#automotive injection molding suppliers

Explore tagged Tumblr posts

Text

Introducing China Automotive Plastic Mould: Precision and Innovation in Automotive Manufacturing

China Automotive Plastic Mould is a leading provider of high-quality plastic moulds for the automotive industry. Specializing in the design and production of moulds, China Automotive Plastic Mould has become synonymous with precision engineering and cutting-edge technology. Our China Automotive Plastic Mould products are renowned for their durability, reliability, and the ability to meet the stringent demands of modern automotive manufacturing.

Each China Automotive Plastic Mould is crafted with meticulous attention to detail, ensuring that the end product is not only functional but also aesthetically pleasing. Our commitment to excellence is evident in every China Automotive Plastic Mould we produce, as we continuously strive to push the boundaries of what is possible in plastic mould technology.

China Automotive Plastic Mould is dedicated to providing moulds that can withstand the rigors of high-volume production while maintaining the highest standards of quality. Our China Automotive Plastic Mould products are used in the creation of a variety of automotive components, from interior trim to exterior panels, showcasing the versatility of our moulds.

Investing in a China Automotive Plastic Mould means investing in a future-proof solution for your automotive plastic component needs. Our China Automotive Plastic Mould is designed to adapt to the evolving requirements of the automotive industry, ensuring that your production lines remain at the forefront of innovation.

China Automotive Plastic Mould is not just a product; it's a partnership with a company that values long-term relationships and is dedicated to the success of your projects. We are proud of our China Automotive Plastic Mould and the role it plays in shaping the future of the automotive industry. Choose China Automotive Plastic Mould for your next project, and experience the difference that precision and innovation can make.

#China Automotive Plastic Mould#injection molding automotive#auto bumper mould#automobile mould#automotive injection molding company#automotive injection molding suppliers

0 notes

Text

Leading Plastic Molding Manufacturer for Custom Solutions

Partner with a trusted Plastic Molding Manufacturer for high-quality, custom plastic parts. Our advanced molding technologies and experienced team ensure precision and consistency in every project. Serving various industries, we provide tailored solutions that meet your exact specifications, from concept to production. Rely on us for durable, efficient, and cost-effective plastic molding services.

#plastic injection molding supplier#electronics manufacturing services#automotive mold manufacturers#aluminium die casting

0 notes

Text

Silicone rubber products - High-strength materials

Silicone rubber products are used in varied applications and industries. Some of them include the food industry, railways, transport industry, medical and pharma, aerospace, automotive, construction, offshore industry, electrical and lighting, power grids, and marine. https://alfarubber.home.blog/2023/10/10/silicone-rubber-products-diversified-industrial-applications/

#Silicon rubber products#O rings manufacturer#Gaskets and Seals#Rubber gasket seal#Rubber Injection Molding#Seal manufacturer#Bush manufacturer#Rubber parts supplier#Dustcap manufacturer#Rubber products supplier#Epdm rubber parts product#Automotive rubber parts#Rubber Grommet manufacturer#Grommet manufacturer

0 notes

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

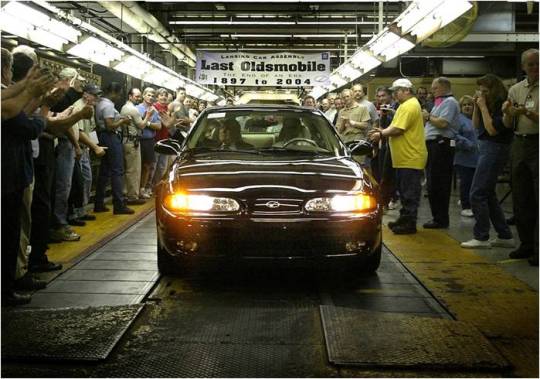

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

94 notes

·

View notes

Text

Revolutionizing Plastics: Cutting-Edge Machinery in Ahmedabad

Ahmedabad, a burgeoning industrial hub in Gujarat, India, is rapidly emerging as a key player in the Plastic Processing Machinery in Ahmedabad sector. The city's dedication to innovation and technological advancement is driving a revolution in the way plastics are processed, shaped, and recycled. This article explores the cutting-edge machinery that is transforming the plastic industry in Ahmedabad, highlighting its impact on efficiency, sustainability, and product quality.

The Rise of Automation and Precision:

A significant trend in Ahmedabad's plastic processing machinery industry is the increasing adoption of automation. Modern machines are equipped with advanced control systems, robotics, and sensors that streamline production processes, minimize human error, and enhance precision. Injection molding machines, for example, now feature sophisticated servo systems that optimize cycle times and reduce energy consumption. Extrusion lines are integrated with automated material handling systems, ensuring consistent product quality and minimizing waste. This shift towards automation not only boosts productivity but also enhances the overall efficiency of plastic manufacturing in the region.

