#Composite Metals Deck Profile Sheets manufacturer

Explore tagged Tumblr posts

Text

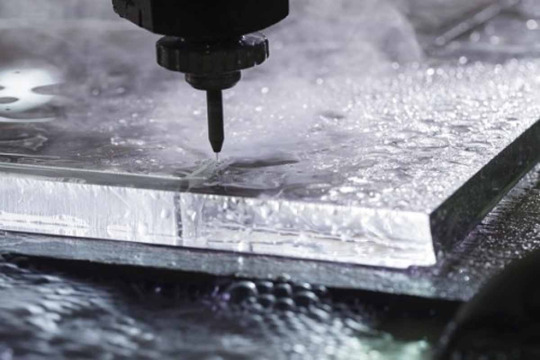

Unleashing Precision and Efficiency: Exploring the Diverse Applications of Water Jet Cutters in Townsville

Water jet cutters have emerged as indispensable tools in the manufacturing, construction, and fabrication industries in Townsville, offering unmatched precision, versatility, and efficiency in cutting a wide range of materials. From metal fabrication and signage production to architectural detailing and aerospace components, water jet cutters play a crucial role in shaping the landscape of Townsville's industrial sector. Let's delve into the unique applications and uses of water jet cutters in Townsville:

Metal Fabrication and Machining:

In Townsville's thriving metal fabrication industry, water jet cutters are widely used for cutting and machining various metals with precision and accuracy. From stainless steel and aluminium to copper and brass, water jet cutters can effortlessly cut thick metal sheets, plates, and profiles to create intricate components, parts, and prototypes for diverse applications. Whether it's fabricating structural steel beams for construction projects or producing precision-engineered parts for machinery and equipment, water jet cutters provide unparalleled versatility and efficiency.

Signage and Graphics:

Water jet cutters are indispensable tools for the signage and graphics industry in Townsville, allowing for the precise cutting of materials such as acrylic, PVC, aluminium composite panels, and stainless steel. Whether it's cutting letters, logos, or intricate designs, water jet cutters can achieve crisp, clean edges and intricate details with ease. Sign makers in Townsville rely on water jet cutters to produce eye-catching signage, wayfinding systems, architectural features, and decorative elements that enhance the visual appeal of public spaces, commercial buildings, and retail establishments.

Architectural Detailing and Cladding:

Water jet cutters play a vital role in architectural detailing and cladding projects in Townsville, where precision and quality are paramount. Architects, designers, and contractors utilise water jet cutters to cut materials such as stone, marble, granite, and porcelain tiles to precise specifications for facade elements, wall cladding, flooring, and decorative features. Water jet cutting allows for intricate patterns, textures, and designs to be achieved, enabling the creation of stunning architectural elements that enhance the aesthetic appeal and functionality of buildings and structures.

Automotive Parts:

Automotive enthusiasts and professionals in Townsville turn to water jet cutters for the production of custom automotive parts and components. Whether it's cutting precision gaskets, brackets, or body panels, water jet cutters offer the versatility and accuracy required to meet the demanding specifications of automotive applications. From classic car restorations to performance upgrades and custom modifications, water jet cutters enable the fabrication of bespoke automotive parts that enhance performance, aesthetics, and functionality.

Marine and Offshore Applications:

In Townsville's maritime industry, water jet cutters are utilised for a variety of marine and offshore applications, including shipbuilding, repair, and maintenance. Water jet cutters can cut materials such as steel, aluminium, and fibreglass-reinforced plastics (FRP) with precision, making them ideal for fabricating hull components, deck fittings, propellers, and marine structures. With their ability to cut thick materials without heat-affected zones, water jet cutters ensure the structural integrity and durability of marine components, even in harsh marine environments.

Water jet cutters have become indispensable tools in Townsville's industrial landscape, offering versatile solutions for cutting, machining, and fabricating a wide range of materials. From metal fabrication and signage production to architectural detailing and aerospace components, water jet cutters play a crucial role in shaping various industries and driving innovation and productivity. As Townsville continues to grow and evolve, water jet cutters will remain essential tools for businesses, industries, and educational institutions seeking to achieve precision, efficiency, and excellence in cutting and fabrication processes.

0 notes

Link

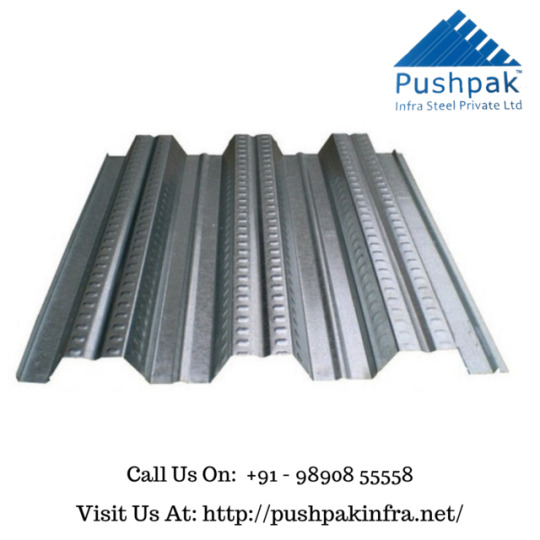

Pushpak Infrasteel is best roofing sheet, Color Roofing Sheets, Metal Roofing Tile Profile Sheets, Color Coated Sheets, Industrial Roofing Sheets, Decking Sheets, Floor Decking Sheets, Metal Decking Sheets, Metal Floor Decking Sheet, Steel Decking Sheets, Profile Sheets, Color Coated Profile Sheets, Pre-Coated Profile Sheets, Color Profile Sheets, Galvalume Profile Sheets, Profile Roofing Sheets, Steel Deck Profile Sheets, Composite Metals Deck Profile Sheets and Composite Deck Profile Sheets Manufacturer company in pune, Maharashtra, India

#Roofing Sheets manufacturer#Color Roofing Sheets manufacturer#Metal Roofing Sheet manufacturer#Metal Roofing Tile Profile Sheets manufacturer#Color Coated Sheets manufacturer#Industrial Roofing Sheets manufacturer#Decking Sheets manufacturer#Floor Decking Sheets manufacturer#Metal Decking Sheets manufacturer#Metal Floor Decking Sheet manufacturer#Steel Decking Sheets manufacturer#Profile Sheets manufacturer#Color Coated Profile Sheets manufacturer#Pre-Coated Profile Sheets manufacturer#Color Profile Sheets manufacturer#Galvalume Profile Sheets manufacturer#Profile Roofing Sheets manufacturer#Steel Deck Profile Sheets manufacturer#Composite Metals Deck Profile Sheets manufacturer#Composite Deck Profile Sheets manufacturer#pune#Maharashtra#India.

0 notes

Text

Advantages of Decking Sheet

Metal Profile sheets with a solid and dependable shear bond that is enhanced by cross embossing in the profile. The composite floor profile is the pinnacle of light-weight steel decking, reducing the need for concrete and offering a cost-effective and simple-to-install alternate floor solution. A profiled Metal Deck sheet is used to create the board, which is then covered with a layer of concrete. When the concrete is poured, the GI decking layer is bound to the concrete by mouldings on the sheet, which prevent the concrete from sliding horizontally and detaching vertically before it has achieved the acceptable degree of hardening. Let’s look into the advantages of decking sheet if choosing the best deck sheet manufacturer in India.

· Since it is light weight and does not need any reinforcement, it significantly decreases the amount of concrete used and the thickness of the pavement.

· Acts as a permanent shuttering as well as a hybrid member.

· There isn't any big reinforcement needed.

· During building, the deck may be used as a working floor.

· Construction that is completed quickly allows a project to be completed sooner.

· Metal deck is also suitable for use as a roofing and cladding material.

