#sandblasting

Explore tagged Tumblr posts

Text

Achilles and Patroclus (Flux) 2, 3 and 4

Rad Husak

Pigment transfer and carbon pencil on sandblasted aluminum

600 × 840 mm

#rad husak#pigment transfer#sandblasting#pencil#pencil art#polish art#mixed media#mixed media art#art#artwork#drawing

13 notes

·

View notes

Text

22 July 2024, 10:25 | Woodlawn Cemetery, Sparta, Monroe County, Wisconsin

Someone was crafting and selling some fine monuments featuring beautiful shape carving around Sparta in the 20th century. This was done with the same sandblasting technology used by monument companies today, yet they don’t make em like they used to, and it’s hard to pin a reason on it. Are we as a society not willing to pay for it? Or do the monument companies see no value in trying to sell it? Are they even willing to pay a craftsperson to do it? Would people be willing to pay extra for it if it was an option? In other words, is there a market for it, and if there is not, why not? Apparently there used to be.

Has our culture devolved into a lack of art appreciation or have the artists stopped producing? And if they have, why? Is it because we don’t teach art appreciation to our children? Is it because we don’t think it has any value in our capitalist society where profit is king? Maybe all the homeless people are artists who have no job opportunities thanks to our lack of valuing what they have been given to give to the world.

The homeless people thing is an exaggeration, of course, but I do believe there are many, many unfulfilled latent artists and craftspersons in the United States. And they don’t even know it. We would all benefit, if only subconsciously, from living in a society that values its artists, because our daily experience in the world would be more beautiful.

These are the things you think about when you work on grave stones all day.

12 notes

·

View notes

Text

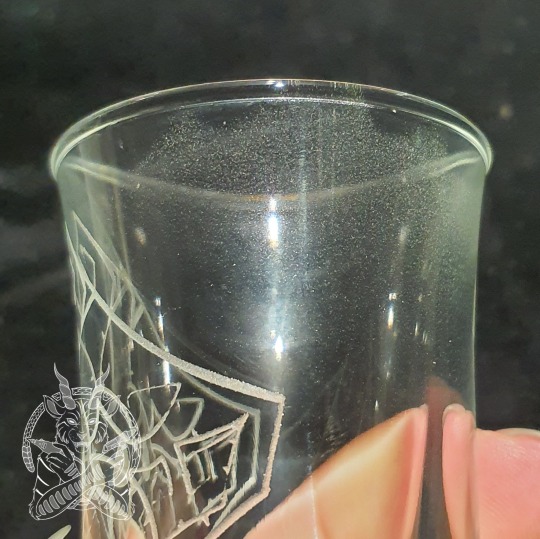

Made some shot glasses with the MSA Ghost skull emblem and spiky vines. Messed up a little and got kind of terrible overspray going on. Didn't mask off high enough nor was careful enough with the airstream direction while sandblasting, so there's some obvious frosting on the insides of three of them, and some less obvious but there-if-you-know-what-to-look-for on a fourth. One each of the big-skull-some-vines and small-skull-more-vines turned out fine.

Made these over a year ago, but didn't photograph them until today.

#msa ghost#mystery skulls animated#mystery skulls animated ghost#msa#skull#spiky vines#sandblasting#sandblasting is love sandblasting is life#shot glass#glasswork#coldworked glass#glassware#Chim made a thing#artisan crafts#artists on tumblr#fan art#fanart

42 notes

·

View notes

Text

Green and Eco-Friendly Blasting Media: Current Development, Trends, and Future Challenges

——An In-Depth Industry Analysis for Manufacturing Managers and Environmental Engineers

Introduction: The Revolution of Blasting Technology in the Era of Environmental Transformation

As global environmental regulations tighten (e.g., EU REACH, U.S. EPA standards) and the ESG (Environmental, Social, Governance) concept gains traction, the manufacturing industry is increasingly demanding sustainable surface treatment technologies. Traditional blasting media, such as silica sand and steel grit, are under scrutiny due to dust pollution, high energy consumption, and health risks. In contrast, green and eco-friendly blasting media are emerging as a core breakthrough for industry transformation. This article combines the latest market data and technological trends to analyze the current development and future challenges in this field, providing strategic insights for decision-makers.

