#thermal spray

Explore tagged Tumblr posts

Text

HVOF Spray Process Offers Complete Metallizing

HVOF exhibits the best possible wear and tear, corrosion, and erosion resistance. The process enhances the lifespans of substrates and machines by protecting the metal surfaces from adverse weather conditions and chemical exposures. The maintenance and replacement costs are reduced in the long run.

For more information on HVOF spray systems visit http://imcmetallizing.com/

0 notes

Link

Tired of noisy neighbors or cold drafts? Commercial building insulation services in Clinton CT, can transform your space into a peaceful, cozy haven. Christmas is almost here. Imagine celebrating the holidays in warmth and quiet! Good insulation makes all the difference, whether for family gatherings or festive vibes. At Lighthouse Spray Foam, we specialize in professional insulation services for your needs. From wall and attic insulation to keeping your home or business safe and sound, our local insulation contractors have you covered. The holidays are about comfort, joy, and family. Let us help you achieve that with expert solutions. Looking for soundproof insulation services in Clinton CT? Contact us today and experience the difference with reliable, quality work. Call Lighthouse Spray Foam now and take the first step toward a cozier space!

#DIY spray foam insulation#Closed-cell spray foam insulation#Spray foam insulation#High-quality thermal insulation#Insulation repair

0 notes

Text

Thermal Spray Coatings Market Overview, Competitive Analysis

0 notes

Text

Acoustic Thermal Spray Chamber (ATSC)

1 note

·

View note

Text

Thermal Spray Coating: A Comprehensive Guide to Surface Protection and Performance Enhancement

Thermal spray coating is a vital surface engineering technique used to enhance the durability, corrosion resistance, and heat tolerance of components across various industries. This process involves depositing molten or semi-molten materials onto a surface to create a protective layer, significantly improving the component's performance and lifespan. WWG Engineering stands out in the field of thermal spray coating, offering a broad range of solutions tailored to specific customer needs.

WWG Engineering’s Expertise in Surface Engineering Solutions

WWG Engineering’s core competency lies in its extensive array of surface modification technologies, with thermal spray coating being a central element of their success formula. The company's expertise in this field is evident in its ability to address diverse operating conditions and customer expectations. Whether clients need to restore machinery and components to their original dimensions, provide temporary fixes, or enhance surface properties for improved functionality, WWG Engineering provides solutions that meet these requirements. Their ability to select the appropriate materials with the exact right chemistry ensures that each coating delivers optimal performance, functionality, and service life, making them a leader in surface engineering solutions.

Wire Metallizing (Flame Wire Spray)

Wire Metallizing, or Flame Wire Spray, is a time-tested thermal spray technique where a metallic wire is melted using an oxygen-fuel flame and then sprayed onto a surface. This method is ideal for corrosion protection and surface restoration. It is widely used in sectors like construction and manufacturing to coat steel structures such as bridges and pipelines. The process is both cost-effective and scalable, offering durable protection against environmental elements and wear, thereby extending the life of critical infrastructure and machinery.

Electric Arc Spray

Electric Arc Spray involves melting two electrically conductive wires through an electric arc to create a molten spray that is deposited onto the surface. This method is particularly beneficial for large-scale applications that require robust, long-lasting coatings. It is commonly used in industries such as oil and gas, marine, and automotive to provide corrosion resistance and wear protection for machinery and structural components. With a high deposition rate and excellent adhesion, Electric Arc Spray is effective for applying thick coatings quickly and efficiently, ensuring enhanced durability for components exposed to harsh environments.

Flame Powder Spray

Flame Powder Spray utilizes powdered materials, including metals and ceramics, which are melted in an oxygen-fuel flame and sprayed onto the substrate. This versatile method is suitable for applications requiring thermal barrier coatings, such as in turbines and engine components. Its ability to handle a variety of materials makes it a valuable technique for industries needing wear-resistant coatings. By improving the resistance of components to friction, corrosion, and high temperatures, Flame Powder Spray contributes to enhanced performance and extended service life in demanding conditions.

Rokide Ceramics Spray

Rokide Ceramics Spray employs ceramic rods as the coating materials, which are melted using a high-temperature flame and then sprayed onto the surface. This technique is well-suited for applications requiring abrasive protection and high-temperature resistance. Commonly used in industries like mining and manufacturing, Rokide coatings provide excellent protection against wear and thermal stress. The resulting ceramic layer is durable and long-lasting, making it ideal for components subjected to harsh operational environments and requiring high-performance protection.

