#acrylic injection molding

Explore tagged Tumblr posts

Text

Exploring Plastic Injection Molding Companies in China: A Focus on Acrylic Injection Molding and Quality Manufacturing

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. This process is highly efficient, allowing for the mass production of complex and durable plastic parts with minimal waste.

Keywords : plastic injection molding companies in China

acrylic injection molding

Injection Mold China

Overmolding

plastic mold

plastic injection molding companies near me

#plastic injection molding companies in China#acrylic injection molding#Injection Mold China#Overmolding#plastic mold#plastic injection molding companies near me

1 note

·

View note

Text

Injection Molding Acrylic | Prototool.com

Prototool.com offers high-quality injection moulding acrylic services for all your needs. Get the best injection moulding acrylic services at the most competitive prices. Visit our site for more info. injection molding acrylic

1 note

·

View note

Text

Pullback, Transformers Throttlebot OC

Pullback grew out of a suggestion from my partner April that I should create my own self-insert OC or -sona as a Transformers character. Initially I considered modding a Bumblebee figure, but all of that painting sounded like a lot of work, so I decided to make my own instead, and ended up with a pretty distinct design.

Pullback is a 1987 Throttlebot who was totally there the whole time. They're a machinist, and their alternate form is a microcar EV legally distinct from a Smart Fortwo.

With the exception of the hollows and slots required by injection molding, I tried to keep Pullback authentic to how modern Transformers toys are constructed. Articulation is a bit limited, with no up and down movement in the foot, no waist articulation, and only a 90° bend at the elbow. But the alt mode rolls pretty well!

I'm still working out the ball and socket joints. Even with ABS-like resin, they bite and grind and lose material. I've found that inserting a bit of plastic film in between seems to firm them up and protect the interfacing surfaces.

Most of the color on this figure is ink again, including the silver. Since silver alcohol ink is really just a suspension of comparatively large particles, it doesn't bind to the resin the way others do, so there's a layer of acrylic clearcoat over those surfaces.

April has modded and repurposed a Legacy figure into her OC Parcel, so here's a couple photo!

Since Pullback is another fanart piece, the files to print a copy are on my Cults page. Note though that they require some extra materials for hinge pins.

16 notes

·

View notes

Photo

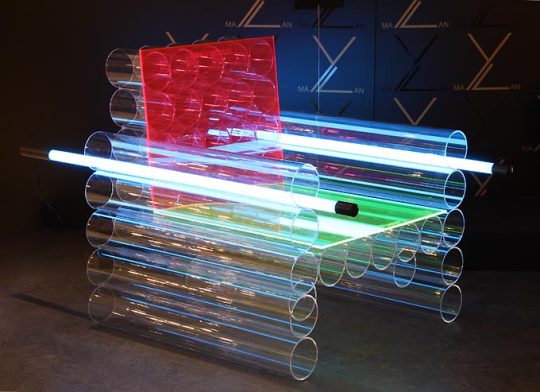

Glasses: Acrylic glass

Both a glass and a polymer, thanks to its amorphous structure, acrylic glass is just another name for poly(methyl methacrylate), or PMMA. A thermoplastic, acrylic glass is marketed under numerous brand names, including Plexiglas, Crylux, Lucite, and Perspex, among numerous others. Because of its transparency and strength, it is often used in places where non-organic glasses are also used.

First produced in the late 1920s, today acrylic glass is produced in a variety of forms and using a variety of methods. In addition to strength and transparency, this plastic has high impact resistance, excellent chemical resistance, and good dimensional stability - it is both lightweight and durable, all of which are properties that lend themselves to its popularity. Its strength is less than that of traditional glass, however, so it cannot replace the latter in all applications, at least not without design changes (i.e., increased thickness of acrylic glass, as compared to traditional glass).

Applications of acrylic glass are too numerous to list here. Nearly any common mold processing methods can be used to shape the polymer, including injection molding and extrusion. Higher quality sheets of the material are made with cell casting, in which the polymerization step and molding step are carried out simultaneously.

