#plastic injection mold tooling

Explore tagged Tumblr posts

Text

Precision Plastic Injection Mold Tooling | PTMS Mold

Explore our advanced plastic injection mold tooling services at PTMS Mold. We offer high-precision tooling solutions tailored to your project requirements. Our expert team utilizes cutting-edge technology to deliver durable and efficient mold tools. Ensure superior quality and performance with our trusted plastic injection mold tooling services.

0 notes

Text

knowing what i know now about injection molding, i have a lotta respect for whoever lego's mold techs and machine operators are because the tolerances of these bricks must be crazy. ik for most pieces they can just avoid a parting line altogether by putting it at the edge of the brick but you cant do that for a lot of them and a majority of the time the parting line is virtually invisible. most of the time you can still feel and identify the parting line pretty easily but with lego there's so much less flash than usual and i have a lot of respect for that. also theyre usually pretty good about finding inconspicuous spots for the gates (or at least ones that dont downgrade the appearance of the part) while not having any short shots or burns, which for some of these gate locations is really impressive to me

#injection molding is actually rly cool and whoever legos plastics ppl are theyre GOOD#which makes sense obvs but it's still really cool to feel like i know why it's good now#i feel like the dream for me would be tooling for lego. that would be amazing#not even necessarily mold making just tooling for them in general. but alas i dont know danish#also other things i didnt mention#for how many pieces are made of abs there's surprisingly little warping which is impressive for abs#and in the same vein abs is more prone to flash and as i said above there's also very little of that which is again. really cool#alright enough of me talking abt plastics for now but it does excite me haha#ALSO ALSO FEEL FREE TO ASK ME MORE ABOUT INJECTION MOLDING IF YOU WANT ANY EXPLANATIONS OR ELABORATIONS ON WHAT I SAID HERE I LVOE TALKING#BT INJECTION MOLDING I LOVE IT.#haha no pressure 2 tho ofc

5 notes

·

View notes

Link

@bentleyinjectionmolding

0 notes

Text

T&R Tooling has established itself as a leading provider of tooling for plastic injection molding in Texas, delivering innovative solutions that help manufacturers improve productivity and product quality. Our high-precision molds are crafted to the exact specifications of each client, ensuring that your injection-molded products meet the highest standards of quality and consistency.

T&R Tooling 282 Elm Grove Rd., Valley View, TX 76272 (940) 726–6020

My Official Website: http://www.trtooling.com/ Google Plus Listing: https://www.google.com/maps?cid=1529569677814869897

Our Other Links:

plastic injection tooling in Texas: http://www.trtooling.com/new-tooling/ prototyping Texas: http://www.trtooling.com/3d-printing/

Service We Offer:

Plastic Injection Molding 3d Printing Tool Repair New Tooling Design Services Quality Assurance

Follow Us On:

Twitter: https://twitter.com/ToolingR31294 Pinterest: https://www.pinterest.com/trtoolingtx/ Instagram: https://www.instagram.com/trtooling/

#tooling for plastic injection molding texas#injection molding tooling repair texas#plastic injection tooling in texas#rapid prototyping Texas#prototyping texas

0 notes

Text

Plastic Tooling Manufacturing

Explore top-quality plastic tooling manufacturing and injection mold manufacturing services at Plastic Injection Molds. We specialize in making high-quality plastic tools that fit your needs. From designing to making, our expertise in creating molds ensures top-notch quality for different uses. Whether you need special plastic parts or detailed molds, we are here for you. We offer affordable and effective solutions for your plastic tooling needs, always making sure to do a great job. Our injection mold manufacturing services are reliable, turning your ideas into reality with skill and knowledge. Choose us for superior plastic tooling and injection mold solutions.