I. Market Status: Policy-Driven Growth and Technological Advancements

1. Market Size and Growth Potential

According to Grand View Research, the global blasting media market reached $5.2 billion in 2023, with the share of eco-friendly media rising from 12% in 2018 to 28% in 2023, achieving a compound annual growth rate (CAGR) of 9.7%. By 2030, the market share of green media is expected to exceed 45%, with the Asia-Pacific region (especially China and India) becoming a growth engine due to manufacturing upgrade demands.

2. Mainstream Eco-Friendly Media Types

Plant-Based Materials (walnut shells, corn cobs): Biodegradable, low dust emission (70% less than silica sand), suitable for precision parts.

Synthetic Ceramic Particles (alumina, silicon carbide): High hardness, reusable 5-8 times, reducing long-term costs.

Ice/Dry Ice: Zero-residue technology, with over 40% penetration in the aerospace sector.

Recycled Glass Beads: Made from waste glass, reducing carbon emissions by 65% compared to traditional processes.

3. Policy and Industry Standards Driving Adoption

The EU Circular Economy Action Plan aims to increase industrial waste recycling to 70% by 2030.

China’s 14th Five-Year Plan tightens blasting dust emission limits to 10mg/m³ (previously 20mg/m³).

Automotive giants (e.g., Toyota, Volkswagen) have incorporated "green blasting certification" into supply chain standards.

II. Technological Advantages and Business Value: Why Choose Green Media?

1. Environmental Benefits

Dust Control: Plant-based media reduce dust concentration to <2mg/m³ (compared to 15-20mg/m³ for silica sand), lowering the risk of silicosis.

Carbon Reduction: Each ton of recycled glass beads reduces CO₂ emissions by 1.2 tons compared to new steel grit.

Waste Management: 95% of synthetic ceramic media can be recycled, reducing landfill costs.

2. Economic Breakthroughs

Lower Lifecycle Costs: In the automotive industry, switching to ice media reduced annual maintenance costs by 18% per production line (source: Frost & Sullivan).

Improved Efficiency: High-precision ceramic particles increase blasting speed by 30% and reduce rework rates.

III. Future Challenges: Technological Bottlenecks and Industry Collaboration

1. Technical Pain Points

Material Limitations: Plant-based media have low hardness (Mohs 2-3), making them unsuitable for hard substrates like high-strength steel.

Cost Barriers: Green media prices remain 20-50% higher than traditional materials, hindering adoption by SMEs.

Lack of Recycling Systems: Only 35% of global companies have media recycling equipment, relying on third-party processing.

2. Industry Collaboration Challenges

Lack of Standardization: Differing definitions of "eco-friendly media" across countries create barriers to cross-border procurement.

Insufficient R&D Investment: SMEs lack funding for new material testing (single certification costs exceed $50,000).

IV. Solutions: Innovation and Ecosystem Building

1. Technological Breakthrough Paths

Composite Material Development: For example, "bio-resin + ceramic" hybrid media balancing hardness and biodegradability.

Smart Blasting Equipment: AI algorithms optimize media usage, reducing waste.

Cryogenic Plasma Technology: A zero-media alternative to physical blasting (currently in the lab stage).

2. Industry Ecosystem Recommendations

Policy Subsidies: Governments should offer tax credits for green media procurement (e.g., U.S. IRA Act).

Industry Alliances: Establish cross-company recycling networks to share regeneration facilities.

Customer Education: Use Life Cycle Assessment (LCA) reports to quantify long-term benefits and boost decision-maker confidence.

V. Conclusion: Green Blasting—A Must for Sustainable Manufacturing

Eco-friendly blasting media are not just a compliance requirement but a strategic choice for cost reduction, efficiency improvement, and brand value enhancement. To overcome the dual challenges of technological evolution and market education, innovation, policy coordination, and industry collaboration are essential to transition this field from an "optional solution" to an "industry standard."