Sources/Further reading: ( 1 - all images ) ( 2 ) ( 3 )

34 notes

·

View notes

Text

@zemfruit

Different acrylic brands can have different properties, but the basics are the same. If you are having issues with the paint not sticking I'd recommend using a primer. I have a jar of tamiya gray primer that's lasted me for years that I use whenever I need to hand paint a large flat surface.

It's also worth noting that part of the injection molding process leaves the parts coated in a thin oily layer that will make it harder for paint to stick. I wash the runners in warm soapy water whenever I do a fully painted build but for smaller detail painting I don't bother.

With very few exceptions I always topcoat my models. It creates a protective layer that seals in any panel lining or paint. The main reason that I do it is to give the models a matte finish that makes it look less plastic-y. Most topcoat comes in either gloss or matte. The few times I haven't used topcoat were on some modern bandai kits that had interesting textures to the plastic that I didn't want to cover up.

I've recently started using Mr. Hobby topcoat recently and yeah, I really like it. But I don't think you'll see a major difference in the results compared to a brand like testors, which I used for years and still use occasionally. Mr Hobby just sprays on very smooth.

Also, weather is important when applying topcoat! You should ALWAYS apply it outside unless you have a very powerful ventilation box (I do not). And so the humidity will affect the finished product. Anything over 50% humidity risks a cloudy finish. This is especially noticeable on dark and large pieces. I actually just topcoated 2 kits at once this weekend because it had been humid for so long that I ended up finishing an entire other kit.

Notice how I've used some masking tape to cover up some of the models. Those are clear parts that I want to make sure don't get matte coat on them, since it will make them look cloudy no matter what.

I also thought it might be nice to shout out a few resources that I use all the time. I read the "layman's gunpla guide" when I was first getting into the hobby, and I still refer to it occasionally when I'm trying out a new technique. It's fairly old at this point but I really like how it is written.

There is also a "help me" Q&A on the Gunpla subreddit that I've used several times. People are very nice and helpful, and they don't leave their responses 90% finished in the notes app for a few weeks like I did (sorry). Hope this helps!

3 notes

·

View notes

Text

Global Surface Protection Films Market 2025 by Company, Regions, Type and Application, Forecast to 2030

This report studies the Surface Protection Films market, by type (Adhesive free and Adhesive), by application (Acrylic Sheet, Injection Molding Products (Ex. Acrylic Sheet), Electronics, Metal Products). According to our (Global Info Research) latest study, the global Surface Protection Films market size was valued at USD 4993.2 million in 2022 and is forecast to a readjusted size of USD 6453.2 million by 2030 with a CAGR of 3.7% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. 3M, Eastman, Avery Denison, ExxonMobil Chemical and ZAGG are the key players and accounted for 6%, 5%, 3.6%, 3%, 2% respectively of the overall Surface Protection Films market share. Global giant market mainly distributed in North America, China and Europe. It has unshakable status in this field. China is the largest consumption region of Surface Protection Films, with a consumption market share nearly 28%. The second place is North America; following China with the consumption market share over 23%. This report is a detailed and comprehensive analysis for global Surface Protection Films market. Both quantitative and qualitative analyses are presented by company, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided.

Sample Plan: https://www.reportsintellect.com/sample-request/2911703 Key Features: Global Surface Protection Films market size and forecasts, in consumption value ($ Million), 2018-2030 Global Surface Protection Films market size and forecasts by region and country, in consumption value ($ Million), 2018-2030 Global Surface Protection Films market size and forecasts, by Type and by Application, in consumption value ($ Million), 2018-2030 Global Surface Protection Films market shares of main players, in revenue ($ Million), 2018-2025

