#injection mould toolmaking

Explore tagged Tumblr posts

Text

Introduction to Product Design and Development in Plastic Injection Moulding from Concept to Creation

Product design and development are crucial stages in the plastic injection moulding process. They involve transforming an idea or concept into a tangible, manufacturable product. Effective design and development not only ensure

the functionality and aesthetics of the final product but also contribute to manufacturing efficiency and cost-effectiveness. In this blog, we will explore the key considerations and steps involved in the product design and development process for plastic injection moulding.

Conceptualisation and Design

The product design phase begins with conceptualising the desired product. Consider factors such as its purpose, target market, and user requirements. Once the concept is defined, detailed design work can begin. Utilise computer-aided design (CAD) software to create 3D models of the product. This allows for visualising the final outcome and identifying any potential design flaws or improvements. Pay attention to aspects like part geometry, wall thickness, draft angles, and assembly requirements. You could collaborate with our in-house designer or other designers, engineers, and other stakeholders to optimise the design for manufacturability and cost efficiency.

Material Selection

Choosing the right plastic material is critical for product performance and durability. Consider factors such as mechanical properties, chemical resistance, heat resistance, and cost. Consult material suppliers or engage with experts to identify the most suitable plastic resin for your specific application. Conduct thorough testing and analysis to ensure that the selected material meets the product’s requirements and can withstand the injection moulding process.

Prototyping and Testing

Prototyping allows for evaluating the design’s functionality, fit, and aesthetics before mass production. Use rapid prototyping techniques, such as 3D printing or CNC machining, we do also offer a rapid aluminium plastic injection mould tool to create physical prototypes. Test the prototypes for structural integrity, dimensional accuracy, and other performance aspects. Iteratively refine the design based on the feedback and results obtained from prototype testing. This process helps identify and address any issues early on, saving time and costs in the long run.

Tooling and Manufacturing Considerations

Collaborate with experienced toolmakers and moulding experts such as ourselves to ensure that the product design is optimised for the injection moulding process. Consider factors like part complexity, draft angles, gate placement, and ejection mechanisms during the design phase. These considerations influence the tooling design and help streamline the manufacturing process. Work closely with our tooling team to create moulds that meet the design requirements while ensuring efficient production and quality control.

Continuous Improvement and Iteration

Product design and development should be viewed as an iterative process. Continuously seek feedback, collect user insights, and analyse market trends to identify areas for improvement. Leverage customer feedback and data to refine and enhance the product design. Embrace innovation and stay updated with the latest technologies and manufacturing techniques to stay competitive in the market.

Conclusion

Successful product design and development in plastic injection moulding require careful consideration of factors like conceptualisation, design optimisation, material selection, prototyping, and manufacturing considerations. By prioritising functionality, manufacturability, and market requirements, businesses can ensure the creation of high-quality products that meet customer needs. Continuous improvement and innovation in the design and development process contribute to the success and growth of plastic injection moulding projects.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#toolmaking#injection moulding#plastic injection moulding#tool making#uk manufacturing#rapidprototyping#rapid prototyping#injection mould toolmaking#plastic injection molding#plastic#manufacturing

0 notes

Text

The Plastic Injection Molding Basics

The plastic injection molding process begins with generating the product design, followed by tooling a mold to fit the product design, melting the plastic resin pellets, and injecting the molten pellets into the mold using pressure.

Steps

Designing the Product

Designers build a part using fundamental design rules related to the injection molding method.

Create a Tooling Mold to Fit the Product Design

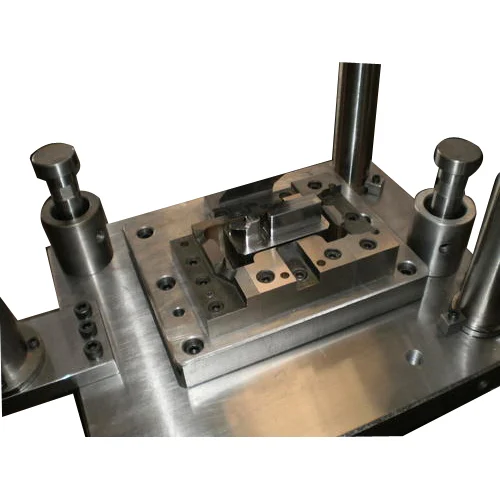

Highly trained machinists and toolmakers use the product design to create a tooling mold for the injection molding machine. A tooling mold, also known as a tool, is the heart and soul of an injection molding machine. They are meticulously built to house the negative cavity for the product design as well as extra features including sprues, runners, gates, vents, ejector systems, cooling channels, and moving components. Tooling molds are constructed from steel and aluminum grades that can survive tens of thousands of heating and cooling cycles. Mold manufacturing can take up to 20 weeks to complete, including fabrication and approval, making it the most time-consuming phase of injection molding. It is also the most expensive component of Plastic Injection Process, and once created, a tooling mold cannot be significantly altered without incurring additional expenditures.

Melt the plastic resin pellets

After obtaining the final mold, operators place it into the injection molding machine, which shuts and begins the injection molding cycle. Plastic pellets are put into both the hopper and the barrel. The reciprocating screw is dragged back, allowing materials to pass through the area between the screw and the barrel. The screw then plunges forward, pushing the material deeper down the barrel and closer to the heater bands, where it melts into molten plastic. The melting temperature is maintained at the material requirements so that no deterioration happens in the barrel or the mold itself.

