#Metal Decking Sheets manufacturer

Explore tagged Tumblr posts

Text

#metal deck manufacturers#roofing services and solution providers#steel wall cladding#structural roof decking#metal building accessories and solutions in india#roofing sheets#complete metal building solutions#standing seam roof manufacturers and suppliers

0 notes

Text

Metal Deck Sheet Manufacturer in Delhi NCR: Your Trusted Partner for Durable Construction Solutions

In the rapidly growing infrastructure and construction industry, the demand for high-quality materials is paramount. Among these, metal deck sheets have emerged as an essential component in modern construction due to their strength, durability, and versatility. For businesses and contractors in Delhi NCR, choosing a reliable metal deck sheet manufacturer ensures both quality and efficiency in their projects. This is where Color Coated Sheet stands out as a trusted name in the industry.

What Are Metal Deck Sheets?

Metal deck sheets are corrugated steel sheets used primarily as structural components in buildings. They act as a base for concrete slabs, reinforcing the overall structure while providing an aesthetically pleasing finish. These sheets are known for their:

High Strength-to-Weight Ratio – Making them lightweight yet robust.

Corrosion Resistance – Ensuring longevity in various environmental conditions.

Ease of Installation – Saving time and labor during construction.

Why Choose ColorCoatedSheet in Delhi NCR?

When it comes to selecting the right manufacturer, several factors come into play, such as quality, customization, and customer service. Here’s why ColorCoatedSheet is a top choice for businesses in Delhi NCR:

Premium Quality Materials At ColorCoatedSheet, we use high-grade raw materials to manufacture metal deck sheets. Our products are designed to withstand heavy loads and extreme weather conditions, ensuring reliability for years to come.

Customization Options We understand that every project has unique requirements. From thickness and dimensions to color coatings, our team offers tailored solutions to meet your specific needs.

Competitive Pricing Affordability without compromising on quality is our promise. We provide the best value for money, making us a preferred choice for builders and contractors in the region.

On-Time Delivery In the construction industry, timely delivery is crucial. Our streamlined processes ensure your metal deck sheets reach you on schedule, every time.

Expert Support Our team of experts is always ready to assist with technical guidance, helping you select the ideal products for your project.

Applications of Metal Deck Sheets

Metal deck sheets find widespread use in various construction scenarios, including:

Residential Buildings: Providing a strong base for floors and roofs.

Commercial Complexes: Supporting large-scale construction with durability.

Industrial Facilities: Used in warehouses and factories for enhanced structural stability.

Bridges and Overpasses: Reinforcing concrete decks for heavy vehicular loads.

Sustainability and Eco-Friendliness

In today’s era, sustainable construction materials are a priority. At ColorCoatedSheet, our metal deck sheets are 100% recyclable, contributing to greener construction practices. Additionally, their energy-efficient designs help in reducing heat absorption, promoting sustainability.

Choose the Best for Your Construction Needs

When searching for a metal deck sheet manufacturer in Delhi NCR, look no further than ColorCoatedSheet. With a proven track record of excellence, we are committed to delivering products that meet and exceed industry standards.

Contact us today to learn more about our offerings and how we can help make your construction projects a success!

Meta Description: Looking for a reliable metal deck sheet manufacturer in Delhi NCR? ColorCoatedSheet offers premium quality, customizable solutions for all your construction needs. Contact us today!

0 notes

Text

Why Metal Decking Sheets Are the Best Choice for Multi-Storey Buildings

Metal decking sheets are the ideal choice for multi-storey buildings due to their strength, durability, and excellent load-bearing capacity. They provide a solid foundation for concrete slabs, ensuring stability and reducing construction time. Metal decking sheets also offer superior fire resistance and corrosion protection, making them a reliable option for long-lasting structural performance.

#decking sheets#metal decking sheets#decking floor sheet#deck floor manufacturers#Decking Sheets 50 mm

0 notes

Text

instagram

Take your construction projects to the next level with SteelDECK52 - the cost-effective, speedy, and superior solution for streamlined construction. Connect with us to explore how we can support your specific project requirements and goals. . Visit Us: www.steeldeckingsheets.com Contact Us: [email protected]| 8550995556 #steeldeck #steeldecks #deckingsheet #highwayconstruction #industrialcontractor #roadcontractors #roadconstruction #deckdepth

#deck profile sheet#deck sheet#decking steel#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#steel decking sheet#gi decking sheet#deck sheet profile#jsw deck sheet#metal deck sheet price#deck sheet manufacturer in india#decking sheet for bridges#Instagram

0 notes

Text

Aluminium Welding and Fabrication: The Essential Guide

Aluminium welding is commonly used in many industries including auto manufacturing aerospace industries construction marine industries etc. This material is highly versatile because of its lightweight, high durability, and immunity to corrosion; it is a darling of manufacturers and engineers. In this article, we will analyze the possibility of welding and fabrication of aluminum materials, its advantages and disadvantages, anthe d necessary equipment and methods.

Key Characteristics of Aluminium:

Lightweight: Aluminium is about 1/3 of the density of steel.

Corrosion Resistance: To be more specific, it develops an oxide film to prevent the process of rusting.

High Thermal Conductivity: Aluminium conducts heat and hence it is not very suitable for welding procedures.

Oxide Layer: The surface oxide has a higher melting point than the base metal so exacting methods are necessary.