Metal Deck Slab is also a steel cum concrete slab with an inbuilt shear connector and concrete on top, forming a composite slab as part of the floor structure provided by deck sheet manufacturer in India. Therefore, the composite floor profile is the pinnacle of light-weight steel decking, reducing the need for concrete and offering a cost-effective and simple-to-install alternate floor solution.

0 notes

Text

Recreational Vehicle: The Complete Guide [RVs] [Features, History, Types & Legality]

RV is an abbreviated form of Recreational Vehicle. RV can be a motor vehicle or a trailer which includes living quarter for accommodation. The usages of RV is temporary accommodation while traveling but some people also use it for main residence purpose.

Features of RV

Typical features of an RV include a sleeping room, bathroom, and a kitchen. RV can be luxurious as well as utilitarian. The utilitarian one has a sleeping quarter and a kitchen whereas the luxurious one may have features like a water heater, air conditioning, televisions and communication systems. RVs can be self-motorized as well as trailers ones which have to towed behind a motor vehicle. Most of the RVs have a single deck but the double deck is also considered by campers. Nowadays more compact size of RVs consists of expandable sides which are called slide outs or canopies.

History of Recreational Vehicles

Early types of the caravan were horse driven and they were important during 1745 when they were used to explore the interior of North American continent. Till 1920 the RVs were popular in America and there were RV camping clubs across the country. In those days many companies were manufacturing house trailers, one of the company was Airstream. Until the 1950s the mobile home industry and RVs industry were the same where mobile homes were shorter than 9 meters long and were easy to transport. In the 1950s, The RVs and mobile home industry separated and this was the time when RVs manufacturers were building self-contained motorhomes. In 1810, wagons were made for accommodation rather than just transporting people and good in France. During the same time in Britain, showmen, and circus used to live in these wagons during the 1920s. Even during 1820s Romani people were using caravans for a living. In 1929, the first motorhome was built in Australia. In 1910, the earliest motorhomes were built for cars and truck in Canada.

What is the use of RVs?

RVs are used as temporary accommodation for traveling. Although some people also use it as a main residence purpose. In the USA and Canada, snowbirding is the word which used to describe the traveling from clod to warmer areas in winter. Whereas, Grey nomad is the term used for a retired person who uses an RV in Australia.

Types of RVs

Class A Motorhome (Bus Conversion) These types of motorhomes are either made on truck chassis which is a specially designed vehicle chassis or even a commercial bus chassis. Most of the Class A motorhome looks like a bus in design and also have a flat or vertical front end. One special feature of this kind of motorhome is that they have large windows. Another feature which changed the industry is that now the motorhome was having wider living area because of slideouts. A portion of the vehicle now can come out to extend the inner area. During this time the vehicle has to be stationary mode. Class B Motorhome (Campervan) These campervans are built by either raising the roof of a conventional van or by replacing the low-profile body such as a.k.a coach-built. But in Australia, you will find a Class B Motorhome quite different from a campervan because it based on a very large type of van which in turn is based on a truck. The weight of these kinds of motorhome can be up to 4500 kilograms. The length of it is up to 6.4 meters. Examples – Ford Trader and Isuzu NPR 300 Many of the Australian campervans are smaller vehicles but the middle ground is mostly populated by a large type of vans which is quite blurry in a definition of a campervan and a motorhome. Examples – Ford Transit, Fiat Ducato, Iveco, and Mercedes-Benz Splinter While in the USA and Canada the motorhome is built on different chassis as it depends on the manufacturer. Examples of chassis are – Dodge Ram Promaster gas, Ford transit, Chevrolet Express gas and Mercedes Benz Sprinter. There are some rules in some state of USA for a vehicle to be qualified as a Class B Motorhome, such as in California. In the state of California, a vehicle should have 4 out of 6 built-in items to qualify as a Class B Motorhome. A water system (sink or a shower) A cooking system A refrigerator A fuel or a 110v electrical system An AC (Air Conditioning) system A toilet Class B Motorhomes These are large motorhomes, a Class c motorhome is usually built upon a minimal truck platform which is connected by a forward engine and the transmission is connected by driver-shaft to a rear axle that propels the dual mounted rear wheels. Most of the Class C motorhomes are powered by gasoline (petrol) and diesel but some have been converted to run on propane (autogas). These vehicles mostly have automatic transmission. During the building phase, the original chassis is taken from a truck factory and is taken to a coach builder which is attached to a forward cab section, that is a van or can be a conventional truck. This kind of chassis is known as cutaway chassis. Ford E350 or E450 chassis were used in North America during the 21 century but earlier it was Dodge/Ram and Chevrolet/GMC chassis which were used. While in Europe most of the Class C motorhomes chassis are manufactured by either Ford or Fiat. The outer structure of the Class C motorhomes is made from fiberglass, plastics, composites and also from lightweight metals. Earlier it was made from a wooden frame which was then covered by a thin sheet of metal. The characteristics of Class C motorhome can be a distinctive cab-over profile like it contains an upper sleeping area, entertainment section or storage space. In United kingdom cab over is also known as Luton body or Luton peak. Interior of a Class c motorhome is equipped with a kitchen cum dining area which has a refrigerator, a microwave oven and a table with a seating facility. There is a lavatory with bath shower, sleeping area, an AC, a water heater, a furnace, and an outside canopy. It can also have a generator and roof-mounted solar panels. A toy hauler is a subcategory of a Class c motorhome, which has a typical configuration and additional space for hauling dirt bikes, bicycle, and ATVs. You can also find a feature in these motorhomes which can pull lightweight trailers such as for boats. Class C motorhome is also called as mini motorhomes. Truck Camper A truck camper has a living space which is usually mounted into the bed of a pickup truck. It is often secured against any tipping or wobbling when the truck is in motion. You should take care in matching the weight balance of the truck camper. The truck camper is useful for those who do not wish to own a motorhome or a trailer and use it for part-time. Truck campers are commonly used for Backwood travel Hunting Fishing Camping In North America, it is generally used to drive off-road via rough roads to reach campsites. It can have features like refrigerators, oven, AC, furnace, water heater, lavatory and shower whereas the small can have a sleeping area and an icebox. Some of the pick-up truck which is used in North America for hauling slideout equipped campers are: Chevrolet/GMC 2500 through 3500 Ram 2500 through 3500 Ford 250 through 350 Popup Camper Other names of popup camper are tent camper, folding camper, tent trailer, and camper trailer. Popup trailers are of very lightweight, you can pull out the bunks and the tent's wall. These bunks and the tent walls are collapsible which can be used for towing and storage. It becomes easing for most of the vehicles to toe them such as minivans, SUVs and small pickup trucks even for compact cars. Travel Trailer Travel trailers are rigid sides design which is generally towed by a pickup truck, SUV or by a minivan. In the past in North America, very large cars were used to tow these travel trailers such as Chevrolet or GMC Suburbans, Ford Broncos, etc. In the UK travel trailers are known as caravans. Teardrop Trailer These are compact and lightweight travel trailers and it looks like a teardrop hence the name. These teardrop trailers can be towed by motorcycles too. Hybrid Trailer These are a hybrid version of a travel trailer and a folding tent trailer. In some designs, you will get a rigid side and a pull-out tent section which is generally beds. In another design, the top section of the walls and also its roof can be lowered over its bottom section to reduce its height for towing. Fifth-Wheel Trailer It has a fifth wheel coupling, a special inbox hitch, which is specially designed to be towed by medium-duty trucks and pickups. These types of trailers body can be extended over the truck bed which can shorten the total length of the vehicle and trailer too. Some of the fifth wheel trailers can extend over 40 feet (12.2m) in length and can be 18000 pounds (8200 Kilograms) in weight. These are very heavy trailers which can be pulled by small Freightliner or full-size class B truck such as Volvo. They were first used for a commercial purpose during the 1960s and since then have become popular. Park Model (Vacation/Resort cottage) These trailers are large and generally, they are 35 to 45 feet in length. It is useful for park camping. These are not suitable for dry camping as they do not have any water storage tanks and also must be used with hookups. These types of trailers are designed to remain stationary for a long time, but they differ from mobile homes in that they are often moved during off seasons.