Using pressure to feed the molten pellets into the mould

The reciprocating screw pushes the molten plastic through the nozzle, which is in a depression in the mold called a mold sprue bushing. The moving platen pressure compresses the mold and nozzle firmly, preventing any plastic from escaping. This Plastic Injection technique pressurizes the melted plastic, allowing it to enter all sections of the mold cavity while displacing cavity air through the mold vents.

#Plastic Injection Molding#Plastic Injection Process#Plastic Injection Process China#Plastic Injection

1 note

·

View note

Text

A Complete Overview Of Mold Making Process & Design Process

The processes of production and product design have changed as well as we've advanced from revolutionary innovations like the light bulb to the telecommunications age of the radio, phone, and television. Modern mold-making by plastic moulding manufacturers has advanced thanks to computers, the internet, renewable energy, and all that comes after.

What Is Mold Making?

Making injection molds for precise plastic components is a technique known as mold making. The molds must be created with extreme precision since they represent one of the biggest manufacturing investments. To guarantee that components can be mass manufactured with repeatable accuracy, modern plastic injection frisbee demands extremely high precision.

Stainless steel plastic injection mold's interior

The creation of the tools used to make, handle, or test things throughout manufacturing must also be flawless. Precision molds of the highest caliber are durable investments for any business. The following factors can affect how much the plastic injection mold costs:

Key Metal

The material selected for a mold is greatly influenced by the anticipated length of a production process. For instance, some plastic moulding manufacturers employ hardened steel (or another equally resistant metal) molds for large production runs and long-term projects and aluminum molds for short production runs and short-term projects. Consider if it is more cost-effective to buy an expensive but long-lasting mold or to use a less costly but less durable mold and replace it as it becomes worn when choosing a material for injection mold making.

Tip: To know more about plastic molds for chocolate making, visit Moulding Injection.

Cavities present

Family molds enable the simultaneous manufacture of several components. The majority of molders advise using one mold per part instead because they frequently result in parts with lower quality and performance characteristics.

Concerning mold production, the number of cavities impacts the time, labor, and costs required to manufacture a mold. In general, a mold design with fewer cavities requires less resource investment than one with more cavities, which requires more resource investment. Expert plastic injection mould manufacturer has to be able to maximize the number of cavities for maximum production effectiveness and the lowest cost.

Mold Base

The steel mold foundation serves as structural support for the mold cavities, inserts, and other parts. Depending on the size, the size, and the type of steel utilized

Cavity/Core Machining

Every mold is unique to the application's component and manufacturing requirements. Mold components including cavities, cores, cooling lines, and ejectors may all be customized. The degree of personalization affects the overall price, particularly if the mold is made of hardened steel or other metals.

Contact the chocolate packaging manufacturer at Moulding Injection. Get high-quality, customised molds as per your requirements.

Partially Complex

The cost of the necessary mold increases with the desired part's complexity. This beneficial link exists because the mold design must take into account all of the part design specifications, including those on tolerance and surface roughness.

What Has Modified?

In the 18th and 19th centuries, plastic injection molding initially became popular. When the Industrial Revolution was at its height, most tasks for toolmakers had to be completed by hand. It took a lot of time to form tools, heat treats them, sharpen them, machine the metal, then drill out the pattern by hand. Any item manufactured by human hands is unique, hence there were frequent conformity issues and no two molds were the same.

Two mold-making innovations that made a substantial difference in the transition from manual to computer-assisted machining are: Moulding Injection offers cutting-edge manufacturing solutions, such as mold design, mold construction, and high-volume part production. We are well known across the world for producing injection molded components of the finest quality and accuracy at incredibly low costs. We offer all of the resources required to swiftly and precisely accomplish any project, from conception to completion.

#plastic chocolate molds#plastic injection mold design#injection frisbee#plastic injection molding manufacturer#plastic injection mould manufacturer#injection molding solutions#best injection molding company

0 notes

Text

All That You Want to Learn About Custom Molding

Are you looking for Lane Divider Wellington in NZ? As a manufacturing cycle, custom molding offers some benefits over other production processes. It includes other varieties of molding. There's a reason that the global plastics market will soar $654.38 billion in value.

A major part of it lies in the extent to which molding serves a wide variety of applications. It finds application across the industry verticals.

What are the goods of using custom moldings?

Indeed, there is no one-size-fits-all term when it comes to manufacturing means. But, we have got reasons why injection molding should be on your list.

Custom molding has broad design flexibility.

Custom molding can design complex pieces as per the needs of the customer. There are some approaches of Custom Mouldings Extrusions that ensure efficient production.

The possibilities within the custom extrusion mean are limitless. It adheres to conventions like rounded corners. Toolmakers and injection molding users can meet even the most intricate requirements.

Custom molding is customizable.

The fact is injection molding resins are good enough to get colorants mixed with them. It produces surface coloring a bit different from the natural. Most stores can recreate Pantone colors for an injection molding means. It makes the process suitable for processes where aesthetics play a vital role.

Custom molding gives you control over quantities.

A custom molding supplier allows you to produce work in any quantity needed for your firm. You can work on medium, low and high prototype runs. Custom Mouldings Extrusions provide you with an affordable solution.