Common Aluminium Welding Methods:

TIG Welding (Gas Tungsten Arc Welding): Recommended for thin sections due to the accuracy and smoothness of the finish.

MIG Welding (Gas Metal Arc Welding): More appropriate for thicker materials to offer a faster rate of production.

Spot Welding: Primarily used in car manufacturing for fastening thin metals such as sheet metal.

Aluminium Fabrication Explained

Fabrication means the shaping of aluminum by processes such as cutting, bending as well as joining to produce particular parts or systems.

Fabrication Processes:

Cutting: Possible to utilize laser cutting, water jet cutting, or CNC machining if accuracy is necessary.

Bending: Aluminium sheets are bent through the use of press brakes/rollers.

Joining: This may be welding, riveting,g, or bonding together of the parts, that is, the use of adhesives to join the parts.

Finishing: Polishing anodizing, or powder coating of the outside view to improve its look and performance.

Industries Using Aluminium Fabrication:

Aerospace: Things like wings and segments of the fuselage as used in the construction of a plane.

Automotive: Fuel-efficient components for lighter cars.

Construction: Windows, doors, and roofing.

Marine: Items such as hulls of ships and structures of decks.

Benefits of Aluminium Welding and Fabrication

Aluminium is a versatile metal, which cannot be substituted in a multitude of industries and applications. Here are the key advantages:

Lightweight Yet Strong: Offers a high strength-to-weight ratio, reducing structural load.

Corrosion Resistance: Excellent for outdoor and marine applications.

Eco-Friendly: Aluminium is 100% recyclable, reducing environmental impact.

Cost-Effective: Despite higher initial costs, its durability and low maintenance make it economical in the long run.

Future Trends in Aluminium Welding and Fabrication

The industry is evolving with advancements in technology and sustainability efforts:

Automation: Robotic welding and CNC machining increase the accuracy and speed of steel production.

3D Printing: Modern manufacturing techniques such as AM are applied to highly complicated aluminum parts.

Sustainable Practices: Focus on reuse and usage of energy-saving practices and policies.

Advanced Alloys: Higher performance non-heat treatable aluminum alloy-based specific applications.

Essential Tools and Techniques

Aluminum welding and fabrication are as important as any other type of welding, but there is a stark difference in the way it has to be done.

Welding Machines: TIG and MIG welders with a pulse to enable control of the heat intensity.

Filler Materials: Base metal compatible aluminum alloy filler rods or wires.

Protective Equipment: Welding helmets gloves and clothing for safety.

Preparation Tools: Wires for brushing the oxide layer away and chemical products for washing the oxide layer off.

Clamping Systems: To keep the component in a fixed position and minimize its movement during the fabrication.

Challenges in Aluminium Welding and Fabrication

Nonetheless, aluminum holds some advantages, yet it needs expertise and tools to work because of its peculiar characteristics.

Warping and Distortion: A high ability to conduct heat can lead to parts distorting as welds are being made.

Porosity: Aluminium reacts with hydrogen and, therefore, porosity is often observed in welds.

Oxide Removal: The oxide layer has to be removed for better adhesion and this can be done through pre-weld cleaning.

Skill Requirements: Welding of aluminum requires skilled professionals and specific parameters to accomplish excellent work.

Final Thoughts

Aluminum welding and fabrication are integral to modern engineering and manufacturing. From selecting the right welding method to leveraging advanced fabrication techniques, working with aluminum requires expertise and precision. As industries push towards lighter, stronger, and more sustainable solutions, aaluminumcontinues to lead the way.For expert aaluminumwelding and fabrication services, trust DARMIS, a name synonymous with quality and innovation in the field. Visit their website to learn more about their offerings and how they can bring your projects to life.

0 notes

Text

Best Quality Screw Manufacturer, Supplier & Exporter

Screws are essential components in numerous industries, playing a vital role in construction, manufacturing, automotive, and beyond. At Ananka Fasteners, we are a trusted Screw Manufacturer, Supplier, Stockist, and Exporter delivering high-quality screws to global clients. With years of expertise, precision engineering, and a commitment to excellence, we provide a wide range of screws that meet diverse industrial requirements.

Introduction

Ananka Fasteners is a leading name in the fastener industry, offering an extensive range of screws crafted from superior materials. We ensure that every screw adheres to international standards and is rigorously tested for quality, durability, and reliability.

Our extensive supply chain and manufacturing capabilities make us a preferred Screw Manufacturer, Supplier, Stockist, and Exporter for industries worldwide. With state-of-the-art facilities, we manufacture screws in various dimensions, materials, and finishes to meet our customers' precise requirements.

Why Choose Ananka Fasteners?

High-Quality Materials: Screws made from stainless steel, carbon steel, alloy steel, and non-ferrous metals.

Global Reach: Supplying screws to industries across North America, Europe, Asia, and Africa.

Customization: Offering tailored solutions for unique industrial needs.

Compliance: Meeting international standards such as ISO, ASTM, DIN, and BS.

Competitive Pricing: High-quality screws at cost-effective rates.

Types of Screws

Screws come in various designs, materials, and finishes based on specific industrial and commercial applications. Here are the most popular types of screws:

1. Wood Screws

Designed for fastening wood materials.

Features a sharp tip for easy penetration into wood.

Available in various lengths and coatings.

2. Machine Screws

Used for precision fastening in machinery and equipment.