Keywords: Green blasting media, eco-friendly surface treatment, sustainable manufacturing, blasting technology trends, industrial carbon neutrality, ESG compliance

Data Sources: Grand View Research, Frost & Sullivan, European Environment Agency, China Ministry of Ecology and Environment. Further Reading:

2024 Global Surface Treatment Technology White Paper

Pathways to Carbon Neutrality in Manufacturing: Starting with Blasting Processes

2 notes

·

View notes

Text

SCARLET SWISH PUNCTUATED

Indiana limestone, partially sandblasted Spanish black marble hemisphere, patinated copper wire, cast & painted dental stone, thinned paint - 10¼"x 12½"x 1½"

All the textures on the limestone were found that way — all I did was cut the edges to help define the textures, and then used a rag with thinned paint to wipe across and accentuate the surface variations.

#sculpture#wall sculpture#my artwork#art by me#limestone#red#marble#copper#dental stone#sandblasting#found object

6 notes

·

View notes

Text

Yuriy while sandblasting the radioactive scrap metal. (Photographer, Pierpaolo Mittica.)

Inside the zone tons of metals lie abandoned, but over the years all this rusty gold has not gone unnoticed, and more or less illegally was recycled and today continues to be. Tons of metal leave the area each month. Since 2007, the Ukrainian government has legalized the recycling of radioactive metals with the blasting method. The workshop is close to the never finished number 5 and 6 reactors of the Chernobyl nuclear power plant, a huge warehouse where twelve men clean and recycle radioactive metals. Their work is terribly dangerous, almost a death sentence in slow motion, as it forces the workers to continuously inhale radioactive particles like caesium, strontium and plutonium.

From the project "Chernobyl Stories" The Ukraine 2014-2019. (source)

#yuriy#sandblasting#radioactive scrap metal#chernobyl#pierpaolo mittica#chernobyl exclusion zone#radioactive metal recycling#environmental disaster#nuclear fallout#cesium#strontium#plutonium#chernobyl stories#dangerous work#chernobyl power plant#slow motion death#photojournalism#abandoned places#radioactive contamination#ukraine#chernobyl zone#nuclear disaster aftermath#occupational hazards#industrial decay#environmental justice#human impact#radiation#nuclear power

4 notes

·

View notes

Text

✨#Pregunta✨

¿Podría Gaara hacerle sandblasting a alguien hasta quitarle la piel de los huesos?

[ENG. Trans.: Could Gaara sandblast the skin out of someone until it's bare bone?]

4 notes

·

View notes

Video

youtube

Sand Etching,How to Sandblast Glass?Mirror Sandblasting ,Frosted Glass E...

0 notes

Text

Telescopic Boom Lift Rental: Reach Higher with Safe & Reliable Equipment

For job sites requiring maximum reach and stability, a telescopic boom lift rental is the ideal solution. At EZ Equipment Rental, we provide high-quality telescopic boom lifts designed to help you work efficiently at elevated heights. Whether you’re in construction, maintenance, or industrial operations, our boom lifts offer the height and power you need to get the job done safely.

What is a Telescopic Boom Lift?

A telescopic boom lift, also known as a straight boom lift, features a long, extendable arm that provides unmatched vertical and horizontal reach. Unlike articulating boom lifts, which have multiple joints for maneuverability, telescopic boom lifts offer a direct extension, making them perfect for jobs that require maximum outreach and height.

Benefits of Renting a Telescopic Boom Lift

When you choose a telescopic boom lift rental, you gain access to several advantages, including:

✅ Extended Reach – Ideal for working on tall buildings, bridges, and large structures. ✅ Stable Performance – Designed for use on rough terrain and outdoor environments. ✅ Heavy-Duty Capacity – Supports higher weight loads for workers and tools. ✅ Increased Efficiency – Allows for quick and direct positioning at elevated heights.

Why Rent from EZ Equipment Rental?

