking resistance.

For the greater assurance of high quality of 500BHN – NSSMC, ESSAR PLATES supplying without any defect in it, testing is conducted. The tests are done using the advanced tool and by using modern tools. The test includes a chemical test, flattening test, PMI test, hardness test, pitting resistance test, IGC test, flaring test, macro test, mechanical test, and micro test.

The ranges of documents the industry is providing are fumigation certification, heat treatment chart, commercial invoice, QAP, raw material test report and material traceability report. This is guaranteeing the potential buyers that yes they have got the expected quality of plates only for various purposes.

The industry is welcoming thorough inspection in the industry that is for the purpose of assuring betterment of production of plates. The inspection is done by a third party inspection agency that is having good experienced and is certified legally. The inspection is conducted by determining few essential parameters that are making the agency to look at all the stages of production and with fill perfection. At the end, the visual inspection by the third party agency report allows the manufacturer in bringing out superior quality of 500BHN NSSMC, ESSAR PLATES.

Standard Specification

Width:1000mm-4500mm

Thickness:5mm-150mm

Length:3000mm -18000mm

Heat: TreatmentRolling/Normalised, N, Q+T

Production: Hot Rolled (HR)Surface

Paint: PVDF, PE, HDP, SMP, EP

For more information Visit our website: https://www.wearplatesindia.com/ Contact Us: +91-982-151-3630 Email: [email protected]

#500 BHN Steel Plate Manufacturers#500 BHN Steel Plate Suppliers#500 BHN Steel Plate Stockists#500 BHN Steel Plate Exporters#500 BHN Steel Plate Manufacturers In India

0 notes

Text

Ensuring Safety with PMI Material Identification and Positive Material Inspection in Pune

Positive Material Identification (PMI) Services by Integrated NDE

Positive Material Identification (PMI) is a critical aspect of quality control and assurance in various industries, ensuring that the materials used in manufacturing and construction meet specified requirements. Integrated NDE offers comprehensive PMI services that cater to the stringent demands of industries such as oil and gas, petrochemicals, power generation, pharmaceuticals, and more.

The Importance of Positive Material Identification

In industrial applications, using the correct material is paramount to maintaining safety, performance, and regulatory compliance. PMI helps prevent material mix-ups, which can lead to catastrophic failures, costly repairs, and safety hazards. By implementing PMI, companies can verify the material composition and ensure that they are using the appropriate alloys for their specific applications.

Advanced Techniques in PMI

Integrated NDE utilizes state-of-the-art techniques and equipment to provide accurate PMI results. Among these techniques are X-ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES), which are highly effective for material identification.

XRF PMI

XRF PMI is a non-destructive testing method that determines the elemental composition of materials. It is particularly useful for analyzing metals and alloys, offering quick and accurate results. XRF PMI is ideal for identifying various elements such as chromium, nickel, molybdenum, and other alloying elements.

OES PMI

OES PMI involves using an optical emission spectrometer to analyze the light emitted by a sample when it is excited by an energy source. This technique is highly sensitive and can detect low levels of elements, making it suitable for detailed chemical analysis and positive material inspection.

Comprehensive PMI Services

Integrated NDE provides a wide range of PMI services tailored to meet the needs of different industries. These services include:

PMI Material Identification

Our PMI material identification services ensure that the materials used in your processes are correctly identified and compliant with industry standards. We help you verify the composition of metals and alloys, providing detailed reports on their chemical makeup.

Positive Material Inspection

Our positive material inspection services are designed to prevent material mix-ups and ensure the integrity of your products. By conducting thorough inspections, we help you maintain quality control and avoid potential issues related to material discrepancies.

Positive Material Identification for Carbon Steel

Carbon steel is widely used in various industries due to its strength and durability. Our PMI services for carbon steel ensure that the material meets the required specifications, preventing failures and ensuring optimal performance.

State-of-the-Art Equipment

Integrated NDE uses advanced PMI equipment to deliver accurate and reliable results. Our tools are calibrated and maintained to the highest standards, ensuring precise measurements and consistent performance. The use of cutting-edge technology allows us to provide quick and efficient PMI inspections, minimizing downtime and maximizing productivity.

Benefits of PMI Services

Implementing PMI services offers several advantages, including:

Safety Compliance: Ensuring that materials meet safety standards and regulations.

Quality Assurance: Verifying the composition and quality of materials to maintain product integrity.

Cost Savings: Preventing costly repairs and downtime caused by material failures.

Regulatory Compliance: Meeting industry-specific requirements and avoiding penalties.

PMI Chemical Analysis

PMI chemical analysis is a crucial part of our services, providing detailed information about the elemental composition of materials. This analysis helps in identifying potential issues and ensuring that the materials used in your processes are suitable for their intended applications.