Typically used with nuts or tapped holes.

Manufactured in various head styles, such as flat, pan, or round.

3. Self-Tapping Screws

They form their own mating threads as they are driven into materials.

Ideal for metal, plastic, and wood applications.

Often used in construction and furniture.

4. Hex Head Screws

Featuring a hexagonal head for easy wrench tightening.

Suitable for heavy-duty industrial and structural applications.

Made with high-strength materials.

5. Drywall Screws

Specially designed for securing drywall sheets.

Typically have a coarse thread and sharp point.

Coated for corrosion resistance.

6. Socket Head Screws

Also known as Allen screws.

Used in precision and high-strength applications.

Common in automotive, aerospace, and machinery industries.

7. Deck Screws

Designed for outdoor construction like decks and fences.

Feature corrosion-resistant coatings for durability.

Ideal for wood-to-wood fastening.

8. Lag Screws

Heavy-duty screws with a hex head.

Used for fastening large and heavy materials.

Common in construction and structural applications.

9. Chipboard Screws

Ideal for fastening particle boards and MDF materials.

Available in self-tapping varieties.

Offer high holding power.

10. Sheet Metal Screws

Designed for fastening thin metal sheets.

Available with sharp or self-tapping points.

Often coated to prevent corrosion.

Coated Screws Types

Coated screws offer enhanced protection against corrosion and environmental damage. Various coating techniques improve the performance and lifespan of screws in challenging conditions. Below are the popular types of coated screws:

1. Zinc-Plated Screws

Provides excellent corrosion resistance.

Suitable for indoor and low-moisture environments.

2. Hot-Dip Galvanized Screws

Features a thick protective zinc layer.

Ideal for outdoor and marine applications.

3. Black Oxide Screws

Aesthetic coating that offers mild corrosion resistance.

Commonly used in machinery and electronics.

4. Phosphate Coated Screws

Provides better adhesion for paint and lubricants.

Often used in drywall and construction projects.

5. Nickel-Coated Screws

Improves the screw's appearance and corrosion resistance.

Suitable for decorative and precision applications.

6. PTFE Coated Screws

Non-stick, anti-corrosive coating.

Used in chemical and high-temperature environments.

7. Stainless Steel Coated Screws

Provides ultimate corrosion resistance.

Used in critical and outdoor applications.

Applications of Screws

Screws are essential components in a wide range of industries, including:

Construction: Securing structures, framing, and drywalls.

Automotive: Fastening critical parts in vehicles.

Aerospace: Precision screws for aircraft components.

Electronics: Miniature screws for devices and gadgets.

Furniture: Fastening wood, MDF, and chipboards.

Marine: Corrosion-resistant screws for shipbuilding.

Conclusion

At Ananka Fasteners, we are committed to providing high-quality screws that meet the rigorous demands of global industries. As a trusted Screw Manufacturer, Supplier, Stockist, and Exporter, we offer a comprehensive range of screws in various materials, coatings, and specifications. Our dedication to quality, competitive pricing, and customer satisfaction makes us a leader in the fastener industry.

If you are looking for reliable screws for your project, Ananka Fasteners is your ultimate solution for premium screws with global delivery.

FAQs

Q1: What types of screws does Ananka Fasteners supply?A1: We supply wood screws, machine screws, self-tapping screws, drywall screws, hex head screws, and more.

Q2: What coatings are available for screws?A2: Our coated screws include zinc-plated, hot-dip galvanized, black oxide, nickel-coated, and PTFE-coated screws.

Q3: Do you offer customized screws?A3: Yes, we provide customized screws tailored to meet specific requirements and applications.

Q4: What industries use your screws?A4: Our screws are utilized across various industries, including construction, automotive, aerospace, electronics, furniture, and marine sectors.

Q5: How can I place an order with Ananka Fasteners?A5: You can contact us through our website, email, or phone for inquiries and orders.

#bestquality#screw#screwmanufacturer#fasteners#fastenersmanufacturer#linkedin#article#screwsupplier#exporter#anankafasteners#ananka#manufacturer#mumbai#supplier#bolt#usa#uk#hex

0 notes

Text

When Should You Use a Fender Washer? | Complete Guide

If you’ve ever dealt with fasteners, you might wonder, “When should I use a fender washer?” This guide is here to make things crystal clear for you. Whether you're a DIY enthusiast or a professional, understanding when and how to use fender washers, along with other specialized washers like shim washers or industrial washers, can save you time, effort, and even prevent costly repairs.

What Is a Fender Washer?

A fender washer is a flat washer with an outer diameter significantly larger than the hole in the center. Its design makes it perfect for distributing load over a larger area compared to standard washers, much like shim washers and tab washers. This helps prevent materials from getting damaged, especially softer ones like wood or plastic.

Why Are Fender Washers Unique?

You might be asking, “Why not just use a regular washer?” Fender washers stand out because:

Larger Surface Area: They spread the force of the bolt or screw across a broader area.

Material Protection: Fender washers reduce the risk of cracking, splitting, or deformation.

Versatility: They work well with various materials like wood, metal, and plastic.

Rust Resistance: Many are made of stainless steel or coated to resist corrosion, making them great for outdoor or marine use.

