#Injection Moulding

Explore tagged Tumblr posts

Text

Plastic injection moulding

#prototyping#prototype#rapid prototyping#prototype machining#plastic injection molding parts#injection molding#plastic injection molding company#injection molding parts#plastic injection molding#injection molding services#plastic injection molded#plastic injection molded parts#plastic injection moulding#plastic injection#injection moulding#injection moulding service

2 notes

·

View notes

Text

Are you looking for PLASTIC MOULD STEEL steel ? Plastic mould steels are widely used for manufacturing mould for plastic. Get in touch with us today to place your requirement!

DIN 2738 #PlasticMouldSteel, The equivalent grade P20+Ni | DIN 2738 | AISI P20+Ni …

DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making moulds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish.

Also the specialized steels that have been created for plastic moulding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity. DIN 1.2738 Steels are low Carbon consisting of Carbon between 0.35 to 0.45%

Mode of Supply:

ViratSpecialSteels is the largest stockiest and supplier of DIN 2738 steel in flat, square and round bar. We provide steel in all sizes as your requirements.

Learn more: https://www.viratsteels.com/p20ni.html

For more information Contact us: [email protected], +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#din2738#mouldsteels#mouldsteelstockist#plastic mould steel#injection moulding

2 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Text

#plastic injection moulding near me#prototype manufacturing near me#injection moulding#plastic injection moulding

1 note

·

View note

Note

As the resident injection molding enthusiast around these parts, wdyt about youtube . com / watch ? v = UrI8qpmvncA. Neat, or marking fluff?

As far as I'm aware closed loop pressure control in injection moulding is a thing already, but I wouldn't be surprised if this is a novel approach or something. Don't know enough about the industry to know whether it's usually something where your foundry/press either has it or doesn't, whereas this sounds like an add-on for an arbitrary moulding machine.

One thing that might be novel about this is predictive control rather than, say, modelling your part at mould making time and plugging that into your machine as a set of parameters for a Kalman filter.

0 notes

Text

Injection Moulding Services

Quickparts’ plastic Injection Moulding services offer a comprehensive suite of solutions, catering to diverse project requirements ranging from rapid prototyping for swift design validation, up to volume production runs, accommodating geometrically complex parts. For more information visit our website https://quickparts.com/gb/injection-moulding-tooling-parts/

0 notes

Text

Kunststoff Spritzguss (Plastic Injection Molding)

0 notes

Text

Why Choosing a Local Injection Moulding Company in Kolkata Saves Time and Cost

Finding the right partner for your manufacturing needs can mean the difference between smooth production and endless delays. If your business relies on plastic parts or components, choosing a local Injection Moulding Company in Kolkata brings clear advantages—especially in terms of saving both time and cost.

Here’s why businesses across industries are turning to Banerjee Machine & Tools Co., a trusted name in the city’s moulding industry, to streamline their production.

1. Faster Turnaround Time

Speed matters in manufacturing. By partnering with a local company, you cut down on transit times and communication lags. There’s no need to wait days for deliveries or chase updates across time zones. A Kolkata-based moulding company can provide faster prototyping, quicker revisions, and on-time delivery of final products. This responsiveness keeps your project timeline on track.

2. Lower Logistics and Transportation Costs

Shipping heavy moulding machinery or large quantities of components from other cities—or overseas—adds a significant layer of cost. Choosing an Injection Moulding Company in Kolkata eliminates these extra transportation expenses. With a local supplier, pickup or delivery is simpler, cheaper, and more reliable.

Banerjee Machine & Tools Co. serves a wide range of industries across Kolkata and West Bengal, offering both on-site delivery and flexible shipping options, which reduces your operational burden.

3. Easier Communication and Collaboration

One of the most underestimated benefits of working locally is the ease of collaboration. You can visit the facility, review samples in person, or hold technical discussions without dealing with language barriers or time zone mismatches. That real-time feedback leads to better designs, fewer revisions, and smarter decisions.

4. Support for Local Industry & Economy

Partnering with a local business strengthens your city’s industrial ecosystem. Supporting companies like Banerjee Machine & Tools Co. helps create jobs, promote local innovation, and grow regional capabilities. It's more than just a transaction—it's a collaboration that contributes to Kolkata’s industrial growth.

5. Customized Solutions for Local Needs

Local manufacturers understand the regional market better. Whether it's adapting to climate factors that affect materials or meeting specific regulatory standards, a company rooted in Kolkata is more likely to tailor its services to suit your unique needs. That adaptability often leads to better product outcomes.