Advanced Extrusion Technology:

Extrusion, a fundamental process in plastic manufacturing, is undergoing a significant transformation in Ahmedabad. Manufacturers are investing in state-of-the-art extrusion lines that can handle a wide range of polymers and produce complex profiles with high precision. Co-extrusion technology, which allows for the simultaneous extrusion of multiple layers of different materials, is gaining popularity, enabling the production of multi-layered films and pipes with enhanced properties. Furthermore, advanced screw designs and die technologies are improving melt homogeneity and reducing material waste, resulting in higher-quality extruded products.

Innovation in Injection Molding:

Injection molding, another crucial process, is witnessing significant advancements in Ahmedabad. High-speed injection molding machines with precise temperature control and injection pressure capabilities are enabling the production of intricate plastic parts with tight tolerances. Multi-component injection molding, which allows for the integration of different materials and colors into a single part, is also gaining traction. Manufacturers are leveraging these technologies to produce complex automotive components, medical devices, and consumer goods with superior quality and functionality.

Sustainable Recycling Solutions:

With growing environmental concerns, sustainability is becoming a key driver of innovation in the plastic industry. Ahmedabad is leading the way in developing cutting-edge recycling machinery that can process a wide range of plastic waste materials. Advanced shredders, granulators, and pelletizing machines are enabling the efficient recycling of post-consumer and post-industrial plastic waste. Furthermore, manufacturers are investing in advanced sorting technologies that can separate different types of plastics, ensuring high-quality recycled materials. This focus on sustainable recycling solutions is not only reducing environmental impact but also creating new business opportunities in the region.

The Impact of Digitalization and Industry 4.0:

The integration of digital technologies and Industry 4.0 principles is revolutionizing the plastic processing machinery industry in Ahmedabad. Machines are now equipped with sensors and data analytics capabilities that enable real-time monitoring of production processes, predictive maintenance, and remote control. This digitalization is improving operational efficiency, reducing downtime, and enhancing product quality. Furthermore, cloud-based platforms are facilitating seamless communication and collaboration between manufacturers, suppliers, and customers, creating a more integrated and efficient supply chain.

The Future of Plastic Processing in Ahmedabad:

Ahmedabad's commitment to innovation and technological advancement is positioning it as a leading hub for cutting-edge plastic processing machinery. The city's manufacturers are continuously investing in research and development to create more efficient, sustainable, and high-performance machines. As the demand for high-quality plastic products continues to grow, Ahmedabad's plastic processing machinery industry is poised for further expansion and innovation, driving the revolution in plastics and shaping the future of manufacturing in India.

0 notes

Text

High-Performance Injection Molding Machines from Daoben Machinery | 30 Ton to 4000 Ton

When precision meets power, you get Daoben Machinery — a leading manufacturer and supplier of plastic injection molding machines, delivering world-class performance across industries. Whether you're producing micro-components or large automotive parts, Daoben has the right solution, from 30 Ton to 4000 Ton machines.

Why Choose Daoben Injection Molding Machines?

1. Wide Clamping Force Range (30T–4000T): From small-scale plastic products to large industrial applications, Daoben offers a complete lineup to match your production needs.

30–150 Ton: Ideal for precision parts, electronics, medical devices

150–1000 Ton: Versatile range for household, packaging, and appliance components

1000–4000 Ton: Heavy-duty molding for automotive, industrial containers, furniture, and more

2. Engineering Excellence: Daoben machines are built with robust frame design, precision control systems, and energy-efficient servo hydraulics. You get faster cycles, higher repeatability, and less energy consumption — translating to real savings and better product quality.

3. Customizable & Industry-Specific Solutions: Need specialized molds or complex configurations? Daoben works with clients to deliver tailor-made systems including:

Multi-component injection (2K/3K)

High-speed injection for thin-wall packaging

PET preform production systems

Medical-grade cleanroom machines

Core Features You Can Expect

✔️ Servo Energy Saving System – Up to 70% energy savings ✔️ Precision Control – Advanced PLC with user-friendly touchscreen ✔️ Strong Tie Bars & Platens – Durable and deformation-resistant under heavy loads ✔️ Modular Design – Quick part replacement and easy maintenance ✔️ Full Support – Pre-sale consultation, mold compatibility assistance, installation, and training

Applications Across Industries

Daoben machines are trusted by manufacturers in:

Automotive

Consumer Electronics

Packaging

Medical & Healthcare

Home Appliances

Logistics (pallets, crates, bins)

Wherever plastic precision matters — Daoben delivers.

Ready to Scale or Upgrade Your Production?

