#hvof spray process

Explore tagged Tumblr posts

Text

HVOF Spray Process: Advanced Technology of Metalizing

HVOF coating process

High-Velocity Oxygen Fuel Coating (HVOF) coating is an advanced thermal spray process whereby fuel and coating material are mixed with oxygen which is then fed into a combustion chamber of the spraying gun. In the combustion chamber, the mixture is ignited at a high temperature and pressure. It is then ejected through the nozzle of the tool at a high speed.

What is HVOF spraying technology used for

Molten or semi-molten materials are sprayed on a metal surface through the HVOF spray process to form a dense and even coating that increases the longevity of the metal parts. The process provides a very high and perfect surface finish.

Multifarious benefits

The process reduces the cost of surface coating, improves electrical properties, and protects metal parts from chemical reactions in a harsh chemical environment.

For more details on the HVOF spray process visit https://imcmetallizing.com/

0 notes

Text

Thermal Spray Coatings in the U.S. Oil & Gas Sector: Key Trends and Market Outlook

The U.S. thermal spray coating for oil and gas market size is expected to reach USD 426.3 million by 2027, expanding at a CAGR of 7.8% over the forecast period, according to a new study by Grand View Research, Inc. Increasing demand corrosion inhibitors from oil rigs in U.S. is significantly driving the market growth.

Thermal coatings are used in a variety of applications including oil and gas, aerospace, petrochemical, marine, and automotive. There are a variety of coatings available that can be used depending upon the specific requirements of the industry. For instance, electric arc wire spray is used for industrial gas turbines, whereas oil and gas industry uses High Velocity Oxygen Fuel (HVOF) and atmospheric plasma spray.

The product demand from downstream industrial segment is expected to increase steadily on account of their increasing use, primarily in numerous products such as gasoline, diesel, pesticides, pharmaceutical, propane, liquid petroleum gas, plastics, and jet fuel. The expansion of downstream segment, particularly in the industrial cities such as Houston, New York, Chicago, Los Angeles, Dallas, and St. Louis, is expected to have a positive impact on the market over the forecast period.

Based on product segment, metal is anticipated to register a significant growth over the forecast period. Metals such as zinc, bronze, aluminum, and copper are used in thermal spraying processes. These methods are utilized in various components across the oil and gas industry, which include pump impellers, casings, pipes, mud pump components, and gate valves. If a material can be heated to its melting point without it boiling away, the materials can be used for spraying. A wide range of steel materials can also be used for corrosion and wear protection in thermal spraying applications.

The flame spray technology segment is anticipated to expand at the fastest growth rate over the forecast period. This process produces surface coatings by using heat from burning oxygen with fuel gas. It is done in order to melt the coating material, which is then propelled onto a substrate. The process is often used as a cost-effective alternative for ceramic and metallic coatings. The process uses a wide variety of ceramic or metallic coatings including molybdenum, stainless steel, low carbon steel, aluminum, zinc, bronze, and nickel-based materials.

U.S. Thermal Spray Coating For Oil & Gas Market Report Highlights

Carbides is expected dominate the product segment during the forecast period owing to its erosion and abrasion resistant properties

Flame spray is the fastest growing application segment in the market on account of growing demand thermal coatings from oil and gas industry

HVOF was the leading technology segment in 2019 owing to its benefits such as reduced cost, improved performance, and improved electrical properties

Some of the key players in the market are Praxair Surface Technologies, Inc.; Metallization Ltd.; Flame Spray Coating Co.; Precision Coatings, Inc.; Montreal Carbide Co. Ltd.; Kennametal Inc.; and Oerlikon Metco

U.S. Thermal Spray Coating For Oil & Gas Market Segmentation

Grand View Research has segmented the U.S. thermal spray coating for oil and gas market on the basis of product and technology:

U.S. Thermal Spray Coating For Oil & Gas Product Outlook (Revenue, USD Million, 2016 - 2027)

Metals

Ceramics

Intermetallics

Polymers

Carbides

Abradables

Others

U.S. Thermal Spray Coating For Oil & Gas Technology Outlook (Revenue, USD Million, 2016 - 2027)

Cold

Flame

Plasma

HVOF

Electric Arc

Others

Order a free sample PDF of the U.S. Thermal Spray Coating For Oil & Gas Market Intelligence Study, published by Grand View Research.

0 notes

Text

Mythri Metallizing India

Mythri Metallizing India

Mythri Metallizing India, headquartered in Bangalore, is a thermal spray coating service provider that specializes in anti-corrosion solutions for steel structures. They have over 20 years of experience in the industry. https://mythrimetallizing.com/

Services: Mythri Metallizing India offers a range of surface finishing and anti-corrosion services, including:

Sandblasting and grit blasting

Spray galvanizing

Stress relieving

Spray painting

Thermal spray aluminum coating

Surface Preparation: Mythri Metallizing uses abrasive blasting techniques, employing materials like grit, sand, quartz, and aluminum oxide, to clean and prepare metal surfaces for coating. This process removes mill scale, oil, grease, dirt, rust, oxides, and paint to ensure proper adhesion of protective coatings.

Thermal Spraying: Mythri Metallizing applies finely divided metallic or nonmetallic materials in a molten or semi-molten state to form a coating, using methods such as electric arc spray, wire flame spray, powder flame spray, HVOF, and plasma spray. https://mythrimetallizing.com/

Zinc coatings are used to protect steel, even at cut edges or breaks, through sacrificial action.