Plasma Spray

Plasma Spray is a high-energy technique where a plasma arc melts the coating material, which is then sprayed onto the surface. This method is highly versatile and can be applied to a wide range of materials, including metals, ceramics, and composites. Plasma Spray is used in industries like aerospace and biomedical engineering to apply high-quality coatings that enhance the thermal, electrical, and wear properties of components. Its capability to produce strong, durable coatings with excellent bond strength makes it suitable for high-performance applications such as turbine blades and medical implants.

HVOF (High-Velocity Oxy-Fuel) Coating

HVOF (High-Velocity Oxy-Fuel) Coating involves spraying molten coating material onto a substrate at supersonic speeds, resulting in a dense and well-bonded coating. This technique is favoured in industries that require superior wear and corrosion resistance, such as aerospace and automotive. HVOF coatings are used to protect components like shafts, valves, and pump impellers from extreme wear and corrosive environments. The resulting coatings offer long-term durability and enhanced performance, making HVOF an ideal choice for demanding applications.

Cold Spray

Cold Spray operates at lower temperatures compared to other thermal spray methods, allowing solid powder particles to be deposited onto a surface without melting. This technique is particularly beneficial for coating temperature-sensitive materials, such as polymers and soft metals. Cold Spray is used for restoring worn surfaces and protecting delicate components without causing thermal damage. Its ability to achieve high bond strength and minimal oxidation makes it suitable for aerospace, electronics, and defence applications, where precise and gentle coating solutions are required.

Conclusion

Thermal spray coating is a sophisticated process essential for enhancing the performance and durability of components across various industries. WWG Engineering excels in delivering customized thermal spray coating solutions, leveraging their expertise to meet specific customer needs. By understanding the critical operating conditions and selecting the right materials with the correct chemistry, WWG Engineering ensures that each coating application achieves optimal results. Their commitment to excellence and innovation in surface modification technologies makes them a leader in the field, offering solutions that improve functionality, performance, and service life for a wide range of industrial applications.

#Thermal Spray Coating Machines#Thermal spray materials supply#Thermal Spray Equipment#Thermal Spray Wire#Thermal Spray Powders Supply#Thermal Spray Aluminium Coating

0 notes

Text

Global Top 13 Companies Accounted for 65% of total Thermal Spray Coating Equipment market (QYResearch, 2021)

Thermal spray is a group of industrial processes that generally include the propelling of micrometer-sized particles of molten or semi-molten materials in order to create a protective or decorative coating on the surface of the desired substrate. The thermal spray coating provides various advantages to the end-users, such as lower coating cost, improved engineering performance, and increased component life. Thermal spray equipment are an integral part of every step in the thermal spray coating process and can be primarily segmented into thermal spray coating systems, dust collection equipment, spray guns and nozzles, feeder equipment, spare parts, noise-reducing enclosures, and others.

According to the new market research report “Global Thermal Spray Coating Equipment Market Report 2023-2029”, published by QYResearch, the global Thermal Spray Coating Equipment market size is projected to reach USD 0.34 billion by 2029, at a CAGR of 0.0% during the forecast period.

Figure. Global Thermal Spray Coating Equipment Market Size (US$ Million), 2018-2029

Figure. Global Thermal Spray Coating Equipment Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Thermal Spray Coating Equipment include Oerlikon Metco, Praxair Surface Technologies, Lincotek Equipment, GTV mbH, United Coatings Technologies (UCT), Metallisation Ltd, Thermion, Flame Spray Technologies (FST), Guangzhou Sanxin Metal S&T, Plasma Giken, etc. In 2022, the global top five players had a share approximately 65.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The global thermal spray market is expected to showcase a growth of ~5% during the forecast period (2021-2027)

0 notes

Text

Thermal Spray Tape

Thermal spray masking tape is a Silicon rubber coated glass cloth tape, or a Aluminum foil-Glass cloth laminated adhesive tape. They are used for shielding protection of Sand blasting, Plasma spray coating, Gas fuelled HVOF, Flame spray, Vapor deposition.