But, it loses value if you get forced into machine types or least orders.

The fact is that 3D printed models exist to make short-run injection molding better. It is an accessible and viable option.

Custom molding offers a combination of parts and materials.

Advanced techniques like co-molding make injection molding an easy means. It allows you to add customization to your products.

Using a process like custom molding means that the injection molded part doesn't limit you. You don't need to rely on materials just suitable for injection molding. For instance, you can set resin around a piece for added strength. It gives the metal part a more attractive appearance. It likewise renders a complex functionality to it.

If you want to buy Moulding Plastic Products New Zealand, you can contact us today.

Custom molding is inexpensive.

Price is one of the benefits of using custom molded parts. You've got another way to produce parts. When compared to bespoke molding, it offers more time, labor, and energy.

Manufacturing firms can work better and faster with custom molding. Hence, it passes down the savings to customers in form of low prices. You can save more money by choosing custom-molded parts. It likewise meets your business requirements.

Corrosion isn't a concern for custom-molded parts. The best thing is that it doesn't contain any material that's prone to corrosion. Hence, custom-molded parts can stand the test of time. For more info on Custom Mouldings Extrusions, stay tuned.

0 notes

Text

Plastic Injection Mould Tooling

https://www.key-plast.com/plastic-mold-making/

Plastic molds are tools that are matched with plastic mold making machines in the plastic processing industry to give plastic products a complete configuration and precise dimensions. Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic injection mold making machines and plastic products, the types and structures of plastic molds are also diverse.

What Is A Plastic Mould Tooling ?

Injection molding tooling is at the heart of plastic injection mold making. Whether it’s a complex operation or simple part, plastic mould tooling – more specifically, tooling design – determines the quality of the injection molding process and the parts produced.

Scientific molding is crucial. It provides largely accurate process of plastic injection mould making that lead to top- quality corridor with constantly tight forbearance and unremarkable confines.

Injection molders and toolmakers experienced in the application and use of scientific molding help clients steer away from arbitrary injection molding tooling design decisions in favor of data-based precision. It sounds elementary, but the factors that could skew injection mould tooling design, engineering, and outcomes are numerous. Engineers specially trained in scientific plastic injection mold making can readily identify and help prevent potential missteps.

Plastic Mould Tooling Capabilities

Plastic injection molds are used when there is a requirement for male or female threads on a plastic component.

An assembly of heated components used to inject molten plastic into the cavities of the injection molding mold.

Includes mechanical action incorporated into the design when a hole, slot, undercut or thread is needed that is not perpendicular to the parting line.

Provides one parting line and the plastic injection moulds splits into two halves; the sprue, runners, gates and cavities are all on the same side.

Plastic Mould Tooling Protection Investment

Preventative:Once a injection molding mould has run a set number of cycles, examinations, conservation and cleaning should be performed. Different types of mold in injection molding age at different rates, so scheduling conservation needs to be proved precisely. Our knowledge and experience gives us the capability to determine the stylish mold conservation schedule specific to each injection moulding mold.

Maintenance:Injection molding tool repairs can be costly. This means it is critically important for injection molds to receive regular maintenance; this is simply the best way to protect your investment and maintain consistent production of quality plastic components. With our on-site plastic injection mould tooling facility we provide quick and efficient mold repairs or revisions.

How To Make Injection Molds?

Injection molding is by far the most protean of all injection molding ways. The presses used in this process vary in size and are rated grounded on pressure or heftiness. Larger machines can injection earth auto corridor. Lower machines can produce veritably precise plastic corridor for surgical operations. In addition, there are types of injection moulds that can be used in the plastic molding and manufacturing process, adding its inflexibility for contrivers and masterminds.The process itself is fairly straightforward; still, there are numerous advancements and customization ways that can be used to produce the asked finish and structure. Plastic injection molds, which are generally made from sword, contain depressions that will form the corridor. Melted plastic is fitted into the earth, filling the depressions. The mold is cooled, and the corridor are ejected by legs. Injection moulding raw material list can be varied.

This process is analogous to a jello mold which is filled also cooled to produce the final product.The mold making costs in this system are fairly high; still, the cost per part is veritably provident. Low part cost along with resin and finish options have all contributed to injection molding’s fashionability in moment’s manufacturing geography.

Mold Making

As a professional injection molding supplier, we complete all plastic injection mould making, from cutting materials to cavity carving, and then to the final assembly. We have advanced high-speed milling machines, electric discharge machines, wire cutting machines, and engraving machines to ensure that the machining accuracy can meet the requirements.

Mold Making

Mold Trial

Generally, the mold is not directly regarded as the final product when it is designed, because it will have such or other defects after it is produced. However, this type of defect There is no guarantee that they will be completely avoided before manufacturing. During the manufacturing process, there may be phenomena that cannot be stored and processed. Therefore, it is necessary to go through the trial model, and then analyze, evaluate and optimize the samples produced by the trial model to meet the requirements. High quality requirements. However, most of the defects of plastic mould tooling products are caused during the plasticization and injection molding stages, and may also be caused by improper manufacturing of plastic molds. Therefore, in order to avoid product defects caused by mold design in injection molding process steps, it is necessary to analyze when making molds. Mold design and process parameters.

