#colour coated sheet

Explore tagged Tumblr posts

Text

Understanding the Role of Color Psychology in Product Design and Branding with Color Coatings

Introduction

Color has a powerful influence on our emotions, perceptions, and decision-making processes. This phenomenon, known as color psychology, plays a crucial role in product design and branding, especially when it comes to color coated sheets used in various construction and manufacturing applications.

Whether you’re a PPGI steel coil manufacturer, a contractor working with color coated sheets, or a business owner looking to enhance your brand's visual identity, understanding the impact of color can help you make more informed choices. From the calming hues of color coated galvalume sheets to the bold statements made by PPGI color coated sheets, the right color can significantly impact the way your products are perceived and the emotions they evoke in your target audience.

In this blog post, we’ll explore the science behind color psychology, delving into how different colors can influence purchasing decisions, brand recognition, and overall product appeal. By the end, you’ll have a deeper understanding of how to leverage the power of color coatings to enhance your product design and branding efforts.

Understanding the Role of Color Psychology in Product Design and Branding with Color Coatings

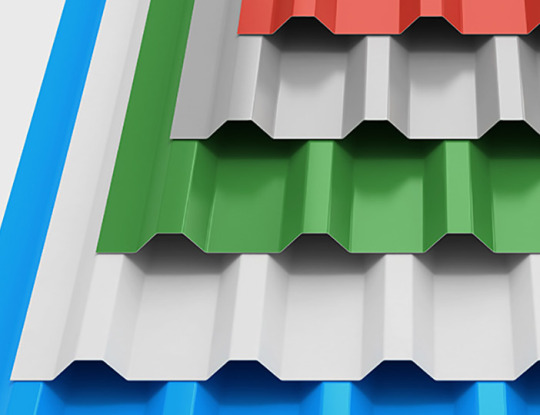

Color plays a vital role in our lives, influencing our emotions, perceptions, and decisions. In the world of product design and branding, understanding color psychology can make a significant difference. When it comes to using color coatings like color coated sheets, color roofing sheets, and pre-painted galvanized steel coils (PPGI), the choice of color can impact not only the aesthetic appeal but also the market success of a product.

Emotional Impact

Colors evoke specific emotions. For example, blue often conveys trust and calmness, making it a popular choice for brands in the finance and health sectors. Red can evoke excitement and urgency, useful for promotions and sales. When you choose PPGI color coated sheets or color coated galvalume sheets for your product design, consider the emotional response you want to elicit from your customers.

Brand Identity

Colors are a powerful tool in establishing brand identity. Think of iconic brands like Coca-Cola with its vibrant red or Apple with its sleek silver and white. These color choices are not random; they are carefully selected to communicate the brand’s values and personality. When designing products with color coated sheets or PPGL, selecting colors that align with your brand’s identity can help reinforce brand recognition and loyalty.

Market Differentiation

In a crowded market, standing out is crucial. Unique and strategic use of color can differentiate your products from competitors. For instance, using a distinct color for your pre-painted galvanized steel coil products can make them instantly recognizable. PPGI steel coil manufacturers often offer a wide range of colors, allowing businesses to find the perfect shade that sets their products apart.

Consumer Behavior

Colors can influence consumer behavior and purchasing decisions. Studies have shown that certain colors can increase appetite, enhance the perception of warmth or coolness, and even affect the perceived value of a product. When you buy color coated sheets for your product designs, keep in mind how these colors will be perceived by your target audience and how they can drive sales.

Product Functionality and Aesthetics

The functional aspect of color coatings cannot be ignored. For example, color roofing sheets not only add to the visual appeal of a building but also provide practical benefits like heat reflection and UV protection. Similarly, PPGI color coated sheets and color coated galvalume sheets offer durability and corrosion resistance while adding an attractive finish. Balancing aesthetics with functionality is key in product design.

