#color coated galvalume sheets

Explore tagged Tumblr posts

Text

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

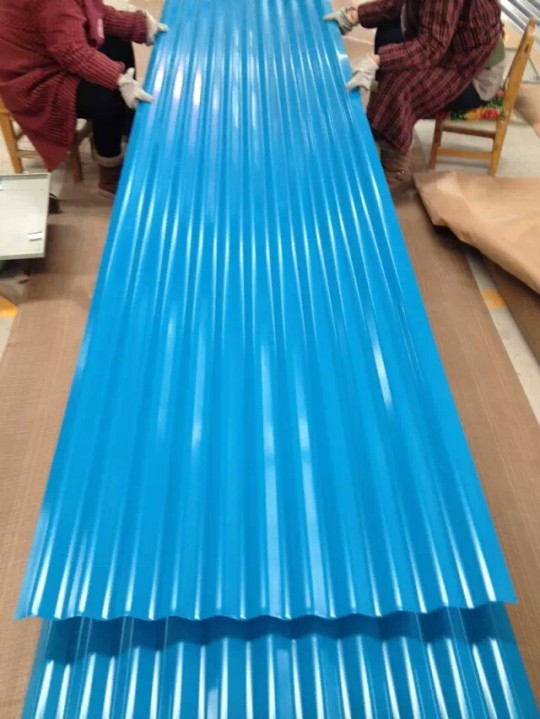

When it comes to construction materials, color-coated steel is quickly becoming a popular choice for its unique blend of aesthetics and sustainability. Available in a wide range of vibrant hues, color coated sheets and roofing sheets can instantly transform the look of any building, from residential homes to commercial properties.

The PPGI (pre-painted galvanized steel) roofing sheets and PPGL (pre-painted galvalume steel) coils used in these color-coated products not only provide a beautiful finish, but also offer superior durability and corrosion resistance. Prepainted galvanized steel coil and color coated galvalume sheets are among the top choices for PPGI steel coil manufacturers looking to meet the growing demand for visually appealing yet environmentally-friendly building materials.

As sustainability becomes an increasingly important factor in construction, color-coated steel provides the perfect solution that blends form and function.

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

Color-coated steel has emerged as a standout material in the construction industry, offering a perfect blend of aesthetics and sustainability. Its popularity is driven by a combination of visual appeal, durability, and environmental benefits. We’ll explore why color coated sheets are becoming the go-to choice for architects, builders, and homeowners alike.

Vibrant and Versatile Roofing Sheet Colors

One of the primary reasons for the growing popularity of color-coated steel is the wide variety of roofing sheet colors available. Whether you are looking for bold, vibrant shades or more subtle, earthy tones, there is a color coated roofing sheet to match any design vision. These sheets add a modern and stylish look to buildings, enhancing their curb appeal and value.

Durable and Long-Lasting PPGI Roofing Sheets

PPGI (Pre-Painted Galvanized Iron) roofing sheets are a popular type of color coated sheet. They are made by applying a layer of paint over galvanized steel, resulting in a product that is both aesthetically pleasing and highly durable. PPGI roofing sheets are resistant to corrosion, weathering, and UV radiation, ensuring they maintain their appearance and functionality over time. This makes them an excellent investment for any building project.

High-Quality Prepainted Galvanized Steel Coil

Prepainted galvanized steel coils are the raw material used to produce various color coated sheets. These coils undergo a thorough manufacturing process that includes cleaning, pre-treatment, painting, and curing, resulting in a high-quality product that meets stringent standards. PPGI steel coil manufacturers are dedicated to producing coils that offer superior performance, ensuring that the end products, like roofing sheets, are of the highest quality.

Sustainable Building Material

Color-coated steel is not only about aesthetics and durability; it is also a sustainable choice. The steel used in these products is often recycled, reducing the demand for virgin materials and minimizing environmental impact. Additionally, the coatings used on these sheets are designed to be environmentally friendly, with minimal VOC (Volatile Organic Compounds) emissions. Choosing color coated roofing sheets can contribute to greener building practices and a more sustainable future.

Versatility of Color Coated Galvalume Sheets

Color coated galvalume sheets offer another excellent option for construction projects. Galvalume is a steel sheet coated with a zinc-aluminum alloy, which provides enhanced corrosion resistance. When combined with a color coating, these sheets offer both superior durability and a stylish appearance. They are ideal for a wide range of applications, from residential roofing to commercial and industrial buildings.

Innovative PPGL Solutions

PPGL (Pre-Painted Galvalume) is similar to PPGI but uses a galvalume substrate instead of galvanized steel. This combination of galvalume’s corrosion resistance and the aesthetic benefits of pre-painting results in a product that is perfect for demanding environments. PPGL sheets are particularly well-suited for coastal areas and regions with harsh weather conditions, providing long-lasting protection and beauty.

Reliable PPGI Steel Coil Manufacturers

The quality of color coated sheets depends heavily on the manufacturers producing the raw materials. Reputable PPGI steel coil manufacturers ensure that their products meet high standards of quality and performance. They invest in advanced technology and rigorous quality control processes to produce coils that offer excellent consistency and reliability. Choosing products from these manufacturers guarantees that your color coated roofing sheets will meet or exceed your expectations.