Inquire Request : https://www.reportsintellect.com/discount-request/2911703 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Surface Protection Films To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Surface Protection Films market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include 3M, Eastman, Avery Denison, ExxonMobil Chemical and ZAGG, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market segmentation Surface Protection Films market is split by Type and by Application. For the period 2018-2029, the growth among segments provide accurate calculations and forecasts for consumption value by Type and by Application. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Type Adhesive Free Adhesive Market segment by Application Acrylic Sheet Injection Molding Products (Ex. Acrylic Sheet) Electronics Metal Products Market segment by players, this report covers 3M Eastman Avery Denison ExxonMobil Chemical ZAGG OtterBox Nitto XPEL Solar Gard (Saint-Gobain) Orafol BELKIN Argotec Tech Armor MOSHI Hexis Graphics (Hexis SA) XtremeGuard Halo Screen Protector Film PowerSupport intelliARMOR Crystal Armor Spigen Air-J BodyGuardz Market segment by regions, regional analysis covers North America (United States, Canada, and Mexico) Europe (Germany, France, UK, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Australia and Rest of Asia-Pacific) South America (Brazil, Argentina and Rest of South America) Middle East & Africa (Turkey, Saudi Arabia, UAE, Rest of Middle East & Africa)

0 notes

Text

Thermoformed Products: The Backbone of Modern Manufacturing

Thermoformed products are indispensable in today's manufacturing and packaging industries, offering versatility, durability, and cost-efficiency. From food packaging to automotive components, these products play a vital role in shaping our daily lives. But what exactly are thermoformed products, and why are they so popular across various industries?

What Are Thermoformed Products?

Thermoforming is a manufacturing process that involves heating a plastic sheet to a pliable temperature, forming it into a specific shape using a mold, and trimming the final product to create a usable item. The result is what we call a thermoformed product.

The process allows manufacturers to produce both simple and complex designs efficiently, making it ideal for a wide range of applications. Popular materials used in thermoforming include acrylic, polycarbonate, polypropylene, and PET.

Applications of Thermoformed Products

Packaging Industry Thermoformed products are widely used in food and consumer goods packaging due to their lightweight, hygienic, and customizable nature. Common examples include clamshell containers, blister packs, and trays. These products not only protect items but also enhance their shelf appeal.

Automotive Sector Thermoforming is extensively used to create durable and lightweight automotive parts such as dashboards, door panels, and protective covers. These components are crucial for improving fuel efficiency and reducing production costs.

Medical Industry In the medical field, thermoformed products are essential for creating sterile and disposable packaging for medical instruments, syringes, and implants. They ensure product safety and compliance with health regulations.

Consumer Goods Thermoformed items like storage bins, display stands, and protective casings are prevalent in the consumer goods market. They are valued for their aesthetic appeal and functionality.

Industrial Applications Custom thermoformed parts are used in industrial equipment, providing solutions that are tailored to specific operational needs.

Advantages of Thermoformed Products

Cost-Effectiveness The thermoforming process is highly efficient, reducing material waste and production costs, especially for large-scale manufacturing.

Design Flexibility Thermoforming allows for intricate designs, making it suitable for creating unique shapes and sizes to meet specific requirements.

Durability and Strength Thermoformed products can be designed to withstand significant wear and tear, making them ideal for demanding applications.

Sustainability Many thermoformed products are recyclable, and advancements in bio-based plastics are making them even more eco-friendly.

Challenges and Innovations in Thermoforming

While thermoforming offers numerous benefits, challenges like material limitations and environmental concerns remain. However, innovations in material science, such as the development of biodegradable plastics, are addressing these issues. Automation and precision technologies are also improving the quality and consistency of thermoformed products.