Cultural Significance

Colors carry different meanings in different cultures. Red might symbolize luck and prosperity in one culture but warning and danger in another. Understanding the cultural context of your target market is essential when selecting colors for PPGI or PPGL products. This cultural awareness ensures that your color choices resonate positively with your audience.

Sustainability and Perception

With growing awareness of environmental issues, the use of sustainable and eco-friendly materials is becoming increasingly important. When consumers see products made with sustainable coated steel, it can enhance the brand’s image as responsible and forward-thinking. Highlighting the eco-friendly nature of your color coated sheets can attract environmentally conscious customers.

Consistency Across Mediums

Consistency in color usage across all marketing mediums strengthens brand recognition. Whether it’s on the packaging, in digital media, or the products themselves, maintaining a consistent color palette helps establish a cohesive brand image. Using pre-painted galvanized steel coils with uniform color schemes ensures that your products remain consistent in appearance, enhancing brand trust.

Color psychology is a powerful tool in product design and branding. The use of color coatings, such as PPGI color coated sheets, color coated galvalume sheets, and other coated steel products, goes beyond mere aesthetics. It influences emotions, reinforces brand identity, differentiates products in the market, and impacts consumer behavior. When you buy color coated sheets for your products, consider the psychological and cultural implications of your color choices. This strategic approach can lead to enhanced brand recognition, increased sales, and a stronger connection with your target audience.

Conclusion

As we’ve discovered, color psychology plays a vital role in product design and branding, particularly when it comes to the use of color coated sheets. Whether you’re a PPGI steel coil manufacturer offering a range of pre-painted galvanized steel coils, a contractor working with color coated galvalume sheets, or a business owner aiming to enhance your brand’s visual identity, understanding the impact of color can help you make strategic decisions that resonate with your target audience.

By leveraging the principles of color psychology, you can create color coated sheets and other products that evoke the right emotions, enhance brand recognition, and ultimately drive sales. From the calming tones of muted color roofing sheets to the bold statements made by PPGI color coated sheets, the right color choices can make all the difference in the success of your products and your brand. As you move forward, continue to explore the power of color and how it can be harnessed to create truly captivating and impactful designs. The future of color coated sheet solutions is bright, and understanding color psychology will be the key to unlocking its full potential.

#ppgi roofing sheet#colour coated sheet#prepainted galvanized steel coil#PPGL#colour coated galvalume sheet

0 notes

Text

Breaking Down the Cost-Effectiveness of Color Coating Solutions

Color coated sheets, whether for roofing, siding, or other construction applications, have become increasingly popular in recent years. These pre-painted galvanized steel or galvalume sheets offer a range of benefits, from improved aesthetics to enhanced durability. But how cost-effective are these color coating solutions compared to traditional options?

In this blog post, we’ll dive into the various factors that contribute to the overall cost-effectiveness of color coated sheets. We’ll examine the upfront costs of the material itself, as well as the long-term savings from improved lifespan and reduced maintenance. By comparing PPGI color coated sheets, color coated galvalume sheets, and other coated steel options, we’ll help you understand the true value proposition of these innovative products.

Whether you’re a contractor, a homeowner, or a manufacturer of PPGI steel coils, this post will provide valuable insights to help you make informed decisions when sourcing color coated sheet materials for your next project. Let’s explore the cost-effectiveness of these versatile and attractive solutions together.

Breaking Down the Cost-Effectiveness of Color Coating Solutions

When it comes to choosing materials for roofing and cladding, cost-effectiveness is a key consideration. Color coating solutions, including options like color coated sheets, color roofing sheets, and pre-painted galvanized steel coils (PPGI), offer a variety of benefits that make them a smart investment. Here's a breakdown of why these materials are not only popular but also economically viable.

Durability and Longevity

One of the primary advantages of color coated sheets and color roofing sheets is their durability. These materials are designed to withstand harsh weather conditions, resist corrosion, and maintain their aesthetic appeal over time. PPGI color coated sheets and color coated galvalume sheets, in particular, are treated with special coatings that enhance their resistance to rust and environmental damage. This means fewer repairs and replacements over the years, translating into significant cost savings.