Stress Relieving: Mythri Metallizing uses heat treatment to improve machining, formability, and ductility, enhancing product performance by increasing strength and other desirable characteristics. https://mythrimetallizing.com/

The Managing Director of Mythri Metallizing India is Madhusudhan D R, who has been in this position since January 2009. He has over 20 years of experience in thermal spray allumnization. https://mythrimetallizing.com/

0 notes

Text

Mythri Metallizing India: Leading the Way in Advanced Surface Coating Solutions

Mythri Metallizing India is a premier provider of metallizing and advanced surface coating solutions, catering to various industries such as infrastructure, automotive, power, marine, and defense. With cutting-edge technology and a commitment to quality, Mythri Metallizing India has established itself as a trusted name in the field of protective coatings and thermal spray applications.

Our Services

1. Thermal Spray Coating

Thermal spray coating is one of our core services, offering superior protection against corrosion, wear, and extreme environmental conditions. Our advanced thermal spray techniques include:

Arc Spray Coating – Ideal for large surface areas, providing excellent adhesion and durability.

Flame Spray Coating – Used for restoring and enhancing the performance of machine components.

Plasma Spray Coating – Suitable for high-temperature applications, ensuring superior resistance and longevity.

HVOF (High-Velocity Oxygen Fuel) Coating – Ensures high-density coatings with exceptional hardness and wear resistance.

2. Galvanizing and Corrosion Protection

We specialize in hot-dip and thermal spray galvanizing techniques, which provide long-lasting protection against rust and oxidation. Our coatings extend the life of infrastructure, bridges, pipelines, and industrial equipment by shielding them from environmental damage.

3. Industrial and Marine Coatings

Our industrial and marine coatings are designed to withstand harsh environments, offering superior protection for:

Ships and offshore structures

Heavy machinery and industrial plants

Power generation facilities and pipelines

Structural steel components

4. Concrete and Structural Protection

Beyond metal, we offer protective coatings for concrete structures, preventing deterioration due to moisture, chemicals, and environmental stress. These coatings enhance the durability and lifespan of bridges, dams, buildings, and industrial facilities.

5. Customized Coating Solutions

We understand that every industry has unique requirements. That’s why we provide tailored coating solutions to meet the specific needs of our clients. Whether it’s for aerospace, defense, automotive, or power generation, we design coatings that optimize performance and longevity.

Why Choose Mythri Metallizing India?

State-of-the-Art Technology – We employ the latest equipment and methodologies to deliver high-quality coating solutions.

Expert Team – Our skilled engineers and technicians bring years of experience and expertise in metallizing and protective coatings.

Industry Compliance – We adhere to international quality standards, ensuring our coatings meet the highest performance and safety requirements.

Cost-Effective Solutions – Our coatings extend the lifespan of assets, reducing maintenance costs and downtime for our clients.

Sustainability Commitment – We use eco-friendly processes and materials to minimize our environmental impact while ensuring durability and efficiency.

Our Commitment to Quality and Innovation

At Mythri Metallizing India, we are committed to continuous improvement and innovation in the field of protective coatings. We invest in research and development to provide cutting-edge solutions that meet the evolving needs of industries worldwide.

Get in Touch

Whether you need corrosion protection, industrial coatings, or customized metallizing solutions, Mythri Metallizing India is here to help. Contact us today to learn more about how our services can enhance the durability and efficiency of your infrastructure and machinery.

#MythriMetallizingIndia#ThermalSprayCoating#IndustrialCoatings#ProtectiveCoatings#CorrosionProtection#Sandblasting#HVOFCoating#GalvanizingSolutions#MetalCoatings#SurfaceProtection#InfrastructureMaintenance#MarineCoatings#AbrasiveBlasting#IndustrialSprayPainting#WearResistance

0 notes

Text

Thermal Spray Coatings Market

Thermal Spray Coatings Market Size, Share, Trends: Oerlikon Metco Leads

Rising adoption of thermal spray coatings in additive manufacturing and 3D printing applications

Market Overview:

The global Thermal Spray Coatings market is projected to grow at a CAGR of 6.8% from 2024 to 2031. The market value is expected to increase significantly during this period. North America currently dominates the market, accounting for the largest share of global revenue. Key metrics include increasing adoption in aerospace and automotive industries, growing demand for advanced surface engineering solutions, and rising investments in research and development.

The Thermal Spray Coatings market is expanding rapidly, owing to rising demand for wear- and corrosion-resistant coatings across a wide range of end-use industries. Technological improvements in coating materials and application techniques are driving market growth, with an emphasis on enhancing coating performance and efficiency.

DOWNLOAD FREE SAMPLE

Market Trends:

The use of thermal spray coatings in additive manufacturing and 3D printing methods is gaining popularity. This trend is being pushed by the potential of thermal spray coatings to improve the surface characteristics and functioning of 3D printed components. Aerospace, automotive, and healthcare industries use this combination to build complicated parts with exceptional wear resistance, thermal insulation, and corrosion protection. The combination of thermal spray coatings and additive manufacturing enables the fabrication of lightweight, high-performance components with customisable surface qualities, opening up new avenues for product design and customisation. This trend is predicted to continue as manufacturers seek novel ways to increase product performance while lowering manufacturing costs.

Market Segmentation:

The Combustion process segment, which comprises flame spray and High Velocity Oxy-Fuel (HVOF) approaches, dominates the Thermal Spray Coatings market. This supremacy is due to the adaptability, cost-effectiveness, and broad variety of applications provided by combustion-based thermal spray techniques. Flame spray, one of the oldest and most known processes, remains popular due to its simplicity and capacity to deposit a wide range of materials, including metals, ceramics, and polymers.