Legality & RVs

in the USA there are regulations that affect the conversion of a school bus into a recreational vehicle. Like in Illinois and California it is required by law that the signaling equipment of the bus like stop sign, flashing lights, etc should be removed. The yellow paint of a typical school bus to be changed too. In other states, it requires that the school bus signage should be removed from the front and rear. In other countries, you may be required to have a second driving license to purchase or legally own a vehicle. Like in the UK, you need an owner of a Passenger Carrying Vehicle (PCV) category D1 or D license to drive the vehicle on UK roads. Read the full article

1 note

·

View note

Text

Kavya Roofing Accessories

In search of new roofing accessories, please contact Kavya Roofing which has been in the industry for over 10 years. We are a manufacturing industry dealing with metal construction systems, roofing materials, roofing or wall cladding sheets, preengineered steel buildings and architect design. We deal with various items such as: COLOR COATED ROOFING & WALL CLADDING SHEETS: three types of corrosionprotected steel for roof and wall cladding applications are described below.

Prepainted galvanized steel ,Prepainted galvanized steel ,Plain galvanized steel:Galvanized Steel: The metallic zinc coating can provide protection againstcorrosion in rural and urban areas. Atmospheric conditions do not shield the steel from corrosion, covered by a metallic Zinc coating.

Galvalume Steel: ZincAluminum alloy coating offers superior heat reflectivity and corosion resistance. Galvalume Steel reflects a high percentage of heat and can withstand, without surface discolouration, any climatic conditions. Kavya Roofing is the largest retailer and manufacturer of Galvanized and Color Coated GI / GL Coils used in the production of Purlins and Plain sheets or Corrugated Sheets.

METAL DECKING SHEETS Metal Deck profile sheets are made from Cold Roll Formed Steel for steel constructions. Composite Deck Slab is a steel and concrete slab with a ribbed steel profile on the bottom and concrete on top, forming a portion of the floor / roof framework called the composite deck slab together.

TILE PROFILE ROOFING SHEETS: Such profiles have unique features such as Light in weight, and a robust sealing process protects such materials against extreme weather. It provides full building protection against fire, cold, and rain.

PLAIN & CORRUGATED GALVANIZED SHEETS:

Galvanized steel corrugated sheets: the most important durability considerations are the strength of the zinc coating and the galvanizing process. CGI sheets are protected against corrosion by a zinc coating added on the sheet of steel.

ROOFING SHEET ACCESSORIES:

Kavya Roofing is fitted with a wide range of accessories such as Gutter, Lighting, Ridges, Louvers, Downpipe, etc., which are constructed from the same material used for Roofing and cladding to ensure durability.

C & Z PURLINS AND MS & GI HOLLOW PIPES

Kavya Roofing Purlins and Girts are made of Galvanized / Hot Rolled Hi-Tensile material. They are mainly used to provide framed structure support systems for lightweight, economical, effective roofing, and cladding.

CORRUGATED POLYCARBONATE SHEETS AND MULTIWALL SHEETS

Polycarbonate sheets are made of polymers. Various moulding processes give the polymer a rainbow profile appearance. The polycarbonate roof sheets are manufactured via the extrusion process.

FIBER REINFORCED PLASTIC SHEETS, PVC ROOFING SHEETS AND UPVC ROOFING SHEETS:

Corrugated sheets from Kavya Roofing FRP are available in various thicknesses and lengths. Their transparency property helps to meet the challenges of any environment, successfully.

VENTILATORS:

Turbo Roof Ventilators are built to absorb the regular and severe weather conditions of any industrial or commercial shed in order to extract heat and dust as much as possible, optimize fresh air entry into the shed and drive wind.

ROOF RIDGE VENTILATORS:

These devices are designed for the elimination of efficient heat humidity, smoke and fumes on any sheet roof profile.

LOUVER WINDOW & DOORS:

Louvre Window is a blind window or shutter with horizontal slats designed to admit light and air, yet to avoid rain and direct sunlight from coming.

PRE-ENGINEERED BUILDINGS :

Preengineered buildings are simple to design, deliver and erect anywhere with low elevation structures such as canopies, warehouses etc.,

THERMAL ALUMINIUM BUBBLE WRAP OR FOIL INSULATIONS:

InsularE is a thermal reflective insulation sheet that is fixed under the metal roofs and provides relief from the radiant heat produced.

ROOF TRUSSLESS AND SELF DRILLING FASTENERS:

With its distinctive profile and construction techniques, Traditional Curved / Arch Truss less Roof is a masterpiece of architecture and design proven to withstand different loads. It's made of Galvalume material the latest in metal roofing, without any structural components needed.

Services:

SHEET REMOVAL & INSTALLATIONS, STRUCTURE INSTALLATIONS AND REPAIR & MAINTAINANCE OF STEEL BUILDINGS:

Kavya Roofing has professionally trained engineers and certified manufacturers & fitters to build structures using appropriate safety measures, suitable equipment & machinery adhering to building design specifications and erection drawings.

0 notes

Text

Steel Fiber Market with Size, Share and Growth estimated to reach up to 2.5 Billion USD by 2023

[103 Pages Report] According to the new market research report "Steel Fiber Market by Type (Hooked, Straight, Deformed, Crimped), Application (Concrete, Composite, Refractories), Manufacturing Process (Cut Wire/Cold Drawn, Slit Sheet, Melt Extract), and Region - Global Forecast to 2023", published by MarketsandMarkets™, the Steel Fiber Market is projected to grow from the estimated USD 2.0 billion in 2018 to USD 2.5 billion by 2023, at a CAGR of 5.0% between 2018 and 2023. The market is growing due to the high demand from infrastructure and construction industries. Steel fiber is used in these industries as they exhibit properties such as superior tensile strength, crack resistance, durability, corrosion resistance, and high shear strength.

Get PDF brochure of report for more details: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=222903687

The hooked segment accounted for the largest share of the overall Steel Fiber Market in 2018.

Hooked steel fiber is the most commonly used type of steel fiber. Hooked steel fiber is used in concrete reinforcement in hydraulic structures, airport and highway paving, industrial floor, refractory concrete, bridge decks, shotcrete linings, and explosion resistant structures. This steel fiber type is affordable and easily available. Hooked steel fiber substantially enhances initial crack strength and provides post-crack strength. Hooked steel fiber forms stronger joints, which results in low maintenance of the concrete structure.

Concrete reinforcement application is expected to register the highest CAGR in the Steel Fiber Market during the forecast period.

Flooring, roof slab, bridges, water tanks, sports stadium, conference halls, tunnel lining, dams, canal lining, and blast-resistant structures come under the concrete reinforcement application. Steel fiber is widely used in concrete reinforcement application in tunnel lining and flooring. Reinforced concrete is used widely as they have high resistance to tensile and shear stresses caused by natural calamities such as earthquakes, winds, and vibrations.

https://www.prnewswire.com/news-releases/steel-fiber-market-worth-2-5-billion-by-2023-exclusive-report-by-marketsandmarkets-tm--873510869.html

APAC is expected to be the largest market for steel fiber during the forecast period.

APAC is the largest Steel Fiber Market, in terms of both value and volume. China, India, and Japan are the fast-growing economies that contribute to the growth of the market in the region. There are many large steel fiber manufacturers in the APAC region, such as Stewols India (India), Hunan Sunshine Steel Fiber (China), and Yuthian Zhitai Steel Fiber Manufacturing (China)). The demand for steel fiber is expected to increase in the region during the forecast period with the increasing demand from infrastructure, construction, textile, and other industries.

