#instrumentation valve

Text

Instrumentation Valve | Venture 11

At Venture11, we understand the critical role that instrumentation valves play in ensuring the accuracy and efficiency of your industrial processes. Our range of instrumentation valves is engineered to provide exceptional performance and reliability, meeting the highest industry standards. Instrumentation valves are essential components in various applications, from controlling and isolating fluid flow to regulating pressure and temperature. Designed with precision and durability in mind, our valves are ideal for use in demanding environments where accuracy and safety are paramount. Our comprehensive selection of instrumentation valves includes ball valves, needle valves, and pressure relief valves, each crafted from premium materials to ensure longevity and resistance to corrosion. Whether you need to manage high pressures, aggressive chemicals, or extreme temperatures, our valves offer the perfect solution.

For more details clicks here - https://www.venture11.au/instrumentation-valve.php

0 notes

Text

Celebrating National Science Day: A Tribute to C.V. Raman by Future Techno Pvt. Ltd.

National Science Day, commemorated every year on February 28th, serves as a testament to the remarkable strides humanity has made in the realm of science and technology. It is a day to honor the contributions of visionary scientists whose groundbreaking discoveries have reshaped our understanding of the world. One such luminary is Sir C.V. Raman, whose legacy continues to inspire and propel scientific innovation forward.

At Future Techno Pvt. Ltd., we recognize the invaluable impact of scientific research and discovery on society. On this National Science Day, we pay homage to the unparalleled genius of C.V. Raman and his monumental contributions to the field of physics. Raman's pioneering work, particularly his discovery of the Raman Effect in 1928, has left an indelible mark on scientific inquiry, paving the way for countless advancements in various disciplines.

The Raman Effect, which elucidates the scattering of light by molecules, revolutionized our understanding of light-matter interactions and earned Raman the Nobel Prize in Physics in 1930. His relentless pursuit of knowledge and unwavering commitment to excellence serve as guiding beacons for scientists and researchers worldwide. Raman's legacy transcends generations, inspiring curiosity, innovation, and a thirst for knowledge.

As we commemorate National Science Day, Future Techno Pvt. Ltd. reaffirms its dedication to fostering a culture of scientific inquiry and innovation. We recognize the importance of investing in research and development to address the challenges of today and unlock the possibilities of tomorrow. Through collaboration, curiosity-driven exploration, and a commitment to excellence, we can continue to build upon the foundation laid by pioneers like C.V. Raman.

In conclusion, National Science Day is a time to celebrate the transformative power of science and acknowledge the trailblazers who have shaped the course of human history. At Future Techno Pvt. Ltd., we honor the legacy of C.V. Raman and salute his enduring impact on scientific discovery. As we look to the future, let us draw inspiration from Raman's quest for knowledge and strive to push the boundaries of what is possible through innovation, curiosity, and dedication.

#nationalscienceday#cvraman#freture techno#ballvalves#bellowsealvalve#safetyvalve#butterflyvalve#control valve#instrumentation valve#instrumentation accessories

0 notes

Text

High Quality Instrumentation Manufacturer Valve in India

PipingProjects.in is one of the leading Instrumentation Valve Manufacturer in India. The market has a wide range of instrumentation valves in various sizes and composed of various materials. This valve is identified by its spherical component with a central port, which enables the control and cessation of fluid flow. PipingProjects.in is a top Instrumentation Valve Manufacturer in Pune.

We are a top Instrumentation Valve Supplier in India. Instrumentation valves are made of a variety of materials and control the flow of liquids and gases in piping systems. Each valve plays a specific job. The ball valve requires a significant amount of torque to turn into the open and close positions, as well as in between. As a result, the fine adjustment of these valves is off.

The valves are opened by the pressure of the fluid passing through the piping system; in the event of a reverse flow, the valves close. When the flow direction is reversed, the instrumentation manifold's valves are thought to be self-actuating, protecting the piping system from any potential harm caused by the water hammer. We are a high quality Instrumentation Valve Manufacturer in Nagpur and Instrumentation Valve Manufacturer in Mumbai.

Explore our weight chart Wire Mesh Weight Chart in kg.