Conclusion

Choosing a local Injection Moulding Company in Kolkata like Banerjee Machine & Tools Co. isn’t just about convenience—it’s a strategic move to gain speed, cut costs, and enjoy more control over your production cycle. Whether you're launching a new product or scaling up your manufacturing, local expertise can give you a competitive edge that offshore alternatives simply can't match.

1 note

·

View note

Text

A leading masterbatch manufacturer wishes a happy Ugadi.

https://plasmix.in/

#masterbatch#masterbatches#masterbatches manufacturer#colour masterbatches#leading masterbatches manufacturer#colour masterbatches manufacturer#filler masterbatches#injection moulding#additive masterbatches

0 notes

Text

Overmoulding is a process where a second layer of material (usually a soft thermoplastic or rubber-like material) is moulded over a base substrate (typically a rigid plastic or metal). Insert Moulding is where a pre-placed insert (metal, plastic, or ceramic) is encapsulated by injected plastic.

Source URL : https://adrecoplastics.co.uk/overmoulding-design-best-practices-achieving-optimal-results

1 note

·

View note

Text

Low and High-Volume Production: Injection Molding

Injection molding is a versatile manufacturing process used to create a wide variety of plastic parts with precision and efficiency. From everyday consumer products to complex industrial components, injection molding can accommodate projects of different sizes and scopes. One of the key advantages of this method is its ability to support both low and high-volume production, each suited to specific needs and circumstances. Let’s explore how injection molding caters to these different production scales.

Low-Volume Production: Flexibility and Innovation

Low-volume production typically involves manufacturing a smaller quantity of parts, usually ranging from 100 to 10,000 units. This approach is ideal for:

-Prototyping and Product Development**: Low-volume production allows companies to create prototypes or limited runs of a product to test functionality, design, and market demand. It’s a cost-effective way to refine a product before committing to mass production.

-Customization: Businesses that require specialized or niche products can benefit from low-volume injection molding. This is common in industries like medical devices or high-end consumer goods, where unique specifications are necessary.

-Short Lead Times: Low-volume production often requires less complex tooling and setup, which reduces lead times. Companies can quickly respond to market needs or adapt to changes without extensive delays.

In low-volume production, cost management is crucial. While the upfront investment in molds and tooling can be significant, techniques like using aluminum molds (instead of steel) or adopting rapid tooling technologies help to minimize expenses. Additionally, this production scale often allows for greater design flexibility, enabling faster iterations and adjustments.

High-Volume Production: Efficiency and Scale

High-volume production involves creating thousands to millions of identical parts. This scale is ideal for industries such as automotive, consumer electronics, and packaging, where large quantities of parts are needed to meet global demand. Key benefits of high-volume injection molding include:

-Cost Efficiency: While the initial tooling costs for high-volume production are higher, the cost per unit decreases significantly as the quantity increases. This makes it highly economical for producing large batches of parts.

-Consistency and Quality: High-volume production ensures that each part meets strict quality standards. Injection molding’s precision guarantees consistent dimensions and features across thousands of units.

-Automation: The process is highly automated, reducing labor costs and increasing production speed. Advanced machinery can operate 24/7, maximizing output and minimizing downtime.

-Material Efficiency: High-volume injection molding often incorporates efficient material usage and recycling practices, which can lower waste and reduce costs over time.

Choosing the Right Scale for Your Project

Deciding between low and high-volume production depends on your project’s specific needs. If you’re testing a new product, exploring niche markets, or working on a time-sensitive project, low-volume production might be your best option. However, if you’re targeting large-scale distribution or need to produce millions of parts with consistent quality, high-volume production is the way to go.

It’s also worth noting that injection molding service providers often offer hybrid solutions. These combine the benefits of both production scales, such as starting with low-volume production for testing and transitioning to high-volume once the product is finalized.

Conclusion

Injection molding is a powerful manufacturing method that can accommodate both low and high-volume production, making it a go-to choice for businesses across industries. Understanding the strengths of each approach will help you optimize costs, time, and product quality to meet your specific goals. Whether you’re creating a prototype or scaling up for mass production, injection molding offers the flexibility and efficiency to bring your vision to life.