Identification of PMI

Our identification of PMI services includes detailed reporting and documentation, providing you with the necessary information to make informed decisions about material usage. We offer comprehensive reports that include elemental analysis, material composition, and compliance verification.

Industries We Serve

Integrated NDE serves a wide range of industries, including:

Oil and Gas: Ensuring the integrity of pipelines, refineries, and other critical infrastructure.

Petrochemicals: Verifying the composition of materials used in chemical processing plants.

Power Generation: Ensuring the reliability and safety of materials used in power plants.

Pharmaceuticals: Maintaining the quality and purity of materials used in drug manufacturing.

Why Choose Integrated NDE?

Integrated NDE is a trusted provider of PMI services, offering expert knowledge and advanced technology to meet your material identification needs. Our team of experienced professionals is dedicated to delivering accurate and reliable results, helping you maintain quality control and ensure the safety of your operations.

For more information about our positive material identification services and how we can assist you, visit our Positive Material Identification page.

#positive material identification#pmi#pmi positive material identification#xrf pmi#pmi inspection#material identification#positive material#positive material inspection#pmi material identification#pmi material#positive materials identification#pmi material inspection#positive material identification for carbon steel#positive material identification equipment#identification of pmi#pmi chemical analysis#pmis#pmi identification#pmi material analysis#positive material ide

0 notes

Text

Sodium Bromide Prices, Pricing, Demand & Supply, Market Analysis | ChemAnalyst

For the Quarter Ending June 2023

North America:

In Q2 2023, the US Sodium Bromide market experienced a bearish trend as prices declined throughout the quarter. The drop in prices was influenced by various factors, including reduced demand from downstream industries such as water treatment and oil drilling, as well as increased imports of lower-priced goods. The sluggish demand led to fewer purchases and a lack of market support, making it challenging for suppliers to maintain price levels. Additionally, the availability of cheaper imports put pressure on the domestic market, further impacting price dynamics. Economic uncertainties and weak demand outlook also contributed to the overall market sentiment. By the end of Q2 2023, Sodium Bromide prices in the US were assessed at USD 1950 per MT on a FOB basis.

APAC:

The Indian Sodium Bromide market witnessed a bearish trend in Q2 2023, with prices declining throughout the quarter. Imports of low-priced goods and reduced production costs further contributed to the drop in prices in June. Weak domestic demand, especially from industries like oil and gas drilling, water treatment, and pharmaceuticals, played a significant role in the overall bearish market sentiment. While the supply chain operated at a moderate pace, imports of Sodium Bromide declined due to sufficient material availability in the domestic market. Despite a slight increase in factory activity, the overall demand remained low to moderate, as inquiries from end-use consumers were slow. The reluctance of downstream industries to procure Sodium Bromide due to ample material availability further dampened the demand outlook. As of June 2023, Sodium Bromide prices in Asia were assessed at USD 1760 per MT on a CFR basis.

Get Real Time Prices of Sodium Bromide: https://www.chemanalyst.com/Pricing-data/sodium-bromide-1131

Europe:

The Sodium Bromide market in the Netherlands experienced a bearish trend in Q2 2023, with prices declining further in June. The contraction of industrial activities and weaker downstream demand were the main factors driving this price drop. Uncertain economic conditions, reflected in a slip in the manufacturing PMI and a technical recession in the eurozone, contributed to the worsening demand outlook. Inflation rates also rose due to higher energy prices. Despite smooth supply chain operations, the sluggish demand from water treatment and oil drilling industries resulted in moderate purchases based on demand requirements. Production costs decreased as the cost support from upstream Bromine dwindled. In May, market sentiments declined further due to a contraction in manufacturing activities and subdued downstream demand, leading to lower purchases and a cautious consumer attitude. After Q2 2023, Sodium Bromide prices in Europe were assessed at USD 1680 per MT on an FD basis.

About Us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

DNV GL Approved Reducer Manufacturers

Arvind Pipes Fittings Industries, Came into existence in the year 1982 well known as Arvind Metal Syndicate. The genesis of ARVIND's birth & growth is "ACCEPTING CHALLENGES."

We will serve you for all your piping requirements under one roof such as high quality pipe Fittings, Butt-weld and Socket- weld Fittings, Flanges & End-Connection in Alloy steel, Carbon steel, Stainless Steel, Nickel alloys.

Our quality management system confirm to ISO 9001-2008. and PED certificated by TUV Rheinland.

Due to modern manufacturing process, equipments and inspection tools practised by us in producing the products and putting them through strict Quality Control Procedure, Our products meet the requirements of International and National standards.