Key Market Players

The steel fiber market comprises major manufacturers such as Arcelor Mittal (Luxembourg), Bekaert (Belgium), Fibrometals (Romania), Nippon Seisen (Japan), Zhejiang Boean Metal Products (China), Green Steel Group (Italy), Spajic Doo (Serbia), Hunan Sunshine Steel Fiber (China), Yuthian Zhitai Steel Fiber Manufacturing (China), and R. STAT (Saint-Jean-Bonnefonds). The study includes an in-depth analysis of these key players in the steel fiber market, including profiling the companies and analyses of key market strategies.

Early buyers will receive 10% free customization on this report.

Don't miss out on business opportunities in Steel Fiber Market.

Read our blog for more details: https://chemabd007.blogspot.com/2019/04/steel-fiber-market-intelligence-with.html

About MarketsandMarkets

MarketsandMarkets is the largest market research firm worldwide in terms of annually published premium market research reports. Serving 1700 global fortune enterprises with more than 1200 premium studies in a year, M&M is catering to a multitude of clients across 8 different industrial verticals. We specialize in consulting assignments and business research across high growth markets, cutting edge technologies and newer applications.

Contact: Mr. Sanjay Gupta MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA: 1-888-600-6441 [email protected]

#Steel Fiber Market#Steel Fiber industry#Steel Fiber companies#Steel Fiber manufacturers#steel fiber

0 notes

Text

Glass Fiber-reinforced Plastics (GFRP)Market: Moving Towards Brighter Future| Owens Corning, JEC Group, PPG Industries, Inc., Johns Manville, Saint-Gobain, AGY

Glass fiber-reinforced plastics (GFRP) are produced by the fiber glass and are used widely in commercial and industrial applications due to their lightweight and durability. They usually have high tensile strength and flexibility as compared to the metals. These materials are widely used in industries like aerospace, construction, automotive, marine, electrical and others. Some of the leading key players profiled in this study: Few of the major competitors currently working in global glass fiber-reinforced plastics (GFRP) market are Owens Corning, JEC Group, PPG Industries, Inc., Johns Manville, Saint-Gobain, AGY, Nippon Sheet Glass Co., Ltd, ASAHI FIBER GLASS Co., Ltd., Braj Binani Group, BGF Industries, Inc., Nitto Boseki Co., Ltd, PFG FIBER GLASS CORPORATION, Celanese Corporation, SAERTEX GmbH & Co. KG, Reliance Industries Limited, Denka Company Limited, RTP Company, Reinforced Plastic Industries, Aeron Composite Pvt. Ltd, FIBREX and others.

Global glass fiber-reinforced plastics (GFRP) market is expected to rise from its initial estimated value by registering a substantial CAGR of 6.70% in the forecast period of 2019-2026. Rising installation of wind energy capacity is the major factor for the growth of this market.

Get Exclusive Sample Report: @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-glass-fiber-reinforced-plastics-gfrp-market

Market Drivers:

· Rising construction activities in developing countries is driving the growth of this market

· Increasing demand of GFRP in transportation industry is another factor driving the market growth

· Growing number of wind energy capacity installations will drive the market growth

· Rising usage of GFRP composite pipes in sewage & water management will also accelerate the growth of the market

Market Restraints:

· High production cost is restraining the growth of this market

· Increasing recyclability issue is another factor restraining the market growth

Key Developments in the Market:

· In February 2019, SABIC announced the launch of their Stamax Stadeck which is specially designed for building and construction market. They are lighter than the wooden planks and have high durability. They are constructed in such a way that these panels can stay outdoors for long periods without rotting or corroding. They are very suitable for fencing, sheathing, decking, wheel chair ramps among others

· In July 2017, Owens Corning Infrastructure Solutions announced that they have acquired Aslan FRP. This acquisition will help the company to expand themselves globally and to add new products and solutions through which they can upgrade the performance of concrete structures. It is lighter-weight and is more corrosion-resistant than conventional steel reinforcements

Complete Report is Available @ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-glass-fiber-reinforced-plastics-gfrp-market

Segmentation: Global Glass Fiber-reinforced Plastics (GFRP) Market

Global Glass Fiber-reinforced Plastics (GFRP) Market By Resin Type (Polyester, Vinyl Ester, Epoxy, Polyurethane, Thermoplastic, Others)

End- User (Wind Energy, Electrical & Electronics, Transportation, Pipes & Tanks, Construction & Infrastructure, Marine, Aerospace & Defense, Other End-Use Industries)

Manufacturing Process (Compression & Injection Molding Process, Layup, Filament Winding, Pultrusion, Resin Transfer Molding (RTM), Other Manufacturing Processes)

Process (Manual, Continuous, Compression Molding, Injection Molding)

Form (Rebar, Powder, Sheet, Panel, Rolls, Others)

Geography (North America, South America, Europe, Asia-Pacific, Middle East and Africa) – Industry Trends and Forecast to 2026

Competitive Analysis:

Global glass fiber-reinforced plastics (GFRP) market is highly fragmented and the major players have used various strategies such as new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others to increase their footprints in this market. The report includes market shares of glass fiber-reinforced plastics (GFRP) market for Global, Europe, North America, Asia-Pacific, South America and Middle East & Africa.

Key Insights in the report:

· Complete and distinct analysis of the market drivers and restraints

· Key market players involved in this industry

· Detailed analysis of the market segmentation

· Competitive analysis of the key players involved

Access Full Report at https://www.databridgemarketresearch.com/reports/global-glass-fiber-reinforced-plastics-gfrp-market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge Market Research provides appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Related Report-

Global Sensor Bearing Market

#Glass Fiber-reinforced Plastics (GFRP)Market#Glass Fiber-reinforced Plastics (GFRP)Market Overview#Glass Fiber-reinforced Plastics (GFRP)Market Size#Glass Fiber-reinforced Plastics (GFRP)Market Share#Glass Fiber-reinforced Plastics (GFRP)Market Trends

0 notes

Text

Speciality & Fine Food Asia 2019 at Singapore(Singapore) 2019-July

protective coatings contacts list, structural steel fabricators companies contacts, roofing / structural steel machinery & tools Trade Shows, steel tubes / pipes / hollow sections B2C ideas, welding machines directory, electrodes contacts list, pre-engineered building systems (pebs) Expos, erectors Business events, colour coated steel sheets B2C opportunities, roofing systems business opportunities, metal roofing systems contacts list, architectural cladding business opportunities, metal cladding B2B Opportunities, facade engineering contact links, metal decking contact links, pre-engineered buildings Exhibitors Directory, metal profiles companies contacts, metal building systems Business events, sandwich panels Exhibitors, light gauge steel structures / buildings B2C opportunities, space frames companies list, structural steel B2B Opportunities, steel gratings & cable trays Trade Shows, steel framing machinery Exhibitors, roll forming roof machinery info, steel / composite structure building Shows, spaceframes contact links, contractors Events, tensile fabric architecture business contacts, estimators Events, green roofs technology companies, fastening/ fixing systems Expos, roof waterproofing Fairs, scaffolding directory, roof insulation business ideas, insulations companies list, fasteners contact info, floorings network, solar roofs / bipv companies contacts, fire protection solutions/passive fireprotection - drywalls events, calcium silicate boards contact info, firestops business ideas, fireproof sprays/ coats / plasters Events, etc. Shows, manufacturing B2C ideas, processing events, oil & gas Expos, mining Trade Fairs, electronics Meetings, power contact links, petrochemical Exhibitors, metallurgical industries Events, etc. building and construction companies companies contacts, fabricators and workshop owners companies list, architects Shows, consultants B2B Opportunities, engineers (mechanical business opportunities, electrical and electronic engineers) Fairs, metal working industry professionals (iron Meetings, steel contacts list, magneisum events, aluminium and other metal industry) Exhibitors Directory, telecommunication industry and equipment B2B ideas, home appliances industry Exhibitors, machinery manufacturing companies, electrical industry contact links, traders of light metals B2B ideas, representatives from the municipalities and other government agencies contact info, representatives from educational institutions such as universities and technical colleges contact info, developers Shows, building owners business opportunities, landlords business, architectural Exhibitors, civil engineering B2B ideas, construction Expos, system integrators B2B Opportunities, consultancy events, interior design Exhibitors Directory, decorator B2B ideas, landscaping contact list, fm & maintenance manufacturers Exhibitors, exporters Meetings, importers network, resellers etc. companies contacts 2019, July, Japan, Tokyo

