#high-velocity oxygen fuel coating

Explore tagged Tumblr posts

Text

Breaking the Mold: Why Hard Chrome Replacement Is the Future of Industrial Coatings

In the realm of industrial coatings, the quest for alternatives to hard chrome plating has been an ongoing pursuit. Traditionally, hard chrome has been a popular choice due to its excellent corrosion resistance, hardness, and wear resistance properties. However, its use comes with significant drawbacks, including environmental concerns related to toxic hexavalent chromium emissions during the plating process and the health risks associated with exposure. As industries increasingly prioritize sustainability and worker safety, the search for viable hard chrome alternatives has intensified. Enter the era of hard chrome replacement – a promising shift that is poised to revolutionize the industrial coating landscape.

The need for hard chrome alternatives has spurred innovation across various sectors, driving the development of advanced coating technologies that offer comparable or superior performance while mitigating environmental and health risks. One such alternative gaining traction is the use of thermal spray coatings, such as high-velocity oxygen fuel coating (HVOF) and plasma spraying. These processes deposit a wide range of materials, including ceramics, metals, and composites, onto substrates with exceptional bond strength and wear resistance. Not only do thermal spray coatings provide excellent corrosion protection and surface hardness, but they also eliminate the hazardous byproducts associated with traditional chrome plating, making them an environmentally friendly choice.

Another promising avenue for hard chrome replacement lies in the realm of electroless nickel coatings. Unlike traditional electroplating methods that rely on an electric current to deposit metal onto a substrate, electroless nickel plating occurs through an autocatalytic chemical reaction, resulting in uniform coatings with precise thickness control. Electroless nickel coatings offer excellent corrosion resistance, hardness, and lubricity, making them ideal for a wide range of industrial applications, from aerospace components to automotive parts. Moreover, the elimination of the electric current requirement reduces energy consumption and eliminates the need for toxic chromium baths, aligning with sustainable manufacturing practices.

Furthermore, advancements in composite coatings, such as diamond-like carbon (DLC) and polymer-based materials, offer a compelling alternative to hard chrome in specific applications. DLC coatings exhibit exceptional hardness, low friction, and superior wear resistance, making them suitable for cutting tools, molds, and automotive components. Meanwhile, polymer-based coatings provide flexibility, chemical resistance, and corrosion protection, catering to industries such as oil and gas, marine, and automotive.

The transition away from hard chrome plating towards sustainable alternatives is not only driven by environmental and health considerations but also by regulatory pressures and market demand for greener solutions. With stricter regulations governing the use of hazardous substances and increasing awareness of the ecological footprint of industrial processes, manufacturers are increasingly seeking alternatives that offer comparable performance without compromising on safety or environmental stewardship.

In conclusion, the future of industrial coatings lies in the adoption of hard chrome alternatives that prioritize sustainability, performance, and safety. Whether through thermal spray coatings, electroless nickel plating, or advanced composites, the era of hard chrome replacement heralds a new chapter in industrial coating technology. By embracing innovative solutions that break away from traditional paradigms, manufacturers can achieve superior performance while safeguarding the environment and the well-being of workers. As we navigate this transition, companies like Ewsllp play a pivotal role in driving innovation and facilitating the adoption of sustainable coating solutions, shaping a brighter and greener future for industries worldwide.

0 notes

Text

Here’s why SR-71 Blackbird Tires were Silver and why were Changed after 10 Takeoffs

By Linda Sheffield Miller

Mar 25 2023

SHARE THIS ARTICLE

Even though the tires could last for approximately 15 full-stop landings SR-71 Blackbird tires were changed after 10 takeoffs.

SR-71 Shop

CLICK HERE to buy unique SR-71 Blackbird merchandise for your HABU collection.

During its career, the SR-71 Blackbird gathered intelligence in some of the world’s most hostile environments. The SR-71 was conceived to operate at extreme velocities, altitudes and temperatures: actually, it was the first aircraft constructed with titanium, as the friction caused by air molecules passing over its surface at Mach 2.6 would melt a conventional aluminum frame.

Its engineering was so cutting edge that even the tools to build the SR-71 needed to be designed from scratch.

There are so many interesting facts about the legendary Blackbird.

For instance, the tires of the SR-71 were silver.

Why were SR-71 tires silver?

SR-71 print

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. SR-71A Blackbird 61-7972 “Skunkworks”

According to the sign accompanying the SR-71 tire on display at the Kansas Cosmosphere and Space Center, Hutchinson, KS, SR-71 tires [like that featured in the photos of this article] were infused with powdered aluminum. The addition of aluminum to the rubber gave a much higher flash point to the tire, helping it withstand the high heat caused by friction with the ground upon landing at extreme speeds. The tires were also filled with nitrogen. By inflating the tires with nitrogen, instead of air, a fire would be less likely to start due to the absence of oxygen. The tire pressure on the SR-71 was 415 psi (compared to the 32-35 psi in your automobile tires!). Each tire costs $2,300 and would last for approximately 15 full-stop landings.

Even though the tires could last for approximately 15 full-stop landings they were changed after 10 takeoffs, as Colonel Ken Collins, former A-12 and SR-71 pilot, explains;

‘The tires were changed after 10 “takeoffs”. The wear & tear was during takeoff. The extreme pressure was at that point of rotation. That the reason we took off with half fuel load and air-air refueled shortly after takeoff, that reduced the tire stress. The temperature in the cockpit at the front windshield got up to 650 degrees F. Early in the experimental flight testing we wore silver suits. At cruise if you touched the side canopy glass it would melt the silver coating on you glove. The coating on the suit was not “silver” metal. The cockpit and the pressure suits were air conditioned. The cockpit got hotter as you burned the fuel. You were ready to get new fuel as it would cool it down.’

Lockheed SR-71 Blackbird model

This model is available from AirModels – CLICK HERE TO GET YOURS.