At EZ Equipment Rental, we offer well-maintained telescopic boom lift rental options to fit your project’s needs. Here’s why customers trust us:

Top-Quality Equipment – Our lifts are inspected and maintained to ensure safety and performance. Flexible Rental Terms – Rent by the day, week, or month based on your project duration. Competitive Pricing – Affordable rental rates with no hidden fees. Expert Support – Our team helps you choose the right boom lift and provides operational guidance.

Common Applications for Telescopic Boom Lifts

A telescopic boom lift rental is commonly used for:

✔ Construction & Roofing – Reaching high structures for installation and repairs. ✔ Bridge & Highway Work – Providing access to elevated areas for maintenance. ✔ Film & Event Production – Setting up lighting and camera equipment. ✔ Warehouse & Industrial Use – Accessing high storage areas and maintenance tasks.

Rent a Telescopic Boom Lift Today!

If you need a telescopic boom lift rental, EZ Equipment Rental is here to help. Contact us today for a free quote and let us provide you with the right equipment to complete your project safely and efficiently.

#industrial equipment#equipment rental#manufacturing#dump trailer#trailers rental#forklift rental#sandblasting#construction

0 notes

Text

Sandblasting Process: Introduction, Materials Used, Pros & Cons

Sandblasting, also known as abrasive blasting, is a powerful technique used to clean, smooth, or shape surfaces by propelling a high-pressure stream of abrasive material. This method is widely applied across industries like construction and manufacturing to remove rust, paint, and other surface contaminants efficiently. Various sandblasting techniques cater to different needs, such as bead blasting for a refined finish, shot blasting for deep cleaning, and soda blasting for delicate applications. For high-quality sandblasting equipment and materials, Quality Spare Center is a reliable provider, offering premium solutions tailored to diverse requirements.

0 notes

Text

8 August 2024 | Kingston Cemetery, Sauk County, Wisconsin

Lovely rural cemetery with many fine examples of mid-20th century hand stencil cutting and sandblastmanship.

#cemetery#cemeteries#grave stone#graveyard#gravestones#stone carving#sandblasting#Viroqua stone lettering#Kingston

6 notes

·

View notes

Text

Mystery Skulls Animated glitter jar, sandblasted with the MSA skull emblem and filled with pink glitter and glow powder in mineral oil.

[Video description: Small glass jar with black plastic screw-top lid, held between thumb and index finger. Size of jar is approximately 3.5cm total height and 1.5cm in diameter. The outer surface is sandblasted with two Mystery Skulls Animated skull emblems, on opposite sides of the jar. The jar is filled with a mix of pink glitter and glow powder suspended in clear mineral oil. First part of the video is a slow turnaround of the jar, showing off the sandblasted parts. The glitter and glow powder has settled to the bottom of the jar.

Second part of the video shows the jar being flipped and twisted around to get the the glitter and glow powder cascading down and swirling around. Third part of the video is the same twirling-about thing but in the dark, to show off the pink glow. End description.]

#glitter jar#Mystery Skulls Animated#MSA#MSA Ghost#Mystery Skulls Animated Ghost#fan art#fanart#glitter#glow powder#UV reactive#glow in the dark#sandblasting#sandblasting is love sandblasting is life#glasswork#coldworked glass#glass#I will put glow powder on or in absolutely every piece of art that I can#Chim made a thing#artisan crafts#artists on tumblr

37 notes

·

View notes

Text

Enhance Surface Quality with Professional Sandblasting Services by Mythri Metallizing India

When it comes to industrial surface preparation, sandblasting stands out as one of the most effective and reliable techniques. At Mythri Metallizing India, we specialize in high-quality sandblasting services in Bangalore, ensuring superior surface treatment for various industries, including manufacturing, automotive, construction, and more.

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is a process that involves propelling fine particles or abrasives at high speed onto a surface to remove contaminants, rust, old coatings, and imperfections. This method enhances the adhesion of coatings and ensures a clean, smooth, and well-prepared surface for further treatments.

Why Choose Sandblasting Services by Mythri Metallizing India?