With decades of industry experience, Daoben Machinery is more than a machine provider — we are your strategic manufacturing partner. Whether you're expanding your facility or replacing outdated equipment, our team is ready to help you select the right machine, optimize your setup, and ensure long-term production success. Daoben machinery joined Chinaplas 2025

📞 Get a Quote Today

Looking for a specific tonnage, configuration, or application? Contact Daoben now to discuss your production goals. Our technical sales team will provide:

Machine specifications tailored to your needs

Competitive pricing & lead times

Consultation on molds and production setup

👉 Email: [email protected] 👉 Visit: www.daobenmachinery.com

0 notes

Text

Equipment Needs for a Startup Manufacturing Plant

Starting a manufacturing plant is an exciting yet challenging venture. One of the most critical aspects of setting up a successful operation is selecting the right equipment. The machinery you choose will impact production efficiency, product quality, and overall profitability.

In this blog, we’ll discuss the essential equipment needed for a startup manufacturing plant, factors to consider when selecting machinery, and tips to optimize your investment.

1. Understanding Your Manufacturing Requirements

Before purchasing any equipment, it’s crucial to define Machinery Solutions your production needs. Consider the following:

Type of Products: What are you manufacturing? (e.g., food, textiles, machinery, electronics)

Production Volume: Will you operate at small, medium, or large scale?

Automation Level: Do you need manual, semi-automated, or fully automated machines?

Budget Constraints: How much can you invest in machinery without compromising cash flow?

Once you have clarity on these factors, you can proceed with selecting the right equipment.

2. Essential Equipment for a Startup Manufacturing Plant

A. Production Machinery

The core of your manufacturing plant lies in the machines that transform raw materials into finished products. Depending on your industry, these may include:

CNC Machines – For precision cutting, drilling, and milling (metalworking, automotive parts).

Injection Molding Machines – For plastic product manufacturing.

3D Printers – For prototyping and small-batch production.

Assembly Line Robots – For automated assembly in electronics or automotive industries.

Packaging Machines – For sealing, labeling, and boxing products.

B. Material Handling Equipment

Efficient movement of raw materials and finished goods is vital. Key equipment includes:

Forklifts & Pallet Jacks – For transporting heavy materials.

Conveyor Belts – For smooth movement of products along the production line.

Cranes & Hoists – For lifting heavy machinery or materials.

C. Quality Control & Testing Equipment

Ensuring product quality is non-negotiable. Invest in:

Spectrometers & Calipers – For measuring dimensions and material composition.

Tensile Testers – To check material strength.

Vision Inspection Systems – For detecting defects in products.

D. Safety & Maintenance Tools

Worker safety and machine longevity should be a priority. Necessary tools include:

Fire Suppression Systems – Especially in chemical or welding plants.

PPE (Personal Protective Equipment) – Helmets, gloves, goggles, etc.

Lubrication Systems – To keep machines running smoothly.

E. Utilities & Support Systems

A manufacturing plant requires reliable infrastructure:

Power Generators – Backup in case of electricity failure.

Compressed Air Systems – For pneumatic tools.

HVAC Systems – To maintain optimal working conditions.

3. Factors to Consider When Choosing Equipment

A. Cost vs. Value

New vs. Used Equipment: New machines offer warranties and latest tech, while used ones are cost-effective but may require more maintenance.

Leasing vs. Buying: Leasing reduces upfront costs, but buying may be better for long-term savings.

B. Scalability

Can the equipment handle increased production in the future? Modular machines allow easy upgrades.

C. Energy Efficiency

Energy-efficient machines reduce operational costs. Look for certifications like ISO 50001.

D. Supplier Reputation & Support

Choose suppliers with good after-sales service, spare parts availability, and training programs.

E. Compliance & Standards

Ensure machinery meets industry regulations (e.g., OSHA, ISO, CE Marking).

4. Tips for Optimizing Equipment Investment

A. Start with Essential Machines First

Avoid overspending on advanced equipment if basic models suffice for initial production.

B. Implement Preventive Maintenance

Regular servicing extends machine life and prevents costly breakdowns.

C. Train Employees Properly

Skilled operators maximize efficiency and reduce machine misuse.

D. Automate Where Possible

Automation improves precision and reduces labor costs in the long run.

E. Monitor Performance with IoT & AI

Smart sensors can track machine health and predict failures before they happen.

5. Common Mistakes to Avoid

Overestimating Production Needs → Leads to underutilized machinery.

Ignoring Future Expansion → Results in costly replacements later.

Neglecting Safety Standards → Increases workplace accidents.

Choosing Cheap, Low-Quality Machines → Frequent breakdowns hurt productivity.

Conclusion

Selecting the right equipment for your startup manufacturing plant is a make-or-break decision. By assessing your production needs, prioritizing essential machinery, and considering factors like cost, scalability, and efficiency, you can build a strong foundation for your business.

Invest wisely, maintain your equipment diligently, and stay updated with industry advancements to ensure long-term success.