For more info:-

Mould Injection Moulding

Plastic Thermoforming

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Mobile Phone Screen Magnifier HD Video Amplifier This is an eye-protecting mobile phone bracket that can enlarge the screen of the mobile phone. This product is suitable for mobile phone models under 7 inches. Design based on Ergonomics principle, Fine tuning the use distance and the bottom bracket can meet the needs of different users. Abandoning injection Molding technology Watching Experience The newly upgraded 3D mobile phone screen magnifier magnifies the mobile phone screen 3-4 times, which will reduce the discomfort and visual fatigue caused by long-term focus on the small screen, and can effectively reduce radiation. Mobile Phone Universal mobile phone screen magnifier uses high-definition zoom optical technology, ABS + 3D screen, 3D visual enjoyment. Effectively prevent radiation from mobile phones. Very suitable for any smartphone. Operational Steps Step 1: Hold the button and pull out the lens Step 2: Pull the fully pulled lenses up Step 3: Set up the mobile phone baffle Step 4: Insufficient height to support the bottom bracket Product Size: 220 x 180 x 9 (mm) Materials: ABS + Acrylic lenses Viewing Distance: The Optimum distance is 1-2 meters. [ad_2]

0 notes

Text

Thermoplastic Acrylic Resin Manufacturer | Supplier in India

We are proud to be a leading manufacturer of thermoplastic acrylic resins in India. Our thermoplastic acrylic resins are made from high-quality raw materials and are formulated to meet the specific needs of our customers. Our thermoplastic acrylic resins are made from high-quality raw materials and are formulated to meet the specific needs of our customers. We offer a wide range of products, including injection molding resins, extrusion resins, thermoforming resins, and casting resins. Our thermoforming resins are ideal for a variety of applications, including sheet and film, signs and displays, toys and games, and medical devices. Our casting resins are ideal for a variety of applications, including jewelry making, architectural castings, mold making, and prototypes. We also offer a wide range of technical support services, including product training, technical assistance, and application support.

#Thermoplasticacrylicresins#manufactureofthermoplasticacrylicresins#Exporterofthermoplasticacrylicresins#supplierofthermoplasticacrylicresins#orcpl#resinmanufacturer#supplieroffiretardantchemical

0 notes

Text

Title Exploring Injection Mold China, Acrylic Injection Molding, and Injection Mold Cost

Target URL https://www.plasticmold.net

Description Injection molding is a cornerstone of modern manufacturing, offering an efficient way to produce high-quality plastic parts at scale. In this blog, we’ll explore the various aspects of injection molding services, the essential plastic injection molding tools, the factors affecting plastic injection molding cost, and the unique benefits of tpe injection molding.

Keywords Injection molding services

plastic injection molding tools

plastic injection molding cost

tpe injection molding

injection mold China

acrylic injection molding

0 notes

Link

Check out this listing I just added to my Poshmark closet: MOBILE PHONE 3D VIDEO AMPLIFIER SCREEN, Enlarge Screen (New In Box) Color Red.

0 notes

Text

Everything You Need to Know about Heavy Gauge Thermoforming

Thermoforming is a plastic processing technology. Different from other plastic processes, the main principle is to heat a hard plastic flat sheet to soften it, then use vacuum adsorption to adsorb the softened sheet to the surface of the mold, and then form it after cooling. Thermoforming is widely used in plastic packaging, lighting, advertising, decoration and other industries.

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in future manufacturing industry.

There are several thermoforming methods used in actual production, and the most basic ones are six: differential pressure forming, overmolding, plunger-assisted molding, suction molding, countermolding, and twin sheet forming.

Thermoforming is divided into heavy gauge thermoforming and thin gauge thermoforming according to the thickness of the sheet. In this article, we will focus on heavy gauge thermoforming.

What is Heavy Gauge Thermoforming

Heavy gauge thermoforming, also known as thick sheet vacuum forming, refers to a technology where the thickness of the raw materials used exceeds 2mm and cannot be formed on a fully automatic machine. Semi-automatic machining and production technology dedicated to thick sheets must be used.

Heavy gauge thermoforming machine is a key process equipment for producing thermoformed plastic parts through vacuum forming manufacturing process using plastic sheets as raw materials. It uses thermoplastic material sheets as raw materials, is heated to the softening temperature in an oven, and then uses the vacuum negative pressure between the plastic sheet and the thermoforming mold to adsorb the plastic sheet in the thermoplastic state to the surface of the thermoforming mold and then cool it for molding.