The SR-71 needed to deflect a large amount of heat as it flew at an average speed of Mach 3, or roughly 2000 mph! At this extreme speed, the metal skin of the SR-71 would heat up to 400 degrees Fahrenheit.

Over 90 percent of the aircraft’s frame was made of titanium to withstand the intense heat. In addition, the SR-71 was painted with a highly sophisticated and specially formulated black paint to radiate excess heat.

The special paint also provided protection against detection by disturbing incoming radar energy, rendering the aircraft less detectable by enemy forcess

youtube

7 notes

·

View notes

Text

Thermal Spray Coating Equipment Market: Growth, Trends, and Future Outlook

Introduction

The Thermal Spray Coating Equipment Market has been experiencing rapid growth due to increasing demand for durable and wear-resistant coatings across various industries. This market is driven by advancements in coating technologies, rising adoption in the aerospace and automotive industries, and the growing emphasis on extending the lifespan of industrial components. As industries continue to prioritize cost efficiency and performance, the thermal spray coating market is expected to expand significantly in the coming years.

Market Overview

Current Market Size and Growth Trends

The global thermal spray coating equipment market was valued at approximately USD 10.5 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2032, reaching an estimated USD 18 billion by the end of the forecast period. This growth is fueled by increasing demand in sectors such as aerospace, automotive, healthcare, and energy.

Regional Market Insights

North America: The largest market, driven by heavy industrialization, aerospace investments, and stringent regulations on corrosion protection.

Europe: Strong presence of automotive and aerospace manufacturers, along with stringent sustainability regulations, fueling growth.

Asia-Pacific: The fastest-growing region, with China, India, and Japan investing in advanced manufacturing technologies.

Latin America & Middle East: Emerging as potential markets due to expanding oil & gas and construction industries.

Key Market Drivers

Rising Demand for Corrosion and Wear Resistance: Thermal spray coatings help protect equipment from wear, oxidation, and extreme environmental conditions, reducing maintenance costs.

Growth in Aerospace & Automotive Sectors: The increasing need for lightweight and heat-resistant coatings in aircraft and automotive components is a key market driver.

Advancements in Coating Technologies: Innovations such as plasma spray, high-velocity oxygen fuel (HVOF), and cold spray techniques are improving coating efficiency and performance.

Expansion of Industrial and Energy Sectors: The power generation, oil & gas, and manufacturing industries are adopting thermal spray coatings to enhance the durability of their equipment.

Leading Players in the Thermal Spray Coating Equipment Market

Major companies dominating the thermal spray coating equipment industry include:

Oerlikon Metco (Switzerland) – A leading player offering advanced thermal spray solutions.

Praxair Surface Technologies (USA) – Specializes in high-performance coating solutions for aerospace and industrial applications.

Flame Spray Technologies (Netherlands) – Focuses on innovative and cost-effective coating systems.

Metallisation Ltd. (UK) – Known for its expertise in arc spray and plasma spray technologies.

TST Coatings (USA) – A key player in advanced ceramic and metallic coating technologies.

Challenges and Roadblocks

Despite strong market growth, the industry faces several challenges:

High Initial Investment Costs: The setup and maintenance costs of thermal spray coating equipment are significant, limiting adoption among small-scale manufacturers.

Lack of Skilled Workforce: Specialized training is required to operate advanced thermal spray systems, creating a talent gap in the industry.

Stringent Environmental Regulations: Compliance with regulations regarding airborne emissions and waste disposal adds complexity to the industry’s operations.

Competition from Alternative Coating Technologies: Techniques such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) provide competition to traditional thermal spray methods.

Future Outlook

The future of the thermal spray coating equipment market looks promising, with increasing R&D investments and industry collaborations driving innovation. The adoption of robotic automation in thermal spray processes, along with eco-friendly coating solutions, is expected to revolutionize the industry. Additionally, the growth of additive manufacturing and 3D printing in industrial applications is creating new opportunities for thermal spray coatings.

Conclusion

The thermal spray coating equipment market is set to witness robust growth, fueled by technological advancements and the expanding need for high-performance coatings across various industries. Companies investing in sustainable, cost-effective, and high-efficiency thermal spray solutions will be at the forefront of this evolving market. As industries strive for greater durability and performance, thermal spray coating technologies will continue to play a crucial role in shaping the future of manufacturing and industrial protection.

Looking to stay ahead in the thermal spray coating industry? Keep up with the latest innovations and market trends by following our blog!

0 notes

Text

Shielding the Future: Insights into the Growing Thermal Spray Coatings Market

Thermal spray coatings have steadily gained traction as an indispensable technology across diverse industries. By offering unmatched surface protection and significantly enhancing the durability of components, these coatings have become a game-changer. With the increasing focus on efficiency, sustainability, and cost optimization, the global thermal spray coatings market is on an upward trajectory, bolstered by emerging trends, innovative applications, and advancements in technology.

Market Size and Growth Potential

The global thermal spray coatings market was valued at USD 10.4 billion in 2023 and is projected to reach USD 14.3 billion by 2028, growing at 6.5% cagr from 2023 to 2028. This surge is driven by rising demand in key sectors like aerospace, automotive, healthcare, and energy.

In the aerospace sector, thermal spray coatings play a crucial role in improving engine efficiency and protecting parts exposed to extreme conditions. Meanwhile, the automotive industry has embraced these coatings for their ability to reduce wear and friction in engine components, resulting in improved fuel economy and reduced emissions.

Emerging Trends Shaping the Market

Sustainability and Eco-Friendly Solutions: Environmental concerns are pushing manufacturers to innovate. Many are exploring eco-friendly coatings by reducing hazardous materials and adopting greener production methods.

Advances in Thermal Spray Technology: Cutting-edge techniques like plasma spraying and high-velocity oxygen fuel (HVOF) are revolutionizing the market. These methods offer superior precision, stronger adhesion, and enhanced performance, enabling a wider range of industrial applications.