Cost-Effective and Low Maintenance

In addition to their aesthetic and environmental benefits, color-coated steel sheets are also cost-effective and require minimal maintenance. Their durability means they need fewer repairs and replacements over time, saving money in the long run. Furthermore, the coatings on these sheets are designed to withstand the elements, reducing the need for frequent painting or cleaning. This makes them a practical choice for both residential and commercial buildings.

Easy Installation and Customization

Color-coated steel sheets are lightweight and easy to install, which can significantly reduce construction time and labor costs. They can be customized to fit specific design requirements, offering flexibility in architectural design. Whether you need sheets cut to size or specific shapes, manufacturers can provide products tailored to your project’s needs. This versatility makes color-coated steel an attractive option for a wide range of building applications.

Enhancing Energy Efficiency

Many color-coated steel products come with reflective coatings that can help improve a building’s energy efficiency. These coatings reflect more sunlight, reducing heat absorption and helping to maintain a cooler indoor environment. This can lead to lower energy costs for cooling, making color-coated roofing sheets a smart choice for energy-conscious builders and homeowners.

Color-coated steel represents a perfect blend of aesthetics and sustainability, offering a range of benefits that make it an excellent choice for modern construction projects. By choosing color-coated steel, you are investing in a product that enhances the visual appeal of your building, supports sustainable practices, and offers long-term cost savings. Whether for residential, commercial, or industrial applications, color-coated steel is a superior choice for today’s construction needs of aesthetics and sustainability.

Conclusion

As the construction industry continues to evolve, the demand for building materials that merge stunning aesthetics with eco-friendly credentials is higher than ever before.

Color-coated steel, with its vibrant color options, superior durability, and impressive sustainability, is perfectly positioned to meet this growing need. From PPGI roofing sheets and color coated roofing sheets to PPGI color coated sheets and color coated galvalume sheets, the versatility of this material allows it to be seamlessly integrated into a wide range of architectural styles.

PPGI steel coil manufacturers are further enhancing the appeal of color-coated steel by continuously improving their production processes to reduce the environmental impact. As homeowners and businesses prioritize sustainability alongside visual appeal, color-coated steel emerges as the ideal solution - a perfect blend of form and function that is poised to transform the future of the built environment.

0 notes

Text

Introduction

In the world of modern construction, the durability and aesthetic appeal of a building often come down to the materials used for roofing. Color-coated sheets have emerged as a leading choice for builders and architects among the many available options. These sheets, made from materials like galvanized steel or aluminum and then coated with a protective layer of paint, offer an impressive balance of functionality, aesthetics, and longevity. One of their most outstanding features is their exceptional weather resistance, making them the perfect solution for roofs in various climates.

In this article, we’ll explore why color-coated sheets are ideal for weather-resistant roofing and how they deliver superior protection while maintaining their look and functionality over time.

1. Superior Weather Resistance

Color coated sheets are specifically designed to withstand the elements, making them an excellent choice for regions with extreme weather conditions. Whether it’s scorching sun, heavy rainfall, snow, or high winds, these sheets provide reliable protection to a building.

UV Protection and Heat Resistance

In hot climates, roofs are subjected to intense sunlight, which can degrade roofing materials over time. Color coated sheets come with a UV-resistant coating that helps reduce the wear and tear caused by constant exposure to the sun. The reflective properties of the color coating also help in minimizing heat absorption, which keeps the building cooler. This feature not only extends the lifespan of the roof but also contributes to energy efficiency by reducing the need for air conditioning.

Corrosion Resistance in Humid and Coastal Areas

One of the major concerns for roofing materials in humid or coastal areas is corrosion due to moisture and salt-laden air. Color coated sheets are designed with anti-corrosive properties, making them highly resistant to rust and degradation even in such harsh environments. The protective layers prevent water or humidity from seeping through and causing structural damage, ensuring the roof remains strong and intact for years.

2. Durability and Long Life Span

The multi-layer coating on color coated sheets is what gives them their impressive durability. Typically, these sheets are made from a base material like galvanized steel, which is then coated with zinc and finished with a high-quality paint or polymer coating. This process ensures that the sheets are highly resistant to mechanical wear, chemical exposure, and weather elements.

Protection from Rain and Snow

Heavy rainfall or snow accumulation can lead to moisture buildup, which often causes traditional roofing materials to degrade over time. However, color coated sheets are specifically engineered to provide an impermeable barrier that prevents water from penetrating through. This ensures that the underlying structure remains dry and unaffected, preventing issues like rust, mold, and leaks. Additionally, in areas prone to snowfall, color coated sheets can shed snow more easily, reducing the stress on the roof.

Wind and Impact Resistance

In areas prone to storms or strong winds, roofing materials need to be able to withstand impact from flying debris or heavy gusts of wind. Color coated sheets, especially those made from high-strength steel, offer superior impact resistance, preventing dents, cracks, or damage that could compromise the roof’s integrity. Their lightweight nature also makes them less susceptible to being lifted or dislodged by strong winds, adding to their long-term durability.

3. Energy Efficiency

Color coated sheets offer energy efficiency benefits, particularly in climates where temperature control is critical. The reflective surface of these sheets helps to reduce heat absorption during hot months, which in turn keeps the building cooler and reduces the reliance on cooling systems.