Heavy Gauge Thermoforming Materials

The main materials for thick gauge thermoforming include: various colors of ABS, acrylic, PETG, PVC, PC, PP, PE, PS, etc. and various modified plastic plain sheets, textured sheets, and transparent sheets.

Application of Heavu Gauge Thermoforming

Heavy gauge thermoforming can be used for product design and manufacturing of rear projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

Heavy gauge thermoforming products mainly include refrigerator liner thermoforming, PS thermoforming, ABS thermoforming, thick sheet thermoforming, thick sheet thermoforming, PMMA thermoforming, etc., which are widely used in medical equipment, food equipment, instrument casings, and electrical appliances. Shells, car body sheaths, pet trays, advertising light boxes, lighting, refrigerator industry, air conditioning industry and home appliance accessories, etc.

Heavy gauge thermoforming products can not only replace injection molding, saving expensive injection mold costs, but also replace traditional manual production. They have the advantages of advanced production technology, fast speed, and reliable quality.

Advantages of Heavy Gauge Thermoforming

It saves raw and auxiliary materials, is light in weight, easy to transport, has good sealing performance, and meets the requirements of environmentally friendly green packaging.

It can pack any special-shaped products, and no additional buffering materials are needed for packaging.

The packaged products are transparent and visible, beautiful in appearance, easy to sell, and suitable for mechanized and automated packaging, which facilitates modern management, saves manpower, and improves efficiency.

Heavy Gauge Thermoforming Machine Components

Heavy gauge thermoforming machines generally consist of sheets positioning system, thermoforming mold positioning system, frame system, heating system, cooling system and electrical control system.

1. The sheets positioning system generally consists of material pressing frame, power cylinder or an oil cylinder, and balance synchronization mechanism. Its function is to tighten the positioning of plastic sheets. The press frame of the walking frame heating method has an upper and lower structure, and is equipped with a transverse locking mechanism to ensure that the press frame can be tightly sealed with the plate backing plate. The frame can be adjusted according to the size of the mold, either manually or automatically.

2. The thermoforming mold positioning system generally consists of upper and lower mold tables, upper and lower mold cylinders or oil cylinders, and synchronization mechanisms. Its function is to tighten the positioning of the thermoforming mold and connect the mold to the vacuum pipeline. There are two positioning methods: manual screw locking or pneumatic automatic locking. The synchronization mechanism can ensure that the upper and lower molds rise and fall simultaneously to ensure vacuum forming accuracy.

3. The frame system generally consists of profile frame, sealed box, and protective door. Protective doors are divided into automatic and manual.

4. The heating system generally consists of heating bricks or heating tubes, oven frames, and power cylinders or motors.

5. The cooling system generally consists of air and water pipes and spray heads.

6. Electrical system: The electrical control system cooperates with the pneumatic or hydraulic system to realize the process requirements (temperature, speed, time) and various program actions of the thermoforming machine. It is mainly composed of PLC and touch screen, contactors, electronic components, temperature regulating instruments, solenoid valves, sensors, etc. There are generally three control methods, manual, automatic and adjustment.

Heavy Gauge Thermoforming Production Process

The principle of heavy gauge thermoforming is similar to that of light gauge thermoforming. The positioned sheet is heated to a softened state in an oven, and the vacuum forming mold forms a closed space around it to instantly remove the air from the mold cavity and tightly cover the sheet. The process of cooling and shaping the mold surface to obtain the finished product.

Thermoforming is a cyclic process, and each cycle mainly includes: loading - heating and softening - backflushing and pre-drawing - pressure forming - cooling and shaping - demoulding and picking. After taking out the plastic parts, place the plate again (can be received or automatically) and proceed to the next cycle.