Expansion in Renewable Energy Applications: As the world shifts towards renewable energy sources, thermal spray coatings are finding a home in wind turbines and solar panel components. These coatings ensure resilience and longevity, vital for maximizing energy efficiency.

Growing Focus on Lightweight Materials: Lightweight materials, such as aluminum and titanium, are increasingly used in automotive and aerospace sectors. Thermal spray coatings are essential in safeguarding these materials against corrosion and wear while retaining their lightweight properties.

Key Players Driving Innovation

Several industry leaders are propelling the thermal spray coatings market forward by introducing new products and investing heavily in research. Notable players include:

Praxair Surface Technologies: Known for their sophisticated surface solutions, Praxair provides thermal spray coatings tailored for aerospace and energy applications.

Bodycote plc: A global powerhouse in heat treatment and surface engineering, Bodycote offers cutting-edge coating services designed to meet the demands of modern industries.

Oerlikon Metco: A leader in surface solutions, Oerlikon Metco caters to diverse sectors like healthcare, automotive, and aerospace with innovative thermal spray products.

Saint-Gobain: Renowned for their comprehensive range of thermal spray powders and coating solutions.

These companies are not only innovating but also collaborating closely with end-users to develop customized solutions that address unique industry challenges.

Future Outlook

The future of the thermal spray coatings market looks promising, with ongoing advancements in materials, processes, and applications. Industries are expected to increasingly rely on these coatings to boost efficiency and protect investments. Moreover, automation and robotics are anticipated to refine the coating process, making it more cost-effective and precise.

Experts predict that collaboration between coating manufacturers and their clients will intensify in the coming years, fostering the development of specialized solutions tailored to evolving industry needs. This collaborative approach will be instrumental in unlocking new opportunities and maintaining the momentum of market growth.

To get deeper Insights Download PDF Brochure :

Thermal spray coatings have cemented their place as a cornerstone technology across various sectors. From extending the lifespan of critical components to enabling new possibilities in lightweight and renewable energy applications, these coatings are integral to modern industry. As sustainability and innovation drive the market forward, businesses that embrace these trends will find themselves at the forefront of this dynamic field.

#ThermalSprayCoatings#SurfaceEngineering#IndustrialCoatings#ThermalSprayTechnology#MarketTrends#AerospaceCoatings#AutomotiveCoatings#Sustainability#Innovation#ThermalSprayManufacturers

0 notes

Text

Mastering Welding Fabrication: A Breakdown of Essential Techniques

Welding fabrication is a vital process in manufacturing, construction, and repair industries. It involves the joining of metals through various welding techniques to create durable, robust, and high-quality structures or components. Whether it’s constructing buildings, bridges, or machinery, welding plays an essential role in almost every sector. There are numerous welding methods, each suited for different applications and materials. Understanding the types of welding fabrication helps in choosing the appropriate method for specific projects, ensuring quality, safety, and cost-effectiveness.

In this article, we’ll explore some of the most common types of welding fabrication, their applications, and their advantages and disadvantages.

1. Arc Welding

Arc welding is one of the most widely used welding processes in the industry. It works by using an electric arc to create heat, which melts the metal at the joint between two workpieces. Once cooled, the metals are fused together, forming a strong bond.

Types of Arc Welding:

Shielded Metal Arc Welding (SMAW): Also known as stick welding, this method uses a consumable electrode coated in flux. When the electrode melts, it creates a weld, and the flux coating burns off, creating a protective gas shield to prevent contamination. SMAW is versatile and can be used on various metals like steel, iron, and aluminum, making it suitable for heavy-duty tasks like building construction and shipbuilding.

Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, this method uses a continuous wire feed as an electrode. The welding area is shielded from contamination by an external gas, such as argon or carbon dioxide. MIG welding is favored for its speed and ease of use and is typically employed in automotive and manufacturing industries.

Gas Tungsten Arc Welding (GTAW): Also called TIG welding, this method uses a non-consumable tungsten electrode and a shielding gas, typically argon, to protect the weld from contamination. TIG welding is known for producing high-quality, precise welds and is often used for welding thin materials like stainless steel and aluminum.

Flux-Cored Arc Welding (FCAW): Similar to MIG welding, FCAW uses a continuous wire feed, but the wire is flux-cored, eliminating the need for external shielding gas in some applications. It’s commonly used for outdoor or heavy-duty work, such as construction and shipbuilding.

2. Oxy-Fuel Welding

Oxy-fuel welding, also known as gas welding, is one of the oldest forms of welding. It uses a combination of oxygen and a fuel gas, typically acetylene, to produce a flame that melts the metal at the joint. This method is suitable for welding ferrous and non-ferrous metals and is widely used in small-scale fabrication and repair work.

Advantages:

Portable and inexpensive equipment.

Versatile, can also be used for cutting metals.

Disadvantages:

Slow welding process.

Limited to thin materials, not suitable for heavy-duty tasks.

3. Resistance Welding

Resistance welding is a process where heat is generated through the resistance of the materials being joined to the flow of electric current. The pressure is applied to fuse the materials together, making it a fast and efficient method for mass production.

Types of Resistance Welding:

Spot Welding: One of the most common types of resistance welding, spot welding is typically used to join two metal sheets by applying pressure and heat to localized areas (or “spots”). It’s widely used in the automotive industry to fabricate car bodies and other sheet metal products.

Seam Welding: Seam welding is similar to spot welding but involves a continuous weld along a seam, making it ideal for applications that require leak-tight seals, such as fuel tanks and pipes.

4. Plasma Arc Welding

Plasma arc welding (PAW) is a precision welding process that uses a high-velocity jet of ionized gas (plasma) to melt and fuse metals. It is similar to TIG welding but provides more control and higher precision, making it ideal for applications that require intricate and detailed welds, such as aerospace and medical device manufacturing.

Advantages:

High level of precision and control.

Suitable for thin materials and complex shapes.

Disadvantages:

Requires specialized equipment and highly skilled operators.

Slower process compared to other welding methods.