High Velocity Oxy-Fuel (HVOF) spraying, a more advanced combustion method, has gained popularity in recent years. HVOF coatings are well-known for their high density, bond strength, and wear resistance, making them suitable for use in the aerospace, automotive, and oil and gas industries. A recent study by the National Aeronautics and Space Administration (NASA) discovered that HVOF-sprayed tungsten carbide-cobalt coatings on turbine engine components can increase their service life by up to 300% when compared to untreated parts.

Market Key Players:

Oerlikon Metco

Praxair Surface Technologies

H.C. Starck

Hoganas AB

Kennametal Stellite

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Shielding the Future: Insights into the Growing Thermal Spray Coatings Market

Thermal spray coatings have steadily gained traction as an indispensable technology across diverse industries. By offering unmatched surface protection and significantly enhancing the durability of components, these coatings have become a game-changer. With the increasing focus on efficiency, sustainability, and cost optimization, the global thermal spray coatings market is on an upward trajectory, bolstered by emerging trends, innovative applications, and advancements in technology.

Market Size and Growth Potential

The global thermal spray coatings market was valued at USD 10.4 billion in 2023 and is projected to reach USD 14.3 billion by 2028, growing at 6.5% cagr from 2023 to 2028. This surge is driven by rising demand in key sectors like aerospace, automotive, healthcare, and energy.

In the aerospace sector, thermal spray coatings play a crucial role in improving engine efficiency and protecting parts exposed to extreme conditions. Meanwhile, the automotive industry has embraced these coatings for their ability to reduce wear and friction in engine components, resulting in improved fuel economy and reduced emissions.

Emerging Trends Shaping the Market

Sustainability and Eco-Friendly Solutions: Environmental concerns are pushing manufacturers to innovate. Many are exploring eco-friendly coatings by reducing hazardous materials and adopting greener production methods.

Advances in Thermal Spray Technology: Cutting-edge techniques like plasma spraying and high-velocity oxygen fuel (HVOF) are revolutionizing the market. These methods offer superior precision, stronger adhesion, and enhanced performance, enabling a wider range of industrial applications.

Expansion in Renewable Energy Applications: As the world shifts towards renewable energy sources, thermal spray coatings are finding a home in wind turbines and solar panel components. These coatings ensure resilience and longevity, vital for maximizing energy efficiency.

Growing Focus on Lightweight Materials: Lightweight materials, such as aluminum and titanium, are increasingly used in automotive and aerospace sectors. Thermal spray coatings are essential in safeguarding these materials against corrosion and wear while retaining their lightweight properties.

Key Players Driving Innovation

Several industry leaders are propelling the thermal spray coatings market forward by introducing new products and investing heavily in research. Notable players include:

Praxair Surface Technologies: Known for their sophisticated surface solutions, Praxair provides thermal spray coatings tailored for aerospace and energy applications.

Bodycote plc: A global powerhouse in heat treatment and surface engineering, Bodycote offers cutting-edge coating services designed to meet the demands of modern industries.

Oerlikon Metco: A leader in surface solutions, Oerlikon Metco caters to diverse sectors like healthcare, automotive, and aerospace with innovative thermal spray products.

Saint-Gobain: Renowned for their comprehensive range of thermal spray powders and coating solutions.

These companies are not only innovating but also collaborating closely with end-users to develop customized solutions that address unique industry challenges.

Future Outlook

The future of the thermal spray coatings market looks promising, with ongoing advancements in materials, processes, and applications. Industries are expected to increasingly rely on these coatings to boost efficiency and protect investments. Moreover, automation and robotics are anticipated to refine the coating process, making it more cost-effective and precise.

Experts predict that collaboration between coating manufacturers and their clients will intensify in the coming years, fostering the development of specialized solutions tailored to evolving industry needs. This collaborative approach will be instrumental in unlocking new opportunities and maintaining the momentum of market growth.

To get deeper Insights Download PDF Brochure :

Thermal spray coatings have cemented their place as a cornerstone technology across various sectors. From extending the lifespan of critical components to enabling new possibilities in lightweight and renewable energy applications, these coatings are integral to modern industry. As sustainability and innovation drive the market forward, businesses that embrace these trends will find themselves at the forefront of this dynamic field.

#ThermalSprayCoatings#SurfaceEngineering#IndustrialCoatings#ThermalSprayTechnology#MarketTrends#AerospaceCoatings#AutomotiveCoatings#Sustainability#Innovation#ThermalSprayManufacturers

0 notes

Text

Revolutionizing Industrial Solutions: The Power of Hydraulic Cylinders, Cold Spray Technology, and Beyond

At WWG ENGINEERING PTE. LTD, we excel in providing innovative mechanical engineering services customized to fulfil the varied requirements of our clients. Our commitment to innovation and excellence has positioned us as a leader in machine refurbishment services, thermal spray solutions, and more. With a deep understanding of industry challenges, we offer a comprehensive suite of services that ensure efficiency, reliability, and longevity in industrial operations.

The Backbone of Machinery: Hydraulic Cylinders

Hydraulic cylinders play a crucial role in various industrial applications, delivering the force needed for lifting, pushing, and pulling substantial weights. They convert fluid power into mechanical force, enabling precise control over movement and positioning. Our hydraulic cylinders are engineered to withstand the toughest environments, offering superior performance and durability. Whether it's for construction machinery, manufacturing equipment, or heavy-duty vehicles, our hydraulic cylinders ensure optimal functionality and minimal downtime.