Infra-Main Tech 2019 at Japan(Tokyo) 2019-July

Infra-Main Tech 2019 trade show event mainly focuses on:

protective coatings Trade Shows, structural steel fabricators contact info, roofing / structural steel machinery & tools Trade Fairs, steel tubes / pipes / hollow sections Trade Fairs, welding machines business ideas, electrodes business ideas, pre-engineered building systems (pebs) contact list, erectors Business events, colour coated steel sheets Trade Shows, roofing systems Exhibitors, metal roofing systems B2C ideas, architectural cladding contact list, metal cladding business ideas, facade engineering companies contacts, metal decking contact list, pre-engineered buildings companies list, metal profiles Exhibitions, metal building systems Events, sandwich panels Exhibitors Directory, light gauge steel structures / buildings Events, space frames Exhibitions, structural steel Exhibitions, steel gratings & cable trays events, steel framing machinery companies, roll forming roof machinery B2C opportunities, steel / composite structure building Expos, spaceframes Shows, contractors Events, tensile fabric architecture Exhibitions, estimators info, green roofs technology Exhibitors, fastening/ fixing systems Expos, roof waterproofing Trade Shows, scaffolding companies, roof insulation business contacts, insulations business, fasteners contacts list, floorings Business events, solar roofs / bipv network, fire protection solutions/passive fireprotection - drywalls business ideas, calcium silicate boards business ideas, firestops Shows, fireproof sprays/ coats / plasters contacts list, etc. Business events, manufacturing companies, processing B2B ideas, oil & gas info, mining contacts list, electronics Meetings, power companies contacts, petrochemical Fairs, metallurgical industries Events, etc. building and construction companies B2C ideas, fabricators and workshop owners B2B Opportunities, architects companies list, consultants Meetings, engineers (mechanical companies contacts, electrical and electronic engineers) info, metal working industry professionals (iron Meetings, steel B2C opportunities, magneisum directory, aluminium and other metal industry) Trade Fairs, telecommunication industry and equipment business, home appliances industry Shows, machinery manufacturing contact links, electrical industry contacts list, traders of light metals Expos, representatives from the municipalities and other government agencies B2B Opportunities, representatives from educational institutions such as universities and technical colleges contact list, developers Trade Fairs, building owners companies contacts, landlords business ideas, architectural contact info, civil engineering Expos, construction Events, system integrators business opportunities, consultancy Exhibitors Directory, interior design contacts list, decorator events, landscaping Exhibitors, fm & maintenance manufacturers Trade Shows, exporters contact list, importers network, resellers etc. business ideas

related products/services/industry/business. This trade show opens top business opportunities to exhibit products and services from protective coatings contact links, structural steel fabricators business opportunities, roofing / structural steel machinery & tools B2B Opportunities, steel tubes / pipes / hollow sections business, welding machines B2B ideas, electrodes business, pre-engineered building systems (pebs) contact info, erectors contact info, colour coated steel sheets Meetings, roofing systems contacts list, metal roofing systems business ideas, architectural cladding B2C ideas, metal cladding B2B Opportunities, facade engineering B2B Opportunities, metal decking contact info, pre-engineered buildings business contacts, metal profiles Shows, metal building systems Shows, sandwich panels contact info, light gauge steel structures / buildings Exhibitors, space frames B2B Opportunities, structural steel companies list, steel gratings & cable trays network, steel framing machinery B2C opportunities, roll forming roof machinery business contacts, steel / composite structure building companies, spaceframes Exhibitors Directory, contractors companies, tensile fabric architecture business, estimators events, green roofs technology Exhibitions, fastening/ fixing systems Exhibitions, roof waterproofing companies, scaffolding business opportunities, roof insulation contact list, insulations contact info, fasteners Shows, floorings Meetings, solar roofs / bipv contact list, fire protection solutions/passive fireprotection - drywalls companies, calcium silicate boards Exhibitors, firestops Trade Shows, fireproof sprays/ coats / plasters info, etc. companies contacts, manufacturing companies contacts, processing Exhibitors Directory, oil & gas contact links, mining contact list, electronics contact info, power Shows, petrochemical Trade Shows, metallurgical industries contact info, etc. building and construction companies business opportunities, fabricators and workshop owners business opportunities, architects B2C ideas, consultants network, engineers (mechanical Exhibitors, electrical and electronic engineers) B2B Opportunities, metal working industry professionals (iron info, steel Meetings, magneisum Events, aluminium and other metal industry) network, telecommunication industry and equipment companies contacts, home appliances industry Shows, machinery manufacturing Events, electrical industry contact info, traders of light metals network, representatives from the municipalities and other government agencies contact list, representatives from educational institutions such as universities and technical colleges Exhibitors Directory, developers companies list, building owners business ideas, landlords B2B Opportunities, architectural business ideas, civil engineering events, construction Events, system integrators events, consultancy events, interior design network, decorator events, landscaping directory, fm & maintenance manufacturers Exhibitions, exporters contact list, importers business, resellers etc. Shows industry.

Find More Details about Infra-Main Tech 2019 event...

We help you to grow your business by providing the required contact details of all companies participating in this event and you can download the same data in excel format using the above links. Location of the Event:Japan(Tokyo) Year-Month:2019-July Official Website:Event Website source https://www.expomahal.com/2019/08/speciality-fine-food-asia-2019-at.html

0 notes

Text

Calgary AB Roofing Guide: Metal Roof Cost of Tin Roofing Shingles in 2019

Whether you're about to replace an aging roof, remodel an ancestral home, or install a brand-new roof on your freshly-constructed Calgary AB property, material costs is one of the biggest factors when it comes to predicting your expenses. Metal roof cost estimates are some of the highest because they undeniably expensive.

On the other hand, they offer one of the longest roofing performances possible because of its exceptional lifespan and durability. However, some Calgary AB homeowners find the roofing material's "too modern" and aesthetically-specific look a turn-off. Manufacturers have listened and delivered the best alternative - metal roofing shingles.

Curious? They give your property a traditional residential look while having the same longevity, lifespan, and durability metal roofs have. Of course, they are roofing materials with their own limitations. Metal Roofing Systems has an excellent breakdown on this -- read it here.

Metal Shingles Roofs Installation Basics & Their Pros and Cons

A metal shingles roof offers a unique look of conventional roof systems including composition shingles, slate, cedar shingles, tiles, and more. Additionally, a metal shingles roof will often cost less than a comparable in quality, architectural standing seam roof, while providing the same level of protection, durability and longevity.

youtube

If you own a classic colonial or a brick house, then a metal shingles is definitely the way to go, especially if you want to preserve that “authentic traditional look”, yet, have all the benefits of a metal roof.

What is It All About?

Interlocking metal shingle roof is the second most popular type of residential metal roofing, after standing seam. There is a huge variety of different metal shingle styles from many different manufacturers. Most common metals used to manufacture metal shingles are G90 galvanized steel and aluminum, though you can also find a few types of copper and even zinc shingles.