5. Electron Beam Welding

Electron beam welding (EBW) is a high-energy welding process that uses a focused beam of electrons to melt and join materials. It’s performed in a vacuum to prevent electron scattering, resulting in extremely precise and high-quality welds. EBW is used in industries like aerospace, automotive, and electronics, where precision is critical.

Advantages:

Produces clean, high-quality welds with minimal distortion.

Suitable for thick materials and deep welds.

Disadvantages:

Expensive equipment and setup.

Limited to applications that can be performed in a vacuum.

6. Laser Beam Welding

Laser beam welding (LBW) uses a concentrated laser beam to melt and join materials. This method is highly accurate and fast, making it ideal for automated welding processes in industries like automotive and electronics manufacturing. It can weld thin materials with minimal heat input, reducing distortion.

Advantages:

High welding speed and precision.

Minimal heat-affected zone.

Disadvantages:

High initial equipment cost.

Limited to thin materials.

7. Ultrasonic Welding

Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic vibrations to create frictional heat between the materials being joined. This method is commonly used for plastics but can also be used for metals. It’s widely applied in the electronics, automotive, and medical industries for welding components without using external heat or adhesives.

Advantages:

Fast, clean, and precise.

Ideal for materials sensitive to heat.

Disadvantages:

Limited to small, thin components.

Requires specialized equipment.

8. Orbital Welding

Orbital welding is a specialized form of automated welding, typically used for joining pipes or tubes. The process involves a welding head that rotates around the stationary pipe, allowing for a continuous and precise weld. Orbital welding is primarily used in industries where high-quality, repeatable welds are essential, such as aerospace, pharmaceuticals, nuclear, and semiconductor manufacturing.

Advantages:

Produces highly consistent and precise welds.

Ideal for clean environments and industries with stringent standards, like pharmaceuticals and semiconductors.

Disadvantages:

Requires specialized, expensive equipment.

Setup can be complex and time-consuming.

Conclusion

Welding fabrication is a diverse and essential process in various industries, each method offering unique advantages suited to specific applications. Whether it’s the simplicity and versatility of arc welding, the precision of TIG or laser welding, or the speed of resistance welding, the right technique depends on factors like material type, joint design, and project scale.

Understanding these different types of welding fabrication through expert training courses allows manufacturers, engineers, and fabricators to choose the most appropriate method, ensuring that their projects are efficient, durable, and cost-effective.

#orbital welding training#orbital welding technology#welding technology#welding types#orbital welding courses

0 notes

Text

High Velocity Oxygen Fuel Nozzle Spray CFD ANALYSIS

Uncover the secrets of HVOF nozzle spray with CFD analysis. Explore internal flow, particle behavior, and optimize coating formation for superior results.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

#CFDAnalysis#CFDConsultingServices#DiscretePhaseModelling#flowrate#graphlertech#HighVelocityOxy-Fuel#HVOF

0 notes

Text

What are the key benefits of HVOF coating services? HVOF (High-Velocity Oxygen Fuel) coating services offer numerous advantages, including exceptional hardness, improved wear resistance, and superior adhesion to substrates. The process involves high-speed combustion to produce a dense and durable coating, making it ideal for applications in aerospace, automotive, and industrial sectors. HVOF coatings enhance component lifespan and performance, providing effective solutions for wear and corrosion challenges.

0 notes

Text

HVOF Spray Guns and Thermal Spray Equipment: The Ultimate Guide by Shot Blaster

Welcome to our comprehensive guide on High-Velocity Oxygen Fuel (HVOF) spray guns and thermal spray equipment. At Shot Blaster, we are committed to providing you with the most authoritative and up-to-date information on these cutting-edge technologies that are revolutionizing industries across the globe.

In this guide, we will delve into the intricate details of HVOF guns and thermal spray equipment, shedding light on their benefits, applications, and the key factors that set them apart. Let's embark on this knowledge-packed journey together.

Understanding HVOF Spray Guns: Powering Precision Coatings

HVOF spray guns are a pinnacle of technological advancement when it comes to precision coatings. These remarkable tools utilize the power of high-velocity oxygen-fueled combustion to propel coatings onto surfaces, ensuring exceptional adhesion, hardness, and longevity.

Our state-of-the-art HVOF spray guns have been meticulously engineered to deliver coatings that exceed expectations across various industries.

The Advantages of HVOF Technology

HVOF technology offers an array of unparalleled advantages that make it stand out in the realm of surface coatings. These include:

Exceptional Adhesion: The high-speed impact of particles during the spraying process ensures a bond that is second to none. This results in coatings that are resilient even in the most challenging environments.

Enhanced Hardness: HVOF coatings exhibit remarkable hardness, making them ideal for applications where wear and corrosion resistance are paramount.

Minimal Heat Impact: Thanks to the supersonic speed of particle deposition, HVOF coatings experience minimal heat transfer. This characteristic is crucial for preventing distortion or damage to the substrate.

Versatile Applications: From aerospace components to industrial machinery, HVOF coatings find applications in diverse industries, contributing to improved performance and longevity.

The Essence of Thermal Spray Equipment: Engineering Excellence

Thermal spray equipment is the backbone of HVOF technology, enabling the precise and controlled application of coatings. Our cutting-edge thermal spray equipment is designed with precision and efficiency in mind, catering to the unique needs of each industry it serves.

Key Features of Our Thermal Spray Equipment

Advanced Control Systems: Our equipment boasts intuitive control systems that allow for precise adjustments of parameters, ensuring consistent and reliable coatings.

Diverse Coating Materials: We understand the significance of material choice in coating applications. Shot Blaster equipment supports a wide range of coating materials, providing flexibility and tailored solutions.

Optimized Particle Acceleration: Achieving optimal particle acceleration is pivotal in HVOF technology. Our thermal spray equipment has been fine-tuned to ensure particles achieve the desired velocity for optimal coating quality.

