Manufacturer of Thermal Spray and Metallizing Machine https://imcmetallizing.com/

Don't wanna be here? Send us removal request.

Text

Shot Blasting Machine Manufacturer in Jodhpur A Shot blasting machine is a mechanical tool that propels abrasive materials at a high velocity on a substrate. The technique is called the surface preparation technique used in various sectors like automotive, aerospace, shipbuilding, and construction. Procure the machine from a trusted shot blasting machine manufacturer in Jodhpur. For more information on shot blasting machines visit: http://imcmetallizing.com/

0 notes

Text

HVOF Spray Process Offers Complete Metallizing

HVOF exhibits the best possible wear and tear, corrosion, and erosion resistance. The process enhances the lifespans of substrates and machines by protecting the metal surfaces from adverse weather conditions and chemical exposures. The maintenance and replacement costs are reduced in the long run.

For more information on HVOF spray systems visit http://imcmetallizing.com/

0 notes

Text

Quality Metalizing Wire is Needed For Metalizing Process

Metalizing process

This is the process used to form a coating on a metal surface such as automotive parts, machine parts, and aeroplane bodies. Metalizing is a general term used to describe all types of thermal spray processes.

Metalizing wire

This is also known as thermal spray wire or arc spray wire used as a feed material for the thermal spraying process. At very high temperatures the wire melts and is then ejected from the thermal spraying gun at high speed onto the targeted metal surface. Metalizing wire can be an alloy of zinc or aluminum, or It can be a plastic material or ceramic.

Different metalizing processes

HVOF, Flame spray, Plasma spray, Twin wire arc spray, and several other thermal spray processes are used in different manufacturing processes. In any of these systems, metalizing wire is required.

For more information on metalizing wire and thermal spray systems visit https://imcmetallizing.com/

0 notes

Text

HVOF Spray Process: Advanced Technology of Metalizing

HVOF coating process

High-Velocity Oxygen Fuel Coating (HVOF) coating is an advanced thermal spray process whereby fuel and coating material are mixed with oxygen which is then fed into a combustion chamber of the spraying gun. In the combustion chamber, the mixture is ignited at a high temperature and pressure. It is then ejected through the nozzle of the tool at a high speed.

What is HVOF spraying technology used for

Molten or semi-molten materials are sprayed on a metal surface through the HVOF spray process to form a dense and even coating that increases the longevity of the metal parts. The process provides a very high and perfect surface finish.

Multifarious benefits

The process reduces the cost of surface coating, improves electrical properties, and protects metal parts from chemical reactions in a harsh chemical environment.

For more details on the HVOF spray process visit https://imcmetallizing.com/

0 notes

Text

Twin Wire Arc Spray Equipment

Thermal spray equipment

A twin wire arc spray equipment is thermal spray equipment that is used to form a metallic coating on a substrate. Two wires of coating materials are taken together in the gun meant for this process to liquefy and spray as a coating mold.

The gun is designed for the process

In the twin wire arc spray equipment, two metallic wires are positioned in the distinct space meant for their positions. A slight gap is maintained between the two wires. An electrical arc is then struck between the two wires, which dissolves the tips of both wires and forms a spray plume.

Advantage of twin arc coating

Twin wire arc spray is widely used in the coating processes where a thick and dense coating is necessary. This spraying system works fast that is advantageous for large coating surfaces.