0 notes

Text

How Coating Can Improve Equipment Performance in the Oil and Gas Industry

The oil and gas industry operates in some of the harshest environments on Earth. Equipment is constantly exposed to extreme temperatures, pressures, corrosive elements, and abrasive wear. These factors can significantly impact the performance and lifespan of critical components.

Coating in oil and gas industry plays a vital role in protecting equipment and enhancing its performance. Coatings act as a barrier between the substrate and the harsh operating environment, offering numerous benefits:

Corrosion protection: Coatings prevent or slow down the degradation of metal surfaces caused by exposure to corrosive substances like saltwater, chemicals, and gases. This extends the lifespan of equipment and reduces the risk of costly failures.

Enhanced wear resistance: Coatings can significantly improve the wear resistance of components, protecting them from abrasion, erosion, and impact damage. This is especially crucial for parts subjected to high friction and movement, such as pipelines, drill bits, and pumps.

Improved thermal performance: Certain coatings can reflect heat or insulate components, helping to maintain optimal operating temperatures and improve efficiency. This is essential for equipment operating in extreme hot or cold conditions.

Friction reduction: Coatings can reduce friction between moving parts, leading to lower energy consumption and improved efficiency. This is particularly beneficial for rotating equipment like pumps and compressors.

Aesthetics and visibility: Coatings can provide a visually appealing finish and improve the visibility of equipment, especially important for safety purposes in low-light environments.

Types of coatings used in the oil and gas industry:

Thermal spray coatings: Applied using a molten metal spray gun to create a thick, protective layer. Thermal coating spray offers excellent resistance to corrosion, wear, and high temperatures.

Cladding: A metallurgically bonded layer applied to a base material to improve specific properties like corrosion resistance or wear resistance.

Diffusion coatings: A process where atoms from a coating material diffuse into the base material, creating a permanent bond with enhanced properties.

Paint and enamel coatings: Organic coatings offering corrosion protection and improved aesthetics. They are typically used for non-critical applications or as a topcoat for other coating systems.

Ceramic coatings: Applied for high-temperature resistance, wear resistance, and corrosion protection. They are often used in demanding applications like turbine blades and downhole tools.

Choosing the right coating for a specific application is crucial for optimal performance and equipment longevity in the oil and gas industry. Factors to consider include the operating environment, desired properties, cost, and application feasibility. Consulting with experienced coating specialists is essential to ensure the selection of the most suitable coating solution.

By implementing effective coating strategies, oil and gas companies can significantly improve equipment performance, reduce maintenance costs, and ensure operational safety and reliability.

0 notes

Text

The Significance Of Appropriate Installation For Spray Foam Thermal Insulation

Spray foam thermal insulation has actually gained appeal lately as a result of its phenomenal insulation buildings. Certainly not merely performs it give an airtight seal, but it also aids protect against heat reduction as well as increase, producing your home much more energy-efficient. However, to enjoy these benefits, proper installation is actually needed. Regrettably, some folks still feel that they can easily set up spray foam insulation by themselves without the aid of specialists, resulting in unfortunate end results. Within this post, we'll review the usefulness of correct setup for spray foam insulation.

Reasons You Need Proper Spray Foam Setup

Accomplishing the wanted thermal efficiency

Among the main main reason whies people pick spray foam insulation is its outstanding thermal functionality. It is actually important to put up the insulation the right way to achieve the intended thermal efficiency. If set up improperly, the spray foam insulation might certainly not stick the right way, making gaps as well as voids that may permit air to go through. This will certainly not just lower its own thermal efficiency yet might additionally bring about moisture buildup, mold and mildew, and also mildew and mold development.

Effective air sealing off

Spray foam insulation is an outstanding air sealing representative. However, to achieve an excellent air tape, proper setup is very important. If improperly set up, the spray foam insulation might not pack the voids and gaps effectively, triggering air leak. Air leak may induce an assortment of complications, including wetness build-up, winds, and high electricity expenses. That's certainly not all; the unsatisfactory air quality in your house might cause illness. Click over here now to find out special info about office insulation.

Steering clear of architectural damage

Appropriate installation of spray foam insulation can aid stop building damages. Spray foam broadens the moment applied, so its own setup needs mindful point to consider. If inaccurately put up, the foam may increase extremely a lot, leading to building harm. A professional installer will certainly recognize how a lot foam is actually enough to develop an impermeable seal and prevent architectural damages.