0 notes

Text

Exploring the Growing Demand for Perforated Sheets and Plastic Manufacturing in the UAE

The United Arab Emirates (UAE) has rapidly transformed into a hub of industrial innovation and infrastructure development. As construction, manufacturing, and design industries grow at a fast pace, so does the demand for high-quality materials like perforated sheets and durable plastic products. This blog will delve into the increasing significance of perforated sheet suppliers in UAE, the expanding network of plastic manufacturing companies in UAE, and how cities like Dubai play a central role in these developments.

Whether you're sourcing materials for architecture, packaging, or general industrial use, understanding the local supply chain is essential. Here, we explore the scope, importance, and trends surrounding perforated sheet suppliers in Dubai, the rise of the plastic factory in UAE, and the growing footprint of every major plastic company in UAE.

What Are Perforated Sheets and Why Are They Important?

Perforated sheets are metal or plastic sheets that have been mechanically punched or laser cut to create a pattern of holes, slots, or decorative shapes. These sheets are used across a variety of applications such as architectural facades, filtration systems, soundproofing, fencing, ventilation, and even in furniture design.

The demand for perforated sheets has grown significantly in the UAE due to:

Urban development: High-rise buildings, malls, and public spaces often utilize perforated sheets for both functional and aesthetic purposes.

Industrial applications: These sheets serve critical functions in manufacturing, mechanical engineering, and agricultural processing.

Environmental efficiency: Perforated materials allow for natural light and air to flow through buildings, promoting energy efficiency and sustainability.

This growing demand has led to a competitive market of perforated sheet suppliers in UAE, with Dubai serving as a key distribution center.

Perforated Sheet Suppliers in UAE: Versatility Meets Innovation

The UAE hosts a robust network of perforated sheet suppliers, offering various materials such as aluminum, stainless steel, galvanized steel, and even plastic-based perforations. These suppliers cater to sectors including construction, interior design, petrochemical, and marine industries.

When seeking perforated sheet suppliers in Dubai, clients often look for:

Customization options: Suppliers offer different thicknesses, hole shapes (round, square, hexagonal), and sizes based on project needs.

Corrosion resistance: Given the UAE’s hot and humid climate, anti-corrosive materials are crucial.

Precision engineering: Laser cutting and CNC punching technology ensure the consistency and quality of perforation patterns.

Dubai, with its strategic location, port access, and industrial zones, has positioned itself as a central hub for suppliers and distributors of perforated sheet materials throughout the Middle East and North Africa (MENA) region.

The Rise of Plastic Manufacturing Companies in UAE

Parallel to the perforated metal industry, the UAE has seen tremendous growth in plastic production and processing. Plastic manufacturing companies in UAE are vital to the regional economy, serving numerous sectors such as packaging, construction, agriculture, healthcare, and automotive.

Some major categories of plastic products manufactured locally include:

Pipes and fittings for plumbing and irrigation systems

Plastic sheets and films for packaging and construction use

Injection-molded parts for household and industrial goods

Thermoformed products like containers and trays

The shift towards local production has been driven by the UAE’s focus on industrial diversification, sustainability, and economic resilience. These companies often invest in cutting-edge technologies to reduce waste, recycle materials, and meet international quality standards.

Plastic Factory in UAE: The Backbone of Industrial Development

The role of a plastic factory in UAE is critical in supporting not only domestic needs but also regional exports. These factories are typically located in industrial zones in emirates like Sharjah, Abu Dhabi, and Ras Al Khaimah, where they benefit from dedicated infrastructure, energy access, and proximity to logistics hubs.

A typical plastic factory in UAE focuses on:

Raw material processing: Using granules or pellets of polymers like polyethylene (PE), polypropylene (PP), and PVC.

Molding and extrusion: Creating everything from bottles to construction panels.

Quality testing: Ensuring that all products meet safety and performance standards.

Many of these factories are adopting eco-friendly practices, including the use of biodegradable plastics and recycling of offcuts and defective products. This aligns with the UAE’s broader push toward environmental sustainability and circular economy models.

Plastic Company in UAE: Innovation and Sustainability

Every plastic company in UAE today is adapting to new consumer expectations and regulatory pressures that demand innovation and sustainability. Whether the focus is on packaging solutions or building materials, the key trends shaping the plastic industry in the region include:

Bioplastics: An increasing number of companies are exploring biodegradable alternatives made from starch, corn, or sugarcane.

Smart packaging: The use of plastic packaging that extends shelf life and improves product traceability is gaining ground.

Closed-loop systems: Recycling initiatives within factories are helping reduce reliance on virgin plastic and minimize environmental impact.

These companies are also leveraging automation and digital manufacturing technologies to increase production efficiency and quality control, ensuring they remain competitive in both local and international markets.