0 notes

Text

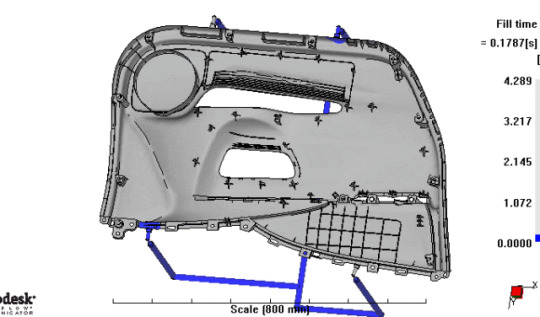

Moldflow: Taking plastic injection molding process to new heights

As plastic parts are used in more and more industries, there is increasing pressure to reduce costs and shorten time to market. Against this background, demand for simulation tools has also increased. When it comes to plastic injection molding process, it’s never been more important to understand details and key points behind it. Moldflow software, as a professional plastic injection molding…

View On WordPress

#injection mold#injection molding process#Injection molding process of plastic parts#injection molds#mold design#mold flow analysis#mold manufacturing#Moldflow#plastic injection molding#Plastic injection molding process#plastic injection molding simulation tool#product design#product development

0 notes

Text

Unlocking Innovation: Exploring Two-Shot Molding and the Power of 2K Molds

Two-shot molding and 2K molding refer to advanced injection molding processes used in the manufacturing of plastic components. Here's a brief explanation of each:

In summary, two-shot molding and 2K molding are advanced techniques that offer increased design flexibility, cost savings, and improved product functionality by allowing the integration of different materials or colors into a single molded part.

#injection mold surface finish#injection mold tooling cost#2k mold#injection mold trial#molding#insert overmolding#plastic injection molding cost#injection molding#injection mold prototype#two shot mold

0 notes

Text

Introduction to Product Design and Development in Plastic Injection Moulding from Concept to Creation

Product design and development are crucial stages in the plastic injection moulding process. They involve transforming an idea or concept into a tangible, manufacturable product. Effective design and development not only ensure

the functionality and aesthetics of the final product but also contribute to manufacturing efficiency and cost-effectiveness. In this blog, we will explore the key considerations and steps involved in the product design and development process for plastic injection moulding.

Conceptualisation and Design

The product design phase begins with conceptualising the desired product. Consider factors such as its purpose, target market, and user requirements. Once the concept is defined, detailed design work can begin. Utilise computer-aided design (CAD) software to create 3D models of the product. This allows for visualising the final outcome and identifying any potential design flaws or improvements. Pay attention to aspects like part geometry, wall thickness, draft angles, and assembly requirements. You could collaborate with our in-house designer or other designers, engineers, and other stakeholders to optimise the design for manufacturability and cost efficiency.

Material Selection

Choosing the right plastic material is critical for product performance and durability. Consider factors such as mechanical properties, chemical resistance, heat resistance, and cost. Consult material suppliers or engage with experts to identify the most suitable plastic resin for your specific application. Conduct thorough testing and analysis to ensure that the selected material meets the product’s requirements and can withstand the injection moulding process.

Prototyping and Testing

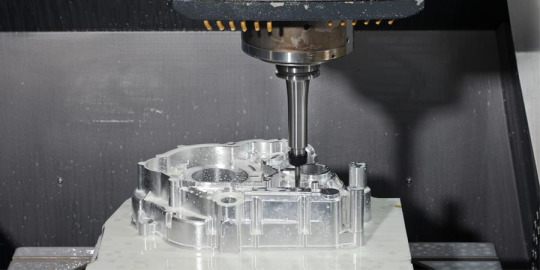

Prototyping allows for evaluating the design’s functionality, fit, and aesthetics before mass production. Use rapid prototyping techniques, such as 3D printing or CNC machining, we do also offer a rapid aluminium plastic injection mould tool to create physical prototypes. Test the prototypes for structural integrity, dimensional accuracy, and other performance aspects. Iteratively refine the design based on the feedback and results obtained from prototype testing. This process helps identify and address any issues early on, saving time and costs in the long run.