Applications that Transcend Boundaries

HVOF guns and thermal spray equipment are redefining possibilities across industries. Here are some prominent applications where these technologies shine:

Aerospace Industry: Critical aerospace components demand coatings that can withstand extreme conditions. HVOF technology ensures superior protection against high temperatures, abrasion, and corrosion.

Oil and Gas Sector: In the oil and gas industry, equipment reliability is paramount. HVOF coatings extend the lifespan of components exposed to harsh environments, contributing to reduced maintenance costs.

Manufacturing and Engineering: The manufacturing sector benefits from the enhanced wear resistance and hardness of HVOF coatings, which lead to increased durability and improved performance.

Elevating Your Operations with HVOF and Thermal Spray

At SHOT BLASTER, we recognize that adopting HVOF technology and utilizing advanced thermal spray equipment can significantly impact your operations. Our commitment to innovation, quality, and excellence ensures that our offerings are tailored to meet the unique needs of your industry.

If you're ready to embrace the future of coatings and enhance the performance of your components, contact us today to explore how our HVOF spray guns and thermal spray equipment can elevate your operations to new heights.

For more details visit URL - https://www.thermalspraygun.com/hvof-gun

0 notes

Text

Maximizing Tool Life with Tungsten Carbide Coatings

Tungsten carbide coating available in powdered form is highly effective in increasing the lifespan of your tools. You can apply it with a thermal spraying process.

Industrial tool manufacturers apply an ultra-thin coating containing molecular compounds. The special coatings on the surface are intended to prevent deterioration of the cutting tools. It can also result in the tool failure within a short time. There are high-quality coatings for cutting tools. But, they also restrict friction and heat while improving the tool’s performance. You can choose tungsten carbide coating if you want to make your tools long-lasting.

Know about WC coating-

WC or tungsten carbide coating is a hard ceramic material, which is available as fine, grey-coloured powder particles. The material is highly resistant to scratch, wear, and abrasion. Because of its extreme hardness, tungsten carbide prevents damage to the surface. It also ensures protection against surface-based attacks, such as fatigue, erosion, and corrosion. As it is ceramic, WC is stable and has a high melting point. Tungsten carbide often mixes with a small amount of metallic powder (including Ni, Cr, and Co).

Choose the tungsten carbide coatings-

Tungsten carbide is a premium coating, and the cost of coating tungsten carbide varies with the material you want to coat. It is the most suitable coating if you have found irreversible damage to the parts of the tools. Instead of buying new cutting tools, you can coat their worn-out parts to save money. In this case, coating the tool with tungsten carbide is a cheap solution.

Tungsten carbide coating has special properties like good strength, high hardness, corrosion resistance, and significant bonding strength. Densely coated carbide also comes with low porosity. Besides, they have some variable properties based on the powder’s grain size and volume fraction.

How does the WC coating benefit your tools?

One of the significant benefits of using WC coatings is that they increase the product’s service life. You can use reliable and efficient coating technology for your tools. The coating will prevent different types of surface damage. Besides, tungsten carbide has a blend of metallurgical and mechanical properties. You can choose WC coating for the exposed part of your machinery.

You can apply the tungsten carbide coating through the innovative HVOF thermal spraying process. In this process, oxygen and fuel gas undergo combustion in a high-pressure chamber where the temperature reaches 5,600F. As a result, high-pressure hot gas comes out through a small nozzle. The gas passes down a long barrel at a very high speed. The coating material, tungsten carbide powder, is essential for the process. You need to inject it into the nozzle, and the particles blend with gases to reach a high velocity.

To sum up, tungsten carbide is a protective coating material for making your cutting tools long-lasting. You can also apply it to other industrial tools and machinery.

Endurance Wear Solutions is a reputed company that provides customized coating services. Its team has 30+ years of expertise in the field.

1 note

·

View note

Text

HVOF Spray Process: Advanced Technology of Metalizing

HVOF coating process

High-Velocity Oxygen Fuel Coating (HVOF) coating is an advanced thermal spray process whereby fuel and coating material are mixed with oxygen which is then fed into a combustion chamber of the spraying gun. In the combustion chamber, the mixture is ignited at a high temperature and pressure. It is then ejected through the nozzle of the tool at a high speed.

What is HVOF spraying technology used for

Molten or semi-molten materials are sprayed on a metal surface through the HVOF spray process to form a dense and even coating that increases the longevity of the metal parts. The process provides a very high and perfect surface finish.

Multifarious benefits

The process reduces the cost of surface coating, improves electrical properties, and protects metal parts from chemical reactions in a harsh chemical environment.

For more details on the HVOF spray process visit https://imcmetallizing.com/

0 notes

Text

Transportation Coating Market Size, Share, Demand, Growth & Trends

According to Future Market Insights’ (FMI) recently published report, the global transportation coating market will account for revenues over US$ 12 Bn by 2022-end. The report has projected future of transportation coatings in being important industrial materials for utilisation in the transportation sector for the five year assessment period (2017-2022).

The report also delivers analysis on key regional segments, wherein Asia-Pacific excluding Japan (APEJ) has been anticipated to remain the most lucrative market for transportation coatings over the assessment period.

Over the past decades, engineered particularly for withstanding mechanical as well as thermal stress, high performance coatings have experienced a substantial adoption in transportation sector. These transportation coating have then been integrated into the vehicle production.

The practice of coating surfaces of metal in long haul trailers and trucks with the high-velocity oxygen fuel (HVOF) has been exercised actively in the production of vehicles as well as their components that are used for the purpose of transportation.

For Critical Insights, Request for PDF Sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-5083

Sales of Solvent-based Coatings to Exhibit Fastest Expansion through 2022

The report has also analysed the global market for transportation coatings based on the types of coatings. Global sales of solvent-based transportation coatings are estimated to bring in nearly US$ 3.5 Bn revenues in 2017. Projected to account for nearly two-fifth share revenue share of the market, solvent-based transportation coatings will exhibit the fastest expansion throughout the assessment period.