1. Mold making and processing: Different customers have corresponding specifications for the product, so plastic molds must be made before production. In this case, the mold is made from plaster of a plastic mold, and the mold is produced using plastic. The lower cost is the plaster mold, followed by the electroplated copper mold, while the aluminum mold is more expensive. When the mold is made, let it dry naturally or dry it, and then treat it according to the specific conditions of the product surface. to

2. When the mold is completely dry, the mold should be placed on the upper iron plate of the vacuum chamber, and then according to the size of the mold, load the mold into the applicable size and then put the paper into the hot wood cabinet to fix it and process it.

3. Fix the plastic sheet on the mold with fixing clips, heat both ends of the plastic sheet until it becomes soft, and then use a vacuum pump to remove the air between the material and the mold, allowing the softened plastic sheet to be adsorbed on the mold and cool. Then blow air in the opposite direction to release the product from the mold.

4. Finishing: The finished product is trimmed and integrated into a product that can be packaged for sale. Thin gauge plastic thermoforming is generally used in food packaging, pharmaceutical packaging, cosmetic packaging and other industries. Product thickness 10-100 silk. Heavy gauge vacuum forming is mainly used in automobile, hardware, electric vehicle and other industries, and the product thickness is 1-10mm or even thicker.

Thermoforming & Injection Molding & Blow Molding

Injection molding

Injection molding is to melt the plastic raw materials, then put them into the mold under high pressure through an injection molding machine, and then cool them into shape.

Blow Molding

Blow molding is a rapidly growing plastic processing method. The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state). After the mold is closed, compressed air is immediately introduced into the parison to blow the plastic parison. It expands and adheres closely to the inner wall of the mold. After cooling and demoulding, various hollow products are obtained.

Main Difference

1. Thermoforming: It is suitable for products with relatively simple structure, single-sided molding and small quantity. Molds are very cheap. The mold cost is only 1/20 of that of injection molds. The mold opening time of products of similar complexity is only 1/4 of that of injection molds. However, complex structures cannot be designed and are generally bonded through adapters. It is also similar to the carbon fiber hot pressing process.

2. Injection molding: suitable for large-volume, high-precision products, the mold cost is very high, and complex structures can be designed.

3. Blow molding: mainly used to produce hollow products, such as bottles, cans and other products. The price of the mold is not much different from that of thermoforming molds.

Case

Medical industry

Why heavy gauge thermoforming?

1. The order quantity of medical products is small. Compared with other consumer products, the steel materials with slightly better mold life of general injection molding can be molded one million times. However, it is difficult for general large-scale medical products to reach this level. The plastic mold The price is transferred to a single product, resulting in a very high unit price (applicable to products with a batch size of less than 5,000 and whose appearance level requirements are not particularly high, especially suitable for the casing of robot products).

2. Compared with injection molding, heavy gauge thermoforming has a simple structure and can still meet most of the needs. It has stable performance, satisfactory surface treatment, and can be adapted to silk screen printing (ABS) of various colors.

Conclusion

Heavy gauge thermoforming can mold plastic products of large size, simple appearance, and imprecise size requirements at one time. In some aspects, it can replace injection molding, fiberglass, metal shells, etc. The blister mold has the advantages of low manufacturing cost and short development cycle. advantage. Its cost is 1/10 to 1/20 of that of an injection mold, and its production cycle is fast. It is gradually widely used in various fields of people's daily life, such as automobile interior and exterior decoration, transportation, building materials, packaging, medical equipment, household appliances, cultural, educational and sanitary ware, sporting goods and so on. Today, with the rapid development of the plastics industry, the use of heavy gauge thermoforming is also expanding.

0 notes

Text

youtube

Factory custom made cnc laser cutting machining service

We are specialize in cnc laser cutting precision metal machining parts, cnc machining acrylic laser cutting service, stainless steel cnc machining casting parts, cnc turning parts, die casting parts, plastic injection molding parts, 3D printing parts etc.

We also can provide the customized service as per customer's product requirement, demand aluminium cnc machining customization parts, micro machining turned milled brass cnc, machining service plastic cnc peek milling parts etc.