Low Maintenance

Another cost-effective aspect of color coated sheets is their low maintenance requirements. Traditional roofing and cladding materials often need frequent upkeep to prevent degradation, but color coated solutions like PPGI steel coils and PPGL sheets require minimal maintenance. Their coated surfaces repel dirt and grime, reducing the need for regular cleaning and associated costs.

Energy Efficiency

Color coated sheets can also contribute to energy savings. Many of these products have reflective coatings that help to deflect sunlight, keeping buildings cool in hot weather. This can reduce the reliance on air conditioning, leading to lower energy bills. When you buy color coated sheets, you are not just investing in a durable material but also in energy efficiency that pays off over time.

Aesthetic Appeal and Versatility

Color coated solutions offer a wide range of colors and finishes, providing versatility for various architectural styles. This aesthetic flexibility can enhance the visual appeal of a building, potentially increasing its market value. Whether you’re using pre-painted galvanized steel coils for an industrial look or color coated galvalume sheets for a sleek modern finish, these materials provide a cost-effective way to achieve a desired aesthetic without compromising on quality.

Ease of Installation

The installation process for color coated sheets is typically straightforward, reducing labor costs. PPGI steel coil manufacturers design their products to be lightweight and easy to handle, making installation quicker and less labor-intensive compared to heavier, more cumbersome materials.

Cost Comparison

When compared to other roofing and cladding materials, color coated sheets are often more affordable upfront. However, their true cost-effectiveness becomes evident when considering the total cost of ownership. Factors like durability, low maintenance, energy savings, and ease of installation all contribute to a lower overall expenditure over the lifespan of the material.

Color coating solutions like PPGI color coated sheets, color coated galvalume sheets, and other coated steel products offer a blend of durability, low maintenance, energy efficiency, aesthetic appeal, ease of installation, and environmental benefits. These factors make them a highly cost-effective choice for both residential and commercial applications. When looking to buy color coated sheets, it's important to consider these long-term benefits, which can significantly outweigh the initial costs, making them a smart and economical investment for any building project.

Conclusion

In conclusion, the cost-effectiveness of color coated sheets is a complex equation that considers upfront costs, long-term durability, and maintenance savings. While the initial investment in PPGI color coated sheets or color coated galvalume sheets may be higher than traditional options, the benefits often outweigh the additional expense.

By choosing high-quality pre-painted galvanized steel coils or other coated steel products from reputable PPGI steel coil manufacturers, you can unlock the true value of color coating solutions. These materials offer enhanced aesthetics, improved weatherproofing, and reduced maintenance requirements, leading to significant cost savings over the lifespan of your project.

Whether you’re a contractor looking to offer your clients the best value, or a homeowner seeking to upgrade your property, carefully evaluating the cost-effectiveness of color coated sheets can help you make the most informed decision. Invest in the long-term performance and visual appeal of your project by exploring the world of color coated sheet solutions today.

#colour coated sheet#ppgi roofing sheet#colour coated roofing sheets price#colour roofing sheet price#PPGL#Coated Steel

0 notes

Text

Me-made Snorkmaiden figure! Created with air-dry clay, acrylic paint, a lil bit of hot glue and lots and lots of love!

She even has her own collector's card! :3 (1/1 because she's one of a kind 💕)

#funfact I made a full plan sheet for her with everything I needed written n sketched out I was SERIOUS when I got the idea to make her#she came out better than I expected for sure! I wanted to sort of show the colour changing of snorks by giving her this peachy coat but I'm#not sure if it worked too well but meh it looks great on the figure! Had to use hot glue to stick her to the platform bc I was out of#super glue 😭😭😭#I used Snorkmimi's og design cause... my- my design of her isn't *really* figure friendly. Especially for someone as inexperienced as me in#the art of the “clay sculpting”#Snorkmaiden#moomin#moomin books#moomins

98 notes

·

View notes

Text

How to Choose the Right Aluminium Colour Coated Sheet Supplier for Your Needs

The Growing Popularity of Aluminium Colour Coated Sheets

Aluminium colour-coated sheets are increasingly being used in industries ranging from construction to signage, roofing, and home décor. These sheets offer the perfect blend of durability, aesthetic appeal, and resistance to the elements. Whether you're building a new structure or working on an industrial project, sourcing high-quality aluminium colour-coated sheets is crucial for achieving both functionality and style. In this blog, we’ll explore the key factors to consider when choosing the right aluminium colour-coated sheet supplier.