Demand for these coatings has been anticipated to rise, owing to their characteristics of being less prone to changes in humidity and temperature. However, high VOC emissions are associated with manufacturing solvent-based transportation coatings that leads to an environment adversity.

This factor has been expected to be a key restraint in adoption of solvent-based transportation coatings. In addition, demand for power coatings is expected to remain steady in the global market for transportation coatings. A robust expansion has been projected for sales of pre-treatment coatings through 2022.

Utilisation of Transportation Coatings from OEMs to Remain a Healthy Practice for Industries in Transportation Business

OEMs are projected to account for approximately half revenue share of the market in 2017, and will further witness a rise in their market share through 2022. OEMs will remain largest end-users of transportation coating. Polymer coatings and epoxies are actively being integrated into the production of vehicle chassis, engine parts, and several other key components.

It will remain a healthy practice for industries in transportation business to utilise transportation coatings through OEMs. The end-use of transportation coatings will continue to register the fastest expansion in the heavy-duty truck industry through 2022.

Metal Coating Application to Account for Largest Revenue Share of Transportation Coating Market in 2017

On the basis of application, the plastic coating application has been estimated by the report to exhibit highest revenue expansion throughout the assessment period. More than US$ 3.8 Bn worth of transportation coatings are estimated to be sold for application in plastic coatings by 2022-end. In addition, the report projects the metal coating applications to account for the largest revenue share of the market in 2017.

Leading companies of transportation coatings are anticipated to focus on boosting the application of coatings on plastic surfaces. Several players in the market are adopting new techniques of fastening such as elastic bonding. These players are also offering aging resistant adhesives for enhancing performance of transportation coatings.

Players focusing on Procuring High-quality Raw Material Grades for Transportation Coatings

Key companies profiled by FMI’s report on global transportation coating market include Akzo Nobel NV, Axalta Coating Systems Ltd., BASF SE, E.I Du Pont De Nemours and Company, Evonik Industries AG, Henkel AG & Co. KGaA, Nippon Paint Holdings Co. Ltd., PPG Industries, Inc., The Dow Chemical Company, and The Sherwin-Williams Company. The market players are focusing on adoption of key strategies for procuring high-quality raw material grades in manufacturing transportation coatings.

Market Taxonomy

Coating Type :

Water-based

Solvent-based

Powder

Pre-treatment

Others

End-user :

Automotive OEMs

Heavy Duty Truck Industry

Bus Manufacturers

Rail Industry

Other End-user

Application :

Metal Coating

Plastic Coating

Carbon Fiber

Other Substrates

Browse Full Report: https://www.futuremarketinsights.com/reports/transportation-coating-market

0 notes

Text

High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market 2022-2028 Size, Share, Trend, Key Palyers with Products

High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market 2022-2028 Size, Share, Trend, Key Palyers with Products

High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Overview The High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market report is latest report published by Fusion Market Research which provides comprehensive information, overview of the demands and describe Impact of Covid-19 on the market during the forecast period 2022–2028. At the beginning of a recently…

View On WordPress

#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Analysis#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Growth#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Industry#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Industry Forecast#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Industry Trends#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Manufacturer#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Parameters#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Prospectus#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Segmentation#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Share#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Size#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Survey#High Velocity Oxygen Fuel (HVOF) Tungsten Carbide (WC) Coatings Market Trends

0 notes

Text

Thermal Spray Coatings Market review -Development Trends, Threats, Opportunities and Competitive Landscape in 2027

Market Highlights

Global Thermal Spray Coatings Market is projected to be valued at over USD 9.7 Billion by 2027 and exhibit a moderate CAGR of around 4.8% during the forecast period.

The growth of the global thermal spray coatings market is primarily driven by the healthy growth of the aerospace industry. In the aerospace industry, the use of high-quality thermal spray coatings results in increased fuel efficiency, reduced maintenance cost, and higher speed in aircraft and rotorcraft engines, as well as other related components. Typical thermal spray coatings applications include rotor-path linings, high-pressure turbine seals, compressor seals, bearings, oil seals, crankshafts, cylinders, and piston rings. The global commercial aircraft industry is expected to witness healthy growth in the coming years. Recovery in the global gross domestic product (GDP), stable commodity prices (including crude oil), growth in passenger travel, especially in Asia-Pacific, Latin America, and the Middle East, are expected to be the key factors driving the growth of the aerospace industry during the forecast period.

Additionally, thermal spray coatings are extensively used in the healthcare industry for various applications such as prosthetics, orthopedics, dental implants, and pacemakers. These coatings exhibit wear resistance, corrosion resistance, high temperature, and biocompatibility. The rising health concerns associated with the sedentary lifestyle and poor eating habits are likely to increase the number of patients suffering from various diseases, which is expected to boost the demand for implantable and surgeries, further fueling the global market. The demand for these surgeries is also promoted by the high disposable income of the consumers and their willingness to live a healthy life. All these factors are driving the demand for thermal spray coating in the healthcare industry and are expected to drive market growth during the review period.

However, thermal spray coatings have disadvantages as well. For instance, plasma spray coatings restrict access to surfaces, and small-diameter internal bores are challenging as it is a line-of-sight process and requires automated gun manipulators. Manual operation is deemed unsuitable. Moreover, thick coatings are difficult to achieve in thermal spray coatings.

Segment Analysis

Global Thermal Spray Coatings Market has been segmented based on Process, Material, and End User.

The global thermal spray coatings market, on the basis of process, is segmented into combustion flame and electrical. Combustion flame is the most commonly used thermal spray coating process accounting for a share of 69% of the global thermal spray coating market. The combustion flame process includes flame spraying, HVOC spraying, and detonation flame spraying. The flame spraying process is widely used for low-intensity applications owing to cost. HVOF (High-Velocity Oxygen Fuel) utilizes high-pressure oxygen and fuel gas; and provides a very dense coating, with low porosity and high bond strength to the metal substrate. HVOF is widely used for jet engine components, automotive components, gas turbines, and industrial machines.