For more details:

Product: Instrumentation Valve Manufacturer

0 notes

Text

Choosing the Right Valves in Instrumentation: A Comprehensive Guide - Arcellor Controls

When considering instrumentation valves, precision, and reliability stand as paramount factors. The selection of the right valves holds immense significance in ensuring the successful execution of any project, as these valves assume a pivotal role in regulating the flow of liquids and gases across diverse industrial applications. At Arcellor Controls India, a distinguished instrumentation valve manufacturer and exporter in India, we grasp the vital importance of choosing the perfect valves to cater to your specific needs. As a trusted instrumentation valves supplier in India, we offer a wide range of instrumentation valves, including Needle Valves, Ball Valves, Gate Valves, Globe Valves, Manifold Valves, Check Valves, Monoflanges Valves, and valve accessories catering to various types of valve in instrumentation systems.

In this comprehensive guide, we will walk you through the essential factors to consider when choosing instrumentation valves.

Understanding the Importance of the Right Valves

Instrumentation valves play a critical role in regulating the flow of fluids or gases within a system. Whether you are involved in the oil and gas industry, chemical processing, petrochemicals, or any other field that relies on precision control, selecting the right valves is crucial. Here's why:

Efficient Flow Control: The right valves help maintain precise control over the flow rate, pressure, and temperature of the medium being transported. This ensures optimal system performance and efficiency.

Safety: In industries dealing with hazardous materials, safety is paramount. Properly selected valves can prevent leaks, spills, and accidents, safeguarding both personnel and the environment.

Longevity: High-quality valves that match the application's requirements are more likely to have a longer service life, reducing maintenance and replacement costs.

Cost-Efficiency: Choosing the right valves initially may require a higher investment, but it often leads to cost savings over time due to improved efficiency and reduced downtime.

Types of Valves in Instrumentation:

We offer a wide range of valves in instrumentation to cater to diverse industry requirements. These include types of valves in instrumentation:

Needle Valves: Ideal for fine control of flow with precision.

Ball Valves: Known for their durability and fast operation.

Gate Valves: Suitable for on/off applications with minimal pressure drop.

Globe Valves: Excellent for throttling applications.

Manifold Valves: Designed for multi-valve installations and isolation.

Check Valves: Ensure one-way flow, preventing backflow.

Monoflanges Valves: Compact, space-saving solutions for instrument connections.

Valves Accessories: Various accessories to enhance valve performance.

Factors to Consider When Choosing Valves

Application Compatibility: The first step in selecting the right valves is understanding the nature of your application. Different valves are designed for specific tasks, so ensure that the valve you choose is compatible with the fluid, pressure, and temperature requirements of your system.

Material Selection: The choice of material is crucial for valve performance and durability. Our diverse material options include Stainless Steel, Alloy, C.S., Duplex, Super Duplex, Hastelloy, Monel, and Inconel (Nickel Alloys) to ensure that you can find a valve suitable for even the most corrosive or high-pressure environments.

Size and Specification: Valves come in a wide range of sizes and specifications. Ensure that the valve dimensions match the piping system's requirements and that it meets the necessary industry standards.

Operation Type: Valves can be operated manually, pneumatically, or electrically. Select the operation type that aligns with your system's automation needs and operator preferences.

Pressure and Temperature Ratings: Pay close attention to the valve's pressure and temperature ratings to prevent system failures and ensure safety.

Flow Control: Depending on your application, you may need precise flow control capabilities. Our needle valves, for instance, excel in providing fine-tuned control.

Reliability and Maintenance: Consider the long-term reliability of the valves, including ease of maintenance and the availability of spare parts.

Applications of Instrumentation Valves

These valves are designed to withstand high pressures and provide reliable performance in applications such as fluid and gas handling, measurement, and control. Here are some common applications of instrumentation valves:

Chemical Processing:

Oil and Gas Industry:

Petrochemical Plants:

Power Generation:

Pharmaceutical and Biotechnology:

Food and Beverage Processing:

Water and Wastewater Treatment:

Aerospace and Defense:

Laboratory and Research:

HVAC ( heating, ventilation, and air conditioning) Systems:

Marine and Shipbuilding:

Mining and Mineral Processing

Automotive Manufacturing:

Power Distribution:

Environmental Monitoring:

Semiconductor Manufacturing:

Other Applications

Final Words!