Advancing Repairs with Cold Spray Technology

Cold spray technology represents a revolutionary approach to repairing and enhancing metal surfaces. Unlike traditional thermal spray methods, cold spray involves the deposition of metal particles at high velocities but at relatively low temperatures. This process results in coatings that are dense, highly adherent, and free from thermal stresses. We utilize cold spray technology to restore worn or damaged components, extending their service life and reducing the need for costly replacements. This innovative technique is particularly effective for repairing critical parts in aerospace, automotive, and defence industries.

Precision and Reliability with White Metal Bearings

White metal bearings are crucial for the smooth operation of rotating machinery, providing low friction and excellent load-carrying capacity. These bearings are commonly used in turbines, compressors, and electric motors, where reliability and longevity are paramount. Our team at WWG ENGINEERING PTE. LTD specializes in the design, manufacture, and refurbishment of white metal bearings, ensuring they meet the highest standards of precision and performance. By employing advanced materials and manufacturing techniques, we deliver bearings that significantly enhance the operational efficiency of our clients' equipment.

Comprehensive Mechanical Engineering Services

Mechanical engineering is at the heart of our operations, driving innovation and excellence in every project we undertake. Our mechanical engineering services encompass a wide range of solutions, including design, analysis, prototyping, and production support. our engineers leverage state-of-the-art tools and methodologies to tackle complex challenges, delivering tailored solutions that meet the specific needs of each client. From optimizing manufacturing processes to developing new products, our mechanical engineering expertise ensures superior outcomes.

Restoring Excellence with Machine Refurbishment Services

Machine refurbishment is a cost-effective alternative to purchasing new equipment, allowing businesses to maximize the value of their existing assets. Our machine refurbishment services at WWG ENGINEERING PTE. LTD involves comprehensive assessments, precision repairs, and performance enhancements. We focus on restoring machines to their original specifications or better, ensuring they operate efficiently and reliably. By extending the lifespan of industrial machinery, we help our clients achieve significant cost savings and minimize environmental impact.

Cutting-Edge Thermal Spray Solutions

Thermal spray solutions are vital for protecting and enhancing the performance of industrial components. we offer a range of thermal spray coating services, including plasma spray, HVOF (High-Velocity Oxy-Fuel), and arc spray. These processes involve the application of molten or semi-molten materials onto surfaces, forming protective coatings that resist wear, corrosion, and high temperatures. Our thermal spray solutions are tailored to meet the specific requirements of each application, ensuring optimal performance and durability.

Precision Application with Thermal Spray Coating Machines

The quality of thermal spray coatings is heavily dependent on the equipment used. At WWG ENGINEERING PTE. LTD, we utilize state-of-the-art thermal spray coating machines that ensure precise and consistent application of coatings. Our machines are designed to handle a wide range of materials and substrates, delivering coatings that meet stringent industry standards. With our advanced thermal spray coating machines, we provide reliable and efficient solutions for enhancing the performance and lifespan of critical components.

Conclusion: Your Partner in Industrial Excellence

At WWG ENGINEERING PTE. LTD, we are dedicated to providing innovative solutions that drive industrial excellence. From hydraulic cylinders and cold spray technology to white metal bearings and comprehensive mechanical engineering services, our offerings are designed to meet the evolving needs of our clients. Our steadfast commitment to delivering top-notch quality, trustworthiness, and exceptional customer service makes us a standout partner in the industry. By leveraging our expertise and cutting-edge technologies, we help businesses achieve their operational goals and maintain a competitive edge.

Discover how WWG ENGINEERING PTE. LTD can elevate your industrial operations. Contact us today to learn more about our services and how we can support your success.

#Hydraulic Cylinder Singapore#Hydraulic Equipment Services#Thermal Spray Solutions#Mechanical Engineering Services#Industrial Bearing Service Singapore

0 notes

Text

Breaking the Mold: Why Hard Chrome Replacement Is the Future of Industrial Coatings

In the realm of industrial coatings, the quest for alternatives to hard chrome plating has been an ongoing pursuit. Traditionally, hard chrome has been a popular choice due to its excellent corrosion resistance, hardness, and wear resistance properties. However, its use comes with significant drawbacks, including environmental concerns related to toxic hexavalent chromium emissions during the plating process and the health risks associated with exposure. As industries increasingly prioritize sustainability and worker safety, the search for viable hard chrome alternatives has intensified. Enter the era of hard chrome replacement – a promising shift that is poised to revolutionize the industrial coating landscape.

The need for hard chrome alternatives has spurred innovation across various sectors, driving the development of advanced coating technologies that offer comparable or superior performance while mitigating environmental and health risks. One such alternative gaining traction is the use of thermal spray coatings, such as high-velocity oxygen fuel coating (HVOF) and plasma spraying. These processes deposit a wide range of materials, including ceramics, metals, and composites, onto substrates with exceptional bond strength and wear resistance. Not only do thermal spray coatings provide excellent corrosion protection and surface hardness, but they also eliminate the hazardous byproducts associated with traditional chrome plating, making them an environmentally friendly choice.

