#injection mold china

Explore tagged Tumblr posts

Text

Exploring Plastic Injection Molding Companies in China: A Focus on Acrylic Injection Molding and Quality Manufacturing

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. This process is highly efficient, allowing for the mass production of complex and durable plastic parts with minimal waste.

Keywords : plastic injection molding companies in China

acrylic injection molding

Injection Mold China

Overmolding

plastic mold

plastic injection molding companies near me

#plastic injection molding companies in China#acrylic injection molding#Injection Mold China#Overmolding#plastic mold#plastic injection molding companies near me

1 note

·

View note

Text

How Hands Craft Precision: A Journey through Injection Parts and Molding Services by PTMS

PTMS's injection parts and molding services exemplify the pinnacle of precision engineering and craftsmanship. With a steadfast commitment to excellence and a focus on meeting the diverse needs of clients, PTMS continues to set the standard for innovation and quality in the manufacturing industry.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

1 note

·

View note

Text

Dong Guan Sincere Tech is a leading injection mold supplier in China, specializing in plastic injection molds for ABS injection molding, silicone molding insert molding etc. With a strong track record, they deliver high-quality molds and precision manufacturing solutions for every industry worldwide in both public and private, meeting the diverse needs of all small and big players worldwide. For more information, please visit https://plas.co/

0 notes

Text

Plastic Injection: A Fascinating Innovation In Manufacturing

Few methods have transformed the complex world of manufacturing as drastically as plastic injection molding. Plastic injection molding influences everything from the biggest automobile parts to the smallest technological components in ways we might not even be aware of. Come along on an engrossing journey into the depths of this intriguing process as we reveal its uses, applications, and effects…

View On WordPress

#Custom Plastic Injection Molding#Plastic Injection#Plastic Injection Molding#Plastic Injection Process#Plastic Injection Process China

2 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Text

Introducing China Automotive Plastic Mould: Precision and Innovation in Automotive Manufacturing

China Automotive Plastic Mould is a leading provider of high-quality plastic moulds for the automotive industry. Specializing in the design and production of moulds, China Automotive Plastic Mould has become synonymous with precision engineering and cutting-edge technology. Our China Automotive Plastic Mould products are renowned for their durability, reliability, and the ability to meet the stringent demands of modern automotive manufacturing.

Each China Automotive Plastic Mould is crafted with meticulous attention to detail, ensuring that the end product is not only functional but also aesthetically pleasing. Our commitment to excellence is evident in every China Automotive Plastic Mould we produce, as we continuously strive to push the boundaries of what is possible in plastic mould technology.

China Automotive Plastic Mould is dedicated to providing moulds that can withstand the rigors of high-volume production while maintaining the highest standards of quality. Our China Automotive Plastic Mould products are used in the creation of a variety of automotive components, from interior trim to exterior panels, showcasing the versatility of our moulds.

Investing in a China Automotive Plastic Mould means investing in a future-proof solution for your automotive plastic component needs. Our China Automotive Plastic Mould is designed to adapt to the evolving requirements of the automotive industry, ensuring that your production lines remain at the forefront of innovation.

China Automotive Plastic Mould is not just a product; it's a partnership with a company that values long-term relationships and is dedicated to the success of your projects. We are proud of our China Automotive Plastic Mould and the role it plays in shaping the future of the automotive industry. Choose China Automotive Plastic Mould for your next project, and experience the difference that precision and innovation can make.

#China Automotive Plastic Mould#injection molding automotive#auto bumper mould#automobile mould#automotive injection molding company#automotive injection molding suppliers

0 notes

Text

HS Mold – Your Partner in Low-Volume Injection Molding for Industrial Design

Industrial design firms are the creative architects of tomorrow’s products. But translating breathtaking concepts into reality can be a budget battle, especially when dealing with limited production runs. Traditional manufacturing often demands high minimum orders, leaving you stranded in financial constraints.

HS Mold: Your GPS to Low-Volume Success

At HS Mold, we specialize in plastic injection molding—your lifeline when industrial design companies need to bring low-volume projects to life. We are among the Plastic injection molding manufacturers in china. We harness the latest technologies and deliver superior quality, even in small production series.

Case Study:Coolant Expansion Tank

Now, let us take you through an instance. A German industrial design firm challenged us to develop the design for a high-performance Coolant Expansion Tank destined for a luxury yacht designed and built in Germany. The catch? They only needed 500 and were on a budget that wouldn’t capsize the project.