Top Scenarios for Using Fender Washers

Let’s dive into where and when you’d need a fender washers, and how they compare to alternatives like precut shims or conical washers:

a. Preventing Damage on Soft Materials

If you’re working with delicate or soft materials, like plywood or plastic, fender washers distribute the pressure evenly, preventing cracks or tears.

b. Securing Large Holes or Oversized Slots

Ever drilled a hole too big? Fender washers come to the rescue by covering the extra space and providing a secure fit for screws or bolts.

c. Automotive Repairs

The name "fender washer" originates from their use in car fenders. They’re ideal for attaching lightweight parts or securing areas where vibration might loosen standard fasteners.

d. Home Improvement Projects

From mounting shelves to fixing furniture, fender washers are your go-to for reinforcing connections without damaging the material.

e. Outdoor Applications

Building a deck or gazebo? Use fender washers along with U bolts or clamps from leading U clamp manufacturers to ensure your outdoor structure stands the test of time.

How to Choose the Right Fender Washer

Picking the right fender washer or related component doesn’t have to be complicated. Here’s how you can make an informed choice:

1. Material Matters

Stainless Steel Washers: Perfect for outdoor use, just like stainless steel shims or SS shim plates.

Brass Shim Sheets: Ideal for lightweight indoor applications.

Nylon Washers: Lightweight and non-conductive, great for electrical projects.

2. Check the Size

Outer Diameter: Match it to the material you’re working with, whether it’s shim sheet metal or a foundation structure.

Inner Diameter: Ensure the washer fits snugly around your screw or bolt.

3. Consider the Application

For heavy-duty applications, industrial washers or spring lock washers might pair better with foundation bolts or U bolts. For lightweight tasks, self-locking washers or shim washers could be more appropriate.

Conclusion

So, when should you use a fender washer? Anytime you need extra support, protection, or a stable connection in your projects. Whether you’re securing a car fender, repairing furniture, or installing foundation J bolts, fender washers and other specialized washers like square washers or tab washers provide reliability and peace of mind.

#FenderWasher#WasherTypes#IndustrialFasteners#FenderWasherGuide#MechanicalParts#ConstructionFasteners#ShimWashers#FenderWasherApplications

0 notes

Text

The Best Plywood Alternatives for Waterproof Applications

When it comes to building projects that require durability, strength, and waterproof qualities, plywood has traditionally been the go-to material. However, with increasing demand for more durable, sustainable, and waterproof materials, many builders and homeowners are turning to substitutes of plywood. These materials offer superior moisture resistance, longer-lasting durability, and can often be more cost-effective than conventional plywood.

In this blog, we’ll explore the best plywood substitutes for waterproof applications, focusing on advanced materials like WPC (Wood-Plastic Composite), and highlight leading manufacturers like Floresta, which specialize in producing these cutting-edge materials in India.

1. WPC (Wood-Plastic Composite): The Top Choice for Waterproof Applications

WPC is one of the best substitutes of plywood when it comes to moisture resistance and waterproof applications. This material is made from a blend of wood fibers and plastic, offering the best of both worlds – the natural appearance of wood with the durability and moisture resistance of plastic. WPC is highly resistant to water, rot, and decay, making it ideal for applications like outdoor furniture, decking, cladding, and even in bathrooms and kitchens.

For those looking for WPC manufacturers in India, Floresta stands out as a trusted brand. They provide high-quality WPC panels that are perfect for waterproof applications, ensuring long-lasting performance even in the harshest environments.

2. PVC Sheets: A Durable, Waterproof Option

Polyvinyl Chloride (PVC) sheets are another popular plywood substitute for areas exposed to moisture. PVC is completely waterproof and resistant to rotting, warping, and swelling – problems commonly associated with traditional plywood. It is lightweight, easy to maintain, and highly durable, making it an excellent choice for both residential and commercial spaces.

PVC sheets are widely used in bathrooms, kitchens, and basements, offering long-lasting performance without the need for frequent repairs or replacements. Many manufacturers, including Floresta, offer high-quality PVC panels that can replace plywood in these moisture-prone areas.

3. HDPE (High-Density Polyethylene) Sheets: Impact-Resistant and Waterproof

HDPE sheets are a high-performance material that is resistant to moisture, chemicals, and abrasion. This makes it an ideal plywood substitute for waterproof applications. HDPE is often used in heavy-duty industrial applications but is also suitable for residential uses such as in kitchens, bathrooms, and other areas exposed to moisture.

While HDPE sheets are not as aesthetically pleasing as some other materials, their durability, ease of maintenance, and moisture resistance make them a great choice for environments where functionality is the top priority.

4. Bamboo Plywood: Eco-Friendly and Water-Resistant

For those looking for a more sustainable alternative to traditional plywood, bamboo plywood is an excellent choice. Bamboo is naturally water-resistant and environmentally friendly, making it an ideal option for green construction projects. While bamboo plywood is not entirely waterproof, it offers better moisture resistance than regular plywood.

For waterproof applications, bamboo plywood can be treated with water-resistant coatings to further enhance its durability. Floresta, known for its innovative materials, provides high-quality bamboo plywood options, ensuring both sustainability and durability.

5. Metal Sheets: For Extreme Waterproofing

For extreme waterproofing needs, metal sheets, such as aluminum or galvanized steel, can serve as an excellent substitute for plywood. These materials are entirely waterproof, highly durable, and resistant to corrosion. Metal sheets are often used in roofing, cladding, and exterior applications where the utmost protection from water is required.