Selecting the ideal instrumentation valves is an imperative decision, wielding a profound influence on your system's overall performance, safety, and efficiency. Arcellor Controls India stands out as your trusted partner in this endeavor, ensuring that you make informed choices and receive instrumentation valves of unparalleled quality, meticulously customized to match the requirements of your project. Our extensive array of valve options and our global export services make us the go-to instrument valves supplier and instrumentation valves manufacturer in India. As a globally recognized instrumentation valve exporter, we have established its presence in various countries, including Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. Our commitment to quality, precision engineering, and competitive pricing has made us a trusted partner for clients worldwide. Contact us today at [email protected] or [email protected] to explore our comprehensive range of instrumentation valves today and experience firsthand the Arcellor Controls India advantage, setting us apart as premier valves in instrumentation supplier.

#instrumentation valve manufacturer#instrumentation valve#types of valves#instrumentation valves#ball valves#needle valves

0 notes

Text

Mcneil is Finest Instrumentation Valve Manufacturers, Suppliers, Exporters in Mumbai, India

Mcneil Instruments Inc offers a variety of Valve instruments. Valves used in plumbing and other related works are manufactured in various parts of India. manifold valve, Needle valve, Ball valve, Check valve, Globe instrumentation valve, Gauge Cock valve, Block bleed valve.

Mcneil is a company that manufactures valves, which are mechanical devices that open, close, or partially obstruct a passageway to control the flow of fluids or gases. Valves are used in a wide range of industries, including oil and gas, chemical processing, water treatment, and HVAC (heating, ventilation, and air conditioning).

Get more information about valves to click this link below:

https://www.mcneilinstruments.com/instrumentation-valve.html

0 notes

Text

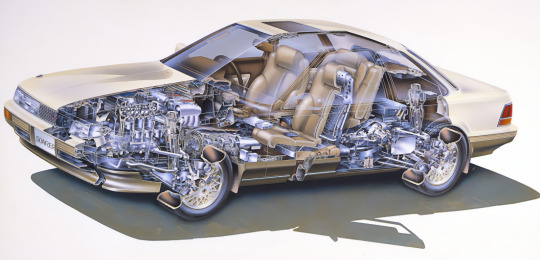

Toyota Soarer 3.0 GT-Limited, 1986. The second generation Z20 Soarer shared its platform with the A70 series Supra. It introduced the Electro Multi Vision digital vehicle information display. The 3.0 GT was powered by a DOHC 24 valve turbocharged straight 6

#Toyota#Toyota Soarer#Toyota Soarer Z20#1986#sports coupé#straight 6#24 valve#DOHC#digital instrumentation

306 notes

·

View notes

Text

Still Alive (Radio Mix)

// Portal (2007)

#portal#portal (game)#still alive#playstation 3#xbox 360#PC#valve#game#instrumental#2007#oktaviaslabyrinth