Mold Trial

Sample Confirmation

The acceptance of the part shall be carried out at least 16 hours after the completion of the molding of the plastic part or the required post-treatment.

1. Inspection of product matching size

The matching dimensions of injection molding mold products refer to the matching dimensions between products or between injection moulding products and related components, including partial matching dimensions and overall relative position dimensions.

2. Trial assembly inspection

When the inspections of basic dimensions, external dimensions, and matching dimensions are completed and the design requirements are basically met, trial assembly inspection can be carried out. This is a very important means in product inspection. It can verify the matching dimensions and verify the space surface.

3. Injection molding quality inspection

When the pre-installation meets the requirements, the apparent quality of the part needs to be comprehensively inspected. At this time, the apparent quality refers to whether the apparent quality meets the requirements under the condition that there are no common defects.

0 notes

Text

What is the exact working of an injection moulding machine?

Injection molding machines are sophisticated machines that use molten materials injected by a reciprocating screw mechanism into a mold to form a single solid object. A hopper, barrel with a reciprocating screw, temperature control devices, clamping unit, as well as injection mold are just few of the many parts that make up this machine.

The first step is to make a mold of the object. Toolmakers manufacture the mold based on the requirements provided by the designer or otherwise engineer in the form of a 3D computer model. Plastic Injection Moulding Manufacturers will always help you. The mold is built so that its two sides, the cavity as well as the core, can split apart at the separating line. When the component has cooled, the injection molding machine may simply eject it. The part could be damaged by catching on the mold if it is poorly designed.

Before injection molding can begin, the machine's parameters and parts must be meticulously set up. Plastic Parts Injection Molding is usually fantastic. The part's size and shape, as well as the material being used, will determine the ideal ranges for the mold's temperature as well as pressure. The machine could be left unattended once the settings have been made and the cycle has begun.

Here's how it goes down:

The machine's hopper is used to deposit raw materials and dye into the barrel. The raw materials are heated and compressed in the barrel until they actually melt and become pliable. At a predetermined temperature, pressure, as well as speed, the reciprocating screw within the barrel would turn, injecting a measured amount of the molten plastic further into the injection mold. Plastic Parts Mass Production is generally done frequently.

After the plastic mold is full, the injection process will stop. The next step is to wait for the component to cool in the mold until it is ready to be removed. Based on the materials, wall thickness, huge look, as well as shape of the object being created, this could take some time. The mold will release its contents once it has cooled. Rapid Injection Molding is also a good process.

The component is ejected from the mold by an internal ejecting mechanism before the next cycle begins. If the finished item is still partially stuck in the mold at this stage, the mold will reopen to allow the part to be ejected in its entirety. You can even get the Customized Plastic Parts. Once the component is out of the way, the hopper will empty its contents into the barrel, starting a new cycle. The injection molding machine is a fully automatic system that can run nonstop around the clock once it has been set up. An important step is to Insert Injection Mold.

For more than seventy years, people have been using the same basic idea behind the plastic molding machine. The process of making ordinary objects by pouring molten plastic into a mold has come a long way since its inception.Injection Mold Inserts are actually fantastic.

0 notes

Text

Quality toolmaking

You may produce cutting-edge tools for plastic injection moulding with the assistance of SDI Plastics since they have the tools, know-how, expertise, and experience with both onshore and offshore toolmaking.

Call on - 7 3807 8666

1 note

·

View note

Text

Guidelines to know about design for manufacturing

There are numbers of factors that you can consider while designing for manufacture through injection moulding. You will have to ensure that your product can be precisely and consistently produced, yet this might require particular features or parts that will require extra efforts on the part of the toolmakers. For ensuring your design is smooth and the injection mould is fruitful, here are ten design guidelines to follow:

Keep it simple

When you wish to know about design for manufacturing, you will have to keep it simple. Design is about clean-lined, uncomplicated products, which are quite functional. Simple lines, shapes, and curves will have your design looking trendy and aesthetically pleasing.

Using standards

When you are designing a product, you should not specify any odd-sized screws and also hard-to-source materials. Designing with 'off the shelf' standard components in mind will keep your design both affordable and efficient. People will assuredly want to use something, which is entirely maintained, so you will have to make your design with the end-user in mind.

Design for ease of fabrication

The design for manufacturing is not a very simple task rather you need to make sure that you take help from the experts and professionals. Do not make everything a challenge for any toolmaker. Part of product design is to make something, which is extremely pleasing to the customer and relatively easy to manufacture.

Avoid thin walls or anything, which will warp during the cooling of your mould. Making the mould with long, spider-web thin walls or chunks will take a long time to cool will likely result in expensive warpage and rejects, leading to the need for a redesign.

Avoid undercuts

You will surely need to think about where the parting line will need to be. You also need to avoid protrusions that will snag on the mould when it is opened. When you are going to choose the best strategy for design for manufacturing, you will have to take help from the experts and professionals. They will surely assist you to know about the details regarding manufacturing products.

0 notes

Text

Mould Design in Plastic Injection Moulding

Injection Moulding is an extremely versatile procedure. It can be utilised for virtually any product. Injection moulding is the industry standard for manufacturing components for products.