Looking forward to your feedback~

https://mxymachining.com

0 notes

Text

From Concept to Cure: The Evolution of Medical Plastics

Overview of Medical Plastics

Medical plastics have become ubiquitous in healthcare applications over recent decades. A wide range of polymers are now used in everything from surgical tools and medical devices to implants, prosthetics, and diagnostic equipment. Some key advantages of plastics for medical applications include their lightweight nature, durability, biocompatibility, and flexibility in design and manufacturing. This article provides an overview of common medical plastics and their uses in modern patient care.

Thermoplastics in Surgical Tools and Medical Devices

Thermoplastics like polyvinyl chloride (PVC) and polyolefins are widely employed in disposable medical tools and devices. These plastics can be easily shaped, formed, and sealed through heating and cooling processes like injection molding and extrusion. Common thermoplastic applications include surgical drapes, gowns, gloves, face masks, catheters, tubing, syringes, and many other single-use items. Thermoplastics offer sterilizability, low cost, and convenience as they can be produced quickly and disposed of after a single use, reducing risks of cross-contamination compared to reusable materials.

Thermoplastics are also used to construct housings and components of more complex medical devices like dialysis machines, ventilators, ultrasound probes, endoscopes, and surgical tools. Their material properties allow intricate geometries to be replicated precisely while withstanding regular cleaning and sterilization cycles. Polycarbonate and acrylic thermoplastics often feature in medical device and equipment construction due to their transparency properties as well.

Engineering Plastics for Implants and Prosthetics

Engineering plastics with advanced material qualities have enabled new frontiers in medical implants and prosthetics. Ultra-high molecular weight polyethylene (UHMWPE) exhibits high strength and wear resistance essential for articulating joint replacements like knees, hips, and shoulders. Since its introduction, UHMWPE has vastly improved implant service lifetimes and mobility for millions worldwide.

Polyetheretherketone (PEEK) possesses radiolucency, making it well-suited for spinal and cranial implants. Its elastic modulus closely matches bone to minimize stress shielding while exhibiting biocompatibility and fatigue resistance. Titanium alloy and stainless steel bone screws, plates and rods are also widely employed in orthopedic and trauma surgery for strength and compatibility with scans.

Meanwhile, thermoplastic elastomers like polyurethanes facilitate lifelike prosthetics with soft tissue properties and resilience. Silicone formulations provide a barrier while transmitting sensory feedback in advanced prosthetic sockets and sleeves. Such optimized plastics enable unprecedented functionality and quality of life restoration for individuals with missing or non-functioning anatomy.

Diagnostic Equipment and Accessories

Diagnostic imaging modalities heavily rely on plastics to construct vital optical, electronic and mechanical systems. Liquid crystal polymers maintain precision tolerances in ultrasound transducer arrays and fiber optic cabling while withstanding stringent sterilization. Epoxy molding compounds encapsulate sensitive circuitry within CT and MRI scanners in protective housings.

Acrylic sheet forming finds use manufacturing view boxes and light boxes in radiology departments as the material effectively diffuses transmitted light for image analysis. Meanwhile polycarbonate excels as a housing material for portable ultrasound carts, endoscopy towers and lab equipment given its impact resistance, clarity and ease of disinfection. An assortment of commodity plastics from polypropylene to nylon further serve construction of trays, stands, handle grips and miscellaneous accessories throughout diagnostic settings.

Labware, Filtration and Storage

Plastics dominate the production of labware, filters and consumable storage products essential for diagnostic testing and biomedical research. Polypropylene and polyethylene provide an optimal combination of clarity, low bind-in, autoclavability and cost effectiveness for lab bottles, flasks, Petri dishes, microtubes, pipette tips and more. These widely inert plastics minimize risk of compound interactions.