Key Qualities of a Reliable Aluminium Colour Coated Sheet Supplier

Product Quality and Durability The primary factor to look for in an aluminium colour-coated sheet supplier is the quality of their products. High-quality aluminium sheets should have excellent corrosion resistance, long-lasting colour retention, and a smooth finish. Look for suppliers who offer coatings that are UV-resistant, weatherproof, and suitable for various climates, especially if you’re using the sheets in outdoor applications like roofing or signage.

Range of Colours and Finishes Aluminium colour-coated sheets are available in a wide range of colours and finishes. A reputable supplier should offer multiple options, allowing you to choose the perfect sheet for your project. Whether you need a matte, gloss, or metallic finish, the supplier should have options that meet your aesthetic and functional requirements. Some suppliers even offer custom colours and finishes to meet specific design needs.

Customization Capabilities Many projects require customised aluminium sheets in terms of size, thickness, and specific coating types. The best suppliers will be able to offer tailored solutions based on your unique project requirements. Whether you need sheets cut to specific dimensions or require a particular type of coating, working with a supplier that offers flexibility can make a huge difference in ensuring your project's success.

Pricing and Delivery Considerations

Competitive Pricing While quality is paramount, cost is always an important consideration. Choose a supplier who offers competitive pricing without compromising on the quality of the sheets. Get multiple quotes and compare prices to ensure you're getting the best value for your money.

On-Time Delivery Timely delivery is crucial to keep your project on schedule. A reliable supplier should be able to meet delivery deadlines and offer consistent availability of stock. Make sure to discuss lead times and shipping arrangements before placing a large order to avoid delays.

Selecting the Right Supplier for Your Project

Choosing the right aluminium colour-coated sheet supplier can greatly impact the success of your project. Focus on suppliers with high-quality products, a range of options, and the ability to customize sheets to meet your needs. Additionally, consider pricing and delivery capabilities to ensure a smooth, hassle-free experience. With the right supplier, you can achieve a finished product that is both visually appealing and durable.

#aluminium sheets#aluminum sheets#aluminium sheet manufacturing company#aluminium roofing sheets#Aluminium Colour Coated sheet supplier

0 notes

Text

Benefits of Using Colour Coated Profile Roofing Sheets!

Did you know what are CCPR Sheets and Benefits? Here, in this blog we share all about advantages of colour coated roofing sheets, and where can be used. We offer a comprehensive range of colour coated profile roofing sheet in Vadodara customized for your specific applications. Call now for order!

#colour coated roofing sheets supplier in Vadodara#advantages of colour coated roofing sheets#colour coated roofing sheet in Vadodara#colour coated profile roofing sheet in Vadodara#Benefits of Using Colour-coated Profile Roofing Sheets

0 notes

Text

Your Investment Our Protection - Kamdhenu Colour max

Upgrade your space with the best with our colour-coated sheets that are crafted with the highest quality materials and advanced technology to ensure long-lasting performance and unmatched durability. With its weather-resistant coatings and a wide range of colors and finishes, you get endless possibilities to express your personal style.

#kamdhenucolourmax#colorcoatedsheets#Colour coated sheets Manufacturers#Color coated sheets#color coated metals sheets#roofing profile sheets

0 notes

Text

Unveiling the Innovation of PPGL: Enhancing Sustainability in Construction

In the realm of construction materials, PPGL has emerged as a cutting-edge solution that combines the durability of galvanized steel with the aesthetic versatility of painted surfaces. From roofing to architectural applications, PPGL offers a myriad of benefits that make it a preferred choice in modern building projects. Here’s an insightful exploration into what PPGL is and why it is gaining prominence across different sectors.