Our product undergo various strict inspection & testing stages at the corporate in-house facilities, such as Chemical, Mechanical, Hydrostatic, Corrosion test, PMI Test, Non-Destructive test etc. before they are despatched to the customers. This assures high value quality of products.

As a testimony to our relentless efforts in satisfying the client's need, we have been retained by various clients across industries like Refineries & Petrochemicals, Oil & Gas, Chemicals & Fertilizers, Cement, Engineering, Construction, Sugar, Nuclear & Thermal, Paper & Pulp etc. We have founded wide acceptance with reputed Engineering consultants under third party Inspection agencies Like Lloyd, BVQ, SGS, H&G, PDIL, CEIL, DNV, TUV etc.

We are supported by some of the most qualified and technically sound professionals, who are well aware about different techniques required to manufacture products. Our team members hold vast industry experience, which help them in sourcing quality raw material from reputed vendors.

We are looking forward for a positive response from your side about your requirement, so that we can provide you with best quality products at the very competitive rate.

0 notes

Text

Tips for maximizing tube, pipe mill efficiency (Part I)

Even under the best of circumstances, making tubular products can be grueling. Mills are complex, they need a lot of scheduled maintenance, and depending on the products they make, the competition is fierce. Many metal tube and pipe producers are under relentless pressure to maximize uptime to maximize revenue, leaving precious little time for routine maintenance.

These days, the industry doesn’t have the best of circumstances. Material costs are sky high and partial deliveries aren’t uncommon. Tube and pipe producers need to maximize uptime and reduce scrap now more than ever, and receiving a partial delivery means making shorter runs. Shorter runs mean more frequent changeovers, which is not an efficient use of time or labor.

“Productive time is extremely valuable right now,” said Mark Prasek, North American tube and pipe sales manager for EFD Induction.

Conversations with industry experts about tips and strategies to get the most out of a mill revealed a few recurring themes:

Getting the maximum yield from a mill starts with getting the maximum yield from each coil. This means matching the original coil to the capacity of the slitter so that the ensuing product, the slit mult, matches the capacity of the mill’s entry equipment.

Preventive maintenance inspections (PMIs) and mill alignments are supremely important. PMIs are equally critical for the mill, peripheral equipment, and consumables. All of them have to work together to make good product, and all of them need regular maintenance.

Bottlenecks must be eliminated. The core functions of the mill (forming, welding, sizing, and straightening the product) set the pace. If the entry and exit portions don’t keep up, this is a good place to start in improving throughput.

Reducing mill stops and starts is one of the most effective ways to reduce scrap.

Personnel need to be motivated, thoroughly trained, and follow written procedures. Consistency is crucial in all three areas.

Running a mill at its maximum efficiency means optimizing dozens of factors, most of which interact with other factors, so it isn’t necessarily easy to optimize a mill’s operations. Sage words from former The Tube & Pipe Journal columnist Bud Graham provide some perspective: “A tube mill is a tool holder.” Keeping this phrase in mind helps to keep it simple. Understanding what each tool does, and how it does it, and how each interacts with the others, is about one-third of the battle. Keeping everything maintained and aligned is another third of it. The final third concerns the operator training program, troubleshooting tactics, and specific operating procedures unique to each tube or pipe producer.

Maximizing Yield

The first consideration in running a mill efficiently doesn’t concern the mill at all. It’s the raw material. Getting the maximum yield from a mill means getting the maximum yield from each coil that feeds the mill. This starts with purchasing decisions.

Coil Length. “Tube and pipe mills thrive when the coil is the longest it can be,” said Nelson Abbey, director of Abbey Products at Fives Bronx Inc. Processing shorter coils means processing more coil ends. Every coil end needs a butt weld, and every butt weld creates scrap.

The difficulty here is that the longest possible coils might come at a premium price; a shorter coil might be available at a better price. The purchasing agent might want to save some money, but this is at odds with the perspective of the folks on the manufacturing floor. Nearly everyone who runs the mill would agree that the price difference would have to be substantial to cover the production losses associated with additional mill stoppages.

Another consideration is the capacity of the uncoiler and any other limitations at the entry end of the mill, Abbey said. Investing in higher-capacity entry equipment to handle larger, heavier coils might be necessary to take advantage of the benefits of buying bigger coils.

The slitter is also a factor, whether slitting is done in-house or if this service is outsourced. Slitters have maximum weights and diameters they can handle, so getting the best match between the coil and the slitter is critical in maximizing yield.

In summary, it’s an interplay among four factors: the dimensions and weights of the coil, the necessary widths of the slit mults, the capability of the slitter, and the capacity of the entry equipment.

Coil Width and Condition. On the shop floor, it goes without saying that the coil has to be the right width and the right gauge for the product to be made, but mistakes happen. Mill operators often can compensate for a strip width that is slightly undersized or oversized, but it’s just a matter of degree. Careful attention to the widths of the slit mults is critical.