Based on material, the global thermal spray coating market has been segmented into metals & alloys, ceramics, polymers, and others. The metal & alloys segment accounted for the largest share of the global thermal spray coatings market in 2019. Metal & alloy coating provides cost-effective surface solutions providing corrosion and oxidation resistance, wear and erosion resistance, and enhance conductivity. The segment includes tungsten, molybdenum, rhenium, niobium, superalloys, zinc, aluminum, stainless steels, NiCr alloys, cobalt-base, Stellites, cobalt/nickel-base, Tribaloys, and NiCrBSi "self-fluxing" alloys and zinc-aluminum alloy coatings. Some of the key applications of metals & alloy coatings include diesel engine cylinder coatings; piston rings or valve stems; turbine engine blades; vanes and combustors; corrosion-prone infrastructure; mining and agricultural equipment; and petrochemical pumps and valves.

Browse Full Report Details @

https://www.marketresearchfuture.com/reports/thermal-spray-coatings-market-6053

By end-user, the global thermal spray coating market has been segmented into aerospace, energy and power, automotive, healthcare, machinery, agriculture, electrical and electronics, and others. Thermal spray coatings are extensively used in the aerospace industry in gas turbine engines, air vessels, rocket exhaust cones, insulating tiles, space shuttles, windshield glass, and engine components. Increasing investment in the defense sector, improving commercial aviation networks, growth of the tourism industry, economic development, and an increase in the number of air passengers is expected to fuel aircraft production, thereby driving the demand for thermal spray coatings. Moreover, thermal spray coatings are extensively used in the aerospace industry in gas turbine engines, air vessels, rocket exhaust cones, insulating tiles, space shuttles, windshield glass, and engine components. Increasing investment in the defense sector, improving commercial aviation networks, growth of the tourism industry, economic development, and an increase in air passengers' number are expected to fuel aircraft production, thereby driving the demand for thermal spray coatings.

Key Players

MRFR has identified the following companies as the Key Players in the Global Thermal Spray Coatings Market — A&A Coatings (US), Oerlikon Group (Switzerland), BryCoat Inc. (US), Surface technology (UK), Bodycote (UK), Plasma-tec, Inc (Canada), General Magnaplate Corporation (US), ASB Industries (US), Exline, Inc (US), H. C. Starck (US), Metallisation Limited (UK), and Flame Spray Coating Company (US).

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/6053

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/polycarbonate-glazing-market-2677

https://www.marketresearchfuture.com/reports/curable-materials-market-4243

https://www.marketresearchfuture.com/reports/methacrylic-ester-market-4255

1 note

·

View note

Text

Thermal Spray Gun | Thermal Spray Coatings

Thermal Spray Gun

The thermal spray gun is a coating process in which finely divided metallic or nonmetallic materials. That consists of a heat source and a coating material in a powder. The coating material may be in the form of molten materials, powder, ceramic-rod or wire, which is melted into small droplets and sprayed onto surfaces at large velocity.

Thermal spray coating is normally utilized to metallic substrates, but also can be carried out to a few plastic substrates. This form of coatings uniquely complements and improves the performance of the thing.

Types of Thermal Spray Gun

There are numerous types of processes used to use a thermal spray coating. They may be the following:

· Metalizing Gun

· Flame Spray Gun

· Arc Spray Gun

· HVOF Gun

· Zinc Spray Gun

· Plasma Thermal Spray Gun

Metalizing Gun - In this metalizing gun the metal takes place with the help of heat. In this, heat melts the metal wire into the liquid. Then it is sprayed on the surface of the subject. On part of abrasive media, we can take rod, wire, and powder to feed inside the gun.

Flame Spray Gun – Flame Spray Gun spraying generally requires only low-cost equipment. It is appropriate for single-piece and series production may be used in both stationary and mobile configurations. Its main applications are corrosion and wear protection. The usage of wire or powder relies upon at the material and the application rate. Zinc, aluminum, and molybdenum are mostly sprayed as wire. Most metal and hard alloys are applied as a powder.

Arc Spray Gun – In this gun, two arcs of wire are generating with the help of an electric supply anode and cathode. These wires when touched generate the spark which leads to heat to the two-wire. Melts down and sprayed over the subject.

HVOF Gun - HVOF Gun known as High-Velocity Oxy-Fuel. HVOF Gun is a thermal spray system utilizing the combustion of gases or liquid. Combustion gases such as hydrogen and liquid fuel such as kerosene are used. Fuel and oxygen combine and atomize within the combustion area under conditions that monitor the correct combustion mode and pressure required for coating.

Zinc Spray Gun - In this, different abrasive media can be used for spraying on the subject. Like anti-corrosive abrasive is used for protecting the surface from corrosion. Othertime, Zinc spray gun, the Aluminum spray gun is used.

Plasma Flame Spray Gun - Plasma fire spray gun is utilized for both huge surfaces just as little inward bore widths surface coatings. Plasma spray measure incorporates the spraying of liquid or warm mollified materials onto a surface to give a covering. Plasma spray gun creates adequate energy to liquefy practically any material in powder structure makes them appropriate for an enormous assortment of surface coatings.

Working of Thermal Spray Gun

Thermal Spray coating technology sprinkle can provide you with thick coatings (approx. thickness scope is 22 microns to several mm, depending on the technique and feedstock), over a massive place at a excessive announcement fee compared to more coating strategies including electroplating, physical and chemical vapor declaration. Thermal Spray gadget is ready for thermal sprinkles to encompass metals, ceramics, alloys, plastics, and composites.

Advantages of Thermal Spray Gun

· Wear Resistance – It can improve overall product quality, reduce maintenance costs and downtime, and help improve energy efficiencies.

· Performance Enhancement – It can enhance product performance in a number of ways. A copper-based coating can be used to improve electrical conductivity.

· Extended Life – It can be used to extend the working life of treated parts and components.