Conserving money

youtube

Suitable installation can conserve money on power costs. Spray foam insulation is actually an outstanding financial investment in creating your home energy-efficient, yet that depends upon the installation. If the insulation is actually put up inaccurately, your heating system and air conditioning bills will certainly skyrocket, countering the discounts you aimed to bring in. The caulking and insulating of all windows, entrances as well as splits are going to aid around conserving power.

Expert installation ensures protection

Spray foam insulation is a mix of chemicals that could be risky otherwise taken care of the right way. It is actually necessary to hire professionals to put in spray foam insulation if you yearn for to make sure security. Specialists understand exactly how to take care of the chemicals and preventive equipment called for, keeping you and your family safe from possible danger.

Spray foam insulation offers numerous benefits, which creates it a preferred insulation alternative one of home owners. Nevertheless, it's important to have actually the insulation put in accurately to obtain optimum perks. Suitable installation can easily help you accomplish the preferred thermal efficiency, stop air leakage, steer clear of structural harm, conserve money on power costs, and also make sure safety and security. Get in touch with experienced specialists to help you mount spray foam insulation in your home.

0 notes

Text

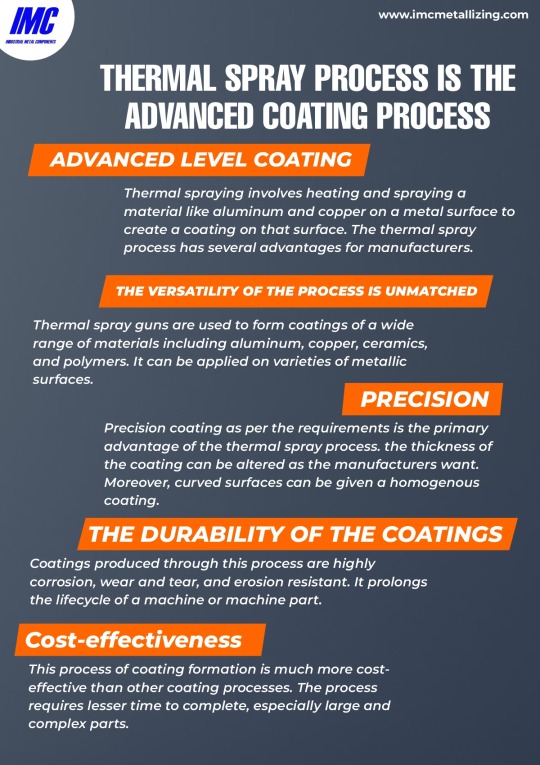

Thermal Spray Process Is The Advanced Coating Process

• Advanced level coating Thermal spraying involves heating and spraying a material like aluminum and copper on a metal surface to create a coating on that surface. The thermal spray process has several advantages for manufacturers. • The versatility of the process is unmatched Thermal spray guns are used to form coatings of a wide range of materials including aluminum, copper, ceramics, and polymers. It can be applied on varieties of metallic surfaces. • Precision Precision coating as per the requirements is the primary advantage of the thermal spray process. the thickness of the coating can be altered as the manufacturers want. Moreover, curved surfaces can be given a homogenous coating. • The durability of the coatings Coatings produced through this process are highly corrosion, wear and tear, and erosion resistant. It prolongs the lifecycle of a machine or machine part. • Cost-effectiveness This process of coating formation is much more cost-effective than other coating processes. The process requires lesser time to complete, especially large and complex parts.

For more information on the thermal spray process visit https://imcmetallizing.com/

#thermal spray#metal spray#thermal spray process#thermal spray gun#metal spray machine#thermal spray powder#thermal arc spray#thermal spray coating equipment#thermal spray system

0 notes

Text

Revolutionizing Industrial Solutions: The Power of Hydraulic Cylinders, Cold Spray Technology, and Beyond

At WWG ENGINEERING PTE. LTD, we excel in providing innovative mechanical engineering services customized to fulfil the varied requirements of our clients. Our commitment to innovation and excellence has positioned us as a leader in machine refurbishment services, thermal spray solutions, and more. With a deep understanding of industry challenges, we offer a comprehensive suite of services that ensure efficiency, reliability, and longevity in industrial operations.