The strip’s edge condition also is an overriding concern. A consistent edge presentation, without burrs or any other inconsistencies, is crucial to maintaining a consistent weld along the strip’s length, said Michael Strand, president of T&H Lemont. The initial coiling, uncoiling for slitting, and recoiling also come into play. A coil that hasn’t been processed with care can develop camber, which is problematic. The forming process as developed by roll tooling engineers starts with a flat strip, not a cambered strip.

Tooling Considerations. “Good tooling design maximizes yield,” said Stan Green, general manager for SST Forming Roll Inc. He pointed out that no single tube forming strategy exists, and therefore no single tooling design strategy exists. Roll tooling suppliers vary, the ways they work the tube vary, and therefore their products vary. The yield also varies.

“The surface of a roll has a continuously changing radius, so the rotational velocity of the tooling varies over the face of the tool,” he said. The tube moves through the mill at just one velocity, of course. Because of this, the design influences the yield. A poor design wastes material when the tooling is new and it only gets worse as the tooling wears, he added.

Operations and Maintenance

For companies that haven’t held the line on training and maintenance, formulating a strategy to optimize the mill’s efficiency starts with the basics.

Training Mill Operators. The first concern is the staff and how they are trained.

“Regardless of the style of mill and what it produces, all mills have two things in common—operators and operating procedures,” Abbey said. Running a mill as consistently as possible is a matter of providing standardized training and adherence to written procedures, he said. Inconsistencies in training can lead to differences in setup and troubleshooting.

“Running a mill profitably is a matter of training, training, and more training,” Strand said.

To get the most out of a mill, from operator to operator and shift to shift, it’s imperative that every operator use consistent setup and troubleshooting procedures. Any procedural differences usually are matters of misunderstandings, bad habits, shortcuts, and workarounds. Invariably these lead to difficulties in running a mill efficiently. These might be home-grown problems, or they might have been imported when a poorly trained operator was hired from a competitor, but the origin makes no difference. Consistency is the key, including operators who bring experience with them.

“It takes years to develop tube mill operators, and you really can’t rely on a generic, one-size-fits-all program,” Strand said. “Each company needs its own training plan suited to its own mills and its own operation.”

Making a Routine of Routine Maintenance. The second concern is routine maintenance.

“Three keys in operating efficiently are machine maintenance, consumable maintenance, and the alignment,” said Dan Ventura, president of Ventura & Associates. “The machine has a lot of moving parts—whether it’s the mill itself or peripheral equipment at the entry or exit end, or the runout table, or what have you—and routine maintenance is important to keep it in top condition.”

Strand concurs. “Using the preventive maintenance inspection schedule is where it all begins,” he said. “It provides the best chance to run a mill profitably. If a tube producer responds only to emergencies, it’s not in control. It’s at the mercy of the next crisis.”

Proper alignment is just as critical is routine maintenance.

“Every piece of equipment on the mill has to be in alignment,” Ventura said. “Otherwise, the mill fights itself.”

Keeping the roll tooling in top shape likewise is necessary.

“In many cases, as the rolls are pushed beyond their useable service life, they work-harden, and eventually they crack,” Ventura said.

Understanding tooling maintenance sheds a lot of light on the importance of all of the maintenance.

“If the rolls haven’t been kept in good condition with regular maintenance, the day comes that they need emergency maintenance,” Ventura said. If the tools have been neglected, reconditioning them is going to require removing two to three times the amount of material they would otherwise need removed, he said. It’s also going to take longer and cost more.

Investing in spare tools can help prevent emergencies, Strand noted. If tooling is used frequently for long runs, more spares are needed than for tooling used rarely for short runs. The tool function also influences the spare level. Fins can break off of the fin pass tooling, and weld rolls succumb to the heat of the weld box, which are problems that don’t plague forming and sizing rolls.

“Regular maintenance is good for the equipment, and proper alignment is good for the product it makes,” he said. If these are neglected, the mill staff spends increasing amounts of time attempting to compensate. This is time that could be spent making good, saleable product. These two factors are so vital, and so often overlooked or neglected, that in Ventura’s opinion they offer the best opportunities to get the most out of a mill, maximizing throughput and minimizing scrap.

Ventura equates mill and consumable maintenance to automobile maintenance. Nobody would drive a car tens of thousands of miles between oil changes and let the tires go bald. This is going to lead to an expensive solution or a wreck, and the same goes for a poorly maintained mill.

Regular tooling inspections after every run also are necessary, he said. Checking the tooling might reveal a problem such as a hairline crack. Finding such damage immediately after removing the tooling from the mill, rather than finding it right before installing it for the next run, provides the most time to get a replacement tool made.