28 notes

·

View notes

Text

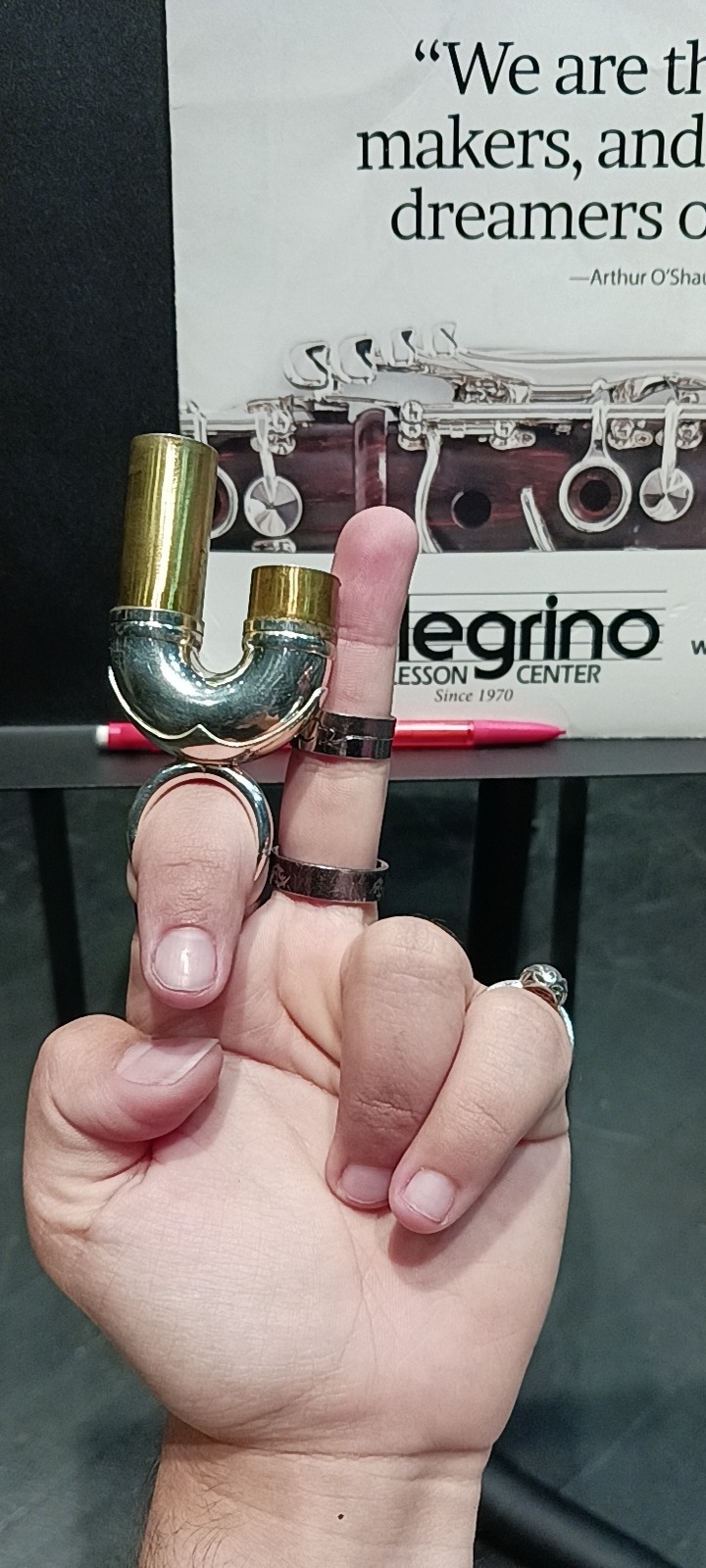

They need to add more stupid attachment thingies to instruments. Instruments need to get scrunklier.

#-Loki#instruments#trombone#F trigger trombone#trumpet#euphonium#compensating valve euphonium#french horn#double french horn#triple french horn#Music

7 notes

·

View notes

Text

Wait fuck I’m learning a wind instrument. The band kids fucking won.

#chit chat#DAMN it#all throughout high school the marching band kids wanted me to become one of them#and i said I’d never take up mouth instruments because they were gross#and now...#sigh#i do admit that i do find the harmonica a little gross and i do have to try and wipe it down after every exercise#but i don’t have to deal with spit valves or reeds or whatever the flutes do#so there is that#harmonica adventures

6 notes

·

View notes

Text

Shitty soldering job, right?

WRONG

That, my friends, is epoxy.

This one got filed under "haha NOPE" because the cost of the repair would not have been worth it. Epoxy does not melt and wipe off the way solder does; I would have had to basically chisel it off, and who knows how long that would have taken me.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#cornet#epoxy#this is what we in the industry often refer to as a “dad fix”#because 9/10 times it is a kid's dad that does stuff like this#moms do it too but in less destructive ways#like telling the kid who forgot to bring valve oil to just use vegetable oil on the valves because oil is oil#less damaging but still a pain#it is well-intentioned but please just don't#or do since then I get paid to fix the problem

2 notes

·

View notes

Text

Band of 107th U.S. Colored Infantry at Fort Corcoran, Arlington, Va. holding saxhorn brass valve instruments. These saxhorns were the type of instruments played at the funeral of African Civil War hero and Captain Andre Cailloux. Many of the instruments were played over the shoulder to play to the army following the band. Instruments today face forward and bands can be in the middle or back of a procession.