Tooling and Manufacturing Considerations

Collaborate with experienced toolmakers and moulding experts such as ourselves to ensure that the product design is optimised for the injection moulding process. Consider factors like part complexity, draft angles, gate placement, and ejection mechanisms during the design phase. These considerations influence the tooling design and help streamline the manufacturing process. Work closely with our tooling team to create moulds that meet the design requirements while ensuring efficient production and quality control.

Continuous Improvement and Iteration

Product design and development should be viewed as an iterative process. Continuously seek feedback, collect user insights, and analyse market trends to identify areas for improvement. Leverage customer feedback and data to refine and enhance the product design. Embrace innovation and stay updated with the latest technologies and manufacturing techniques to stay competitive in the market.

Conclusion

Successful product design and development in plastic injection moulding require careful consideration of factors like conceptualisation, design optimisation, material selection, prototyping, and manufacturing considerations. By prioritising functionality, manufacturability, and market requirements, businesses can ensure the creation of high-quality products that meet customer needs. Continuous improvement and innovation in the design and development process contribute to the success and growth of plastic injection moulding projects.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#toolmaking#injection moulding#plastic injection moulding#tool making#uk manufacturing#rapidprototyping#rapid prototyping#injection mould toolmaking#plastic injection molding#plastic#manufacturing

0 notes

Text

It's crucial to pick a manufacturer who can accommodate your particular requirements when it comes to producing custom plastic goods and plastic tooling. Make sure the organisation has the expertise and resources necessary to produce the products you need. Plastic Navigation Industrial Ltd, is one of the best and reliable custom plastic products manufacturers in USA with a team of highly professional and experienced employees.

For more details visit our website.

#plastic mold maker#plastic prototypes#one stop manufacturing for plastic products#injection molding company#plastic tooling

0 notes

Text

Top plastic molds manufacturer in coimbatore 2023 updated

When it comes to plastic molds manufacturer in Coimbatore, there are several reliable options to choose from. Coimbatore is known for its thriving manufacturing industry and has a range of plastic mold manufacturers that cater to various industries. Here are some top plastic molds manufacturers in Coimbatore:

Santhana Lakshmi Industries

With over 30 years of experience, Santhana Lakshmi Industries is a reputed plastic molds manufacturer in Coimbatore. They specialize in producing high-quality injection molds for industries like automotive, electrical, and consumer goods. We are a reputed manufacturer of plastic molds in Coimbatore. The company offers a comprehensive range of products, including injection molds, blow molds, and rotational molds, among others.

Best Precision Tool

Best Precision Tool is a well-established plastic molds manufacturer that has been in the industry for over two decades. They have a team of experienced professionals who specialize in designing and manufacturing plastic injection molds for various industries. We are a leading manufacturer of plastic injection molds in Coimbatore. The company has state-of-the-art manufacturing facilities and a team of experienced professionals who ensure the production of high-quality molds.

Tech Plaastic Industrie

Tech Plastic Industrie is another prominent plastic molds manufacturer in Coimbatore. They have a state-of-the-art manufacturing facility that produces high-quality molds for industries like automotive, medical, and consumer goods.

Shree Plastics

Shree Plastics is a reliable manufacturer of plastic molds in Coimbatore. They specialize in producing molds for industries like automotive, electrical, and consumer goods.

AKR Industries

AKR Industries is a leading manufacturer of plastic injection molds in Coimbatore. They have a team of experienced professionals who specialize in designing and manufacturing molds for industries like automotive, electrical, and consumer goods. We are a prominent manufacturer of plastic injection molds in Coimbatore. The company has a team of experienced professionals who specialize in creating customized molds for different applications.

Raman Tools and Dies

Raman Tools and Dies is a leading manufacturer and supplier of plastic molds in Coimbatore. The company has a well-equipped manufacturing unit and a team of skilled professionals who ensure the production of high-quality molds.

Sree Sastha Engineering

Sree Sastha Engineering is a reputed manufacturer of plastic molds in Coimbatore. The company offers a wide range of products, including injection molds, blow molds, and compression molds, among others.