Integration Across Industries

One of the notable features of the UAE’s industrial landscape is how perforated sheet suppliers in UAE and plastic manufacturing companies in UAE often serve overlapping sectors. For example:

In construction, both perforated metal sheets and plastic formworks are essential materials.

In agriculture, perforated plastic sheets are used for irrigation systems alongside metallic perforated filters.

In interior design, combinations of plastic panels and metal screens are commonly used for acoustic and visual design elements.

This level of integration allows for a more flexible, dynamic supply chain and fosters innovation across disciplines.

Future Outlook

The future of perforated sheet suppliers in Dubai and the broader UAE plastic manufacturing sector looks promising. With major upcoming events, infrastructure projects, and global trade agreements on the horizon, demand for locally manufactured materials will continue to rise.

Government initiatives supporting local production, such as "Make it in the Emirates," further reinforce the importance of building strong, self-sufficient supply chains. These policies are designed to promote investment in industrial innovation, sustainability, and export capabilities.

As technology evolves and market demand shifts toward environmentally responsible practices, we can expect even more innovative solutions from every plastic company in UAE and factory involved in material processing.

Conclusion

The UAE is solidifying its position as a leader in both metal and plastic materials manufacturing. From specialized perforated sheet suppliers in UAE to large-scale plastic manufacturing companies in UAE, the country’s industrial sector is evolving to meet modern construction, design, and packaging needs.

Dubai, in particular, continues to be a central player, offering seamless access to regional and global markets. With innovation, sustainability, and quality at the forefront, these industries will no doubt shape the future of manufacturing in the UAE and beyond.

#Perforated sheet suppliers in UAE#Perforated sheet suppliers in Dubai#plastic manufacturing companies in uae#plastic factory in uae#plastic company in uae

0 notes

Text

Cold Runner Systems Market set to hit $4.4 billion by 2035

Industry revenue for Cold Runner Systems is estimated to rise to $4.4 billion by 2035 from $2.4 billion of 2024. The revenue growth of market players is expected to average at 5.6% annually for the period 2024 to 2035.

Cold Runner Systems is critical across several key applications including injection molding, precision components manufacturing, medical devices production and packaging solutions. The report unwinds growth & revenue expansion opportunities at Cold Runner Systems’s Product Type, Application, Technology and Material Type including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Cold Runner Systems market is characterized by intense competition, with a number of leading players such as Yudo Group, Husky Injection Molding Systems Ltd, Mold Masters, Incoe Corporation, Synventive, Meusburger Georg GmbH & Co KG, MasterFlow AB, Ewikon Cooling System GmbH, CitoForm GmbH, Tempo Industries, Unitherm AG and Dongguan Tianying Mold Fitting Co. Ltd.

The Cold Runner Systems market is projected to expand substantially, driven by emerging technological innovations and increased demand in the automotive & packaging industries. This growth is expected to be further supported by Industry trends like Reduction in Operational Costs.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/cold-runner-systems-market-research-report

Moreover, the key opportunities, such as advancements in automotive and aerospace industries, expansion in medical and consumer electronics sectors and growth of eco-friendly manufacturing practices, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, Japan, China and India.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like high initial setup cost and material limitations, Cold Runner Systems market’s supply chain from raw material suppliers / component manufacturing units / assembly & testing providers to end users is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Vietnam, India and Brazil for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

Need Custom Rubber Moulded Parts for Your Industry?

India has emerged as a leading hub for industrial rubber components, offering world-class manufacturing capabilities and a wide range of products tailored to meet global standards. From high-performance sealing solutions to durable vibration-dampening components, Indian manufacturers are catering to various sectors such as automotive, aerospace, electrical, electronics, heavy machinery, and more. Among the key players in this space are o ring manufacturers, custom rubber moulded products manufacturer, and suppliers of metal bonded rubber parts, all known for their quality, precision, and reliability.

O Ring Manufacturers: Precision and Performance

O-rings are one of the most widely used sealing components in the world. They are essential for preventing fluid and gas leakage in machinery, engines, pumps, and valves. Leading o ring manufacturers in India produce a vast variety of O-rings in different sizes, cross-sections, and materials such as Nitrile (NBR), Viton (FKM), EPDM, Silicone, and PTFE. These manufacturers ensure that the products meet international standards like ASTM, ISO, and DIN, making them suitable for global markets.

Whether it’s a small precision component for a medical device or a large-diameter seal for industrial machinery, Indian O-ring manufacturers have the technical expertise and production capabilities to deliver high-quality results. They also offer customization based on specific temperature ranges, chemical exposure, and pressure conditions.

Custom Rubber Moulded Products Manufacturer: Tailored Industrial Solutions

Every industry has unique requirements, and that’s where a custom rubber moulded products manufacturer plays a crucial role. These manufacturers specialize in designing and producing rubber parts that are molded to fit specific applications. The process involves developing molds based on customer drawings or specifications and using materials best suited for the intended use.