Metal shingles are manufactured using a stamping press, through which the metal coil is fed, and the die stamps the shingle in two or three steps. First, the profile of the shingle is stamped out, with the lock flanges. Then, in step 2 and/or 3, the locks are made, and the shingle comes out of the press and is packaged into the box.

Did you know? Most metal shingles come painted with Kynar 500 or equivalent premium paint, with a total of seven layers of paint and primer, baked onto the metal coil.

Install Roof Shingles

Distinguishing characteristic of metal shingles is the low profile and a four-way interlocking design. Low profile allows for easy walking on metal shingles (during installation), without damaging the shingles, along with a simplified roof flashing system (easier to install, and hence costs less compared to standing seam).

Many popular styles of metal shingles include cedar shingle and natural slate impression. – These metal shingles can closely resemble both types of premium roofing materials, but will cost either the same (as in case with cedar shingles) or considerably less (slate impression metal shingles) to install. Metal shingles will also last a lot longer than cedar shingles.

Another popular type of metal shingles is a simple flat tile impression, which is basically a smooth surface metal shingle, with stiffening ribs in the middle, which create the look of separate tiles. Same stiffening ribs are used in all other types of metal shingles.

Installation Basics:

Most metal shingles systems are installed from the eave of the roof, up. The first course of shingles is locked or hooked onto the drip edge / starter trim, which is nailed or screwed to the properly prepared roof deck. Metal shingles are attached to the roof using nail and either special built-in hems or clips.

Once the first row of shingles is installed, most roofing contractors start “building a stair” or staggering the shingles and adding rows on one side of the roof so that each new diagonal run of shingles would have as many shingles as possible. Basic premise here is that you don’t want to install one row at a time, by going from one end of the roof to another. You want to run as many rows of shingles at once, as possible. See the video below, which will demonstrate the installation of aluminum interlocking metal shingles.

Installing curb flashing on a metal shingles roof (read full post here)

With an understanding of their look and function, there is no way they are inexpensive. However, you'd be surprised -- you're saving much more with metal roof cost estimates. Because you'll possibly replace your asphalt shingles and roofs more frequently, you'll save up on using metal roofing shingles.

The initial price of metal roofs can be high but the long-term benefits make them truly worthwhile investments. Modernize has an excellent summary on metal roof cost vs traditional asphalt shingles -- check it out!

Metal Roof Material Costs

It’s important to understand that “metal roofing” is a broad term covering a range of materials with a large disparity in price. Metal roofing materials will generally run you anywhere from $7.00 to $9.00 per square foot, depending on which kind you choose. However, there are more affordable options, like steel panels, which usually cost you slightly less, as well as high-end materials, like copper roofing, which tend to average a little bit more on the pricier side. Here are the most common types of metal roofs and their individual costs:

Standing seam metal roofs will cost you about $4.00 to $6.50 per square foot.. This is the most common metal roof design due to its availability in the U.S. The design features vertical panels that are joined by interlocking seams.

Corrugated steel panel roofs are the least expensive type of metal roofing, costing about $1.20 to $5.00 per square foot comparable to the price of asphalt shingle roofing. It is thin and lightweight, which means it can be installed over existing roofing. This cuts down on the costs of removing old roofing. However, the quality tends to match the price, as these panels are vulnerable to leaks and rust.

Steel & Aluminum shingle roofing runs $3.00 to $9.00 per square foot. Metal roofing tiles and shingles aren’t as affordable as corrugated panels, however they are a better deal. They typically last 40 years or more and are much more resistant to leaks and rust than corrugated metal roofing panels.

Stone coated steel tiles and shingles tend to cost $1.85 to $4.00 per square foot. This metal roof type allows for aesthetic diversity by offering the benefits of metal roofing with the look of more traditional clay or slate shingles.

Copper Zinc Metal Roofs cost between $4.00 to $15.00 per roofing square foot, and are considered one of the highest quality metal roofing types.

You can choose any paint finish you would like for a metal roof, depending on the preferred color and desired energy efficiency. Paint quality varies, ultimately affecting the price of the materials you purchase for installation. This should be included in your metal roofing quote from a professional metal roof installer.

Keep in mind that underlayment and the other accessories needed for metal roofing installation tends to cost $4.00 to $5.00 per square foot.

Metal Roofing vs Asphalt Shingles

A metal roofs costs $7 to $10 per sq. foot compared to Asphalt shingles costing from 1.50 to $5.50 per sq. foot.

A metal roof lasts 40 to 80 years, while asphalt shingle roofs will last 20+ years.

Metal roofing also has the advantage of an 85.9% average return on home investment and lowers your insurance rate due to fire resistance compared to asphalt roofs.

(Read More Here)

However, are metal roof shingles inferior to their predecessors materially? They share many similarities, but corrugated and standing seam metal roofing have different characteristics that you may find greatly advantageous in many situations. Learn more about them here!

Corrugated Metal Roofing vs. Standing Seam – Pros & Cons, Plus Costs

Back in the day, metal roofing was used to cover homes, barns, commercial roofs, factory buildings, and churches before asphalt shingles were even invented. Metal was solid, affordable, and durable roofing material.

Nowadays, metal roofing is enjoying some impressive resurgence in popularity and demand, whether it’s standing seam, corrugated metal sheets, or ribbed metal panels.

Corrugated metal panels are often used in commercial and low-end residential applications, but standing seam is becoming a lot more prominent and extremely popular in high-end residential and commercial retrofits and new roof installations.

Both of these systems have their pros and cons that must be considered before deciding which particular system will best suit your needs.

From Metal to Corrugated Galvanized Iron Sheets

Metal, namely copper, has been used as a roofing material since about 970 BC. Corrugated metal panels were invented the early 1800’s. It was the “new and improved” metal roofing system featuring wavy or ribbed panel profile. Corrugating the sheets of metal, which was hot-dip galvanized iron at the time, increased their strength and longevity.

During the installation, corrugated metal panels are overlapped by one or two ridges, through-fastened onto the roof deck or frame, and commonly sealed with caulk (in between the corrugated panels at the point of overlap) to keep rainwater and moisture out. Needless to say caulking is the least permanent part of the corrugated metal roof.

Standing seam metal roofing became the “new and improved” roofing option in the mid-1900’s. The “standing” or raised seams made the durable roofing material even more weatherproof. The ridges that run the length of standing seam metal roofs are the seams between the metal panels.

Bending the panel edges up to a height of ½ to 1 ½ inches, then folding them over makes standing seam metal roofs more weatherproof. The raised seams force rainwater and moisture to run down off the roof in the “channels” between the seams instead of working its way between the metal panels.

Difference in Price (read the entire post here)

With a full understanding of metal roofing shingles benefits to your property, it pays to have exceptional installations to prolong the lifespan and durability of your new metal roof. No Payne Roofing is a decades-experienced and exceptionally-trained roofing contractor in Calgary AB that guarantees only high-quality results from all its projects. Contact us today!

% Source Here: Calgary AB Roofing Guide: Metal Roof Cost of Tin Roofing Shingles in 2019

%BLOGLINK%% 44 Hawkcliff Pl NW, Calgary, AB T3G 2S2, Canada 587-227-0517 https://goo.gl/maps/VogLjhuvPXYGWQfG9

0 notes

Text

Metal Roof Shingles: Effective as Corpus Christi, TX Metal Roofs?

Metal roofing is no novelty. In fact, corrugated and standing seam metal roofing have become mainstream roofing materials. However, property owners rarely discuss the capabilities of metal roof shingles. True enough, these are as formidable as their traditional counterparts except they can imitate the appearance of asphalt shingle roofs. In turn, you get a beautiful roof that has all the trimmings and advantages of metal.