GKR Plast

GKR Plast is a prominent manufacturer of plastic injection molds in Coimbatore. The company has a team of experienced professionals who specialize in creating customized molds for different applications.

Veejay Enterprises

Veejay Enterprises is a well-known manufacturer of plastic molds in Coimbatore. The company offers a comprehensive range of products, including injection molds, blow molds, and rotational molds, among others.

Neelam Plastics

Neelam Plastics is a leading manufacturer of plastic injection molds in Coimbatore. The company has a state-of-the-art manufacturing unit and a team of skilled professionals who ensure the production of high-quality molds. All of the above-mentioned plastic molds manufacturers in Coimbatore have a track record of producing high-quality injection molds that meet industry standards. Choosing the right manufacturer that suits your specific requirements is essential to ensure the success of your project.

1 note

·

View note

Text

How Hands Craft Precision: A Journey through Injection Parts and Molding Services by PTMS

PTMS's injection parts and molding services exemplify the pinnacle of precision engineering and craftsmanship. With a steadfast commitment to excellence and a focus on meeting the diverse needs of clients, PTMS continues to set the standard for innovation and quality in the manufacturing industry.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

1 note

·

View note

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more : https://www.viratsteels.com/hot-work-steel.html https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

Month 4, day 4

Plastic! :D

I still have work to do to get it the way my roommate wanted me to try doing, which is specifically adding things like tool marks and injection mold seams to make it look like a model kit. Which I think I can do? But anyway this is a good base to at least experiment with as I go :D

#the great artscapade of 2024#art#my art#render#blender render#cycles render#procedural texture#I thiiiiiink I know how to do the tool marks#definitely know how to do the finger prints lol I can just copy that part of the Cycles glass tutorial#also I think this would look better if I added a smidge of subsurface scattering#just a twinge#but it's WAY past my bedtime as usual so I'm gonna go to bed :)

2 notes

·

View notes

Text

T&R Tooling is a leading provider of plastic injection molding in Northern Texas. With years of experience and a team of skilled professionals, we specialize in delivering high-quality, precision-molded plastic components for a wide range of industries. Our state-of-the-art facility is equipped with advanced machinery and technology to handle projects of any complexity.

T&R Tooling 282 Elm Grove Rd., Valley View, TX 76272 (940) 726–6020

My Official Website: http://www.trtooling.com/ Google Plus Listing: https://www.google.com/maps?cid=1529569677814869897

Our Other Links:

plastic injection tooling in Texas: http://www.trtooling.com/new-tooling/ rapid prototyping Texas: http://www.trtooling.com/3d-printing/

Service We Offer:

Plastic Injection Molding 3d Printing Tool Repair New Tooling Design Services Quality Assurance

Follow Us On:

Twitter: https://twitter.com/ToolingR31294 Pinterest: https://www.pinterest.com/trtoolingtx/ Instagram: https://www.instagram.com/trtooling/

#plastic injection molding northern texas#custom injection mold tools texas#tooling for plastic injection molding texas#plastic injection tooling in texas#prototyping texas

0 notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

extruder screw barrel

There are plenty of enterprises these days creating plastic derivatives. Yet, every firm or manufacturing corporation requires a plastic type of tool. one essential part of plastic processing tools is a screw barrel, which has a threaded design for melting, mixing, and shaping plastic materials. This unique barrel, which is used in conjunction with a screw to efficiently melt, compress, and inject molten plastic into molds, is essential to the manufacturing processes that produce plastic goods. Without an Extruder Screw Barrel technique, any plastic derivative department can't achieve the final stage. Also, with the service of these Screw Barrels, the derivative unit can effortlessly achieve the crucial quantity of creation.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#ScrewBarrel#PlasticProcessing#IndustrialTools#ManufacturingComponents#MachineryParts#commercial#marketing#ecommerce#branding#sales

1 note

·

View note