Library of Congress

Smith, William Morris, photographer

Created / Published

1865

#african#afrakan#kemetic dreams#africans#brownskin#brown skin#afrakans#library of congress#william morris#1865#fort corocran#arlington#va#saxhorn brass#valve instruments#civil war heros#photographers#photographer

16 notes

·

View notes

Text

Whoever pioneered making a valve this shape should be shot

#euphonium#baritone#tuba#low brass#brass#brass instrument#valves#brass valves#valve instrument#2nd valve

4 notes

·

View notes

Text

Taming the Beast: Selecting the Right Instrument Valve for High-Pressure Applications

In the complex world of high-pressure applications, the importance of selecting the right instrument valve cannot be overstated. Instrument valves play a crucial role in managing and controlling the flow of fluids in various industrial processes. From oil and gas to chemical and petrochemical industries, the challenges of high-pressure environments demand a careful and informed approach to valve selection. This article explores the key considerations, safety measures, material compatibility, testing procedures, and best practices essential for taming the beast that is high-pressure instrumentation.

Understanding the Challenges:

High-pressure environments bring forth a myriad of challenges, making the selection of instrument valves a critical aspect of any industrial operation. The stakes are high, with safety concerns at the forefront. A failure in valve performance can lead to catastrophic consequences, not only risking equipment integrity but also the safety of personnel. Therefore, it becomes imperative to delve into the specific challenges associated with high-pressure applications to make informed decisions when choosing instrument valves.

Safety Considerations:

Safety should always be the top priority when dealing with high-pressure systems. Selecting instrument valves that comply with industry standards and regulations is non-negotiable. Engineers and technicians must consider factors such as pressure ratings, temperature limitations, and the potential for corrosion or erosion. Additionally, the valve's design and construction must align with the specific demands of the application to ensure robust and reliable performance under extreme conditions.

Material Compatibility:

The compatibility of materials used in instrument valves with the fluids they will handle is a critical aspect often overlooked. Corrosion, erosion, and chemical reactions can compromise the integrity of the valve over time, leading to leaks or failures. Engineers must carefully evaluate the materials of construction, ensuring they can withstand the aggressive nature of high-pressure fluids. Stainless steel, alloy materials, and specialized coatings may be necessary to guarantee longevity and performance in corrosive environments.

Testing Procedures:

Rigorous testing procedures are essential to validate the reliability of instrument valves in high-pressure applications. Pressure testing, leak testing, and endurance testing are vital steps in the selection process. Only by subjecting the valves to conditions that mimic real-world scenarios can engineers ensure their capability to withstand the demands of high-pressure environments. Documentation of testing procedures and results should be meticulously maintained to comply with industry standards and provide a clear record of the valve's performance characteristics.

Best Practices for Long-Term Valve Performance:

To ensure long-term valve performance in high-pressure applications, it is crucial to adhere to best practices. Regular maintenance schedules, monitoring for signs of wear or damage, and implementing preventive measures are essential. Employing advanced technologies such as remote monitoring and diagnostics can enhance predictive maintenance strategies, allowing for proactive interventions before issues escalate.

Taming the beast of high-pressure applications requires a strategic and informed approach to instrument valve selection. By prioritizing safety considerations, addressing material compatibility, conducting rigorous testing, and implementing best practices for long-term performance, industries can navigate the challenges of high-pressure environments with confidence. In doing so, they not only protect their investments but also safeguard the well-being of personnel and the integrity of critical processes.

#instrumentation valve#instrumentation accessories#instrumentation fittings#instrumentation valve manufacturer#freture techno

0 notes

Text

I started renting a valve trombone from my school a few days ago and I can say, with full confidence, that it is now one of my favorite instruments. It’s like a trumpet, but bigger and lower and 1000 times cooler. The only thing cooler than it is the tuba, because nothing can compare to the tuba.

4 notes

·

View notes

Text

How do control valves work in the instrumentation industry?

Industrial process control valves are integral to the intricate landscape of the instrumentation industry, controlling the flow of fluids and gases. At Arcellor Controls (India), a premier instrumentation valve manufacturer and exporter, we understand the significance of these devices in ensuring precise control and optimal performance.

In this blog post, we delve into the inner workings of control valves, shedding light on their importance, components, and applications.

Understanding Control Valves - Instrumentation Valves: The Basics

Control valves also known as Instrumentation Valves are designed to regulate the flow of liquids or gases in a pipeline. They achieve this by increasing or decreasing the flow passage using a valve plug, which is controlled by an external signal. The ability to control various factors in a process system not only ensures the smooth functioning of the system but also its safety and efficiency.