HS Mold: Where Experience Meets Collaboration

Immediately, our seasoned engineers went to work. While the initial design considered ultrasonic welding for budgetary reasons, we quickly realized a potential leak in the plan. The watertight seal is crucial to a marine application. Welding simply could not provide the watertightness required for this application. Transparency is our guide. We kept an open discussion with the design firm in a feasible alternative. Our in-house capabilities and experience in low-volume injection molding assisted in guiding the client to what was feasible: vibration friction welding, a revolutionary process we had perfected. It means excellent sealing capabilities with this method, a worry-free voyage for the yacht owner, and all on an affordable budget.

Above Manufacturing: Collaborative Refinements

We indeed committed to more than just the process of manufacturing. Our engineers critically analyzed the design and identified the areas of refinement. We created a detailed DFM (Design for Manufacturability) report with proposals for modifications such as optimizing weld lines, making changes in product thickness, and adding structural ribs. All these added refinements, along with the possibility granted by low-volume injection molding from HS Mold, were able to streamline production and better product quality with more consistent results.

A Successful Voyage: Collaboration Sets Sail

Through the use of vibration friction welding and close collaboration on design optimization, we were able to deliver water tanks far beyond what the customer expected. The superior seal allowed a carefree experience, while the optimized design provided an end product of the highest quality. This success story further established the great partnership between this Industrial Design firm and HS Mold.

HS Mold: Your Low-Volume Injection Molding Partner

This project is an excellent testament to the power of collaboration between Industrial Design firms and HS Mold, one of the leading manufacturers of plastic injection molding in China. We don’t just make; we make you win. Innovative solutions, clear communication, and collaboration allow us to ensure the realization of your vision even under a tight budget and with low-volume needs. Are you ready to chart the course for success with low-volume injection molding? Contact HS Mold today and learn how our experience will help guide you through the rough waters of product development!

0 notes

Text

Plastic Injection Molding: Pioneering Modern Manufacturing - Topwell Technology

Plastic injection molding is a revolutionary process in manufacturing that has reshaped the production of plastic components across industries. This method, which involves injecting molten plastic into a custom-designed mold, is renowned for its precision, efficiency, and versatility. Among the wide range of materials used, ABS plastic stands out due to its strength, durability, and adaptability.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to produce complex plastic parts in high volumes. The process involves:

Designing a Mold: A custom mold is created to the exact specifications of the desired product.

Melting the Plastic: Plastic materials, such as ABS, are heated until molten.

Injection into Mold: The molten plastic is injected into the mold cavity.

Cooling and Ejection: The plastic solidifies as it cools, and the finished product is ejected from the mold.

This method is highly efficient for creating consistent and detailed plastic components, from automotive parts to medical devices.

Why ABS Plastic is a Preferred Material

ABS (Acrylonitrile Butadiene Styrene) plastic is a top choice for injection molding due to its unique properties:

Durability: ABS offers excellent impact resistance, making it ideal for robust applications.

Lightweight: Despite its strength, ABS is lightweight, which is crucial in industries like automotive and consumer electronics.

Design Flexibility: ABS is easy to mold and can be used to create intricate designs with smooth finishes.

Cost-Effective: It offers high performance at a reasonable cost, making it a popular choice for manufacturers.

Choosing a Reliable Mold Manufacturer

The quality of the mold directly impacts the success of the plastic injection molding process. A skilled and experienced mold manufacturer ensures:

Precision Design: Accurate molds for complex and high-quality components.

Durable Materials: High-grade steel and aluminum for mold longevity.

Custom Solutions: Molds tailored to specific client requirements.

Topwell Moulding, a leading mold manufacturer, stands out in this domain. With cutting-edge technology, skilled professionals, and a focus on customer satisfaction, Topwell Moulding delivers unparalleled solutions for plastic injection molding and ABS plastic molds.

Topwell Moulding: Redefining Mold Manufacturing

At www.topwellmoulding.com, innovation meets expertise. Topwell Moulding specializes in creating molds that cater to diverse industries, including automotive, electronics, medical, and more. Key features include:

Advanced Manufacturing Facilities: Equipped with state-of-the-art machinery for precision mold crafting.

Experienced Team: A dedicated team ensures every mold meets rigorous quality standards.

Sustainability Focus: Commitment to environmentally friendly practices in mold production and plastic injection molding.