Though metal sheets might not have the aesthetic appeal of natural wood, they are incredibly effective for waterproofing, especially in commercial and industrial environments.

6. Cement Board: A Tough and Moisture-Resistant Option

Another great alternative to plywood for waterproof applications is cement board. Made from a mixture of cement and reinforcing fibers, cement boards are highly resistant to moisture, making them an excellent choice for wet areas like bathrooms, kitchens, and basements. Cement boards do not swell or degrade with exposure to water, unlike plywood.

Though cement boards are often heavier and harder to work with than plywood, their waterproof properties make them invaluable for specific applications.

Why Choose WPC and Other Alternatives?

Traditional plywood, although a versatile material, can easily succumb to water damage, leading to mold, rot, and warping. The waterproof alternatives mentioned above provide enhanced durability, long-lasting protection, and resistance to environmental stressors. In addition, they are often more eco-friendly, cost-effective, and easier to maintain.

For homeowners, architects, and builders in India, turning to WPC manufacturers in India like Floresta for high-quality, waterproof materials can significantly improve the longevity and performance of building projects, especially in high-moisture areas.

Conclusion

As the demand for stronger, more durable materials grows, WPC and other substitutes of plywood are stepping in to offer better waterproofing capabilities and sustainability. Materials like PVC sheets, HDPE, bamboo plywood, and cement boards are excellent choices for waterproof applications. Brands like Floresta offer high-quality WPC products, providing a reliable solution for those seeking waterproof alternatives to traditional plywood.

When selecting a material for your next project, consider the environmental impact, durability, and the specific waterproofing needs of the space. With the right plywood substitute, you can ensure your project stands the test of time, regardless of moisture exposure.

Also, Read:

The Future of WPC Boards in Sustainable Architecture

The Role of Termite Proof Boards in Delhi

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

Top Trends in HPL Sheet Installation for Modern Homes in Bangalore

Over the last couple of years, the owners of houses in Bangalore have become more inclined towards looking for modern and lasting materials to improve the beauty and usefulness of their homes. High-Pressure Laminate (HPL) sheets are gaining popularity in both indoor and outdoor usage as they are strong, come in stylish designs and are easy to clean and maintain. From the installation of gates to external cladding and even the implementation of designer panels HPL sheets are modern and flexible materials. In this article, we will delve into the trends in the installation of HPL sheets in Bangalore and the reasons behind it gaining popularity in contemporary housing designs.

1. Durability Meets Aesthetic Appeal

The growing popularity of HPL sheet installation in Bangalore can be largely attributed to the balance of durability and aesthetics. HPL sheets are well regarded for their ability to resist harsh environmental factors like sunlight, heat, and moisture. It is therefore not surprising that these sheets are perfect for outside use, especially in Bangalore, which has tropical sun and onsets of monsoons with painful downpours.

Homeowners are increasingly opting for HPL cladding sheets near Bangalore to give their homes a sleek, modern look while ensuring long-term durability. The wide variety of textures, colours, and finishes available allows homeowners to select HPL sheets that complement the overall design of their property, making it a trendsetter in modern architecture.

2. HPL for Gate Installations

When it comes to gate design, choosing the right material is crucial for both security and aesthetics. The best HPL gate sheet near Bangalore offers a durable yet elegant solution for gates. These sheets are not only tough and resistant to wear and tear but also add a contemporary touch to the home’s entrance. The growing trend in Bangalore is to incorporate HPL sheets into gate designs to create a polished and professional look while ensuring the gate stands up to the city's weather conditions.

Additionally, HPL cladding sheets near Bangalore are being used to enhance the appearance of gate structures, giving them a refined and modern appeal.

3. Sustainable Design with WPC Decking and Louvers

The modern-day home builder is very concerned about sustainability and WPC decking manufacturers, especially in Bangalore are addressing the issue by making more and more green building materials. WPC is an ideal wood-plastic hybrid which combines the aesthetic appeal of wood and the toughness of plastic. WPC decking is more extensively used for external structures such as terraces, balconies and gardens.

WPC decking suppliers in Bangalore have a range of styles and designs to suit the ever-increasing demand for green outdoor options. Besides decking, WPC louvers are also making louvres that can be fitted on the outer walls of the house improving energy efficiency and also improving the aesthetics of the house. Also, these louvres help to manage the amount of sunlight and air that gets through, which is practical and stylish at the same time.

4. Customizable Exterior Solutions with HPL and WPC

One more trend is on the rise nowadays, which is the incorporation of HPL and WPC materials to design bespoke exterior solutions. Homeowners are now combining louvers for exterior walls in Bangalore with HPL cladding to achieve a unique architectural style that blends aesthetics with functionality. Their combination enables the collaboration of artistic and practical solutions. For instance, the design can be enhanced and made appealing also considering the need for strong and insulating barriers.

5. Minimal Maintenance and High Performance

One of the notable benefits of HPL sheets and WPC decking, and most of the manufactured furnishing materials, is how often they require maintenance. Unlike wood or metals and other conventional materials, HPL and WPC do not warp, scratch, stain, or fade. This is especially beneficial for the modern-day consumer who wishes to have the appearance of expensive materials but without excessive caring for them.

In conclusion, HPL sheet installation in Bangalore has become an inseparable aspect of modern home design owing to its versatility, durability, and beauty. As manufacturers of WPC decking near Bangalore are constantly improving with sustainable materials, the mixing of these products has begun to set a trend towards modern green architecture. Be it searching for the HPL gate sheet or wanting to know about the louvers for exterior wall, in Makmore we help you in making the right decisions and finding best of both style and utility for your home.