Products manufactured include rubber grommets, bellows, diaphragms, bumpers, seals, boots, and pads. These are used in applications that demand flexibility, weather resistance, electrical insulation, or shock absorption. Indian manufacturers employ state-of-the-art molding techniques such as compression molding, injection molding, and transfer molding.

Quality assurance is a top priority, with most companies adhering to ISO certifications and employing strict testing procedures at each stage of production. From small to large volume production, they are equipped to deliver consistency, precision, and cost-efficiency.

Metal Bonded Rubber Components: Strength Meets Flexibility

One of the most innovative offerings in the rubber industry is metal bonded rubber products. These components combine the elasticity of rubber with the strength and structural integrity of metals such as aluminum, brass, or steel. Common products include engine mounts, suspension bushings, anti-vibration pads, and rollers.

Indian manufacturers have mastered the metal-to-rubber bonding process, ensuring strong adhesion between the two materials. This is achieved through advanced chemical treatments, surface preparation, and high-pressure molding processes. The resulting components are durable, shock-resistant, and capable of withstanding harsh environments and heavy loads.

Industries that benefit from metal bonded rubber parts include automotive, railways, construction equipment, and industrial machinery. These components enhance performance, reduce noise and vibration, and extend the life of the machinery they’re installed in.

Why Choose Indian Manufacturers?

Indian rubber product manufacturers offer a unique blend of quality, affordability, and customization. They leverage cutting-edge machinery, skilled labor, and a deep understanding of global market needs to deliver products that compete with international brands.

Moreover, with a strong focus on R&D and sustainability, many companies are moving toward eco-friendly practices, using recyclable materials and energy-efficient production techniques. Their ability to scale production and maintain timely deliveries makes them reliable partners for OEMs and industrial buyers worldwide.

Conclusion

Whether you're in need of sealing components from trusted o ring manufacturers, tailored parts from a custom rubber moulded products manufacturer, or durable metal bonded rubber products, India is home to some of the best suppliers in the world. With a focus on quality, customization, and innovation, Indian manufacturers continue to play a key role in powering industrial applications across the globe.

0 notes

Text

Automotive Injection Molding - Precision Manufacturing for High-Quality Auto Parts

Automotive Injection Molding by Keiteq offers advanced solutions for producing precise and durable automotive components. This process ensures high efficiency and consistency, making it ideal for creating complex parts like dashboards, bumpers, and interior panels.

#electronics manufacturing services#automotive mold manufacturers#electronic manufacturing services#aluminium die casting#automotive molding#plastic injection molding supplier#plastic injection molding company

0 notes

Text

Desiring to buy products from a certified grommet manufacturer? Visit Alfa Rubber

Alfa Rubber is a certified grommet manufacturer. Our grommets can be widely used to cover or protect holes and openings in any set-up. Thus, call us today! To know more about our services. https://alfarubber.com/quality-systems/

#Dustcap manufacturer#Rubber parts supplier#Rubber products supplier#Automotive rubber parts#Epdm rubber parts product#Rubber Grommet manufacturer#Rubber Bush manufacturer#Grommet manufacturer#O rings manufacturer#Silicon rubber products#Gaskets and Seals#Rubber gasket seal#Rubber industries in India#Rubber Injection Molding#Seal manufacturer#Bush manufacturer

0 notes

Text

Top Check Valve Types and Their Prices: For Water Pumps, Air Lines, and Hydraulic Use

Check valves are essential components in piping systems, preventing back flow and ensuring unidirectional flow. Used across Udhhyog (industrial) applications like water treatment, air compressors, and hydraulic equipment, they improve system safety and efficiency.

What is a Check Valve?

A check valve allows flow in one direction and prevents reverse flow. It's a passive valve, meaning it operates without manual control or external power. Common in plumbing, industrial udhhyog, and HVAC systems, check valves protect pumps and pipelines from damage.

Types of Check Valves

1. Swing Check Valve

Best For: Low-pressure water lines

Function: Flap swings open with flow, closes with backflow

Used In: Plumbing, water treatment plants

2. Lift Check Valve

Best For: High-pressure systems

Function: Disc lifts when flow starts, drops with backflow

Used In: Boilers, steam lines

3. Ball Check Valve

Best For: Wastewater and slurry applications

Function: Ball moves to open/close flow

Used In: Chemical & mining udyog

4. Dual Plate (Wafer) Check Valve

Best For: Compact piping setups

Function: Two spring-loaded plates open with flow

Used In: Oil & gas pipelines

5. Diaphragm Check Valve

Best For: Sanitary systems

Function: Flexible diaphragm controls flow

Used In: Pharma, food & beverage udhhyog

Check Valve Material Comparison

Material Ideal For Corrosion Resistance Cost Stainless Steel Industrial Udhhyog, oil, steam High High Brass Residential plumbing Medium Medium PVC Water lines, chemical Udhhyog High Low Cast Iron Sewage & waste lines Medium Moderate