Disadvantages of Thermal Spray Gun

· Disguises the substrate – They are so efficient in many cases, what material the substrate was made of after the coating process, unless stringent records are kept.

· Cannot precisely evaluate effectiveness – Once it has been applied it is often difficult to tell exactly how well the coating has gone on.

· Costly set up – It require very expensive apparatus, which can result in a high initial set up cost.

Applications of Thermal Spray Gun

· Wear Resistant Coatings against abrasion, erosion

· Corrosion-Resistant Coatings

· Heat Resistant Coatings

· Thermal Insulation or Conduction Coatings

· Electromagnetic Shielding

· Medical Coatings

Uses of Thermal Spray Gun

Thermal spray coatings are more accepted for electrical purposes. Conductive elements such as copper slag can be applied for conductors. Ceramic elements may be utilized for electrical packing. Conductive metals are more applied to magnetically shield delicate electronics.

Very solid and thick thermal spray deposits have been applied on an innovative basis as cavitations tight materials and in combination with weld overlays as a replacement technique.

Thermal Spray Gun Manufacturer in India

We manufacture the best-designed models for thermal spray gun as per their applications. The prices of thermal spray gun are within the budget of the customers, they can afford them easily. From ordering to delivering, Blast rooms give assurance of providing the best service. The thermal spray guns available here are capable of working on any type of work-piece geometry.

#Thermal Spray Gun Manufacturer in India#Thermal Spray Coatings#Plasma Flame Spray Gun#Zinc Spray Gun#Arc Spray Gun

1 note

·

View note

Text

Thermal Barrier Coatings (Tbc) Will Experience A Significant Temperature Difference When Exposed To Heat Flow.

A highly innovative or cutting-edge protective layer called thermal barrier coating (TBC) enables insulating devices to function at extremely high temperatures. It is a substance that operates at higher temperatures on metal surfaces (such gas turbine or aero-engine components), typically as a means of controlling exhaust heat. Thermal Barrier Coatings are created using a variety of materials, including epoxy resins, polymers, zirconia, aluminates, polymers, and epoxy resins. The metal base, the metallic bond coat, the thermally generated oxide (TGO), and the ceramic top coat are the four layers that make up most thermal barrier coatings.

Yttria-stabilized zirconia is the heat barrier coating material that is used the most frequently (YSZ). Due to its poor thermal conductivity, Thermal Barrier Coatings (TBC) will experience a significant temperature difference when exposed to heat flow. Turbine heat is decreased by using thermal barrier coatings. It ensures that production and performance of turbines are enhanced, increasing the overall productivity of businesses that use turbines.Growing acceptance of high-velocity oxygen fuel (HVOF) and air plasma technologies is anticipated to drive product demand for these components and their advantages across numerous sectors.

Discover More About Thermal Barrier Coating@ https://bit.ly/3NiJ7fC

0 notes

Text

High Velocity Oxygen Fuel Nozzle Spray CFD ANALYSIS

INTRODUCTION

High Velocity Oxy-Fuel(HVOF) Spray is used to coat corrodible components with resistive materials. It utilizes highly compressed fuel that combust with oxygen to accelerate the momentum and temperature of the particle and also to make the flow supersonic.

Supersonic nature of flow in an atmospheric condition producing sequential pressure expansion and contraction letting out a phenomenon called Shock Diamonds. These Shock Diamonds a.k.a pressure pulsations produced due to hyper pressure gradient with respect to atmospheric pressure.

With the aid of the CFD technology, the complex Pressure Gradient of supersonic flow nature can be vividly captured and the design progress can be accelerated. Thus, CFD is an important tool for Flow physics as it will reduce the time consuming and expensive experimental procedures.

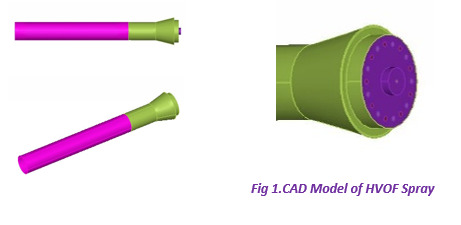

SCOPE OF THIS RESEARCH WORK

To model the combustion of fuel and oxygen in a compressed chamber.

Get a higher temperature and velocity pulsation proportional to pressure pulsation.

Injection of spray material using Discrete Phase Modelling (DPM).

MODEL ACQUISITION PROCESS

The HVOF Setup is experimentally analysed in Annamalai University, Chidambaram. From the resource the component is manually measured and the model is generated in CAD software package Pro-E Wildfire 5.0.

CFD ANALYSIS

With a goal of capturing shock diamonds of the supersonic flow of HVOF Spray, CFD is utilized in a following systematic way.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

VALIDATION STUDY

CFD procedure has lot of variables such as grid count, turbulence model, and discretization scheme, so it is important for a CFD engineer to play between those variables without affecting the solution accuracy. A commercial Computational Fluid Dynamics (CFD) code, ANSYS CFX V14.5 with a k-ε Standard turbulence model with Eddy Dissipation Model for combustion was used and the impact of supersonic flow in an atmospheric pressure and the Pressure pulsation was obtained.

The numerical results are compared with the experimental data to arrive at the best computational procedure (BCP) and Discrete Phase Modelling (DPM) is proceeded to introduce the surface coat material into the domain.

INFLUENCE OF CFD TECHNIQUE IN THIS PROBLEM

The Shock Diamond occurrence mainly depends on the hyper pressure difference between the atmosphere and combustion chamber. It depends on the flow rate of fuel, oxygen and volume of the combustion chamber.

Working with a leading Stress Analysis Services provider or well-known Product Design Companies will make new routes possible.

CONCLUSION

A Special phenomenon of Fluid flow is acquired in computational methodology

Surface Coat material injection and Combustion of fuel-oxygen is modelled

#CFDAnalysis#CFDConsultingServices#DiscretePhaseModelling#flowrate#graphlertech#HighVelocityOxy-Fuel#HVOF

0 notes