#HPL cladding sheets in Bangalore#HPL sheet installation in Bangalore#HPL Sheet distributor in Bangalore#hpl sheet manufacture#Hpl Sheet Work#hpl cladding sheet works#hpl cladding works#hpl sheet for gate#hpl gate sheet near me

0 notes

Text

Bolts: The Incredible Mechanics Behind Fastener and How They Revolutionized Construction

Bolts Fastener are one of the most simple and ubiquitous fasteners used in construction and mechanical assemblies. At their core, fastener are cylindrical rods with threads on one end that can be tightened or loosened by turning. When fitted through holes and tightened with a nut, fastener securely join two or more components together. Different Types of Bolts There are many varieties of fastener used for different applications. Bolts are commonly used to join metal parts and feature hexagonal heads that can be driven with a wrench. Lag fastener, also called coach screws, have large, cylindrSical heads and sharp threads that allow them to grip into wood or similar materials. Carriage fastener have a rounded head that sits flush and a square shoulder under the head to prevent rotation. Stove fastener are short fastener used to join thin sheets of metal, often found in appliances. Socket head cap screws feature a spherical head that can be driven with a hex key or socket tool. Allen fastener have a hexagonal socket in the head that is tightened with an Allen wrench. Material Composition Fastener are most commonly made of steel or stainless steel. Carbon steel fastener are inexpensive and strong for general construction use. Stainless steel holds up well to corrosion and is commonly used in wet or saltwater environments. Other materials may include brass, aluminum, titanium and specialty alloys depending on the application requirements and operating environment. Higher grades of steel such as alloy steels provide better strength characteristics but at increased cost. The material selection depends on factors like tensile strength needed, operating temperature range, and resistance to corrosion or wear expected. Thread Standards and Specifications Thread standards ensure fastener and nuts from different manufacturers properly interface. Fastener are identified by their diameter, length, thread type, class or grade of material. Common thread standards include unified coarse (UNC), unified fine (UNF), and metric threads. Fastener may have additional specifications for plating, finish, strength class or grade based on standards set by organizations like ASME, SAE, and ISO. Proper specifications ensure fastener reliably provide the clamping force and performance needed for particular engineering applications. Advantages of Bolted Joints There are several advantages that make bolted joints a popular mechanical fastening method: - Versatility - Fastener can join a wide variety of materials and assembly configurations from light fixtures to heavy machinery. - Removability - Bolted connections allow easy disassembly without damaging components for maintenance, repair, or replacement. - Adjustability - Fastener can be tightened or loosened to precisely control clamping force and preload on joints. - Strength - Properly selected and installed fastener provide very high tensile and shear strength for securely joining parts. - Tolerance for error - Bolted joints still function properly despite minor variations in hole alignment or part dimensions. - Economy - Fastener provide strong connections at relatively low cost compared to other joining methods like welding. Fastener in Construction In construction, fastener play a crucial structural role. Anchor fastener secure wooden framing members to concrete or masonry foundations. Lag fastener join beams, joists, and decking to walls or support posts. Machine fastener assembly prefabricated structural members and connect rebar in reinforced concrete slabs and footings. Carriage fastener hold together window and door frames, siding panels, and roofing sheets. Stove fastener install appliance panels and fasten thin gauge sheet metal. Due to their versatility, strength, economy and removability— fastener represent one of the most important innovations that enabled modern construction techniques. Get more insights on, Bolts

For Deeper Insights, Find the Report in the Language that You want.

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Full Screw Bolt#Half Screw Bolt#Construction Sector#Automotive Industry#Aerospace Industry#Raw Material Price Volatility#Technological Advancements

0 notes

Text

#standing seam roof manufacturers and suppliers#structural roof decking#steel wall cladding#metal deck manufacturers#metal building accessories and solutions in india#roofing services and solution providers#complete metal building solutions#pre-engineered buildings manufacturer in india#roofing sheet suppliers#roofing sheets

0 notes

Text

Metal deck sheets are essential components in modern construction, widely used to enhance structural integrity and provide stability in various building projects. If you are looking for a Metal Deck Sheet Manufacturer in Delhi NCR, it's essential to understand the basics, benefits, and considerations when selecting a reliable provider like Colorcoatedsheet. This article explores everything you need to know about metal deck sheets, including what to look for in a manufacturer, benefits of using these sheets, and how to make the best choice for your construction needs.

0 notes

Text

instagram

#decking steel#deck sheet#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#deck sheet profile#jsw deck sheet#deck sheet manufacturer in india#decking sheet for bridges#decking sheet for flyover#decking sheet for sealink#Instagram

0 notes

Text

Why is Stainless Steel pipe a First choice for marine manufacture?

Advantages of Stainless Steel Pipes in Marine Applications

The great expanse of the sea gives a unique set of demanding situations for materials used in shipbuilding and marine creation. Constant exposure to saltwater, intense weather conditions, and the ever-present hazard of corrosion necessitate strong and dependable substances. Among these substances, stainless-steel pipes reign ideal, providing an unmatched mixture of power, corrosion resistance, and durability. This weblog delves into the reasons why chrome steel pipes are the go-to desire for marine manufacturing, exploring special pipe sorts and highlighting legitimate suppliers.