Thermal Reflectivity

The special coating on these sheets is designed to reflect solar radiation rather than absorb it. This helps keep the interior temperature of the building lower, reducing the need for constant air conditioning. Over time, this can result in significant energy savings and contribute to a building's overall energy efficiency.

Insulation Capabilities

Many color coated sheets are available with additional insulation layers or coatings that help further reduce heat transfer. This is especially useful for buildings in colder climates, where the insulation properties help retain warmth and reduce heating costs.

4. Aesthetic Appeal and Versatility

Color coated sheets are not just functional; they are also aesthetically pleasing. Available in a wide range of colors, finishes, and textures, these sheets allow architects and builders to achieve a modern, clean look for both residential and commercial properties.

Customizable Appearance

One of the primary advantages of using color coated sheets is the variety of options they offer. The color coating is available in numerous shades, from earthy tones to vibrant, eye-catching hues. Builders can choose colors that complement the overall design of the building, giving it a polished and sophisticated appearance.

Glossy and Matte Finishes

Depending on the aesthetic preferences of the project, color coated sheets can be finished in either glossy or matte textures. This allows for greater versatility in design, whether the goal is to create a sleek, modern look or a more understated, traditional appearance.

5. Low Maintenance and Cost-Effectiveness

One of the significant advantages of color coated sheets is their low maintenance requirements. Once installed, they require minimal upkeep to retain their protective and aesthetic qualities. The durable paint finish prevents the need for frequent repainting or treatment, even after prolonged exposure to the elements.

Easy Cleaning and Maintenance

Thanks to their smooth surface, color coated sheets are easy to clean and maintain. Dirt, dust, and debris can be washed away with simple water, and the coating prevents any damage from environmental pollutants. This helps maintain the sheet’s aesthetic appeal and structural integrity without the need for costly maintenance interventions.

Long-Term Cost Savings

Although color coated sheets might have a slightly higher upfront cost compared to traditional roofing materials, their long lifespan and minimal maintenance requirements lead to significant long-term cost savings. The weather-resistant properties of the coating extend the life of the roof, reducing the need for repairs or replacements. Additionally, the energy savings provided by the sheets’ reflective properties make them a cost-effective option for the long term.

6. Environmental Sustainability

As the construction industry increasingly focuses on sustainability, color coated sheets stand out as an environmentally friendly roofing option. Many manufacturers produce these sheets using recycled materials, and the durability of the product ensures a longer lifespan, which reduces the need for frequent replacements and the associated environmental impact.

Recyclable and Eco-Friendly

Most color coated sheets, particularly those made from metal, are fully recyclable. At the end of their long service life, they can be recycled and repurposed, reducing waste and contributing to sustainability goals. The eco-friendly coatings used on these sheets also have low environmental impact, making them an ideal choice for green building projects.

Conclusion

Color coated sheets are the perfect choice for weather-resistant roofing because they offer a combination of durability, energy efficiency, aesthetic flexibility, and low maintenance. Their ability to withstand extreme weather conditions—intense sun, heavy rain, snow, or high winds—makes them a reliable and long-lasting roofing solution. Furthermore, their sustainable design and energy-saving benefits ensure that they contribute to the overall efficiency and environmental goals of any building project. By choosing color coated sheets for roofing, builders can ensure the structure remains protected while enhancing its visual appeal for years to come.

0 notes

Text

#Galvanized steel coil#SGCC#DX51/52/52/54#E-galvanized steel coil#SECC#Galvanized steel tube#galvalume steel coil#Color coated steel coil#roofing sheet#Stone roofing sheet#Aluminum foil#Aluminum coil#Prepainted Aluminum coil#Stainless steel coil#Aluminum steel tube#■ Shanghai AIYIA Industrial Co.#Ltd.#■ Projects Manager | Mrs Elena#■ Phone: +86 21 63768818#■ Mobile: +86 17717619167#■ Website: www.shaiyia.com#■ Email:[email protected]

1 note

·

View note

Video

youtube

Color coated prepainted galvanized coil ppgi prepainted galvanized steel...

#Corrugated Iron Sheets Galvanized Roofing Sheet#colored coated steel coil galvanized coil#galvalume roofing tile#colour stone coated roofing tile#polygold pre-coated steel coil

0 notes

Text

PPGI and PPGL Sheets Supplier in Rajasthan

Meghmani Metal Industries is a Manufacturer and Supplier of PPGI and PPGL Sheets in in Rajasthan, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. What is PPGI? PPGI sheets are made of galvanized iron coated with a layer of paint. The galvanization process involves coating steel with zinc to prevent rust and corrosion, while the pre-painted layer provides additional protection and color. What is PPGL? PPGL sheets are similar to PPGI but utilize a Galvalume substrate, which is a combination of zinc and aluminum. This combination offers superior corrosion resistance and thermal performance, making PPGL sheets an excellent choice for harsh environments. Features of PPGI and PPGL Sheets: Corrosion Resistance: Both materials are designed to withstand harsh weather conditions. Aesthetic Appeal: Available in various colors and finishes, PPGI and PPGL sheets enhance the visual appeal of structures. Lightweight: Easy to handle and install, reducing labor costs. Versatility: Suitable for residential, commercial, and industrial applications. Thermal Efficiency: PPGL, in particular, offers better thermal insulation properties. Applications of PPGI and PPGL Sheets Roofing Wall Cladding Industrial Sheds Fencing Home Appliances What is the difference between PPGI and PPGL sheets? Manufacturers create PPGI sheets from galvanized steel, while they produce PPGL sheets from Galvalume, which contains both zinc and aluminum. PPGL generally offers better corrosion resistance and thermal performance. How do I maintain PPGI and PPGL sheets? Regular cleaning with water and mild detergents is recommended. Avoid abrasive cleaners to preserve the finish. Meghmani Metal Industries is PPGI and PPGL Sheets Supplier in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Understanding the Role of Color Psychology in Product Design and Branding with Color Coatings