H2: Price Guide – Check Valves by Size and Type

Valve TypeSize (Inches)Price Range (INR)Swing Valve1” – 4”₹150 – ₹1,500Lift Valve1” – 3”₹250 – ₹2,000Ball Valve1” – 6”₹200 – ₹2,500Wafer Valve2” – 12”₹400 – ₹6,000Diaphragm Valve1” – 2”₹300 – ₹1,800

Note: Prices vary by brand, material, and supplier region (TradeIndia, Justdial listed vendors).

Applications Across Udyog (Industrial Use)

Water Pumps

Prevents reverse flow that could damage pump seals.

Essential in municipal and agricultural udyog sectors.

Air Compressor Lines

Maintains unidirectional flow and protects the system.

Used in automotive, manufacturing, and food packaging.

Hydraulic Systems

Prevents pressure drops due to backflow.

Used in earth-moving machinery and injection molding units.

How to Choose the Right Check Valve

1. Identify Flow Media

Water, air, chemical, or slurry

2. Check Operating Pressure & Temperature

Match valve rating with system needs

3. Material Compatibility

PVC for chemicals, SS for pressure lines

4. Space & Installation Type

Use wafer-style in compact layouts

Top Manufacturers & Where to Buy

TradeIndia: Verified suppliers for industrial check valves

Justdial: Find local distributors with stock availability

Indiamart: Compare prices and request bulk quotes

Local GMB Listings: Optimize your business with listings and reviews

FAQ – Check Valves

Q1. What is the purpose of a check valve?

A check valve prevents backflow in a piping system. It's used to protect equipment like pumps and compressors by ensuring fluid flows in only one direction.

Q2. What is the most common check valve?

The swing check valve is the most widely used due to its simple design, affordability, and ease of installation in water pipelines.

Q3. Can I use a check valve vertically?

Yes, many check valves like spring-loaded or lift types are designed for vertical installation, especially in air and water lines.

Q4.How much does a 1-inch check valve cost?

A standard 1-inch check valve typically ranges from ₹150 to ₹600 depending on material (PVC, brass, SS) and type (swing, ball).

0 notes

Text

GV Mold: Achieving Optimal Performance with Expert Plastic Injection Molds

GV Mold has established itself as a leader in the plastic injection molding industry by delivering high-quality molds that optimize performance across various applications. With over three decades of experience, the company specializes in creating precision components for industries such as automotive, electronics, home appliances, and industrial applications. GV Mold's expertise in mold design and engineering ensures that every product meets stringent quality standards while enhancing manufacturing efficiency. Their commitment to innovation and customer satisfaction makes them a trusted partner for businesses seeking reliable plastic injection molding solutions.

The Role of Expert Mold Design in Performance Optimization

Expert mold design is the foundation of achieving optimal performance in plastic injection molding. At GV Mold, skilled engineers use advanced CAD software to create detailed 3D models that serve as blueprints for mold construction. This meticulous approach ensures that every mold is optimized for manufacturability, addressing potential issues such as sink marks or warping before production begins. By integrating Design for Manufacturing (DFM) principles, GV Mold ensures that product designs are compatible with manufacturing constraints, enhancing overall production efficiency and reducing defects.

Advanced Tooling Techniques for Enhanced Precision

Tooling is a critical aspect of plastic injection molding, and GV Mold excels in creating molds with exceptional precision and durability. Using CNC machining and high-grade materials such as steel or aluminum, their engineers construct molds capable of handling complex geometries and tight tolerances. These advanced tooling techniques guarantee consistent quality across large production runs, minimizing downtime and waste while maximizing productivity. By focusing on precision tooling, GV Mold enables manufacturers to produce reliable components efficiently over extended production cycles.

Leveraging DFM and Mold Flow Analysis for Efficiency

GV Mold integrates Design for Manufacturing (DFM) and Mold Flow Analysis (MFA) into its operations to optimize production efficiency and minimize defects. DFM ensures that product designs are optimized for manufacturability by addressing issues such as part geometry or material flow early in development. MFA simulates the behavior of molten plastic within molds to predict potential challenges like uneven cooling or air pockets. Together, these methodologies streamline production cycles while maintaining high standards of quality, enhancing productivity and reducing waste.