Another promising avenue for hard chrome replacement lies in the realm of electroless nickel coatings. Unlike traditional electroplating methods that rely on an electric current to deposit metal onto a substrate, electroless nickel plating occurs through an autocatalytic chemical reaction, resulting in uniform coatings with precise thickness control. Electroless nickel coatings offer excellent corrosion resistance, hardness, and lubricity, making them ideal for a wide range of industrial applications, from aerospace components to automotive parts. Moreover, the elimination of the electric current requirement reduces energy consumption and eliminates the need for toxic chromium baths, aligning with sustainable manufacturing practices.

Furthermore, advancements in composite coatings, such as diamond-like carbon (DLC) and polymer-based materials, offer a compelling alternative to hard chrome in specific applications. DLC coatings exhibit exceptional hardness, low friction, and superior wear resistance, making them suitable for cutting tools, molds, and automotive components. Meanwhile, polymer-based coatings provide flexibility, chemical resistance, and corrosion protection, catering to industries such as oil and gas, marine, and automotive.

The transition away from hard chrome plating towards sustainable alternatives is not only driven by environmental and health considerations but also by regulatory pressures and market demand for greener solutions. With stricter regulations governing the use of hazardous substances and increasing awareness of the ecological footprint of industrial processes, manufacturers are increasingly seeking alternatives that offer comparable performance without compromising on safety or environmental stewardship.

In conclusion, the future of industrial coatings lies in the adoption of hard chrome alternatives that prioritize sustainability, performance, and safety. Whether through thermal spray coatings, electroless nickel plating, or advanced composites, the era of hard chrome replacement heralds a new chapter in industrial coating technology. By embracing innovative solutions that break away from traditional paradigms, manufacturers can achieve superior performance while safeguarding the environment and the well-being of workers. As we navigate this transition, companies like Ewsllp play a pivotal role in driving innovation and facilitating the adoption of sustainable coating solutions, shaping a brighter and greener future for industries worldwide.

0 notes

Text

HVOF Spray Process Offers Complete Metallizing

HVOF exhibits the best possible wear and tear, corrosion, and erosion resistance. The process enhances the lifespans of substrates and machines by protecting the metal surfaces from adverse weather conditions and chemical exposures. The maintenance and replacement costs are reduced in the long run.

For more information on HVOF spray systems visit http://imcmetallizing.com/

0 notes

Text

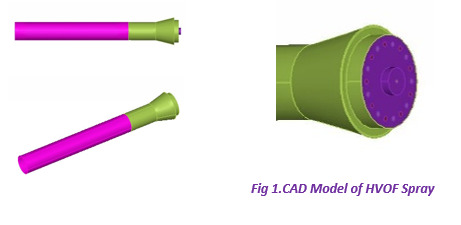

High Velocity Oxygen Fuel Nozzle Spray CFD ANALYSIS

INTRODUCTION

High Velocity Oxy-Fuel(HVOF) Spray is used to coat corrodible components with resistive materials. It utilizes highly compressed fuel that combust with oxygen to accelerate the momentum and temperature of the particle and also to make the flow supersonic.

Supersonic nature of flow in an atmospheric condition producing sequential pressure expansion and contraction letting out a phenomenon called Shock Diamonds. These Shock Diamonds a.k.a pressure pulsations produced due to hyper pressure gradient with respect to atmospheric pressure.

With the aid of the CFD technology, the complex Pressure Gradient of supersonic flow nature can be vividly captured and the design progress can be accelerated. Thus, CFD is an important tool for Flow physics as it will reduce the time consuming and expensive experimental procedures.

SCOPE OF THIS RESEARCH WORK

To model the combustion of fuel and oxygen in a compressed chamber.

Get a higher temperature and velocity pulsation proportional to pressure pulsation.

Injection of spray material using Discrete Phase Modelling (DPM).

MODEL ACQUISITION PROCESS

The HVOF Setup is experimentally analysed in Annamalai University, Chidambaram. From the resource the component is manually measured and the model is generated in CAD software package Pro-E Wildfire 5.0.

CFD ANALYSIS

With a goal of capturing shock diamonds of the supersonic flow of HVOF Spray, CFD is utilized in a following systematic way.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

VALIDATION STUDY

CFD procedure has lot of variables such as grid count, turbulence model, and discretization scheme, so it is important for a CFD engineer to play between those variables without affecting the solution accuracy. A commercial Computational Fluid Dynamics (CFD) code, ANSYS CFX V14.5 with a k-ε Standard turbulence model with Eddy Dissipation Model for combustion was used and the impact of supersonic flow in an atmospheric pressure and the Pressure pulsation was obtained.

The numerical results are compared with the experimental data to arrive at the best computational procedure (BCP) and Discrete Phase Modelling (DPM) is proceeded to introduce the surface coat material into the domain.

INFLUENCE OF CFD TECHNIQUE IN THIS PROBLEM

The Shock Diamond occurrence mainly depends on the hyper pressure difference between the atmosphere and combustion chamber. It depends on the flow rate of fuel, oxygen and volume of the combustion chamber.

Working with a leading Stress Analysis Services provider or well-known Product Design Companies will make new routes possible.

CONCLUSION

A Special phenomenon of Fluid flow is acquired in computational methodology

Surface Coat material injection and Combustion of fuel-oxygen is modelled

#CFDAnalysis#CFDConsultingServices#DiscretePhaseModelling#flowrate#graphlertech#HighVelocityOxy-Fuel#HVOF

0 notes

Text

HVOF Spray Guns and Thermal Spray Equipment: The Ultimate Guide by Shot Blaster

Welcome to our comprehensive guide on High-Velocity Oxygen Fuel (HVOF) spray guns and thermal spray equipment. At Shot Blaster, we are committed to providing you with the most authoritative and up-to-date information on these cutting-edge technologies that are revolutionizing industries across the globe.