Introduction

Color has a powerful influence on our emotions, perceptions, and decision-making processes. This phenomenon, known as color psychology, plays a crucial role in product design and branding, especially when it comes to color coated sheets used in various construction and manufacturing applications.

Whether you’re a PPGI steel coil manufacturer, a contractor working with color coated sheets, or a business owner looking to enhance your brand's visual identity, understanding the impact of color can help you make more informed choices. From the calming hues of color coated galvalume sheets to the bold statements made by PPGI color coated sheets, the right color can significantly impact the way your products are perceived and the emotions they evoke in your target audience.

In this blog post, we’ll explore the science behind color psychology, delving into how different colors can influence purchasing decisions, brand recognition, and overall product appeal. By the end, you’ll have a deeper understanding of how to leverage the power of color coatings to enhance your product design and branding efforts.

Understanding the Role of Color Psychology in Product Design and Branding with Color Coatings

Color plays a vital role in our lives, influencing our emotions, perceptions, and decisions. In the world of product design and branding, understanding color psychology can make a significant difference. When it comes to using color coatings like color coated sheets, color roofing sheets, and pre-painted galvanized steel coils (PPGI), the choice of color can impact not only the aesthetic appeal but also the market success of a product.

Emotional Impact

Colors evoke specific emotions. For example, blue often conveys trust and calmness, making it a popular choice for brands in the finance and health sectors. Red can evoke excitement and urgency, useful for promotions and sales. When you choose PPGI color coated sheets or color coated galvalume sheets for your product design, consider the emotional response you want to elicit from your customers.

Brand Identity

Colors are a powerful tool in establishing brand identity. Think of iconic brands like Coca-Cola with its vibrant red or Apple with its sleek silver and white. These color choices are not random; they are carefully selected to communicate the brand’s values and personality. When designing products with color coated sheets or PPGL, selecting colors that align with your brand’s identity can help reinforce brand recognition and loyalty.

Market Differentiation

In a crowded market, standing out is crucial. Unique and strategic use of color can differentiate your products from competitors. For instance, using a distinct color for your pre-painted galvanized steel coil products can make them instantly recognizable. PPGI steel coil manufacturers often offer a wide range of colors, allowing businesses to find the perfect shade that sets their products apart.

Consumer Behavior

Colors can influence consumer behavior and purchasing decisions. Studies have shown that certain colors can increase appetite, enhance the perception of warmth or coolness, and even affect the perceived value of a product. When you buy color coated sheets for your product designs, keep in mind how these colors will be perceived by your target audience and how they can drive sales.

Product Functionality and Aesthetics

The functional aspect of color coatings cannot be ignored. For example, color roofing sheets not only add to the visual appeal of a building but also provide practical benefits like heat reflection and UV protection. Similarly, PPGI color coated sheets and color coated galvalume sheets offer durability and corrosion resistance while adding an attractive finish. Balancing aesthetics with functionality is key in product design.

Cultural Significance

Colors carry different meanings in different cultures. Red might symbolize luck and prosperity in one culture but warning and danger in another. Understanding the cultural context of your target market is essential when selecting colors for PPGI or PPGL products. This cultural awareness ensures that your color choices resonate positively with your audience.

Sustainability and Perception

With growing awareness of environmental issues, the use of sustainable and eco-friendly materials is becoming increasingly important. When consumers see products made with sustainable coated steel, it can enhance the brand’s image as responsible and forward-thinking. Highlighting the eco-friendly nature of your color coated sheets can attract environmentally conscious customers.

Consistency Across Mediums

Consistency in color usage across all marketing mediums strengthens brand recognition. Whether it’s on the packaging, in digital media, or the products themselves, maintaining a consistent color palette helps establish a cohesive brand image. Using pre-painted galvanized steel coils with uniform color schemes ensures that your products remain consistent in appearance, enhancing brand trust.

Color psychology is a powerful tool in product design and branding. The use of color coatings, such as PPGI color coated sheets, color coated galvalume sheets, and other coated steel products, goes beyond mere aesthetics. It influences emotions, reinforces brand identity, differentiates products in the market, and impacts consumer behavior. When you buy color coated sheets for your products, consider the psychological and cultural implications of your color choices. This strategic approach can lead to enhanced brand recognition, increased sales, and a stronger connection with your target audience.

Conclusion

As we’ve discovered, color psychology plays a vital role in product design and branding, particularly when it comes to the use of color coated sheets. Whether you’re a PPGI steel coil manufacturer offering a range of pre-painted galvanized steel coils, a contractor working with color coated galvalume sheets, or a business owner aiming to enhance your brand’s visual identity, understanding the impact of color can help you make strategic decisions that resonate with your target audience.