There are some limitation needs to consider. Here are the rules to follow when designing your product to make sure quality and durability:

Wall Thickness

Keeping your walls thin will ensure a faster cooling rate and less materials used. Lower cooling rate and less material used will result in a shorter cycle time. This allows you more parts in a shorter amount of time, for less production cost

To strengthen parts, ribs are more effective than thicker walls. Adding ribs at right angles to a wall will add considerably to its overall strength. It is a common mistake to thicken the walls of a design to achieve this effect when ribs are a cheaper and more effective option.

Ribs should be about half the main wall thickness. There can be some leniency here, but not too much or the ribs will be completely ineffective. Half is the generally accepted standard and is more than enough to increase a wall’s strength.

Coherence

Try to make your design uniform throughout. That is, wall thickness, rib thickness and corner radii, for instance, should all be the same values. This will help the part to cool uniformly.

Corners & Edges

Corners could be an issue in a mould and will not come out flush. It is difficult to form plastic into a flawless corner. The outcome will look amateurish and messy, not to mention the power of the components can be compromised.

Corners and edges should be rounded wherever possible. Sharp edges do not always come out perfectly when the part is ejected from the mould.

Add a slight angle to the sides of your mould to allow easy release. A one- or two-degree angle should be applied to the mould on the face perpendicular to the parting line. This will allow for easy removal of the part from the mould.

Ribs

These are structural factors for your component, utilised for general stability control. Ribs are thin wall protrusions which extend vertically from a plane or wall. Adding ribs instead of thicker walls will provide greater structural support.

Bosses

These are empty, cylindrical protrusions. These are normally integrated in a style for accepting screws or other mating parts of your style. Making sure these are secured by attaching them a wall. Putting in ribs will means the bosses will stay straight as well as accommodate the part it was made for without an issue.

External Undercuts

A depression or protrusion in the exterior of the mould – the cavity half – could create issues if trying to divide parts from the mould. Adjust the parting line to lodge this.

Internal Undercuts and Overcuts

Related to external undercuts, these depressions or protrusions are within the mould – on the centre half. Adjust the parting line to lodge this.

Protrusions on the part that will snag on the mould core or cavity when it is opened can make it impossible to remove from the mould.

Threads

When your mould has a thread, always position it vertical to the parting column. This will make sure that the delicate thread isn’t damaged. It’s better, preferably, to not comprise a thread at all in the design. Making your design simple will lower the odd of something going wrong.

Injection mouldingdesign makes a superior product. The myriad possibilities far outdo the limitations. Designing for an excellent injection moulded part is the core of the design process. These restrictions are the guidelines for making a flexible end product.

Colour use

Where possible, use lighter colours for your moulds. The mould is already cool when the molten material is being injected. As such it begins the setting process immediately and will sometime leave setting patterns. Using lighter colours will help y.to hide these patterns.

Injection mouldingis the industry standard for creating lasting, quality parts. To be able to take advantage of this technology your design must meet its minimum requirements. Small considerations are all it takes and the result is a successful product that will meet all of your quality needs.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#plastic injection molding#plastic injection moulding#injectionmoulders#injection moulding#injectionmouldtooling#injection mould toolmaking#toolmaking#tool making#toolmakers#tooling#rapid prototyping#productdevelopment#product design#productdesign#made in uk#made in britain

2 notes

·

View notes

Link

Agentdraw Ltd, are a leading manufacturing company within the UK plastics industry that specialise in the production of injection moulded components. Our aim is to support your success by providing you with a complete service, from strong, in-house design and engineering through to comprehensive production tooling and manufacturing solutions.Whatever your requirement, you can rest assured that we have a proven track record for developing and mass producing successful products and technologies.

1 note

·

View note

Text

Overview of the Development of Plastic Products

In this post, we go over the many sorts of analyses done while developing a plastic part to assure product quality. Injection moulding is the most widely used industrial technique for producing plastic items. With injection frisbee, a wide variety of things are produced, each with a distinct size, degree of complexity, and use. A mould, raw plastic material, and an injection moulding machine are required for the injection moulding process. The plastic is melted in the injection moulding machine, injected into the mould, cooled, and solidified to create the completed product.

An examination of the mould flow should be done before the first prototype of a plastic injection moulding die is started. Mould flow analysis is not necessary for every application. Plastic engineers will offer suggestions for including mould flow analysis in the production budget based on the product geometry and tolerance specifications.

What is a Mold Flow Analysis in Plastic Product Design?

Mold flow analysis enables businesses to enhance the design of their injection moulds and create better products through the use of software to mimic plastic flow.

Manufacturers can identify potential issues by performing mould flow analysis to gain a view of how the material they are employing will fill a mould hole. This will predict how to produce parts that are as light, sturdy, and consistent as possible from each cavity in the mould. The plastic is melted in the injection moulding machine, injected into the mold, cooled, and solidified to create the completed product. This can also offer a chance to optimise the melt temperature, moulding pressures, fill cycle times, etc. before the first piece of art is produced. By using software for mould flow analysis, you can virtually alter the mould before the actual cutting and reduce production costs.

Mold Flow Analysis In Plastic Product Design

i) Fill/Pack Analysis

The filling and packing study allows the designer and toolmaker to predict how the selected resin will behave as it flows through the mould to produce your items. To optimise the fill and pack for an injection moulding tool, the following qualities will need to be improved:

To facilitate smooth resin flow, the gate and runner sizes must be adjusted.