Nylon and polycarbonate reinforce syringes and lab centrifuge containers against high speeds and mechanical stresses. PTFE and PVDF excel as biomaterial compatible membrane choices for important separations in areas like dialysis, blood filtration and cell culture. Meanwhile, plastics like PET and HDPE offer practical sterile storage and transportation solutions for reagents, blood products and clinical specimens with excellent barrier properties.

Future Outlook

Advancements in polymers and manufacturing technologies will undoubtedly yield further medical product innovations to come. Areas of active R&D include smart plastics possessing sensing, actuating and communication abilities for integrated diagnostics. 3D printed personalized implants fabricated from biodegradable polyesters address shortages while minimizing invasive surgery. Tissue engineering scaffolds may someday harness biopolymers ability to encourage natural regeneration. Always guided by principles of biocompatibility and sterility, medical plastics will remain at the forefront of patient care improvement for generations to come.

0 notes

Text

two shot plastic tumbler glass mold

China 2 component mold maker, offer two shot plastic tumbler glass, bi injection smoothie cups, multi color drinking glass mold, gyratory acrylic travel cups mold

#China mold#bi material mold#2 component mold#two color plastic tumbler glass mold#2k smoothie cups mold#rotary mold drinking glass#double arcylic travel cups mold

0 notes

Text

Waterproofing your basement

Waterproofing your basement is essential to protect your home from water damage, mold growth, and structural issues. Here are some effective tricks to help you keep your basement dry and safe:

Identify and Fix Cracks: Inspect your basement walls and floor for any cracks or holes. These can be entry points for water. Use hydraulic cement or masonry caulk to fill small cracks. For larger cracks, consult a professional to assess the situation and recommend the best course of action.

Apply Waterproof Coatings: Use a waterproof sealant or coating on your basement walls and floor. These products create a barrier that prevents water from seeping through the concrete. Some popular options include silicate-based concrete sealers, acrylic coatings, and epoxy injections. Be sure to follow the manufacturer's instructions for proper application.

Install a French Drain: A French drain is a trench filled with gravel and a perforated pipe that directs water away from your home's foundation. It is installed along the perimeter of your basement, either inside or outside, to collect and divert water before it can enter your basement. This is an effective solution for homes with persistent water issues.

Use a Sump Pump: A sump pump is installed in a pit at the lowest point of your basement. It pumps out water that accumulates in the pit, preventing it from flooding your basement. Make sure to choose a pump with adequate capacity for your needs and install a backup battery in case of power outages.

Improve Yard Drainage: Ensure that your yard slopes away from your home's foundation. This prevents water from pooling near your basement walls. You can also install gutters and downspouts to direct rainwater away from your house. Extend the downspouts at least 5 feet away from your foundation.

Maintain Gutters and Downspouts: Regularly clean your gutters and downspouts to prevent clogs that can cause water to overflow and seep into your basement. Make sure the downspouts are properly connected and divert water away from your home.

Ventilate Your Basement: Proper ventilation helps reduce humidity levels in your basement, which can prevent mold growth and moisture-related issues. Use a dehumidifier to maintain a relative humidity level below 50%. Consider installing exhaust fans in bathrooms and kitchens to remove excess moisture.

Insulate Pipes and Walls: Insulate your basement pipes to prevent condensation, which can contribute to moisture buildup. Additionally, insulate your basement walls to reduce temperature fluctuations that can lead to condensation and moisture problems.

Use Waterproof Floor and Wall Coverings: If you plan to finish your basement, choose waterproof flooring options such as ceramic tile, vinyl, or moisture-resistant laminate. For walls, use moisture-resistant drywall or cement board instead of regular drywall.

Regularly Inspect and Maintain: Periodically inspect your basement for signs of water intrusion, such as damp spots, discoloration, or musty odors. Address any issues promptly to prevent further damage. Regularly maintain your waterproofing systems, such as sump pumps and French drains, to ensure they continue to function effectively.

By implementing these tricks and staying vigilant, you can significantly reduce the risk of water damage in your basement and protect your home's structural integrity.

0 notes