By leveraging the principles of color psychology, you can create color coated sheets and other products that evoke the right emotions, enhance brand recognition, and ultimately drive sales. From the calming tones of muted color roofing sheets to the bold statements made by PPGI color coated sheets, the right color choices can make all the difference in the success of your products and your brand. As you move forward, continue to explore the power of color and how it can be harnessed to create truly captivating and impactful designs. The future of color coated sheet solutions is bright, and understanding color psychology will be the key to unlocking its full potential.

#ppgi roofing sheet#colour coated sheet#prepainted galvanized steel coil#PPGL#colour coated galvalume sheet

0 notes

Text

Unveiling the Innovation of PPGL: Enhancing Sustainability in Construction

In the realm of construction materials, PPGL has emerged as a cutting-edge solution that combines the durability of galvanized steel with the aesthetic versatility of painted surfaces. From roofing to architectural applications, PPGL offers a myriad of benefits that make it a preferred choice in modern building projects. Here’s an insightful exploration into what PPGL is and why it is gaining prominence across different sectors.

What is PPGL?

PPGL, which stands for Pre-Painted Galvalume, is a coated steel product that combines the corrosion resistance of galvalume steel with a protective layer of paint applied before it is formed into sheets or coils. This dual protection ensures superior durability and aesthetic appeal, making PPGL suitable for a wide range of applications in construction and manufacturing.

Advantages of PPGL

PPGL offers several advantages that contribute to its popularity and widespread use:

Corrosion Resistance: The galvalume coating provides excellent corrosion resistance, while the paint layer adds an additional barrier against the elements, ensuring long-lasting protection for buildings and structures.

Aesthetic Versatility: PPGL is available in a variety of colors, textures, and finishes, allowing architects and designers to achieve their desired aesthetic vision without compromising on durability or performance.

Durability: PPGL is known for its strength and durability, making it suitable for harsh environments and demanding applications where resilience is essential.

Environmental Sustainability: PPGL is made from recycled materials and is recyclable at the end of its lifespan, contributing to sustainable building practices and reducing environmental impact.

Applications of PPGL

PPGL finds extensive applications across various industries and projects:

Roofing: It is widely used for roofing residential homes, commercial buildings, and industrial facilities due to its durability, weather resistance, and aesthetic appeal.

Cladding: PPGL serves as an attractive and protective cladding material for walls and facades, enhancing the architectural style and longevity of buildings.

Automotive and Appliances: In the manufacturing sector, PPGL is used for automotive components, appliances, and other consumer goods due to its strength, formability, and corrosion resistance.

Building a Sustainable Future with PPGL

PPGL continues to redefine standards in construction materials, offering a blend of durability, aesthetic versatility, and environmental sustainability. Whether enhancing the durability of rooftops, elevating architectural designs, or reinforcing industrial structures, PPGL remains at the forefront of innovation in building materials. As the demand for resilient and sustainable solutions grows, PPGL stands as a testament to advancing technologies that support a greener and more resilient future for construction worldwide.

0 notes

Text

Dear friend: Have a nice day . I am KONNON from Shandong Xinghan Materials Co., Ltd. The company has passed the international quality management system, energy management system, and occupational health and safety management system. Recognized as a provincial and municipal key export and foreign exchange earning enterprise. The company has 18 main production lines for pickling, cold rolling, hot-dip galvanizing, hot-dip galvalume, thick plate galvanizing, galvanized aluminum-magnesium, color-coated coils, corrugated sheets, etc., with an annual output of 1 million tons of pickling coils. , a production capacity of 1 million tons of cold-rolled coils. 900,000 tons of rolled steel plates. The scale of hot-dip galvanized, hot-dip aluminum-zinc silicon steel plate, thick galvanized steel plate is 450,000 tons, and color-coated steel plate is 300,000 tons. We produce various types of high-quality plates with a thickness of 0.12-2.5mm and a width of less than 1250mm. Among them, the special product high-strength and ultra-thin series steel plates are favored by foreign customers and have been exported to more than 100 countries and regions such as Africa, the European Union, South America, Southeast Asia, Central Asia, etc. Areas, mainly used in roofs, wall construction, color-coated substrates and automobile industry and other fields and areas. We value every partner and look forward to your arrival. You are welcome to visit the factory. Could you please tell me the detailed specifications of the product I need, such as (zinc layer, paint film, material, hardness, tensile strength, elongation, yield, hardness, how many tons are needed, port of receipt, etc.) These data will help I will provide you with the best quality, best service, and guaranteed after-sales at competitive prices. Sending you my best wishes. KONNON Shandong Xinghan Materials Co., Ltd. International Business Department 1 sales Manager Email: [email protected] Company website: www.xinghantudu.com WhatsApp: +8613082787470 https://zggb.en.alibaba.com/Fully

0 notes

Text

Galvalume Metal Roof

The Superiority of Galvalume Metal Roofs: A Wise Choice for Durability and Sustainability

In the realm of roofing materials, the choice often comes down to durability, sustainability, and longevity. Galvalume metal roofing has emerged as a premier option, redefining the standards of roofing solutions. Comprising steel coated with a mixture of zinc and aluminum, Galvalume exhibits exceptional strength, corrosion resistance, and environmental sustainability. This article delves into the myriad benefits that make Galvalume metal roofs a wise choice for homeowners and businesses alike.