“Some companies are working right through scheduled shutdowns,” Green said. He understands that it’s hard to abide by a scheduled shutdown in times like these, but he noted that it’s extremely risky. Shipping and trucking companies are so overloaded, or understaffed, or both, that deliveries just aren’t timely these days.

“If something on the mill breaks and you have to order a replacement, what are you going to do to get it delivered?” he asked. Of course, air freight is always an option, but that sends the cost of the shipment spiraling.

Mill and roll maintenance isn’t just a matter of following maintenance schedules, but coordinating maintenance schedules with production schedules.

“To do this effectively, you really have to think long term,” Strand said.

Breadth and depth of experience count in all three areas—operations, troubleshooting, and maintenance. Companies that have just one or two mills to make tubing for their own use usually have few people dedicated to mill and tooling maintenance, said Warren Wheatman, vice president of T&H Lemont’s Tooling Business Unit. Even if the maintenance people are extremely knowledgeable, a small department simply has a shallower reservoir of experience to draw from than a large maintenance department, putting the smaller staff at a disadvantage. If the company doesn’t have an engineering department, the maintenance department has to do its own troubleshooting as well as the repairs.

Strand added that training for both operations and maintenance departments is more important now than ever before. The wave of retirements associated with the aging of the baby boom generation means that much of the tribal knowledge that once kept companies going through thick and thin is being depleted. And while many tube and pipe producers still can rely on consultations and advice from equipment vendors, even this expertise isn’t as plentiful as it once was, and it too is shrinking.

Welding

The welding process is just as critical as any other process that takes place when making a tube or a pipe, and the welding machine’s role can’t be overestimated.

Induction Welding. “About two-thirds of our orders are for retrofits these days,” Prasek said. “They’re usually replacing old, problematic welders. Throughput is the primary driver right now.”

Many are behind the eight ball because the raw material shows up late, he said. “Often when the material finally does show up, the welder goes down,” he said. A surprising number of tube and pipe producers are even using machines based on vacuum tube technology, which means they are nursing along machines that are at least 30 years old. Service knowledge on such machines isn’t abundant, and replacement tubes themselves can be hard to find.

The challenge for the tube and pipe producers still using them is how they age. They don’t fail catastrophically, but they degrade slowly. A workaround is to use less weld heat and run the mill slower to compensate, which makes it easy to avoid the capital expense of investing in a new machine. This creates a false sense that everything is just fine.

Investing in a new induction welding power supply can make a big difference in the mill’s electricity consumption, Prasek said. Some states—especially those with large populations and stressed electrical grids—offer a generous tax rebate following the purchase of energy-efficient equipment. A second motivator to invest in a new one is the potential for new production possibilities, he added.

“Often a new welding unit is so much more efficient than an old one that it provides substantially more welding capacity without upgrading the electrical service, saving thousands of dollars,” Prasek said.

Critical also are the alignments of the induction coil and the impeder. A properly selected and mounted induction coil has an optimal location relative to the weld rolls, and it needs a proper and consistent clearance around the tube, said John Holderman, general manager for EHE Consumables. The coil will fail prematurely if not set properly.

An impeder’s job is simple—it impedes current flow, directing it to the strip edges—and like everything else on the mill, positioning is critical, he said. The proper position is right at the weld apex, but this isn’t the only consideration. The mounting is critical. If it’s affixed to a mandrel that isn’t rigid enough to support it, the impeder’s position can shift and it can actually drag on the ID along the bottom of the tube.

Taking advantage of a trend in welding consumable design, the split coil concept, can have a big impact on mill uptime.

“Large-diameter mills have been using split-coil designs for a long time,” Holderman said. “Replacing a single-piece induction coil requires cutting the pipe, replacing the coil, and rethreading the mill,” he said. A split-coil design, which is in two pieces, gets around all that time and effort.

“They have been used on large mills as a matter of necessity, but it took some fancy engineering to apply this principle to small coils,” he said. The manufacturers simply had less to work with. “Small two-piece coils have specialized hardware and cleverly designed clamps,” he said.

Regarding the process of cooling the impeder, tube and pipe producers have two conventional choices: the mill’s central coolant system or a separate, dedicated water system, which can be expensive.

“It’s best to cool the impeder with clean coolant,” Holderman said. To this end, a small investment in a dedicated impeder filtration system for mill coolant can go a long way toward improving an impeder’s longevity.

The mill’s coolant often is used on the impeder, but mill coolant collects metal fines. Despite all efforts to trap the fines in a central filter or capture them with a central magnet system, some get through and find their way to the impeder. This is no place for metal fines.