At Mythri Metallizing India, we offer cutting-edge sandblasting solutions designed to meet diverse industrial needs. Our expertise and advanced technology provide the following benefits:

1. Superior Surface Preparation

Our sandblasting techniques effectively remove corrosion, rust, and existing coatings, ensuring optimal surface preparation for painting, coating, and metallizing applications.

2. Advanced Equipment & Materials

We use high-performance grit blasting and abrasive media to achieve the desired surface roughness and cleanliness, complying with industry standards.

3. Customizable Solutions

We tailor our sandblasting services based on material type, surface conditions, and project requirements, ensuring the best results for steel structures, machinery parts, pipelines, and more.

4. Eco-Friendly & Safe Practices

Our sandblasting process follows strict environmental and safety regulations, utilizing dust control measures and protective equipment to ensure a hazard-free work environment.

5. Expert Team & Timely Delivery

With a skilled workforce and efficient processes, we guarantee timely project completion without compromising on quality.

Applications of Our Sandblasting Services

Our sandblasting solutions cater to various industries and applications, including:

Industrial Equipment & Machinery: Removes rust and coatings to enhance durability.

Steel Structures & Bridges: Surface cleaning for repainting and protection against corrosion.

Pipelines & Storage Tanks: Internal and external surface treatment for longevity.

Automotive & Marine: Preparation for painting and refinishing.

Construction & Infrastructure: Cleaning and prepping surfaces for concrete and metal structures.

Contact Us for Professional Sandblasting Services

If you're looking for reliable sandblasting services in Bangalore, Mythri Metallizing India is your trusted partner. We deliver top-notch abrasive blasting solutions that enhance the durability and efficiency of industrial surfaces.

📍 Location: Survey No 150 & 151,, Plot no 177/178, 11th Main Road, 3rd phase, Peenya industrial area, Bengaluru, Karnataka 560058

📞 Contact: +91-9845063120 🌐 Website: https://mythriindia.com

Ensure the longevity of your industrial assets with our expert sandblasting solutions. Get in touch with us today!

0 notes

Text

How Do Ceramic Sandblasting Beads Improve the Fatigue Resistance of Metal Parts?

1.Introduction of Surface Residual Compressive Stress

2.Optimization of Surface Roughness and Stress Distribution

3.Cleaning and Defect Removal Capabilities

Optimize your surface treatment process and obtain a customized ceramic sandblasting solution. Please contact our technical team!

2 notes

·

View notes

Text

Mythri Metallizing India

Mythri Metallizing India

Mythri Metallizing India, headquartered in Bangalore, is a thermal spray coating service provider that specializes in anti-corrosion solutions for steel structures. They have over 20 years of experience in the industry. https://mythrimetallizing.com/

Services: Mythri Metallizing India offers a range of surface finishing and anti-corrosion services, including:

Sandblasting and grit blasting

Spray galvanizing

Stress relieving

Spray painting

Thermal spray aluminum coating

Surface Preparation: Mythri Metallizing uses abrasive blasting techniques, employing materials like grit, sand, quartz, and aluminum oxide, to clean and prepare metal surfaces for coating. This process removes mill scale, oil, grease, dirt, rust, oxides, and paint to ensure proper adhesion of protective coatings.

Thermal Spraying: Mythri Metallizing applies finely divided metallic or nonmetallic materials in a molten or semi-molten state to form a coating, using methods such as electric arc spray, wire flame spray, powder flame spray, HVOF, and plasma spray. https://mythrimetallizing.com/

Zinc coatings are used to protect steel, even at cut edges or breaks, through sacrificial action.

Stress Relieving: Mythri Metallizing uses heat treatment to improve machining, formability, and ductility, enhancing product performance by increasing strength and other desirable characteristics. https://mythrimetallizing.com/

The Managing Director of Mythri Metallizing India is Madhusudhan D R, who has been in this position since January 2009. He has over 20 years of experience in thermal spray allumnization. https://mythrimetallizing.com/

0 notes