Durability and Longevity

One of the most prominent advantages of Galvalume metal roofs is their durability. The combination of steel and protective coatings provides exceptional resistance against corrosion, chipping, and general wear and tear. This durability ensures that the roof can withstand harsh weather conditions such as heavy rains, snow, hail, and intense sunlight without compromising its integrity. This longevity often translates into reduced maintenance costs and fewer repairs over the roof's lifespan.

Excellent Corrosion Resistance

Galvalume roofs owe their exceptional resistance to corrosion to the synergistic effect of zinc and aluminum. Zinc offers sacrificial protection, corroding preferentially to safeguard the underlying steel. The addition of aluminum further enhances this protection, forming a robust oxide layer that shields the steel from environmental elements. As a result, Galvalume roofs can last significantly longer than traditional roofing materials, providing a reliable barrier against rust and corrosion.

Energy Efficiency and Environmental Sustainability

Beyond durability, Galvalume metal roofs contribute significantly to energy efficiency. The reflective properties of the coating reduce heat absorption, keeping buildings cooler during hot weather. This leads to lower energy consumption for air conditioning, consequently reducing carbon emissions and energy bills. Moreover, the use of recyclable materials in Galvalume production aligns with sustainability goals, as these roofs can be recycled at the end of their lifecycle, reducing environmental impact.

Variety in Design and Aesthetics

Contrary to the misconception that metal roofs lack aesthetic appeal, Galvalume offers a diverse range of design options. Homeowners can choose from various profiles, colors, and textures to complement the architectural style of their property. From sleek and modern designs to mimicking the appearance of traditional roofing materials like tile or wood, Galvalume metal roofs offer versatility without compromising on durability or performance.

Fire Resistance and Safety

Galvalume metal roofs are highly fire-resistant, providing an added layer of safety for homes and commercial buildings. The non-combustible nature of steel makes it an excellent choice in areas prone to wildfires or regions where fire safety is a concern. This fire resistance not only protects the structure but also adds to the overall safety measures, potentially reducing insurance premiums for property owners.

Installation Efficiency and Cost-effectiveness

Another significant advantage of Galvalume metal roofs lies in their installation efficiency. These roofs are lightweight, which simplifies the installation process and reduces labor costs. Additionally, their durability and low maintenance requirements contribute to long-term cost-effectiveness, making them a wise investment for property owners looking for a reliable and economical roofing solution. Galvalume metal roofs stand as a testament to innovation, combining durability, sustainability, and aesthetic appeal in one roofing solution. Their exceptional resistance to corrosion, longevity, energy efficiency, and fire resistance make them a superior choice for homeowners and businesses seeking long-term value and peace of mind. As the demand for resilient and sustainable building materials grows, Galvalume metal roofs continue to shine as an exemplary choice, offering a blend of performance, aesthetics, and environmental responsibility. Embracing Galvalume roofing signifies a commitment to a durable, eco-friendly, and aesthetically pleasing roofing solution that stands the test of time.

1 note

·

View note

Text

Breaking Down the Cost-Effectiveness of Color Coating Solutions

Color coated sheets, whether for roofing, siding, or other construction applications, have become increasingly popular in recent years. These pre-painted galvanized steel or galvalume sheets offer a range of benefits, from improved aesthetics to enhanced durability. But how cost-effective are these color coating solutions compared to traditional options?

In this blog post, we’ll dive into the various factors that contribute to the overall cost-effectiveness of color coated sheets. We’ll examine the upfront costs of the material itself, as well as the long-term savings from improved lifespan and reduced maintenance. By comparing PPGI color coated sheets, color coated galvalume sheets, and other coated steel options, we’ll help you understand the true value proposition of these innovative products.

Whether you’re a contractor, a homeowner, or a manufacturer of PPGI steel coils, this post will provide valuable insights to help you make informed decisions when sourcing color coated sheet materials for your next project. Let’s explore the cost-effectiveness of these versatile and attractive solutions together.

Breaking Down the Cost-Effectiveness of Color Coating Solutions

When it comes to choosing materials for roofing and cladding, cost-effectiveness is a key consideration. Color coating solutions, including options like color coated sheets, color roofing sheets, and pre-painted galvanized steel coils (PPGI), offer a variety of benefits that make them a smart investment. Here's a breakdown of why these materials are not only popular but also economically viable.

Durability and Longevity

One of the primary advantages of color coated sheets and color roofing sheets is their durability. These materials are designed to withstand harsh weather conditions, resist corrosion, and maintain their aesthetic appeal over time. PPGI color coated sheets and color coated galvalume sheets, in particular, are treated with special coatings that enhance their resistance to rust and environmental damage. This means fewer repairs and replacements over the years, translating into significant cost savings.

Low Maintenance

Another cost-effective aspect of color coated sheets is their low maintenance requirements. Traditional roofing and cladding materials often need frequent upkeep to prevent degradation, but color coated solutions like PPGI steel coils and PPGL sheets require minimal maintenance. Their coated surfaces repel dirt and grime, reducing the need for regular cleaning and associated costs.

Energy Efficiency

Color coated sheets can also contribute to energy savings. Many of these products have reflective coatings that help to deflect sunlight, keeping buildings cool in hot weather. This can reduce the reliance on air conditioning, leading to lower energy bills. When you buy color coated sheets, you are not just investing in a durable material but also in energy efficiency that pays off over time.