“They heat up in the induction field and burn themselves into the impeder casing and ferrite, which leads to premature failure and then downtime to change the impeder,” Holderman said. “They also build up on the induction coils and eventually cause damage from arcing there as well.”

Laser Welding. For stainless steel mills, laser welding has a substantial and growing role. Initially these were laser units with CO2 resonators, but those have yielded the field to fiber lasers. This technology has two characteristics that fit in well with tube or pipe mill operations: consistency and reliability.

“A laser source is extremely stable in how it generates and delivers heat. The weld is consistent all day long,” said Kevin Arnold, Midwest sales manager for IPG Photonics. “The systems have the ability to self-regulate to deliver a consistent output.” Another characteristic is its ability to focus the heat, which means this technology can make a successful weld with less heat input than other welding methods. Less heat equates to less distortion. Also, the highly focused heat often allows mills to run faster than with other heat sources, he said, improving throughput.

Perhaps just as important is the ease of setup and maintenance. Gone are the mirrors and complicated focusing system that need to be kept in precise alignment and scrupulously clean when using CO2 technology.

“The laser beam delivery system is an order of magnitude simpler,” he said.

Closely related is reliability. Fewer moving parts means greater uptime. The dependability of today’s laser machines, compared to first lasers used in metal fabrication decades ago, isn’t even comparable, he said.

“In the early days, manufacturers could live with a finicky laser,” he said. “These days, a fiber laser machine is reliable, day in and day out, working in the background, almost invisibly, like a loyal employee,” he said.

And while it’s understood that laser power sources aren’t inexpensive, the prices have dropped substantially over the decades.

“Twenty years ago, a tube or pipe producer would need tens of millions of dollars in annual revenue to afford a laser welding system,” he said. “These days it’s much less, in some cases as little as $1 million per year.”

Power Outages. Strand noted that some businesses have to deal with occasional power cuts, which is a big problem for processing industries.

“It’s usually not a problem in the U.S., but it’s not uncommon in South America,” he said. As populations grow and get ahead of infrastructure development, this is inevitable. Demand for electricity outstrips the supply, and the power utility (or government) has no choice but to institute rotating intermittent power cuts.

Of course, power outages can and do happen in the U.S. Brownouts during peak consumption periods are a fact of life in some states. Prasek and Strand both noted that some companies embrace occasional power cuts. They get a better rate on the power they use in return for the inconvenience of occasional power shutdowns.

1 note

·

View note

Text

Home Inspection North East calgary

NexLevel Inspection is a prominent company that specializes in providing high-quality inspection services across various industries. With a strong reputation for reliability, accuracy, and attention to detail, NexLevel Inspection has established itself as a leader in the field.

One of the key areas of expertise for NexLevel Inspection is non-destructive testing (NDT). NDT techniques are essential in evaluating the structural integrity and reliability of materials and components without causing any damage. NexLevel Inspection employs a wide range of advanced NDT methods such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, radiographic testing, and visual inspection. These techniques allow the company to identify defects, cracks, leaks, and other flaws that could compromise the safety and functionality of various structures and equipment.

NexLevel Inspection serves multiple industries, including manufacturing, aerospace, oil and gas, petrochemical, power generation, and construction. The company's team of highly trained and certified inspectors possesses extensive knowledge and experience in their respective fields. They are equipped with state-of-the-art equipment and follow stringent protocols to ensure accurate and reliable inspection results.

The dedication to quality and customer satisfaction is evident in NexLevel Inspection's commitment to adhering to industry standards and regulations. They work closely with their clients to understand their specific needs and tailor their inspection processes accordingly. Whether it's ensuring compliance with industry codes and standards, conducting routine inspections, or performing comprehensive assessments, NexLevel Inspection provides a comprehensive range of inspection services to meet their clients' requirements.

In addition to their expertise in NDT, NexLevel Inspection also offers other specialized services. These include weld inspection, corrosion monitoring, risk-based inspection, heat exchanger inspection, and positive material identification (PMI). By offering a diverse portfolio of inspection solutions, NexLevel Inspection aims to be a one-stop destination for companies seeking reliable and efficient inspection services.

NexLevel Inspection prides itself on its commitment to safety, quality, and professionalism. The company continuously invests in training and technology to stay at the forefront of the industry. By employing innovative approaches and staying up to date with the latest advancements, NexLevel Inspection ensures that their clients receive accurate and timely inspection results.