To know more about metal roof shingles, here are a few things to know about them. MetalRoofingSystems has a great breakdown all about their pros, cons, and costs

Metal Shingles Roofs Installation Basics & Their Pros and Cons

If you are a homeowner interested in installing a new metal roof on your home, but you are afraid that your home may end up looking like some sort of a barn or way “too modern” for your neighborhood, then you should consider installing an architectural metal shingles roof that can provide the same superior performance as other premium systems.

A metal shingles roof offers a unique look of conventional roof systems including composition shingles, slate, cedar shingles, tiles, and more. Additionally, a metal shingles roof will often cost less than a comparable in quality, architectural standing seam roof, while providing the same level of protection, durability and longevity.

If you own a classic colonial or a brick house, then a metal shingles is definitely the way to go, especially if you want to preserve that “authentic traditional look”, yet, have all the benefits of a metal roof.

What Is It All About?

Interlocking metal shingle roof is the second most popular type of residential metal roofing, after standing seam. There is a huge variety of different metal shingle styles from many different manufacturers. Most common metals used to manufacture metal shingles are G90 galvanized steel and aluminum, though you can also find a few types of copper and even zinc shingles.

Metal shingles are manufactured using a stamping press, through which the metal coil is fed, and the die stamps the shingle in two or three steps. First, the profile of the shingle is stamped out, with the lock flanges. Then, in step 2 and/or 3, the locks are made, and the shingle comes out of the press and is packaged into the box.

Did you know? Most metal shingles come painted with Kynar 500 or equivalent premium paint, with a total of seven layers of paint and primer, baked onto the metal coil.

Styles:

Distinguishing characteristic of metal shingles is the low profile and a four-way interlocking design. Low profile allows for easy walking on metal shingles (during installation), without damaging the shingles, along with a simplified roof flashing system (easier to install, and hence costs less compared to standing seam).

Many popular styles of metal shingles include cedar shingle and natural slate impression. – These metal shingles can closely resemble both types of premium roofing materials, but will cost either the same (as in case with cedar shingles) or considerably less (slate impression metal shingles) to install. Metal shingles will also last a lot longer than cedar shingles.

Another popular type of metal shingles is a simple flat tile impression, which is basically a smooth surface metal shingle, with stiffening ribs in the middle, which create the look of separate tiles. Same stiffening ribs are used in all other types of metal shingles.

youtube

Installation Basics: (Read More Here)

However, how does it measure up against its predecessors? Reading up on the advantages, disadvantages, and prices of both corrugated and standing seam metal roofing will definitely clear the air when it comes to deciding between the three best roofing materials in the market today.

RemodelGurus has an excellent comparison article on both corrugated and standing seam metal roofs. Here it is below:

Corrugated Metal Roofing vs. Standing Seam – Pros & Cons, Plus Costs

Back in the day, metal roofing was used to cover homes, barns, commercial roofs, factory buildings, and churches before asphalt shingles were even invented. Metal was solid, affordable, and durable roofing material.

Nowadays, metal roofing is enjoying some impressive resurgence in popularity and demand, whether it’s standing seam, corrugated metal sheets, or ribbed metal panels.

Corrugated metal panels are often used in commercial and low-end residential applications, but standing seam is becoming a lot more prominent and extremely popular in high-end residential and commercial retrofits and new roof installations.

Both of these systems have their pros and cons that must be considered before deciding which particular system will best suit your needs.

From Metal to Corrugated Galvanized Iron Sheets

Metal, namely copper, has been used as a roofing material since about 970 BC. Corrugated metal panels were invented the early 1800’s. It was the “new and improved” metal roofing system featuring wavy or ribbed panel profile. Corrugating the sheets of metal, which was hot-dip galvanized iron at the time, increased their strength and longevity.

During the installation, corrugated metal panels are overlapped by one or two ridges, through-fastened onto the roof deck or frame, and commonly sealed with caulk (in between the corrugated panels at the point of overlap) to keep rainwater and moisture out. Needless to say caulking is the least permanent part of the corrugated metal roof.

Standing seam metal roofing became the “new and improved” roofing option in the mid-1900’s. The “standing” or raised seams made the durable roofing material even more weatherproof. The ridges that run the length of standing seam metal roofs are the seams between the metal panels.

Bending the panel edges up to a height of ½ to 1 ½ inches, then folding them over makes standing seam metal roofs more weatherproof. The raised seams force rainwater and moisture to run down off the roof in the “channels” between the seams instead of working its way between the metal panels.

Difference in Price (Read The Rest Here)

With both corrugated and standing seam metal roofs in hand, you can now make a decision whether to use metal roof shingles for a mix of traditional aesthetics and modern technologies or traditional metal roofs for that modern appeal. True enough, making this decision is purely on aesthetics because metal roofs share advantages such as a lengthy lifespan and exceptional durability. The Spruce has an excellent write-up on what makes metal roofs the best among the rest.

12 Things to Know About Metal Roofing

Metal roofing has now entered the mainstream and has become a viable option for nearly all homes, except those with very flat roof pitches. Nor do all metal roofs scream "metal." There are now shingle-style metal roofing products that are almost indistinguishable from traditional asphalt shingle roofs. If you are wondering about the merits of metal roofing, here are 12 things to know.

Metal Roofs Are Not Just a Novelty

Once, metal roofing was found only on high-end, architect-designed homes. That's no longer true. Metal roofing is increasingly found on conventional houses, thanks to increasing availability and improved manufacturing processes. According to industry statistics, market share for metal roofing has been increasing at a rate of roughly 3 percent each year over the past few years; currently, about 15 percent of all roofing installations use metal roofing materials. At the same time, the market share for asphalt shingle roofing has fallen, now accounting for about 59 percent of the total roofing installed.

Metal Roofing Can Be Installed Over Existing Roofs

Metal roofs can be installed over your existing roof without tearing off shingles, provided local building codes allow it. While shingle removal is the preferred route, tear-off is messy and raises the cost of the job.

A potential problem with this type of installation is trapped water vapor. If trapped between the metal roofing and old roofing, moisture can build up and cause mold and rot. But roofers can install a vented metal roof that eliminates this potential problem. Or, installing the new metal roofing over furring strips (1 x 3s or similar) will raise the metal and provide a ventilating air pocket between layers.

Make sure to consult local buiding codes before having a metal roof installed directly over old shingles. Some jurisdictions may require full tear-off whenever a new roof is installed.

Metal Roofs Are No Noisier Than Asphalt Roofing

Although its a common misconception that metal roofs are noisy when rain or hail falls on them, the reality is that when properly installed, metal roofing is really no noisier than any types. Metal roofing is typically installed over a solid substrate. Additionally, the attic and insulation provide a sound barrier. From interior living spaces, inhabitants almost never notice any increase in sound levels when a metal roof is installed.

Metal Roofing Does Not Attract Lightning (Read More Here)

With a full understanding of what metal roof shingles and metal roofing can do for you (and fall short of doing), you can now make an informed decision on which type of metal roof to have.

In addition, an excellent installation or replacement prolongs the lifespan and durability of your roof. When it comes to excellent metal roofing in Corpus Christi, TX, you can depend on Galvan Builders. We are a decades-experienced roofer that has installed hundreds of metal roofs and metal roof shingles across our local area. Contact us today for a FREE quote!

Learn More Here: Metal Roof Shingles: Effective as Corpus Christi, TX Metal Roofs?

Galvan Builders Construction Company 4938 Williams Drive, Corpus Christi TX 78411 361-857-4341 https://goo.gl/maps/hRuKHVsqsXXBvgRK8

0 notes

Text

Concepts For Deck And Porch Railings

Aluminum sheets are used extensively all around the world and mainly due to its numerous properties the makes use of are diverse in nature. Architectural doorways just like the highly esthetic arch wooden doorways are suitable for people residing in residential neighborhoods, the place details such as doors, gardens, lawn or windows make an enormous distinction amongst homes. Extrusion is the method in which completely different materials are used to create a fixed cross-sectional profile. Stainless steel jewellery is an effective possibility for people who wish to put on jewelry whereas they're on an outing.