Unveiling the Advantages of Stainless Steel Pipes in Marine Applications

Stainless metallic’s excellent residences make it a perfect cloth for pipes in marine environments:

Superior Corrosion Resistance: The presence of chromium in stainless-steel bureaucracy is a passive oxide layer that protects against saltwater corrosion, a vital thing for structures constantly scuffling with the ocean’s harshness.

High Strength and Durability: Stainless steel offers a wonderful energy-to-weight ratio, making pipes perfect for load-bearing packages at the same time as preserving a lightweight gain. This translates to improved gas performance for vessels and more desirable structural integrity for offshore platforms.

Low Maintenance: Stainless metal’s inherent corrosion resistance minimizes renovation needs, lowering expenses and downtime for marine devices and structures.

Fire Resistance: Many grades of stainless steel possess exceptional hearth resistance, a crucial safety function for ships and offshore installations.

Hygienic Properties: Certain chrome steel grades show off terrific hygiene properties, making them appropriate for applications regarding food and water transportation on ships.

Types of Stainless Steel Pipes for Marine Use

There are two number one forms of stainless steel pipes utilized in marine manufacturing:

Seamless Stainless Steel Pipes: These pipes are fashioned by piercing a solid billet of stainless steel, resulting in a non-stop, uniform structure with exceptional energy and pressure resistance. They are the favored choice for crucial applications like excessive-stress piping structures and boiler tubes.

Welded Stainless Steel Pipes: These pipes are created by rolling a flat sheet of stainless steel right into a cylindrical form and welding the seam. They offer a fee-powerful opportunity to seamless stainless steel pipe tube manufacturers for programs with much less worrying strain requirements, such as ventilation systems and deck railings.

Finding Reliable Suppliers: Stainless Steel Pipe Suppliers, Exporters, and Manufacturers

Selecting the right provider for your stainless-steel pipe wishes in marine applications is crucial. Here are some elements to not forget:

Product Quality: Ensure the provider adheres to identified standards like ASTM or ASME, making sure the pipes meet the vital electricity and corrosion resistance necessities for marine environments.

Product Availability: Choose a dealer presenting a wide variety of sizes, thicknesses, and grades of stainless-steel pipes to cater on your precise venture wishes. Look for suppliers with seamless and welded pipe alternatives.

Experience and Expertise: Partnering with a dealer with revel within the marine industry ensures they understand the precise demands of such applications and can provide technical guidance on pipe selection and setup.

Certifications: Look for suppliers with relevant certifications like ISO 9001, indicating their commitment to first-class control structures.

Manilaxmi Industrial Corporation: Your Trusted Partner for Marine-Grade Stainless Steel Pipes

At Manilaxmi Industrial Corporation, we’re India’s leading stainless steel and welded pipes supplier, producer, and exporter of great chrome steel pipes. We understand the critical position stainless steel performs in marine packages and are devoted to providing merchandise that meets the stringent demands of the maritime enterprise.

Our extensive inventory contains a wide range of:

Seamless Stainless Steel Pipes: We offer various sizes, thicknesses, and grades of seamless pipes, making sure you find an appropriate answer in your excessive-strain marine applications.

Welded Stainless Steel Pipes: Our welded pipes offer a powerful option for applications wherein stress necessities are less stressful.

Additional Marine-Grade Products: We provide a comprehensive selection of stainless-steel products mainly ideal for marine environments, inclusive of sheets, plates, and fasteners.

We prioritize outstanding customer service and offer technical guides to assist you in selecting the maximum suitable chrome steel pipes for your marine challenge.

#Pipes#Tubes#Flanges#Buttwelded Pipe Fittings#Forged Fittings#Tube Fittings#Sheets#Plates & Coils#Bars#Fasteners

1 note

·

View note

Text

Coil Coating Market: Navigating Regulatory Challenges for Growth

Coil coatings are coating materials that are applied as a thin layer protective film onto metal coils and sheets. They help protect the underlying substrate from corrosion and other environmental damages. Coil coatings provide excellent gloss retention and color stability. They find applications in construction, appliances, automobiles and other general industrial applications.

The global coil coatings market size is estimated to be valued at US$ 1,510.97 billion in 2024 and is expected to exhibit a CAGR of 4.3% over the forecast period from 2023 to 2030. Key Takeways Key players operating in the coil coatings market are Beckers Group., Akzo Nobel N.V., PPG Industries, Inc., The Sherwin-Williams Company, Nippon Paint Holdings Co., Ltd. Key players are focusing on developing bio-based and sustainable coil coating products to capitalize on the growing environmental consciousness. For instance, Beckers Group offers Beckryl waterborne and sustainably certified coil coatings. The growing construction industry across the globe is driving the demand for coil coatings. Coil coatings find widespread application in roofing, siding, decking, and other building components in the construction of commercial and residential buildings. Rapid urbanization and infrastructure development are augmenting the growth of the global construction industry. Geographic expansion into emerging economies is another key trend observed in the coil coatings market. Leading manufacturers are focusing on setting up production facilities or acquiring regional players in high growth markets like Asia Pacific, Middle East & Africa and South America. This allows them to better serve the local demand and leverage growth opportunities. For example, AkzoNobel has production sites across 20 countries to serve customers globally. Market key trends Sustainable product innovation is a major trend in the coil coatings market. Customers are increasingly preferring eco-friendly coatings manufactured using bio-based resins and low or zero VOCs. To cater to this demand, manufacturers are investing in R&D to develop novel and greener coating formulations. For instance, Beckers Group offers Xyladecor coil coating made from wood extracts and Nippon Paint provides Novacq water-based coil coating with very low environmental footprint. Such innovations will drive further revenue growth of the market over the coming years.