Overall, NexLevel Inspection is a trusted partner for companies looking for comprehensive inspection services. With their expertise, advanced techniques, and commitment to excellence, they play a crucial role in maintaining the integrity and safety of structures and equipment across various industries.

home inspection in NE calgary home inspection North East calgary, calgary home inspections home inspections calgary home inspector calgary Home Inspections for big homes

0 notes

Text

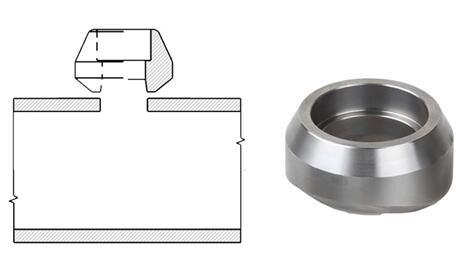

A branch becoming is used to create internally bolstered connections from the run pipe to the outlet pipe between forty five and ninety degrees. A Weldolet fitting is a famous department becoming this is part of the butt-weld becoming own family. These fittings are welded onto the outlet to the run pipe and are used in higher pressure packages. The Astm A105 Weldolet is a solid grade that connects the pipe to reduce the pressure at the grade. Those items have a comparable or higher schedule than the time table on the run pipe. Asme B31.Three Weldolet allows bring fluids at pressures as consistent with the limits visible in petroleum refineries and other industries. The A234 Wpb Weldolet covers popular carbon and alloy metal material that can be produced in seamless and welded types. A weldolet is available in a size range between ¼ to 36 inches. An Mss Sp 97 Weldolet covers material with dimensions, end, testing, and tolerance of integrally bolstered branched outlet fittings. A category 3000 Weldolet can preserve nominal stress of 2000psi with a maximum check stress of 3000psi. Our enterprise is a Weldolet producer in India that observe all requirements of the nearby and global legislature to produce the great merchandise in the industry.

PIPE WELDOLET SPECIFICATION

Connect Type - Bevelled and Welded

Dimensions - MSS-SP-97, ASME B31.3, B31.1, B31.8, B31.4, ASME/ANSI B16.11

Thickness - Schedule 5S to120S

Size From - 1/8″to 24″

Class - 6000LBS, 3000LBS, 9000LBS

EXTERNAL COATING

Teflon Coating, Oxidized, Zinc Plating, Chrome Plating, Mirror Buffed, Hot Dipped Galvanizing, Epoxy Coating, Electro Polished, Passivation

TESTING AND DOCUMENTS

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

PACKING

Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

FLANGESNUTS

Manufacturer of all types of fastners and flanges

0 notes

Text

What is the Right Mortgage for Buying a Fixer-Upper?

You have found your dream house but it will take significant work to make it a home. You do not have cash in savings to pay for both a down payment and the repair costs. Not to worry - this is not a hopeless situation. Fortunately, there are two types of mortgage loans available for just this scenario: The Federal Housing Administration (FHA) 203(k) rehabilitation loan or Fannie Mae HomeStyle Renovation Mortgage.

FHA 203(k) Mortgage

The Federal Housing administration has provided a home loan that allows buyers to borrow enough money to cover the price of the home plus the estimated repair costs if that total is no more than 110% of the estimated appraised value of the home after the proposed renovations.

There are several requirements for FHA 203(k) loans. First borrowers must provide a down payment of at least 3.5% and have a minimum credit score of 580. (Although if you put down at least 10% for the down payment, the FHA will accept credit scores as low as 500.) Because it is an FHA loan, borrowers will also be required to pay 1.75% of the loan amount upfront as mortgage insurance and 0.85% on the principal balance for insurance annually for the life of the loan. In order to avoid paying mortgage insurance forever, buyers could consider refinancing sometime after the renovations are completed.

The property must cost less than the FHA mortgage limit for the area and the repairs must total more than $5,000. Almost any type of repairs are allowed, including demolishing a home and fixing up the foundation before rebuilding. This type of loan is not generally for do-it-yourself buyers though. Borrowers are required to hire a 203(k) consultant or contractor who will oversee all the renovations.

Fannie Mae HomeStyle Renovation Mortgage

This loan is great for those who have some major renovations to do as home buyers can borrow money to cover repairs that cost up to 50% of the completed property appraised value. The renovations can include almost anything: remodeling, repairs and even energy efficiency enhancements, as long as the improvements are permanently affixed to the property and increase the home value.

The loan amount will pay for labor and material costs as well as inspections, permits and licenses, and architecture and engineering fees. In addition to all of that, the loan can also include an optional 10% reserve for contingencies. The lender will oversee all renovations.

Investors are also allowed to take out HomeStyle Renovation mortgages with down payments of 15% or more. Investors may not borrow 203(k) loans.

The requirements for HomeStyle Renovation loans include down payments of at least 5% and credit scores of 680 or more. Property prices must fall under the conventional mortgage limits for the area and the work must be completed in 12 months. Private mortgage insurance (PMI) will be required for any loans with down payments of less than 20%.