The tool will be the appropriate size for the tonnage needs.

Practical sink mark identification

Improved gate location is possible.

Molding parameters, such as pressure, can be altered and verified

One can verify the selected resin.

One can pinpoint the placement of the gas traps.

ii) Study of Cooling (Steady State And Transient Analysis)

For calculating cycle time, the cooling phase is frequently crucial. Analyzing the cooling phase will reveal the coolant conditions needed to maximise the efficiency of the suggested cooling architecture. To avoid making expensive and difficult changes to the mould, it is possible to compare the effectiveness of high-conductivity mould inserts and cooling features like baffles and bubblers in advance. An investigation of cooling can help with:

Cycle time reduction

The injection moulding tool's coolant pathways have been optimised.

choice of inserts with high conductivity

Warpage impact is discernible

Assessment of baffles and bubblers

detection of circuit pressure decreases

iii) Warp Analysis

A warp analysis is used to determine the root cause of warping and offer a solution, such as moving the gate, adjusting the design specifications, or minimising the variances in wall thickness. Designers employ the injection moulding technique to mass-make intricate, precise objects.

After the part has been designed, it is crucial to confirm that it can be produced within tolerance and won't warp excessively. Many factors, including the part design, the resin selected, the fibre orientation, the moulding procedure, and the cooling system, might influence warp. By doing a warp analysis, we can pinpoint the root causes of post-moulding part distortion and create the framework for upcoming changes that will lessen or even eliminate the distortion.

iv) Structural Finite Element Analysis (FEA)

When plastics are used in more performance-demanding applications, engineers need a technique to evaluate the design of a part to ensure its performance throughout the planned lifetime. The strength of each part cavity is predicted using FEA analysis. The FEA analysis predicts the weak regions (along with the strongest spots), which can be strengthened for breakpoints, fracture points, and durability during the length of the product's existence. The selection of material or resin, part designs, moulding procedures, and assembly methods can all be enhanced from there to deliver a part of a higher quality.

To know more about customized injection frisbee, visit Moulding-Injection.

Conclusion

These several analyses are related to one another and must be taken into account all at once. These analyses frequently yield information on displacement, temperature profile, stress, creep behaviour, strain, etc. These analysis techniques aid in the resolution of plastic issues, which encourages the production of lower-priced, higher-quality products. When constructing plastic parts, it is essential to comprehend how the plastic will behave in the environment and the operating stress it will experience.

#injection frisbee#chocolate packaging manufacturer#plastic injection mold design#plastic injection molding manufacturer

0 notes

Text

The Importance of the Right Kind of Toolmaking Process

It is important that the new project design should be crafted into existence keeping in mind all the specific requirements. The whole process of toolmaking should include carefully choosing the relevant materials, concept designs to get to the final manufacturing of the part and getting a finished design. It is utilized in various sectors such as electronic, pharmaceutical, Medical, and various others. The production is taken into place only after the approval of the trial samples. Various products including plastic cups can be manufactured.

Read more Full Article The Importance of the Right Kind of Toolmaking Process

#Plastic Injection Moulding#plastic Custom Moulding#Roof tile clips#Toolmaking#Plastic Cups#Plastic Moulding

1 note

·

View note

Text

Know More About EuroMold Trade Fair

New Post has been published on https://www.kj4mks.com/know-more-about-euromold-trade-fair/

Know More About EuroMold Trade Fair

H1: What Is Euromold? Euromold is the leading trade fair in the world in product development for more than twenty years. Anybody such as developers, product managers, executives, etc., who want to launch their new products or ideas will find the right space for interacting with professionals and experts from around the globe. In the whole process, injection mould manufacturers in India and the exhibitors will present the latest engineering, design, molding and tool making, additive manufacturing, or 3D printing. The injection molding company will be awarded an exceptional position in the 3D printing sector to create customized parts if needed. In addition, 3D printing has become a crucial part of classic mold making and tooling. Euromold is the greatest trade show that supports 3D printing / Additive manufacturing. H2: The Trade Exhibition One of the major features of Euromold is the intersectoral exhibition. It offers good solutions for various branches. Unlike other similar fairs, in the intersectoral exhibition, euromold focuses more on holistic thinking that shows how the products manufactured from different departments come together to make innovative opportunities and perspectives. Manufacturers from different industries come to Euromold to exhibit their ideas. In the intersectoral exhibitions, you can find these sectors mentioned below. – Designs – Mold making and tooling – Engineering – 3D printing and additive manufacturing – Production When you come to the exhibition, be prepared to see the best tools, pattern making, processing and finishing machines, and much more. What Are The Reasons To Exhibit? When you decide to come to the intersectoral exhibit, you can – Meet the direct contacts at one place. – Discover the recent and happening market trends and novelties – Plan presentations and get a chance to attract visitors. – Expand the visibility of your brand and increase awareness.