Aesthetic Appeal and Versatility

Color coated solutions offer a wide range of colors and finishes, providing versatility for various architectural styles. This aesthetic flexibility can enhance the visual appeal of a building, potentially increasing its market value. Whether you’re using pre-painted galvanized steel coils for an industrial look or color coated galvalume sheets for a sleek modern finish, these materials provide a cost-effective way to achieve a desired aesthetic without compromising on quality.

Ease of Installation

The installation process for color coated sheets is typically straightforward, reducing labor costs. PPGI steel coil manufacturers design their products to be lightweight and easy to handle, making installation quicker and less labor-intensive compared to heavier, more cumbersome materials.

Cost Comparison

When compared to other roofing and cladding materials, color coated sheets are often more affordable upfront. However, their true cost-effectiveness becomes evident when considering the total cost of ownership. Factors like durability, low maintenance, energy savings, and ease of installation all contribute to a lower overall expenditure over the lifespan of the material.

Color coating solutions like PPGI color coated sheets, color coated galvalume sheets, and other coated steel products offer a blend of durability, low maintenance, energy efficiency, aesthetic appeal, ease of installation, and environmental benefits. These factors make them a highly cost-effective choice for both residential and commercial applications. When looking to buy color coated sheets, it's important to consider these long-term benefits, which can significantly outweigh the initial costs, making them a smart and economical investment for any building project.

Conclusion

In conclusion, the cost-effectiveness of color coated sheets is a complex equation that considers upfront costs, long-term durability, and maintenance savings. While the initial investment in PPGI color coated sheets or color coated galvalume sheets may be higher than traditional options, the benefits often outweigh the additional expense.

By choosing high-quality pre-painted galvanized steel coils or other coated steel products from reputable PPGI steel coil manufacturers, you can unlock the true value of color coating solutions. These materials offer enhanced aesthetics, improved weatherproofing, and reduced maintenance requirements, leading to significant cost savings over the lifespan of your project.

Whether you’re a contractor looking to offer your clients the best value, or a homeowner seeking to upgrade your property, carefully evaluating the cost-effectiveness of color coated sheets can help you make the most informed decision. Invest in the long-term performance and visual appeal of your project by exploring the world of color coated sheet solutions today.

#colour coated sheet#ppgi roofing sheet#colour coated roofing sheets price#colour roofing sheet price#PPGL#Coated Steel

0 notes

Text

our company is a Chinese company that produces galvanized, galvalume and stainless steel metals. For example: galvanized sheet, galvanized coil, color-coated sheet and other products.

If you are interested in our products, please tell me your needs: products, materials, specifications and quantities, etc., I will serve you with the best price and best service! Also feel free to contact me if you have any questions. Call me!

Lily

Company Name: Shandong Dingxinda Metal Manufacturing Co., Ltd.

watsapp: +86 155 5325 3390

Email:[email protected]

0 notes

Text

#Galvanized steel coil#SGCC#DX51/52/52/54#E-galvanized steel coil#SECC#Galvanized steel tube#galvalume steel coil#Color coated steel coil#roofing sheet#Stone roofing sheet#Aluminum foil#Aluminum coil#Prepainted Aluminum coil#Stainless steel coil#Aluminum steel tube#■ Shanghai AIYIA Industrial Co.#Ltd.#■ Projects Manager | Mr Chris#■ Phone: +86 21 63768288#■ Mobile: +86 17717628692#■ Website: www.shaiyia.com#■ Email:[email protected]

0 notes

Link

Pushpak Infrasteel is best roofing sheet, Color Roofing Sheets, Metal Roofing Tile Profile Sheets, Color Coated Sheets, Industrial Roofing Sheets, Decking Sheets, Floor Decking Sheets, Metal Decking Sheets, Metal Floor Decking Sheet, Steel Decking Sheets, Profile Sheets, Color Coated Profile Sheets, Pre-Coated Profile Sheets, Color Profile Sheets, Galvalume Profile Sheets, Profile Roofing Sheets, Steel Deck Profile Sheets, Composite Metals Deck Profile Sheets and Composite Deck Profile Sheets Manufacturer company in pune, Maharashtra, India

#Roofing Sheets manufacturer#Color Roofing Sheets manufacturer#Metal Roofing Sheet manufacturer#Metal Roofing Tile Profile Sheets manufacturer#Color Coated Sheets manufacturer#Industrial Roofing Sheets manufacturer#Decking Sheets manufacturer#Floor Decking Sheets manufacturer#Metal Decking Sheets manufacturer#Metal Floor Decking Sheet manufacturer#Steel Decking Sheets manufacturer#Profile Sheets manufacturer#Color Coated Profile Sheets manufacturer#Pre-Coated Profile Sheets manufacturer#Color Profile Sheets manufacturer#Galvalume Profile Sheets manufacturer#Profile Roofing Sheets manufacturer#Steel Deck Profile Sheets manufacturer#Composite Metals Deck Profile Sheets manufacturer#Composite Deck Profile Sheets manufacturer#pune#Maharashtra#India.