If you are willing to wait a little for repairs and do the work to meet the loan standards, home renovation loans like the FHA 203(k) or the Fannie Mae HomeStyle Renovation mortgage can help you buy the fixer-upper you love.

At Key One Financial Inc , we are available by phone at 844-539-6631 to answer any questions that you have about this important topic and to give you the best advice for your particular situation. Whatever you decide is best for you - we can help you.

2 notes

·

View notes

Text

Survey on Pathological Lesion and Its Financial Losses in Ovine Slaughtered at Jimma Municipal llll Abattoir, Jimma, Ethiopia-Lupine Publishers

Dairy and Veterinary Sciences Journal| Lupine Publishers

Abstract

A cross-sectional study was conducted from October 2016 to July 2017 on ovine slaughtered at Jimma municipal abattoir with the aim of identifying main pathological lesions causing organs and carcass condemnation, and associated direct financial losses. In this, 384 sheep were recruited to the study using systematic random sampling and standard antemortem (AM), and postmortem inspection (PMI) procedures were employed. Nasal discharge, tick infestation, coughing, lameness, emaciation, depression and salivation are recorded as the major AM findings of the current study. Accordingly, 47 (12.2%) sheep showed signs of diseases and abnormalities; of which 23(6%) were conditionally approved whereas 11 (2.9%) sheep were unfit and judged to be detained and rejected. In the present study age, body conditions and geographic origin of the animals were considered as study variables, and the results showed BCS and age groups had statistically higher (p ≤ 0.05) rejection probabilities. PM examination findings indicated a total of 192 lesions were encountered, of which 48.9%, 29.2%, 6.8%, and 5.7% lesions were recorded from livers, lungs, GIT, and hearts and kidneys, respectively. During the PM inspection, both total and partial condemnation judgments were passed on organs and carcass appeared with a sign of abnormality. C. teniculosis 58 (30.2%), calcification 36(18.7%), abscess 31(16.2%), hydatid cyst 23 (12%), hepatitis 10 (5.2%), pericarditis 4(2%), bruise 3(1.6%) and nephritis 2(1%) were found to be the major pathological lesions recorded. In two sheep all organs and carcass were totally condemned as their entire bodies appeared yellowish. The direct loss due to the condemnation of organs and carcasses at Jimma municipal abattoir was also investigated in slaughtered sheep, and there were about 56,576 USD losses per year. In conclusion, this study has identified the pathological lesions affecting edible organs and meat, and then rendering them unfit for human consumption. The study also estimated pathological lesions associated direct financial losses at Jimma abattoir. Therefore, further studies focusing on the primary causes of the abnormalities were recommended in the study area.

Keywords: Abattoir; Financial loss; Lesion; Organ condemnation; PMI; Sheep; Jimma

Introduction

The livestock sector globally is highly dynamic, contributes 40% of the global value of agricultural output and support the livelihoods and food security of almost a billion people (Thornton [1]). Within African society, small ruminant comprises a greater proportion of the total wealth of the rural families, because of the low input requirements such as low initial capital, fewer resources and maintenance cost. They are also able to produce milk and meat in readily usable quantities using marginal lands and poor pasture and crop residues. Furthermore, their production cycle makes them need only short periods to reconstitute flocks after a disaster and respond quickly to the demand (Getenby, [2]). Ethiopia is the leading African country in livestock population, having around 34-40 million TLU (Tropical livestock unit) out of which 17% and 12% cattle and small ruminants, respectively, are found in Ethiopia (Ministry of information (MOI) [3]. According to (Development, pp Statis, [4]), the population of sheep and goats in Ethiopia is estimated to be 26.1 and 21.7 million respectively. It was the third largest number of sheep and goat among African nations and rank eighth in the world (Alemu and Merkel, [5]).

They generate cash income from export of meat, edible organs, skins and live animals (Ibrahim, 1998). There is also a high domestic meat demand from these animals, particularly during religious festivals. Even though this sub-sector contributes much to the national economy, its development is hampered by various constraints. These include endemic animal diseases, insufficient nutrition, poor husbandry, and lack of sufficient infrastructure, trained labor and government policies (PACE, [6]). Each year a large loss results from the death of animals and weight loss during transportation; and condemnation of edible organs and carcasses at slaughter.

Abattoir meat inspection is essential to remove gross abnormalities from meat and its products, to prevent the distribution of contaminated meat and to assist detecting and eradication of certain livestock diseases. More specifically, antemortem inspection attempts to avoid introduction of clinically diseased animals into slaughter house and also serves to obtain information that will be useful in making sound post mortem inspection. Likewise, postmortem inspection is the center around which meat hygiene revolves since it provides information essential for evaluation of clinical signs and pathological process that affect the wholesomeness of meat (Herenda, et al. [7]).