For more information visit https://imcmetallizing.com/

0 notes

Text

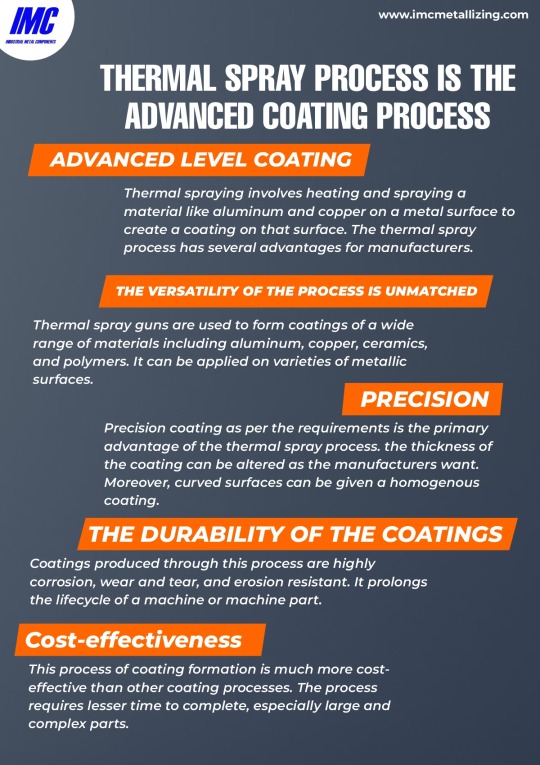

Thermal Spray Process Is The Advanced Coating Process

• Advanced level coating Thermal spraying involves heating and spraying a material like aluminum and copper on a metal surface to create a coating on that surface. The thermal spray process has several advantages for manufacturers. • The versatility of the process is unmatched Thermal spray guns are used to form coatings of a wide range of materials including aluminum, copper, ceramics, and polymers. It can be applied on varieties of metallic surfaces. • Precision Precision coating as per the requirements is the primary advantage of the thermal spray process. the thickness of the coating can be altered as the manufacturers want. Moreover, curved surfaces can be given a homogenous coating. • The durability of the coatings Coatings produced through this process are highly corrosion, wear and tear, and erosion resistant. It prolongs the lifecycle of a machine or machine part. • Cost-effectiveness This process of coating formation is much more cost-effective than other coating processes. The process requires lesser time to complete, especially large and complex parts.

For more information on the thermal spray process visit https://imcmetallizing.com/

#thermal spray#metal spray#thermal spray process#thermal spray gun#metal spray machine#thermal spray powder#thermal arc spray#thermal spray coating equipment#thermal spray system

0 notes

Text

Benefits of Employing Thermal Spray Process

Thermal Spray Technology is considered as a versatile process which is widely applied to accomplish a range of coatings across a variety of materials.

Great wear resistance: Thermal spray process coating transforms the surface into a hard and durable surface which can withstand rough usage and wear and tear. It is extremely beneficial to be employed in various applications that has friction, like bearings or gears.

Resistance to corrosion: Thermal spray process involves coating the surface to provide safety against chemical attack, corrosion, and various other types of environmental degradation. This spraying process make the metals ideal to be used across harsh or hostile environments.

Thermal insulation: Thermal spray coatings work as a solid thermal barrier, which keeps heat locked in or released as per the type of application. This spray process is beneficial for both energy efficiency as well as personal safety.

Click on https://imcmetallizing.com/ to know more.

#Thermal Spray Process#thermal spray#thermal spray coating#thermal spray gun#thermal arc spray#thermal spray coating equipment#thermal spray system

0 notes

Text

All that You Need to Know About HVOF Spray Process

Metallisation High Velocity Oxygen Fuel (HVOF), is considered as an additive process which involves firing powdered metal at the substrate with great velocities. From past few decades, HVOF is increasingly showcased as a highly durable alternative which competes with hard chrome plating.

Adds to durability: HVOF Spray Process is popular to add durability and toughness to the metals. The coating has a dense structure which prevents wear and tear which does not flake or chip off.

Perfect bond to substrate: HVOF spray process coating results in substantially higher bond with the substrate as compared to traditional thermal spray coatings, which results in adding to the bond strength.

Versatile applications: HVOF coatings can be employed as per the different needs and industrial processes. Some of the commonly sprayed materials include metal carbides and superalloys.

Know more about the HVOF Spray Process, click on https://imcmetallizing.com/.

0 notes

Text

Perks of Using Arc Spray System

Arc spray is considered extremely well, and is applied employing a cost effective method. Largely applied on metallic coatings, it is quite handy to be used across various industrial operations as well. Use of Arc Spray System is highly beneficial in the following ways:

Large scale application: The Arc Spray System are used in a wide range of applications and considered versatile among all the other thermal spray systems.

Simple to use: These systems are quite convenient to be used to apply corrosion protection coatings for the steel fabrication or engineering coatings to re-build or alter the surface properties different the sprayed objects.

Easy transitioning: These Arc Spray System are favored in applications that involve switching between anti-corrosion and engineering wires.

Less quantity application: Even though the cost of Arc Spray System is relatively higher than the wire flame systems, but the amount of material sprayed is limited. The preset power of machine but keeping the spray rates higher can be attained by arc spray than flame spray system.

Know more at www.imcmetallizing.com.

0 notes

Text

Flame Spray System: Uses and Advantages

The quality of flame spray system must be supreme to ensure that the coating task is performed seamlessly. Using high end flame spray system helps in achieving even coating bonds to the surface which is done with a minimum 50 microns extending till several mm. • Cost-effective: Wire flame spray system is used extensively as compared to other spray systems since this type of flame spray is cost-effective to buy • Value for money: It pledges to deliver a high running costs owing to the presence of higher gas/oxygen costs which makes it best for less frequent operation. • High quality: This spray system employs less wire which ultimately brings down the overall cost and expense on a larger scale. • Flexible: These wire flame spray systems are also considered as extremely flexible to be used across large sites wherein 3 phase electricity is not available. To order flame spray system for your industrial operations, click on www.imcmetallizing.com.

1 note

·

View note