Conclusion

Plastic injection molding, especially with ABS plastic, is at the heart of modern manufacturing. By partnering with reliable mold manufacturers like Topwell Moulding, businesses can achieve efficiency, precision, and high-quality results. Explore their innovative solutions at www.topwellmoulding.com and take your manufacturing to the next level.

0 notes

Text

In3dtec Technology Co Ltd. is a leading injection molding company in China, known for its commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and technicians, In3dtec has the expertise to handle projects of any size and complexity.

0 notes

Text

Small Batch Plastic Molding in china

Hsmolds.net specializes in small batch plastic molding in China, offering precision and efficiency. With a focus on quality, they cater to diverse industries, ensuring customized solutions for every project. Their state-of-the-art facilities and skilled workforce guarantee exceptional results while adhering to strict quality standards. From design to production, HSMolds.net delivers reliable and cost-effective plastic molding solutions tailored to clients' needs.

0 notes

Text

Discover top-tier Injection Molding Services in China with RCH Plastic. Our state-of-the-art facilities and experienced team ensure high-quality, precision parts for various industries. From concept to production, we offer competitive pricing, fast turnaround, and strict quality control. Visit for more details https://www.rchplastic.com/injection-molding/

0 notes

Text

Elevate Your Production: Expert Injection Mold Tooling in China

Discover the pinnacle of precision and efficiency with PTMS injection mold tooling services in China. As industry leaders, we leverage cutting-edge technology and vast expertise to deliver top-quality molds tailored to your exact specifications. Whether you require prototypes or high-volume production molds, we have the solutions to optimize your manufacturing process. Trust us to exceed your expectations and streamline your production workflow. Learn more about our services at injection mold tooling china.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

0 notes

Text

The Plastic Injection Molding Basics

The plastic injection molding process begins with generating the product design, followed by tooling a mold to fit the product design, melting the plastic resin pellets, and injecting the molten pellets into the mold using pressure.

Steps

Designing the Product

Designers build a part using fundamental design rules related to the injection molding method.

Create a Tooling Mold to Fit the Product Design

Highly trained machinists and toolmakers use the product design to create a tooling mold for the injection molding machine. A tooling mold, also known as a tool, is the heart and soul of an injection molding machine. They are meticulously built to house the negative cavity for the product design as well as extra features including sprues, runners, gates, vents, ejector systems, cooling channels, and moving components. Tooling molds are constructed from steel and aluminum grades that can survive tens of thousands of heating and cooling cycles. Mold manufacturing can take up to 20 weeks to complete, including fabrication and approval, making it the most time-consuming phase of injection molding. It is also the most expensive component of Plastic Injection Process, and once created, a tooling mold cannot be significantly altered without incurring additional expenditures.

Melt the plastic resin pellets

After obtaining the final mold, operators place it into the injection molding machine, which shuts and begins the injection molding cycle. Plastic pellets are put into both the hopper and the barrel. The reciprocating screw is dragged back, allowing materials to pass through the area between the screw and the barrel. The screw then plunges forward, pushing the material deeper down the barrel and closer to the heater bands, where it melts into molten plastic. The melting temperature is maintained at the material requirements so that no deterioration happens in the barrel or the mold itself.

Using pressure to feed the molten pellets into the mould

The reciprocating screw pushes the molten plastic through the nozzle, which is in a depression in the mold called a mold sprue bushing. The moving platen pressure compresses the mold and nozzle firmly, preventing any plastic from escaping. This Plastic Injection technique pressurizes the melted plastic, allowing it to enter all sections of the mold cavity while displacing cavity air through the mold vents.

#Plastic Injection Molding#Plastic Injection Process#Plastic Injection Process China#Plastic Injection

1 note

·

View note

Text

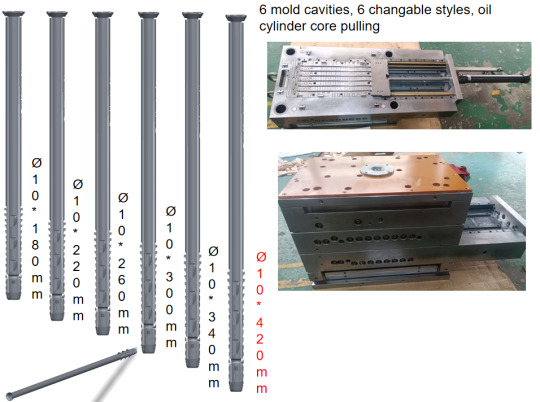

Mould for Plastic Wall Plug

Cavities 6 for 6 changable styles from 180-420mm size Cavities 6 for 3 changable styles from 220-260mm size Cavities 10 for 5 changable styles from 180-160mm size Cavities 12 for 4 changable styles from 80-140mm size