Objective Of EuroMold Brazil 2020 The EuroMold trade fair in Brazil takes place once every two years. The purpose behind conducting the trade far is to show that EuroMold reacts to recent economic development and the increasing demand for mold, tools, engineering, design, simulation, and visualization. Features Of EuroMold Brazil In the event, toolmakers, industrial designers, manufacturing engineers, product managers, executives, and buyers of large industries will share recent manufacturing mold and product development trends. The trade fair will have visitors and exhibitors from the process chain interested in molding manufacturing in South America and Brazil. From the rapid economic growth, the industrial city n souther Brazil can be benefited from h investment from domestic and international companies. The focus of the EuroMold trade fair is on the areas such as sub-contracting, automobile, household appliances, consumer goods, electric and electronic industries, travel and leisure, and air and space travel. EuroMold- International Participation In July, the international participation in the EuroMold trade fair reached 32%. The participation by countries are the following: Italy with 20.2%, Spain with 7,5%, Portugal with 6,7%, France with 7,1%, China and Taiwan with 4,8%, Austria with 6,3%, Hungary with 2,4%, Switzerland with 6%, India and Turkey with 3,2%, the United States with 4%, Great Britain, Hong Kong, Czech Republic, and Belgium with 2% each one, Slovenia with 1,2%, Japan and Luxembourg with 0,8% each one, Bulgaria, Finland, Latvia, Romania, Iran, Israel, Singapore, Korea south, Ukraine, Sweden, and Russia with 0.4% each one.

EuroMold- Production Areas

In most of the EuroMold trade fair, the production area rate goes like Molds and tools with 30.6%, software, and hardware with 8.6%, design of models with an 11.3%, tools with 8.1%, machinery with 8.3%, prototypes and tools with 7.2%, material and auxiliary with 5.3%, engineering with a 6.9%, assurance, and automation with 3.2%, design with a 4.4%, and others with 3.9%.

EuroMold Stands Of Foreign Companies

EuroMold offers booths from different companies. In recent years, the Czech Republic and Hungary got their first-ever booth in the world trade. Turkey has the largest stand at Euromold with a total area of 500 square meters. Two companies, namely Hongkong Mold and Die council and China Die and Mold Association, will represent China. The other countries are Great Britain, Italy, India, Iran, and Taiwan. Continue Reading The main objective of the EuroMold trade fair is to strengthen the molding industry and bring in new innovative ideas for the success of the molding industry.

2 notes

·

View notes

Text

Make The Best Chinese Injection Molding Service

The electric launch machine is one of the essential tools for the plastic mould manufacturing, die throwing tooling and material stamping industries. The times of a ��dark art” method of applying EDM are a issue of the past.

Nowadays, having an automated tool changer, pallet changer, precision EDM tooling, CMM, and lots of preparing, it's rather possible to perform the team 24/7. By adding these numerous methods in the manufacturing process immediately, the China mold Business or any one of plastic mold companies may have complete control. That significantly assists with making detail mold parts and die components in an appropriate manner injection moulding in china.

The first charge outlay is rather high, and a steady flow of function is needed to justify the investment. However, with climbing labor expenses and an acute shortage of experienced help, the fee becomes more reasonable.

Primary organizations

Makino's EDGE2S EDM is a great exemplory instance of utilizing an incorporated method of mould and die manufacture. Sodick EDM and Charmilles-Agie are two different major companies in the manufacturing mobile concept. Sodick's C32 statements to function as the world's most inexpensive EDM and could be a simple method to have started. Charmilles-Agie gets the Form 1000 as some sort of chief for high precision production of mould , die and medical components. The Robofil can be an industry common for WEDM.

All of these models may be incorporated to use the automated software changer, precision tooling, pallet changer and coordinate measuring machine. Process 3R and Erowa both have a complete type of resources to produce that possible.

Program 3R has their Work Spouse 2, which is a small model for pallet changing, equally on the machine dining table and in the machine spindle. They also have an extensive list of pallets, magnetic chucks, electrode slots and just about anything possible, linked to the electrical discharge machine.

Erowa has their Software Active automatic instrument changer/pallet changer that's modular in design. This is a good way to start because you can put more equipment as you'll need it.

How much we came

Just a few years back, if you had been to head into a normal American toolmaking shop, you would find several Eltee Pulsitron EDM machines. We were holding great within their day, really successful and correct, but they certainly were an information machine with very limited abilities.

After the CNC EDM was produced and companies began thinking with regards to automation, the Eltee was banished to the restoration office, wherever it is still very useful.

One error software stores frequently produce is to use and combine their EDM department in a piecemeal fashion. So, they could get out and get some Program 3R pallets with a magnetic toss, a small shell raise to maneuver the pallets around, and believe that it will work. It'll not. The entire method must be looked at in general and each stage should be attached to the others for the program to work.

A few of the older features are extremely badly laid out and this prevents the entire program. Nevertheless, by interacting with the suppliers and with the EDM operators who actually make use of this material, it can be done very successfully.

Cord EDM machine

The WEDM can also be included in the entire process. Instruments and workpieces can be pre-staged for automatic loading in to the machine.

1 note

·

View note

Text

electrode to make a cavity of a plastic

You may be able to throughput a lot of detail, and EDM can do much, but surface grinding is still an essential part of the toolmaker. Both milling and grinding machines need good accessories to carry out tasks properly. A typical milling area should include a granite surface plate, Gage and the indicator of the test surface, the indicator of fall and standing height gauge to mark the lines, square and the indicator lock, angle plates, square block machine, magnetic and nonmagnetic breast plates, and turning accessories. A vertical EDM machine uses an electrode to make a cavity of a plastic injection machine molding.Our machine function steady-going, is good selling at home and abroad, and well received.