Steelmaking course of, with a view to enhance the quality of steel, must get rid of the molten iron carbon, sulfur and other dangerous impurity, the simplest course of is to make use of oxidation technique, however some iron and impurity aspect with oxidation to produce ferrous oxide (FeO), whereas FeO in solubility in liquid metal, in order that in liquid steel increased oxygen, can obtain zero.25% ~ 0.forty five%.

Stable and even distribution of warmth throughout the hair, elimination of damaging spots, and environment friendly heat retention are a number of the highlights of ceramic technology. Delicate Steel is basically Steel which is a composition of Iron and Carbon. TaylorMade Golf has launched the popular Burner Plus iron, engineered for the ten handicap bomber. Manganese is active good steel powder , the chemical performance is vigorous than iron, manganese will be part of steel liquid when can and FeO response formation insoluble in molten metal of oxide slag, floating YuGangShui level, reducing oxygen in steel.

Metal being an alloy of iron is a lot more flexible thus, it is extremely simple to mould it into shapes with out the fear that it could break. In case you live in a neighborhood where loud sounds are the norm, aluminum is the most effective materials that you should use in your sidings. Wooden storage doors may be easily painted or stained within the colour of your choice. As you are installing the log vinyl siding you need to take care that the pattern of the logs is seen and also that you have allowed enough of the vinyl siding materials to account for the varied climate situations.

The issue with circumstances fabricated from decrease quality supplies is that the shell of the case is inclined to wreck. Learn the step of creating Aluminum Castings and basic Steel Manipulation in the stainless steel manufacturers. The heat of welding reduces yield and supreme strengths of aluminum alloysthat get their power from articial growing older and people who derive their strengthfrom cold-working.

The MP-fifty two options twin CNC-milled pocket cavities behind the face in the 3- by means of 7-irons. Liquid raw iron referred to as "pig iron" is poured in and some scrap steel is added in to balance the warmth. Every price-discount, power effectivity, materials conservation, and job era good thing about recycling adds as much as assist construct a powerful financial system for our country.

0 notes

Link

Trapezoidal Metal Profile sheets with strong and reliable shear bond performance which is augmented by cross embossing located in the profile. The composite floor profile offers the ultimate in the light weight steel decking which reduced concrete usage to provide a cost effective and alternative floor solution that easy to install.

0 notes

Photo

Pushpak Infrasteel is deck Profile Sheets manufacturer Company in Pune, India. We offer a huge collection of Deck Profile Sheets, Steel Deck Profile Sheets, Composite Deck Profile Sheets, and Composite Metals Deck Profile Sheets at competitive prices in all over India. For more information call us at +91 - 98908 55558 or visit us at http://pushpakinfra.net/

#Steel Deck Profile Sheets manufacturer#Composite Deck Profile Sheets manufacturer#Composite Metals Deck Profile Sheets manufacturer#Steel Deck Profile Sheets manufacturer in pune#Composite Deck Profile Sheets manufacturer in pune#Composite Metals Deck Profile Sheets manufacturer in pune

0 notes

Photo

Pushpak Infrasteel is deck Profile Sheets manufacturer Company in Pune, India. We offer a huge collection of Deck Profile Sheets, Steel Deck Profile Sheets, Composite Deck Profile Sheets, and Composite Metals Deck Profile Sheets at competitive prices in all over India. For more information call us at +91 - 98908 55558 or visit us at http://pushpakinfra.net/

#Steel Deck Profile Sheets manufacturer#Composite Deck Profile Sheets manufacturer#Composite Metals Deck Profile Sheets manufacturer#Steel Deck Profile Sheets manufacturer in pune#Composite Deck Profile Sheets manufacturer in pune#Composite Metals Deck Profile Sheets manufacturer in pune

0 notes

Text

Steel Fiber Market expected to be worth 2.5 Billion USD by 2023, at a CAGR of 5.0%, from 2018–2023

According to the new market research [103 Pages report] "Steel Fiber Market by Type (Hooked, Straight, Deformed, Crimped), Application (Concrete, Composite, Refractories), Manufacturing Process (Cut Wire/Cold Drawn, Slit Sheet, Melt Extract), and Region - Global Forecast to 2023", published by MarketsandMarkets™, the Steel Fiber Market is projected to grow from the estimated USD 2.0 billion in 2018 to USD 2.5 billion by 2023, at a CAGR of 5.0% between 2018 and 2023. The market is growing due to the high demand from infrastructure and construction industries. Steel fiber is used in these industries as they exhibit properties such as superior tensile strength, crack resistance, durability, corrosion resistance, and high shear strength.

Get PDF brochure of report for more details: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=222903687

The hooked segment accounted for the largest share of the overall Steel Fiber Market in 2018.

Hooked steel fiber is the most commonly used type of steel fiber. Hooked steel fiber is used in concrete reinforcement in hydraulic structures, airport and highway paving, industrial floor, refractory concrete, bridge decks, shotcrete linings, and explosion resistant structures. This steel fiber type is affordable and easily available. Hooked steel fiber substantially enhances initial crack strength and provides post-crack strength. Hooked steel fiber forms stronger joints, which results in low maintenance of the concrete structure.

Concrete reinforcement application is expected to register the highest CAGR in the Steel Fiber Market during the forecast period.

Flooring, roof slab, bridges, water tanks, sports stadium, conference halls, tunnel lining, dams, canal lining, and blast-resistant structures come under the concrete reinforcement application. Steel fiber is widely used in concrete reinforcement application in tunnel lining and flooring. Reinforced concrete is used widely as they have high resistance to tensile and shear stresses caused by natural calamities such as earthquakes, winds, and vibrations.

prnewswire.com/news-releases/steel-fiber-market-worth-2-5-billion-by-2023-exclusive-report-by-marketsandmarkets-tm--873510869.html

APAC is expected to be the largest market for steel fiber during the forecast period.

APAC is the largest Steel Fiber Market, in terms of both value and volume. China, India, and Japan are the fast-growing economies that contribute to the growth of the market in the region. There are many large steel fiber manufacturers in the APAC region, such as Stewols India (India), Hunan Sunshine Steel Fiber (China), and Yuthian Zhitai Steel Fiber Manufacturing (China)). The demand for steel fiber is expected to increase in the region during the forecast period with the increasing demand from infrastructure, construction, textile, and other industries.

Key Market Players

The steel fiber market comprises major manufacturers such as Arcelor Mittal (Luxembourg), Bekaert (Belgium), Fibrometals (Romania), Nippon Seisen (Japan), Zhejiang Boean Metal Products (China), Green Steel Group (Italy), Spajic Doo (Serbia), Hunan Sunshine Steel Fiber (China), Yuthian Zhitai Steel Fiber Manufacturing (China), and R. STAT (Saint-Jean-Bonnefonds). The study includes an in-depth analysis of these key players in the steel fiber market, including profiling the companies and analyses of key market strategies.

Early buyers will receive 10% customization on this report.

Don't miss out on business opportunities in Steel Fiber Market.

Read our blog for more details: https://chemabd007.blogspot.com/2019/04/steel-fiber-market-intelligence-with.html

About MarketsandMarkets

MarketsandMarkets is the largest market research firm worldwide in terms of annually published premium market research reports. Serving 1700 global fortune enterprises with more than 1200 premium studies in a year, M&M is catering to a multitude of clients across 8 different industrial verticals. We specialize in consulting assignments and business research across high growth markets, cutting edge technologies and newer applications.

Contact: Mr. Shelly Singh MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA: 1-888-600-6441 [email protected]

#Steel Fiber industry#Steel Fiber Market#Steel Fiber companies#Steel Fiber manufacturers#steel fiber#construction#construction industry

0 notes

Link

0 notes