0 notes

Text

Injection molding plastic

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#plastic injection molded#injection molding#injection molding parts#injection molding components#plastic injection molding#plastic injection molding company#plastic injection molding parts#injection molded#injection molded parts#injection mould#injection moulding#injection moulding service#plastic mold#plastic molded#plastic molding

3 notes

·

View notes

Text

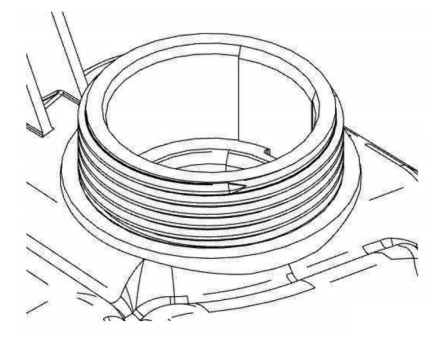

Common problems and solutions for forming thread injection molds

1 Common problems of forming thread Molding thread with a thread-off structure in injection mold is a common injection mold structure, some problems often occur in production, which make mold unable to produce normally. Following takes unthreaded structure of injection mold of a car expansion kettle as an example to illustrate how to solve these problems. Common problems: ①Plastic part thread…

View On WordPress

0 notes

Text

The Role of Injection Moulding in Modern Plastic Manufacturing

Injection moulding has revolutionized plastic manufacturing, providing industries with an efficient and reliable method for mass production of high-quality plastic components. At the forefront of this industry is the Holloway Group, a company renowned for delivering cutting-edge injection moulding services across sectors like construction, engineering, and agriculture. Their expertise ensures that businesses receive precisely manufactured plastic parts that meet the highest standards for durability, consistency, and sustainability.

What is Injection Moulding?

Injection moulding is a manufacturing process where molten plastic is injected into a mould to create a specific shape. This technique is ideal for producing high volumes of identical plastic products, making it the preferred method for many industries. The process involves several stages, including material selection, mould design, and production, each crucial in achieving the desired product characteristics. Holloway Group excels in all these areas, utilizing advanced technologies to ensure precise and efficient production.

The Injection Moulding Process

The injection moulding process at Holloway Group is streamlined to meet both small-scale and large-scale production needs. It begins with the selection of the appropriate plastic material, which could include recycled plastics as part of the company’s commitment to sustainability. The chosen plastic is then heated until it becomes molten and is injected into a mould under high pressure. The mould is designed to the exact specifications of the product, ensuring that each piece produced is consistent in shape and quality.

Once injected, the plastic cools and solidifies within the mould, after which it is ejected, and the cycle begins again. This process is repeated thousands, or even millions, of times, making it one of the most cost-effective methods for producing large quantities of plastic parts. Holloway Group’s state-of-the-art machinery and expertise allow them to handle complex designs, ensuring precision in every piece.

Benefits of Injection Moulding

Cost-Efficiency: Injection moulding is highly cost-effective for producing large volumes of plastic products. Once the initial mould is designed and created, the cost per unit decreases significantly, making it an ideal solution for mass production.

Precision and Consistency: The ability to produce identical parts with exact specifications is one of the key advantages of injection moulding. Holloway Group’s precise mould design and advanced technology ensure that each product meets stringent quality standards.

Sustainability: Holloway Group is committed to reducing the environmental impact of plastic production. Through the use of recycled materials and innovative waste-reduction techniques, they help businesses achieve sustainability goals without compromising on quality.

Versatility: Injection moulding can be used to create a wide variety of plastic products, from small, intricate components to large, complex shapes. This versatility makes it applicable across industries like construction, agriculture, and engineering, all of which Holloway Group serves.

Speed and Efficiency: The injection moulding process is fast and efficient, allowing for quick turnaround times. Once the mould is created, the production cycle is swift, with minimal downtime, enabling Holloway Group to meet tight deadlines for their clients.

Injection Moulding at Holloway Group

Holloway Group stands out in the plastic manufacturing industry for its comprehensive injection moulding services. They not only offer production but also assist clients in the design and prototyping phases, ensuring that every project is optimized for success. Their commitment to sustainability is evident in their use of recycled plastics, which are integrated into various applications, supporting environmentally-conscious production practices.

Moreover, Holloway Group’s expertise spans multiple sectors, allowing them to tailor their services to meet specific industry requirements. Whether it’s for construction components, agricultural tools, or engineering parts, the company’s injection moulding capabilities ensure the delivery of high-quality, durable products.

Conclusion

Injection moulding plays an integral role in modern plastic manufacturing, offering a cost-effective, efficient, and sustainable solution for mass production. With Holloway Group’s experience and advanced technology, businesses can rely on their injection moulding services to deliver top-tier plastic products that meet precise specifications. Through their focus on innovation, precision, and sustainability, Holloway Group continues to lead the industry, shaping the future of plastic manufacturing across various sectors.

1 note

·

View note

Text

Sustainable plastic solutions

Sustainable plastic solutions aim to address the environmental challenges posed by traditional plastics by developing alternatives that minimize ecological impact.

sustainableplasticsolutions

0 notes