Components and Operation - Instrumentation Valves:

A control valve has several key components that collaborate seamlessly to regulate fluid flow. The primary components include:

Valve Body: The valve body houses the flow path through which the fluid or gas passes. It features an inlet and an outlet, with a movable element known as the valve plug.

Actuator: The actuator is responsible for driving the movement of the valve plug. It responds to external signals from process control systems and adjusts the valve position accordingly.

Positioner: The positioner receives signals from the controller and accurately positions the actuator, ensuring precise control over the valve opening.

Valve Plug and Seat: These components create a seal, controlling the flow by adjusting the space through which the fluid can pass. The valve plug's position determines the flow rate.

Working Principle - Instrumentation Valves

The operation of control valves can be summarized in a few simple steps:

Signal Input: The control system sends a signal to the actuator based on the desired process conditions.

Actuator Action: The actuator responds to the signal by either opening, closing, or modulating the valve.

Flow Regulation: As the valve opens or closes, the flow of fluid or gas is adjusted. This, in turn, influences the process variables like pressure, temperature, and level.

Feedback Loop: Modern control systems incorporate feedback mechanisms that constantly monitor the process variables and adjust the valve position accordingly to maintain the desired conditions.

The Diverse Range of Control Valves

We provide a diverse range of valves in instrumentation, each tailored for specific applications:

Needle Valves: Precision is the hallmark of these valves. They allow for accurate flow control in smaller passages, especially when low flow rates are needed.

Ball Valves: A versatile choice, ball valves can control the flow of liquids, gases, and slurries. With a quick turn of the handle, they either allow or block flow, making them ideal for shutoff applications.

Gate Valves: Used primarily for on/off control, gate valves provide a straight-line fluid flow, ensuring minimal flow resistance.

Globe Valves: These are ideal for regulating flow in a pipeline. With a movable disc-type element and a stationary ring seat, they offer precise control.

Manifold Valves: Efficient and robust, these are used in applications where there's a need to consolidate multiple instruments.

Check Valves: These are essential for preventing backflow in systems, ensuring that flow is in one direction only.

Monoflanges Valves: Designed to replace multiple valves with one standard solution.

Valves Accessories: Essential components that enhance the functionality and longevity of the valves.

Arcellor Controls (India): The Gold Standard in Instrumentation Valves

At Arcellor Controls India, our reputation as a leading instrumentation valve manufacturer and exporter isn't just based on words. We offer a wide range of valves including Needle valves we are also known as a Needle valves manufacturer we offer SS Needle valves, High-pressure needle valves, and more, Ball Valves, Gate Valves, Globe Valves, Manifold Valves, Check Valves, Monoflanges valves, and valves accessories in various sizes, specifications, materials, and types. Our commitment to quality and precision means that our customers can always find the perfect solution for their project requirements.

Moreover, our reach isn't limited to India. As renowned instrumentation valve exporters, we have made a mark in countries like Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. Our competitive pricing coupled with uncompromised quality has made us a preferred choice for countless industries worldwide.

Final Thoughts!..

Control valves are the unsung heroes of the instrumentation industry, ensuring that systems run efficiently and safely. With a vast array of options, it’s vital to choose the right valve for your specific needs. Whether it's the meticulous design of our Needle Valves or the robust construction of our Ball Valves, at Arcellor Controls India, we are devoted to delivering excellence to our clients worldwide.

So, if you're in the market for premium quality instrumentation valves that stand the test of time, look no further. Explore our extensive range today and find the perfect fit for your project requirements.

#instrumentation valves#types of valves in instrumentation#flange types#flange#valves in instrument#needle valves#types of instrumentation valves#instrumentation valve#flanges#instrumentation valves.

0 notes

Text

From my experience with the more cursed instruments I gotta say they all would make really great spell focuses for bards and even better magic wands adjacent things. The three most cursed instruments might have to be the Bassoon, Sarrusophone, and valved Trombone, each something that feels magical all differently...

#Sarrusophone#bassoon#wizard#wizard posting#band#valved Trombone#bard#musical instruments#having tried playing them all the Bassoon is the only one that i ended up buying

5 notes

·

View notes