0 notes

Text

“Why You Should Consider Steel roofing for Your Commercial Project”

Introduction

In today’s fast-paced world, the choice of roofing for commercial local roof repair Austin projects is more crucial than ever. With various materials available in the market, each claiming to be the best, how do you decide? If you're grappling with this question, let me introduce you to a game-changer: steel roofing. This article will delve deep into “Why You Should Consider Steel Roofing for Your Commercial Project,” outlining all the benefits and considerations that come along with it.

Steel roofing has gained immense popularity among commercial roofing solutions, thanks to its durability, sustainability, and aesthetic appeal. Whether you're building a new structure or replacing an existing roof, steel roofing offers a myriad of advantages that may be just what your project needs.

What is Steel Roofing?

Before diving into its benefits, let’s understand what steel roofing entails. Steel roofing consists of panels or shingles made from steel sheets coated with protective layers to resist corrosion and rust. These roofs are available in various styles and colors, making them versatile for different architectural designs.

Types of Steel Roofing Materials Galvanized Steel: Coated with zinc to prevent rusting. Galvalume Steel: A combination of aluminum and zinc for added protection. Stainless Steel: Offers superior corrosion resistance but at a higher cost. Tin Roofing: An older form but still used in some applications.

Each type has unique properties and uses, making it essential to choose the right one based on your project's needs.

Benefits of Choosing Steel Roofing Durability That Lasts Decades

When considering roofing materials, durability is paramount. Steel roofs can withstand harsh weather conditions like heavy snow loads, high winds, and severe rain without compromising structural integrity. Most manufacturers offer warranties ranging from 20 to 50 years, making them an excellent long-term investment.

Did You Know?

Steel roofs can last up to 70 years with proper roof inspection austin maintenance! That’s nearly double the lifespan of traditional asphalt shingles.

Energy Efficiency

One significant aspect of steel roofing is its energy efficiency. The reflective surface can significantly reduce cooling costs during hot months by reflecting solar radiation away from your building. This benefit translates into lower energy bills and a reduced carbon footprint.

Reflection Rates

| Material | Reflection Rate (%) | |-------------------|---------------------| | Asphalt Shingles | 15 - 25 | | Metal Roofing | 60 - 80 |

As seen in the table above, metal roofing outshines traditional materials in terms of reflectivity.

Sustainable Option

With increasing awareness about environmental issues, many businesses seek sustainable options for their projects. Steel is highly recyclable—up to 90% can be reused at the end of its life cycle without losing quality. Opting for steel roofing not only enhances your company’s image as eco-friendly but also contributes positively to global sustainability efforts.

Low Maintenance Requirements

Unlike other m

0 notes

Photo

#paintedcolorcoatedsteel#colorcoatedgalvanizedsteel#steelpaintedcolor#prepaintedgalvanizedsteel#3ddarkwoodencolorsteel#3dwoodpaintedsteel#mattsteel#mattpaintedsteel#mattppgi#colorcoated aluminum coils/sheets#laminated PVC film steel

Manufacturer of Galvanized steel(GI)/Galvalume steel(GL) /Prepainted color PPGI

/PPGL/Printeck PPGI /Laminated PVC Film Steel /Color Coated Aluminum in coils or sheets/Roofing sheets

E-mail:[email protected]

skype : andy_wang0427

whatsapp/wechat:0086 13771589131

Jiangyin Fengcai Metal Industry Co., Ltd

#steel coils#metal roofing#aluminum roofing#laminated PVC Film metal#color coated galvanized steel#prepainted galvanized steel#printech galvanized steel#matt ppgi#wrinle ppgi#galvalume steel#color coated galvalume steel#fence sheets#metal siding#ceiling sheets

0 notes

Text

Dear friend: Have a nice day . I am KONNON from Shandong Xinghan Materials Co., Ltd. The company has passed the international quality management system, energy management system, and occupational health and safety management system. Recognized as a provincial and municipal key export and foreign exchange earning enterprise. The company has 18 main production lines for pickling, cold rolling, hot-dip galvanizing, hot-dip galvalume, thick plate galvanizing, galvanized aluminum-magnesium, color-coated coils, corrugated sheets, etc., with an annual output of 1 million tons of pickling coils. , a production capacity of 1 million tons of cold-rolled coils. 900,000 tons of rolled steel plates. The scale of hot-dip galvanized, hot-dip aluminum-zinc silicon steel plate, thick galvanized steel plate is 450,000 tons, and color-coated steel plate is 300,000 tons. We produce various types of high-quality plates with a thickness of 0.12-2.5mm and a width of less than 1250mm. Among them, the special product high-strength and ultra-thin series steel plates are favored by foreign customers and have been exported to more than 100 countries and regions such as Africa, the European Union, South America, Southeast Asia, Central Asia, etc. Areas, mainly used in roofs, wall construction, color-coated substrates and automobile industry and other fields and areas. We value every partner and look forward to your arrival. You are welcome to visit the factory. Could you please tell me the detailed specifications of the product I need, such as (zinc layer, paint film, material, hardness, tensile strength, elongation, yield, hardness, how many tons are needed, port of receipt, etc.) These data will help I will provide you with the best quality, best service, and guaranteed after-sales at competitive prices. Sending you my best wishes. KONNON Shandong Xinghan Materials Co., Ltd. International Business Department 1 sales Manager Email: [email protected] Company website: www.xinghantudu.com WhatsApp: +8613082787470 https://zggb.en.alibaba.com/Fully

0 notes