In this guide, we will delve into the intricate details of HVOF guns and thermal spray equipment, shedding light on their benefits, applications, and the key factors that set them apart. Let's embark on this knowledge-packed journey together.

Understanding HVOF Spray Guns: Powering Precision Coatings

HVOF spray guns are a pinnacle of technological advancement when it comes to precision coatings. These remarkable tools utilize the power of high-velocity oxygen-fueled combustion to propel coatings onto surfaces, ensuring exceptional adhesion, hardness, and longevity.

Our state-of-the-art HVOF spray guns have been meticulously engineered to deliver coatings that exceed expectations across various industries.

The Advantages of HVOF Technology

HVOF technology offers an array of unparalleled advantages that make it stand out in the realm of surface coatings. These include:

Exceptional Adhesion: The high-speed impact of particles during the spraying process ensures a bond that is second to none. This results in coatings that are resilient even in the most challenging environments.

Enhanced Hardness: HVOF coatings exhibit remarkable hardness, making them ideal for applications where wear and corrosion resistance are paramount.

Minimal Heat Impact: Thanks to the supersonic speed of particle deposition, HVOF coatings experience minimal heat transfer. This characteristic is crucial for preventing distortion or damage to the substrate.

Versatile Applications: From aerospace components to industrial machinery, HVOF coatings find applications in diverse industries, contributing to improved performance and longevity.

The Essence of Thermal Spray Equipment: Engineering Excellence

Thermal spray equipment is the backbone of HVOF technology, enabling the precise and controlled application of coatings. Our cutting-edge thermal spray equipment is designed with precision and efficiency in mind, catering to the unique needs of each industry it serves.

Key Features of Our Thermal Spray Equipment

Advanced Control Systems: Our equipment boasts intuitive control systems that allow for precise adjustments of parameters, ensuring consistent and reliable coatings.

Diverse Coating Materials: We understand the significance of material choice in coating applications. Shot Blaster equipment supports a wide range of coating materials, providing flexibility and tailored solutions.

Optimized Particle Acceleration: Achieving optimal particle acceleration is pivotal in HVOF technology. Our thermal spray equipment has been fine-tuned to ensure particles achieve the desired velocity for optimal coating quality.

Applications that Transcend Boundaries

HVOF guns and thermal spray equipment are redefining possibilities across industries. Here are some prominent applications where these technologies shine:

Aerospace Industry: Critical aerospace components demand coatings that can withstand extreme conditions. HVOF technology ensures superior protection against high temperatures, abrasion, and corrosion.

Oil and Gas Sector: In the oil and gas industry, equipment reliability is paramount. HVOF coatings extend the lifespan of components exposed to harsh environments, contributing to reduced maintenance costs.

Manufacturing and Engineering: The manufacturing sector benefits from the enhanced wear resistance and hardness of HVOF coatings, which lead to increased durability and improved performance.

Elevating Your Operations with HVOF and Thermal Spray

At SHOT BLASTER, we recognize that adopting HVOF technology and utilizing advanced thermal spray equipment can significantly impact your operations. Our commitment to innovation, quality, and excellence ensures that our offerings are tailored to meet the unique needs of your industry.

If you're ready to embrace the future of coatings and enhance the performance of your components, contact us today to explore how our HVOF spray guns and thermal spray equipment can elevate your operations to new heights.

For more details visit URL - https://www.thermalspraygun.com/hvof-gun

0 notes

Text

Maximizing Tool Life with Tungsten Carbide Coatings

Tungsten carbide coating available in powdered form is highly effective in increasing the lifespan of your tools. You can apply it with a thermal spraying process.

Industrial tool manufacturers apply an ultra-thin coating containing molecular compounds. The special coatings on the surface are intended to prevent deterioration of the cutting tools. It can also result in the tool failure within a short time. There are high-quality coatings for cutting tools. But, they also restrict friction and heat while improving the tool’s performance. You can choose tungsten carbide coating if you want to make your tools long-lasting.

Know about WC coating-

WC or tungsten carbide coating is a hard ceramic material, which is available as fine, grey-coloured powder particles. The material is highly resistant to scratch, wear, and abrasion. Because of its extreme hardness, tungsten carbide prevents damage to the surface. It also ensures protection against surface-based attacks, such as fatigue, erosion, and corrosion. As it is ceramic, WC is stable and has a high melting point. Tungsten carbide often mixes with a small amount of metallic powder (including Ni, Cr, and Co).

Choose the tungsten carbide coatings-

Tungsten carbide is a premium coating, and the cost of coating tungsten carbide varies with the material you want to coat. It is the most suitable coating if you have found irreversible damage to the parts of the tools. Instead of buying new cutting tools, you can coat their worn-out parts to save money. In this case, coating the tool with tungsten carbide is a cheap solution.

Tungsten carbide coating has special properties like good strength, high hardness, corrosion resistance, and significant bonding strength. Densely coated carbide also comes with low porosity. Besides, they have some variable properties based on the powder’s grain size and volume fraction.

How does the WC coating benefit your tools?

One of the significant benefits of using WC coatings is that they increase the product’s service life. You can use reliable and efficient coating technology for your tools. The coating will prevent different types of surface damage. Besides, tungsten carbide has a blend of metallurgical and mechanical properties. You can choose WC coating for the exposed part of your machinery.