Aerospace machine tools providing aerospace 5-axis machining do everything from round holes, through pinholes to die ejector openings. Some of the work done in typical precision mills include base to the square of the core and cavity blocks, die blocks, nails and basic finishing blows, finishing lines and parting and closing angles offs locking assembly slides. A wire machine uses a wire to cut metal for surgery machining for manufacturing. You can have several configurations including brick machines, CNC drill and tap the area, CNC milling, CNC or milling. Ningbo Yinzhou Nuoya Cement Block Machine Factory, a professional manufacturer and exporter of all kinds of Single and Multi Spring brick machine,concrete brick machine,block machine.

We are a member of Building Block Association with excellent and advanced technology. Breast plates, precision lathes, angle plates and grinding wheel dressers must be of the highest quality.The mills used in a precision tool and die shop or injection mould making shop is some of the most Custom Screw Barrels Suppliers important brick machine tools of all. These should be reliable. Block machine is more closely related to making tools for other machines, people often overlook the use of machines. These silent workhorses include surface grinding machines Aerospace axis machining centers milling machines and, of course their qualified and skilled operators. Also you can groove and thread parts on a CNC turning center. Our line of products has already exceeded rest of the industry.

Our factory stick hard and fast to the principle of quality first, service supreme, technology one-up, implement people foremost, vitalize industry with science and technology, constantly upgrade quality, production and service ability. What can be done with a brick machine? In manufacturing, you can use this tool for milling, drilling, milling, drilling and counter boring. EDM can be vertical or wire. Let buyer relieved in buying and desirable in using. We give guarantee to keep in good repair for long term. Aerospace grinding, however, is absolutely essential to the manufacturing process of tools. EDM can also take advantage of CNC operations. With the extensive use of electrode EDM machining, the need for precision grinding has declined in volume. Just imagine not having the ability to do this work and the whole process stops.

0 notes

Text

The Future Of Plastic Injection Molding

The processes of production and product design have developed as we've advanced from revolutionary breakthroughs like the light bulb to the telecommunications age of radio, phones, and TVs. The advancements in current injection frisbee are driven by computers, the internet, renewable electricity, and all that follows after. However, before we can grasp where we're headed, we must first understand how we got here.

What Is Moldmaking and How Does It Work?

Moulds must be created with extreme precision since they are one of the most significant manufacturing investments. To ensure that parts can be mass-produced with repeatable accuracy, modern plastic moulding manufacturers demands great precision.

This level of precision is also necessary for the design of the tools that are used to make, hold, or test objects during the manufacturing process. The following factors can influence the price of a plastic injection mould:

Metal Core

The material for a mould is heavily influenced by the projected time of a production process. Aluminium moulds, for example, are used for short production runs and short-term projects, while hardened steel (or a similarly robust metal) moulds are used for large production runs and long-term projects. When choosing a material for injection mould making, plastic injection mould manufacturer evaluate if it is more cost-effective to invest in a costly but long-lasting mould or to use a less expensive but less durable mould and replace it when it wears out.

Count of Cavitation

Most plastic moulding manufacturers, however, advocate using one mould per part instead, because they usually produce components of lower quality and performance.

When it comes to mould making, the number of cavities has an impact on the amount of time, labour, and money required. In general, fewer cavities in a mould design equals less resource investment, whereas more cavities equal more resource investment. Experienced chocolate packaging manufacturer should be able to optimise the number of cavities in order to achieve the highest production efficiency at the lowest cost.

The Mold's foundation

The cost of producing a mould foundation varies depending on the grade of steel used, modifications incorporated, and the size of the mould.

Machining of the core and cavity

All moulds are made to order to satisfy the application's component and production requirements. Cavities, cores, cooling lines, and ejectors are some of the mould parts that may be customised.

Part Difficulty

The more complicated the desired portion is, the more expensive the mould will be. Because the mould design must meet all of the component design criteria, including surface texture and tolerance, this positive link exists.

What Has Changed Since Then?

During the 18th and 19th centuries, plastic molds for chocolate making became popular. Toolmakers had to do practically everything by hand at the height of the Industrial Revolution. Creating tools, heat treating them, honing them, cutting metal, and drilling out the pattern by hand took a long time. Conformity issues developed often as a result of the uniqueness of everything manufactured by human hands, and no two moulds were exactly the same.

The following are two mold making technologies that had a key role in the shift from manual to computer-assisted machining:

Milling Machines with CNC Control

CNC milling machines began as two-dimensional Bridgeport milling machines with CNC accessories. For increasingly complicated moulds, today's milling machines enable even quicker speeds and precision.

CAD Software

By expediting the mould design process, CAD systems have had a substantial influence on the mould making industry's progress. They made it possible for industry experts to swiftly edit, test, and modify 2D—and eventually 3D—renderings. MIT's Sketchpad and the French UNISURF were among the first systems to transform the design process, and their more complex descendants are still used in mould making operations.

Moldmaking in the Future

Many industry executives have chimed in on what's occurring and what's ahead as manufacturing capabilities advance:

Plastic alternatives' chemical technology is not only advancing, but it's also swiftly becoming a requirement.

#custom injection mould manufacturer#plastic injection mould manufacturer#plastic moulding manufacturers#chocolate packaging manufacturer

0 notes