View On WordPress

#Anchor bolt#china factory#Expansion bolt#Fixings Products#injection mold#injection mold design#injection molding#mold design#mold maker#mold making#Nails#plastic parts#Plastic Wall Plug#Screws#Wall anchors.#wall plugs

0 notes

Text

Cost-Effective Solutions: Exploring the Advantages of Outsourcing Injection Molding to China

In ultra-modern globalized economy, groups are continuously in search of fee-effective solutions to preserve competitiveness while handing over first rate merchandise. One such answer that has won huge recognition is outsourcing injection molding to China. With its well-mounted manufacturing infrastructure, professional workforce, and aggressive pricing, China has come to be a hub for injection mildew suppliers and custom plastic injection molding offerings. In this text, we're going to delve into the advantages of leveraging injection mold supplier China knowledge in injection mildew making and custom plastic injection molding.

Injection Mold Supplier: Access to Expertise

China boasts a tremendous community of injection mold providers renowned for their expertise and revel in within the enterprise. These providers have the technical expertise and modern centers to supply molds of remarkable best and precision. By outsourcing to a good injection mould provider in China, groups can tap into this understanding while not having to invest closely in their personal production infrastructure.

China Mold Making: Cutting-Edge Technology and Innovation

The mildew making enterprise in China is characterised by using continuous technological advancements and innovation. Chinese mold makers constantly attempt to undertake the trendy production techniques and technologies to enhance efficiency and productivity. From laptop-aided layout (CAD) and computer-aided manufacturing (CAM) software program to superior CNC machining and 3-D printing technologies, China mold making offers get admission to to contemporary tools and processes that enable the manufacturing of complicated and elaborate molds. This emphasis on innovation interprets into quicker lead instances, advanced product great, and in the end, fee savings for agencies outsourcing their mildew making desires to China.

Custom Plastic Injection Molding China: Scalability and Flexibility

Another key gain of outsourcing injection molding to China is the scalability and versatility it offers. China's giant manufacturing capability permits for fast scaling of manufacturing to fulfill fluctuating call for degrees. Whether it is a small batch manufacturing run or a large-scale manufacturing undertaking, Chinese injection molding companies have the capability to house various manufacturing requirements. Moreover, those agencies are adept at handling custom tasks, imparting tailor-made answers to fulfill the specific specifications and design necessities of each consumer. This flexibility enables agencies to adapt quickly to changing marketplace dynamics and purchaser possibilities, thereby enhancing their aggressive area.

Cost Efficiency and Competitive Pricing

One of the number one motives companies opt to outsource injection molding to China is the good sized price savings it affords. China's lower labor prices, favorable exchange fees, and economies of scale make contributions to aggressive pricing for injection molding offerings. By leveraging China's cost-powerful production skills, corporations can lessen production costs with out compromising on great. This price efficiency extends past exertions and manufacturing charges to encompass financial savings in tooling and overhead expenses, making China an appealing destination for outsourcing injection molding.

Conclusion

In end, outsourcing injection molding to China gives a multitude of blessings for corporations seeking price-effective manufacturing answers. From get admission to to understanding in injection mold making to modern-day era, scalability, flexibility, and aggressive pricing, China's production surroundings provides a compelling proposition for companies seeking to streamline their manufacturing procedures and optimize fees. By partnering with a good injection mildew dealer in China, organizations can benefit from efficient, exceptional custom plastic injection molding China offerings that meet their unique desires and drive achievement in cutting-edge aggressive market.

0 notes

Text

Industrial Plastic Mold Manufacturing Solutions in China: HS Mold – Shaping the Future of Production

The artistry and precision of industrial plastic mold manufacturing solutions in China, a field where HS Mold has proudly stood as a leader for years. In today’s ever-evolving industrial landscape, plastic reigns supreme. From intricate automotive components to life-saving medical devices, plastic products permeate every facet of our lives.