You can apply the tungsten carbide coating through the innovative HVOF thermal spraying process. In this process, oxygen and fuel gas undergo combustion in a high-pressure chamber where the temperature reaches 5,600F. As a result, high-pressure hot gas comes out through a small nozzle. The gas passes down a long barrel at a very high speed. The coating material, tungsten carbide powder, is essential for the process. You need to inject it into the nozzle, and the particles blend with gases to reach a high velocity.

To sum up, tungsten carbide is a protective coating material for making your cutting tools long-lasting. You can also apply it to other industrial tools and machinery.

Endurance Wear Solutions is a reputed company that provides customized coating services. Its team has 30+ years of expertise in the field.

1 note

·

View note

Text

Mythri Metallizing India

Mythri Metallizing India

Mythri Metallizing India, headquartered in Bangalore, is a thermal spray coating service provider that specializes in anti-corrosion solutions for steel structures. They have over 20 years of experience in the industry. https://mythrimetallizing.com/

Services: Mythri Metallizing India offers a range of surface finishing and anti-corrosion services, including:

Sandblasting and grit blasting

Spray galvanizing

Stress relieving

Spray painting

Thermal spray aluminum coating

Surface Preparation: Mythri Metallizing uses abrasive blasting techniques, employing materials like grit, sand, quartz, and aluminum oxide, to clean and prepare metal surfaces for coating. This process removes mill scale, oil, grease, dirt, rust, oxides, and paint to ensure proper adhesion of protective coatings.

Thermal Spraying: Mythri Metallizing applies finely divided metallic or nonmetallic materials in a molten or semi-molten state to form a coating, using methods such as electric arc spray, wire flame spray, powder flame spray, HVOF, and plasma spray. https://mythrimetallizing.com/

Zinc coatings are used to protect steel, even at cut edges or breaks, through sacrificial action.

Stress Relieving: Mythri Metallizing uses heat treatment to improve machining, formability, and ductility, enhancing product performance by increasing strength and other desirable characteristics. https://mythrimetallizing.com/

The Managing Director of Mythri Metallizing India is Madhusudhan D R, who has been in this position since January 2009. He has over 20 years of experience in thermal spray allumnization. https://mythrimetallizing.com/

0 notes

Text

Thermal Spray zinc coating on steel and iron surface

Thermal spray zinc coating, also known as thermal spraying or metal spraying, is a surface protection technique used to apply a layer of zinc onto a substrate. It involves the application of molten or semi-molten zinc particles onto a prepared surface using a thermal spray gun. In the Thermal spray zinc coating process, the zinc particles are propelled at high velocity toward the substrate, where they bond and solidify, forming a protective coating.

An overview of the thermal spray zinc coating process:

Surface Preparation:

The substrate to be coated is thoroughly cleaned to remove any contaminants such as dirt, rust, oil, or old paint. The surface is usually abrasive blasted to create a rough profile, which enhances the adhesion of the zinc coating.

Zinc Material Selection:

Zinc wire or powder is commonly used as the feedstock material for thermal spraying. The zinc can be either pure or alloyed with other elements to enhance specific properties such as corrosion resistance or hardness.

Thermal Spray Equipment:

A thermal spray gun or torch is used to melt the zinc feedstock and propel it toward the prepared surface. There are several thermal spray processes available, including flame spraying, arc spraying, and high-velocity oxy-fuel (HVOF) spraying.

Coating Application:

The thermal spray gun melts the zinc material at high temperatures. Compressed air or other gases are used to accelerate the molten zinc particles toward the substrate. As the particles impact the surface, they flatten and solidify, forming a dense and adherent zinc coating.

Coating Build-up and Finishing:

The coating thickness can be controlled by adjusting the spraying parameters such as spray distance, spray angle, and travel speed. Multiple passes may be required to achieve the desired coating thickness. After the coating is applied, it is usually post-treated by techniques such as grinding, machining or polishing to achieve the required surface finish.

Conclusion

Thermal spray zinc coatings offer excellent corrosion protection to the underlying substrate. Zinc acts as a sacrificial anode, which corrodes preferentially to the base material, thus providing cathodic protection. The coating can be used in various industries, including automotive, aerospace, marine, oil and gas, and infrastructure, to protect steel structures and components from corrosion.

It's important to note that specific application requirements, environmental conditions, and industry standards should be considered when selecting and applying thermal spray zinc coatings. Consulting with coating experts or professionals in the field is recommended to ensure proper coating selection and application for your specific needs.

0 notes

Link

A mixture of gaseous or liquid fuel and oxygen is fed into a combustion chamber, where they are ignited and combusted continuously. The fuels can be gases (hydrogen, methane, propane, propylene, acetylene, natural gas, etc.) or liquids (kerosene, etc.). The jet velocity at the exit of the barrel (>1000 m/s) exceeds the speed of sound. A powder feed stock is injected into the gas stream, which accelerates the powder up to 800 m/s.

#pune carbide coating#hvof coating process in india#thermal coatings india#Metal Spray Coating in india#ceramic coating spray india#hvof spray process in india#HVOF-spraying process india#aluminium carbide coating mumbai#Surface coating mumbai#Electric Arc Ceramic Coating

1 note

·

View note

Text

Thermal Spray Coating Equipment and Services Market: A Comprehensive Outlook for North America

The Thermal Spray Coating Equipment and Services Market is experiencing significant growth, particularly in North America, driven by a surge in demand across various industries. The rising need for enhanced durability, wear resistance, and corrosion protection in automotive, aerospace, and oil & gas sectors has fueled the adoption of thermal spray technologies. This market presents immense opportunities, backed by advancements in coating techniques, material innovations, and increasing investments in industrial infrastructure.