Porter’s Analysis Threat of new entrants: New entrants face high capital requirements to enter the mature coil coatings market.

Bargaining power of buyers: Large buyers in the automotive and construction industries can negotiate lower prices from suppliers due to their purchasing power.

Bargaining power of suppliers: The presence of many suppliers ensures that no individual supplier has significant influence over prices.

Threat of new substitutes: There exists a threat from substitute materials like powder coatings and galvanizing for end-use applications.

Competitive rivalry: The rivalry among existing players is very high as they compete on the basis of product quality, price and service. Geographical Regions North America accounted for the largest share of the global coil coatings market in terms of value in historical year. This is attributed to the presence of well-established construction and automotive industries in the region. Asia Pacific is expected to be the fastest growing geographical market for coil coatings between the forecast period. This growth can be attributed to increasing automobile production and construction activities in developing countries like China and India.

0 notes

Text

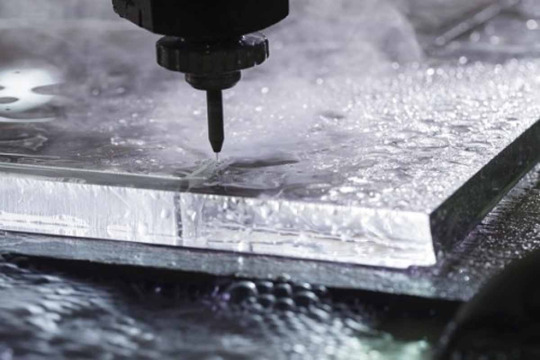

Unleashing Precision and Efficiency: Exploring the Diverse Applications of Water Jet Cutters in Townsville

Water jet cutters have emerged as indispensable tools in the manufacturing, construction, and fabrication industries in Townsville, offering unmatched precision, versatility, and efficiency in cutting a wide range of materials. From metal fabrication and signage production to architectural detailing and aerospace components, water jet cutters play a crucial role in shaping the landscape of Townsville's industrial sector. Let's delve into the unique applications and uses of water jet cutters in Townsville:

Metal Fabrication and Machining:

In Townsville's thriving metal fabrication industry, water jet cutters are widely used for cutting and machining various metals with precision and accuracy. From stainless steel and aluminium to copper and brass, water jet cutters can effortlessly cut thick metal sheets, plates, and profiles to create intricate components, parts, and prototypes for diverse applications. Whether it's fabricating structural steel beams for construction projects or producing precision-engineered parts for machinery and equipment, water jet cutters provide unparalleled versatility and efficiency.

Signage and Graphics:

Water jet cutters are indispensable tools for the signage and graphics industry in Townsville, allowing for the precise cutting of materials such as acrylic, PVC, aluminium composite panels, and stainless steel. Whether it's cutting letters, logos, or intricate designs, water jet cutters can achieve crisp, clean edges and intricate details with ease. Sign makers in Townsville rely on water jet cutters to produce eye-catching signage, wayfinding systems, architectural features, and decorative elements that enhance the visual appeal of public spaces, commercial buildings, and retail establishments.

Architectural Detailing and Cladding:

Water jet cutters play a vital role in architectural detailing and cladding projects in Townsville, where precision and quality are paramount. Architects, designers, and contractors utilise water jet cutters to cut materials such as stone, marble, granite, and porcelain tiles to precise specifications for facade elements, wall cladding, flooring, and decorative features. Water jet cutting allows for intricate patterns, textures, and designs to be achieved, enabling the creation of stunning architectural elements that enhance the aesthetic appeal and functionality of buildings and structures.

Automotive Parts:

Automotive enthusiasts and professionals in Townsville turn to water jet cutters for the production of custom automotive parts and components. Whether it's cutting precision gaskets, brackets, or body panels, water jet cutters offer the versatility and accuracy required to meet the demanding specifications of automotive applications. From classic car restorations to performance upgrades and custom modifications, water jet cutters enable the fabrication of bespoke automotive parts that enhance performance, aesthetics, and functionality.

Marine and Offshore Applications:

In Townsville's maritime industry, water jet cutters are utilised for a variety of marine and offshore applications, including shipbuilding, repair, and maintenance. Water jet cutters can cut materials such as steel, aluminium, and fibreglass-reinforced plastics (FRP) with precision, making them ideal for fabricating hull components, deck fittings, propellers, and marine structures. With their ability to cut thick materials without heat-affected zones, water jet cutters ensure the structural integrity and durability of marine components, even in harsh marine environments.

Water jet cutters have become indispensable tools in Townsville's industrial landscape, offering versatile solutions for cutting, machining, and fabricating a wide range of materials. From metal fabrication and signage production to architectural detailing and aerospace components, water jet cutters play a crucial role in shaping various industries and driving innovation and productivity. As Townsville continues to grow and evolve, water jet cutters will remain essential tools for businesses, industries, and educational institutions seeking to achieve precision, efficiency, and excellence in cutting and fabrication processes.

0 notes