Your Trusted Partner in Industrial Precision Plastic Mold Manufacturing in China

1.Collaboration is Key: In-Depth Needs Mold Analysis and Design

Our team of experts works hand-in-hand with clients to capture your vision and translate it into a functional design. Cutting-edge Computer-Aided Design (CAD) technology empowers meticulous rendering of every industrial plastic molds detail, ensuring the final product flawlessly embodies the initial concept.

2.Material Selection Tailored to Your Specifics

The right material underpins optimal performance. Industrial Mold material recommendations are based on factors like product usage, environmental considerations, and cost. Whether it’s specialty plastics offering superior strength and wear resistance, such as PEEK for high-temperature applications or ABS for its exceptional balance of strength and cost, or metals delivering exceptional precision and stability, like tool steel for durability or aluminum for lightweight industrial plastic molds, HS Mold provides mold manufacturing solutions that cater to your specific requirements.

Transforming Designs into Reality: HS Mold’s Processing and Manufacturing Expertise

1.Precision and Efficiency with CNC Technology:

Computer Numerical Control (CNC) technology plays a pivotal role. Renowned for its accuracy and efficiency. Hs Mold is top leading CNC machined components manufacturers in China transforms design concepts into tangible mold products. Different CNC machining techniques are employed based on project needs. For instance, 3-axis milling might be suitable for simpler mold geometries, while 5-axis machining can handle complex shapes with superior precision.

2.Advanced Techniques for Enhanced Complexity:

The application of Electrical Discharge Machining (EDM) and laser cutting further elevates the sophistication and intricate details of the industrial plastic mold manufacturing solutions in China. EDM allows for the creation of complex shapes on hardened steels un achievable with traditional machining methods, while laser cutting offers exceptional precision for thin-walled molds or intricate features.

3.Ensuring Quality: HS Mold’s Commitment to Rigorous Testing and Control

Unwavering quality inspections throughout the manufacturing process guarantee the mold’s precision and stability. Coordinate Measuring Machines (CMM) are utilized to ensure dimensional accuracy down to the micron, while pressure testing identifies any potential leaks.

4.Industrial Mold Prototype Testing: A Crucial Evaluation Step

Industrial Mold Prototypes solutions undergo comprehensive testing to assess mold performance. Only rigorously tested industrial molds that meet all quality benchmarks proceed to the next production stage.

Beyond Industrial Plastic Mold Manufacturing Solutions in China: Seamless Assembly and Continuous Improvement

1.Expert Assembly and Fitting: A dedicated team performs final fitting and adjustments, ensuring each industrial plastic mold component integrates seamlessly for unwavering production line support.

2.Innovation is Key: At HS Mold, we are relentless in our pursuit of improvement. We actively refine and upgrade industrial plastic mold manufacturing solutions based on valuable client feedback and ever-changing market trends.

Exceptional Customer Service Throughout the Journey

From initial industrial plastic mold manufacturing solutions project consultation to post-sales support, a professional customer service team fosters close communication with clients, guaranteeing that every need is promptly addressed.

HS Mold: Your Partner in Shaping the Future

Industrial plastic mold manufacturing solutions in China at HS Mold encompass more than just technology and products. They represent a commitment to service, innovation, and collaboration. In a dynamic marketplace, choosing HS Mold as your trusted partner means selecting a company dedicated to shaping a brighter future together. As both businesses and consumers, we can anticipate a future enriched by high-quality, innovative plastic mold products, adding vibrancy and boundless possibilities to our lives.

Image Suggestions:

1.Include an image showcasing the mold design process on a computer screen, with an HS Mold logo prominently displayed.

2.Include an image of a CNC machine in action, creating a mold, with an HS Mold technician overseeing the process.

3.Include an image showcasing different mold types, such as an injection mold and a compression mold, both manufactured by HS Mold.

HS Mold is among the top Mold Manufacturers in China , providing high-quality solutions. Having 20 years experience in injection mold making services and custom plastic injection molding , it is also a product engineering services company that offers high-quality plastic product development services, from rapid prototyping to high mix low volume production.

Our strong engineering team works closely with you throughout all stages of development. With our extensive knowledge and custom product manufacturing capabilities, we provide solutions tailored to our customers’ needs and create maximum value for our clients. Therefore, we are recognized as reliable mold manufacturers and suppliers in China

#Plastic Injection Mold Manufacturers in China#Mold Manufacturers and Suppliers in China#plastic injection molding china#cnc machining parts manufacturer in china#cnc parts manufacturer in china

1 note

·

View note