Material Selection for Enhanced Performance and Sustainability

Selecting the right material is crucial for achieving durable and high-performing plastic components while ensuring sustainability. GV Mold provides expert guidance in material selection based on application-specific requirements such as strength, flexibility, heat resistance, or chemical compatibility. For example, biodegradable plastics may be recommended for eco-friendly applications, while thermoplastics like ABS or polycarbonate are ideal for electronics due to their insulating properties. By aligning material properties with functional needs and sustainability goals, GV Mold ensures that every product performs reliably while meeting cost considerations.

Enhancing Collaboration Through Early Supplier Involvement

Early Supplier Involvement (ESI) is a strategic approach embraced by GV Mold to improve product development outcomes. By integrating suppliers early in the design phase, GV Mold fosters collaboration that leverages supplier expertise on materials and manufacturing processes. ESI reduces costs associated with late-stage modifications while improving communication between stakeholders. This proactive strategy enhances risk management by addressing challenges early on, resulting in competitive products that meet market demands efficiently while maintaining high standards of quality.

Quality Assurance and Continuous Improvement

Quality assurance is central to GV Mold’s operations, ensuring that every mold meets stringent standards before entering production. The company employs rigorous inspection protocols using advanced tools like 3D scanning and automated measurement systems to verify accuracy and consistency across all molds and parts. First article inspections (FAIs) validate mold performance under real-world conditions, guaranteeing reliable results once products are in use. This dedication to quality has earned GV Mold the trust of leading manufacturers worldwide, custom plastic injection mold who rely on their expertise for critical projects.

Why Choose GV Mold for Expert Plastic Injection Molds?

GV Mold’s comprehensive approach makes them an ideal choice for businesses seeking reliable plastic injection molding solutions from concept to creation. Their ability to provide end-to-end services—including design consultation, tooling construction, and full-scale production—ensures seamless execution at every stage of a project. By combining technical expertise with innovative methodologies like DFM/MFA integration and precision tooling capabilities, GV Mold delivers products that exceed expectations while helping clients optimize their manufacturing processes.

With its commitment to precision engineering and customer satisfaction, GV Mold continues to lead the way in providing top-tier plastic injection molds designed for optimal performance in today’s competitive industries.

0 notes

Photo

Are you looking for DIN 2738 ( P20 + Ni) Steels in India ? Have you understand the advantages of using DIN 2738 Steel (P20 +Ni)?

Virat Special Steels announced as the largest stockiest of DIN 2738 ( P20 + Ni) which is supposed to be an upgraded version of the plastic mold steel 2311. Just like plastic mold steel 2311, DIN 2738 is also supplied in a pre hardened condition. The most specific use of DIN 2738 is that for the purpose of making plastic injection die molds.

Besides the fact that DIN 2738 is supplied in pre hardened condition, some of the other important characteristics of this steel are s follows:

In the state, when the same is supplied to the customers, the level of hardness of the steel is at 280-320 HB. The nickel content in the steel increases by 0.8% – 1.5% on further hardening.

This steel is micro alloyed. The best characteristic of this steel, which makes it perfect for the making of plastic injection die molds, is the fact that it is very good in machining. As a result of this, it becomes absolutely suitable for various purposes like Texturing, polishing of the outsides of various products, provides excellent corrosion resistance to the products, etc.

Other than the making of plastic injection die molds, there are many other applications of this steel. Some of those applications have been discussed below:

This steel can be used for making dies for many different industries like the automotive industry, domestic goods industry, etc.

Plastic molds of various sizes, big as well as small, can be easily made from the use of DIN 1.2738 (AISI P20).

It is useful in the manufacturing of numerous dies and products like high finishing plastic die, Boaster plates used in presses, shoe / Sow blocks and die hammers, which are used for the making of drop hammers, press cassetes, forging dies, Upsetter blockers, and various other dies and molds made for different plastic products.

This steel has a very high demand in the market for the simple reason that this modern and upgraded version of plastic mold steel 2311, offers increased alloy element, which not only increases its hardness, but it also provides extra life. Thus, the parts manufactured through the use of this steel last for a much longer duration.

At the same time, the quality of polishing that is done on this steel is also very good. The hardness present in the steel is also uniform throughout the product. Almost all Leading steel company like Virat Special Steels is Stocking and supplying this product and the demand for the same is increasing on a constant basis.

Virat Special Steels is the largest stockist and supplier of P20 + Ni and P20 tool steel in flat, square and round bars. We provide steel in all sizes as your requirements. P20 Steels is available in flat, square and round shape.

Consult our team who will assist you for the PlasticMouldSteels query.

Learn more : https://www.viratsteels.com/plastic-mould-steel.html

Any queries feel free to contact us : [email protected] or on mobile number +91-9814021775

#viratsteels#plasticmouldsteels#metalworking#metallurgy#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#toolsteel#toolsteelsupplier#viratsteelindia#p20#p20ni#plasticmould#diesteel#nipponsteel#mouldsteelstockist#gurgaon#ludhiana#pune#india

2 notes

·

View notes