The Backbone of Machinery: Hydraulic Cylinders

Hydraulic cylinders play a crucial role in various industrial applications, delivering the force needed for lifting, pushing, and pulling substantial weights. They convert fluid power into mechanical force, enabling precise control over movement and positioning. Our hydraulic cylinders are engineered to withstand the toughest environments, offering superior performance and durability. Whether it's for construction machinery, manufacturing equipment, or heavy-duty vehicles, our hydraulic cylinders ensure optimal functionality and minimal downtime.

Advancing Repairs with Cold Spray Technology

Cold spray technology represents a revolutionary approach to repairing and enhancing metal surfaces. Unlike traditional thermal spray methods, cold spray involves the deposition of metal particles at high velocities but at relatively low temperatures. This process results in coatings that are dense, highly adherent, and free from thermal stresses. We utilize cold spray technology to restore worn or damaged components, extending their service life and reducing the need for costly replacements. This innovative technique is particularly effective for repairing critical parts in aerospace, automotive, and defence industries.

Precision and Reliability with White Metal Bearings

White metal bearings are crucial for the smooth operation of rotating machinery, providing low friction and excellent load-carrying capacity. These bearings are commonly used in turbines, compressors, and electric motors, where reliability and longevity are paramount. Our team at WWG ENGINEERING PTE. LTD specializes in the design, manufacture, and refurbishment of white metal bearings, ensuring they meet the highest standards of precision and performance. By employing advanced materials and manufacturing techniques, we deliver bearings that significantly enhance the operational efficiency of our clients' equipment.

Comprehensive Mechanical Engineering Services

Mechanical engineering is at the heart of our operations, driving innovation and excellence in every project we undertake. Our mechanical engineering services encompass a wide range of solutions, including design, analysis, prototyping, and production support. our engineers leverage state-of-the-art tools and methodologies to tackle complex challenges, delivering tailored solutions that meet the specific needs of each client. From optimizing manufacturing processes to developing new products, our mechanical engineering expertise ensures superior outcomes.

Restoring Excellence with Machine Refurbishment Services

Machine refurbishment is a cost-effective alternative to purchasing new equipment, allowing businesses to maximize the value of their existing assets. Our machine refurbishment services at WWG ENGINEERING PTE. LTD involves comprehensive assessments, precision repairs, and performance enhancements. We focus on restoring machines to their original specifications or better, ensuring they operate efficiently and reliably. By extending the lifespan of industrial machinery, we help our clients achieve significant cost savings and minimize environmental impact.

Cutting-Edge Thermal Spray Solutions

Thermal spray solutions are vital for protecting and enhancing the performance of industrial components. we offer a range of thermal spray coating services, including plasma spray, HVOF (High-Velocity Oxy-Fuel), and arc spray. These processes involve the application of molten or semi-molten materials onto surfaces, forming protective coatings that resist wear, corrosion, and high temperatures. Our thermal spray solutions are tailored to meet the specific requirements of each application, ensuring optimal performance and durability.

Precision Application with Thermal Spray Coating Machines

The quality of thermal spray coatings is heavily dependent on the equipment used. At WWG ENGINEERING PTE. LTD, we utilize state-of-the-art thermal spray coating machines that ensure precise and consistent application of coatings. Our machines are designed to handle a wide range of materials and substrates, delivering coatings that meet stringent industry standards. With our advanced thermal spray coating machines, we provide reliable and efficient solutions for enhancing the performance and lifespan of critical components.

Conclusion: Your Partner in Industrial Excellence

At WWG ENGINEERING PTE. LTD, we are dedicated to providing innovative solutions that drive industrial excellence. From hydraulic cylinders and cold spray technology to white metal bearings and comprehensive mechanical engineering services, our offerings are designed to meet the evolving needs of our clients. Our steadfast commitment to delivering top-notch quality, trustworthiness, and exceptional customer service makes us a standout partner in the industry. By leveraging our expertise and cutting-edge technologies, we help businesses achieve their operational goals and maintain a competitive edge.

Discover how WWG ENGINEERING PTE. LTD can elevate your industrial operations. Contact us today to learn more about our services and how we can support your success.

#Hydraulic Cylinder Singapore#Hydraulic Equipment Services#Thermal Spray Solutions#Mechanical Engineering Services#Industrial Bearing Service Singapore

0 notes