Overview of the Thermal Spray Coating Market

Thermal spray coatings involve the application of materials, such as metals, ceramics, or polymers, onto a surface using heat and pressure to create a protective layer. This technology is widely used to improve the performance and longevity of components exposed to harsh environments, extreme temperatures, or mechanical stress. Industries such as aerospace, automotive, power generation, healthcare, and oil & gas have embraced thermal spray coatings due to their ability to reduce maintenance costs, enhance operational efficiency, and improve the lifespan of machinery.

The North American market for thermal spray coating equipment and services is poised for growth, with significant demand for both advanced coatings and the equipment used to apply them.

Market Trends Shaping the Industry

Several key trends are shaping the North American thermal spray coating market:

1. Increasing Demand from the Aerospace Sector

The aerospace industry is one of the major drivers of the thermal spray coating market in North America. As aircraft manufacturers and MRO (maintenance, repair, and overhaul) providers seek to improve the efficiency and durability of critical components, the use of thermal spray coatings for turbine blades, landing gear, and engine components has become increasingly important. Thermal spray coatings enhance the corrosion resistance and thermal stability of parts exposed to extreme conditions, thereby improving performance and reducing maintenance downtime.

2. Rising Popularity of Eco-friendly Coatings

With growing concerns over environmental regulations and sustainability, there is an increasing demand for eco-friendly thermal spray coatings. Technologies such as High-Velocity Oxy-Fuel (HVOF) and cold spray techniques are gaining traction due to their ability to produce coatings with minimal environmental impact. These methods use less harmful materials and generate fewer emissions, aligning with the industry's push towards greener solutions.

3. Automotive Industry’s Shift Towards Lightweight Materials

The automotive industry is undergoing a transformation with the growing trend toward lightweight materials to improve fuel efficiency. Thermal spray coatings are applied to critical automotive parts such as engine components, transmission systems, and braking systems to reduce wear and tear, ensuring longer life and better performance. The shift towards electric vehicles (EVs) is also opening up new opportunities for thermal spray coatings, particularly in battery manufacturing and EV powertrain components.

4. Technological Advancements in Equipment

The development of advanced thermal spray equipment, including robotic systems and automated processes, is another factor driving market growth. These technologies improve the precision and efficiency of coating applications, enabling manufacturers to meet higher standards of performance and quality. Innovations in coating materials, such as nanostructured coatings and multi-functional coatings, are further enhancing the capabilities of thermal spray processes.

Market Analysis and Forecast

The North American thermal spray coating equipment and services market is projected to grow steadily, with analysts predicting 17.8 Billion at aCAGR of over 4.1 % from 2024 to 2030. This growth is primarily driven by the increasing need for protective coatings in key industries, technological advancements, and the expansion of industrial manufacturing facilities across the region.

United States: The U.S. accounts for the largest share of the North American market due to its strong presence in aerospace, automotive, and energy sectors. The country’s robust industrial base and the increasing focus on innovation have fueled the demand for high-performance coatings.

Canada: In Canada, the oil & gas industry is a major driver of thermal spray coatings, particularly for the protection of pipelines and equipment used in harsh environments. The Canadian market is also expected to benefit from increasing investments in infrastructure development.

Mexico: Mexico's growing automotive and aerospace manufacturing sectors are contributing to the region's overall market expansion. The country is becoming an attractive destination for thermal spray coating services, supported by its competitive manufacturing landscape.

Expert Insights and Market Share

Industry experts highlight the growing significance of thermal spray coatings in the context of sustainability and cost-efficiency. By reducing the need for frequent repairs and replacements, thermal spray coatings offer long-term savings for manufacturers, contributing to their widespread adoption.

Market Players: Key players in the North American thermal spray coating equipment and services market include Praxair Surface Technologies, Oerlikon Metco, and Bodycote. These companies are focusing on expanding their product portfolios and enhancing service capabilities to meet the increasing demand from various industries.

Market Share: The aerospace sector holds the largest share of the thermal spray coating market, followed by automotive and power generation. However, the oil & gas industry is expected to witness significant growth, particularly in the U.S. and Canada, driven by the need for enhanced corrosion protection.

Challenges and Opportunities

Despite the promising outlook, the thermal spray coating market faces challenges such as the high cost of equipment and the complexity of certain coating processes. However, advancements in automation and robotics are expected to reduce costs and improve accessibility for small and medium-sized enterprises.

The growing emphasis on R&D investments is also creating opportunities for the development of innovative coatings and equipment, further driving market growth. In addition, the trend toward digitization in manufacturing is expected to improve process control and quality assurance, contributing to the continued evolution of the thermal spray coating industry.

Download PDF Brochure :

A Promising Future for North America

The Thermal Spray Coating Equipment and Services Market in North America is set for sustained growth over the coming years, driven by increasing demand from key industries and advancements in coating technologies. With a focus on sustainability, innovation, and performance, thermal spray coatings are becoming a vital part of modern manufacturing, offering protection and enhancing the durability of components across multiple sectors.

As the market continues to evolve, companies that invest in advanced equipment, eco-friendly solutions, and customized services will be well-positioned to capitalize on the growing demand for thermal spray coatings in North America.

#ThermalSprayCoatings#IndustrialCoatings#AerospaceTechnology#AdvancedMaterials#SurfaceProtection#CoatingInnovation#NorthAmericaMarket

1 note

·

View note