What is PPGL?

PPGL, which stands for Pre-Painted Galvalume, is a coated steel product that combines the corrosion resistance of galvalume steel with a protective layer of paint applied before it is formed into sheets or coils. This dual protection ensures superior durability and aesthetic appeal, making PPGL suitable for a wide range of applications in construction and manufacturing.

Advantages of PPGL

PPGL offers several advantages that contribute to its popularity and widespread use:

Corrosion Resistance: The galvalume coating provides excellent corrosion resistance, while the paint layer adds an additional barrier against the elements, ensuring long-lasting protection for buildings and structures.

Aesthetic Versatility: PPGL is available in a variety of colors, textures, and finishes, allowing architects and designers to achieve their desired aesthetic vision without compromising on durability or performance.

Durability: PPGL is known for its strength and durability, making it suitable for harsh environments and demanding applications where resilience is essential.

Environmental Sustainability: PPGL is made from recycled materials and is recyclable at the end of its lifespan, contributing to sustainable building practices and reducing environmental impact.

Applications of PPGL

PPGL finds extensive applications across various industries and projects:

Roofing: It is widely used for roofing residential homes, commercial buildings, and industrial facilities due to its durability, weather resistance, and aesthetic appeal.

Cladding: PPGL serves as an attractive and protective cladding material for walls and facades, enhancing the architectural style and longevity of buildings.

Automotive and Appliances: In the manufacturing sector, PPGL is used for automotive components, appliances, and other consumer goods due to its strength, formability, and corrosion resistance.

Building a Sustainable Future with PPGL

PPGL continues to redefine standards in construction materials, offering a blend of durability, aesthetic versatility, and environmental sustainability. Whether enhancing the durability of rooftops, elevating architectural designs, or reinforcing industrial structures, PPGL remains at the forefront of innovation in building materials. As the demand for resilient and sustainable solutions grows, PPGL stands as a testament to advancing technologies that support a greener and more resilient future for construction worldwide.

0 notes

Text

Word Alternatives: Colours

BLACK atramentous, charcoal, coal, crow, darksomeness, denigration, duskiness, ebony, funereal, jet, inkiness, melanism, melanotic, midnight, niello, obsidian, pitch, raven, sable, singe, sloe, smirch, smoke, sombrous, soot, swarthiness, swartness, tar

BLUE aquamarine, azure, berylline, cerulean, cerulescent, cyan, cyanosis, cyanotic, electric blue, ice-blue, indigo, lividity, midnight, navy, Oxford blue, pavonian, pavonine, peacock blue, robin's egg blue, royal blue, sapphire, turquoise, ultramarine

BROWN adust, auburn, beige, biscuit, braise, bay, bronze, brune, brunette, buff, burnt umber, burnt sienna, caramel, castaneous, chestnut, chocolate, cinnamon, cocoa, coffee, drab, dun, embrown, fawn, grege, hazel, henna, infuscation, khaki, mushroom, ochre, paper bag, pumpernickel, raw sienna, raw umber, roan, rubiginous, rufous, russet, rust, scorch, seal, sepia, sorrel, suntan, sunburn, tan, taupe, toast, umber, walnut

GRAY ashiness, canescence, cinereous, cineritious, dullness, ecru, fuscous, glaucescence, greige, grisaille, gunmetal, hoar, iron, lead, mousiness, oyster, pewter, slatiness, smokiness, steel, taupe

GREEN aerugo, aestival, avocado, beryl, chartreuse, chloremia, chlorophyll, chlorosis, chlorotic, emerald, foliaged, glaucescence, grass, greensickness, ivy, jade, loden green, holly, olivaceous, olive, patina, patinate, pea-green, smaragdine, springlike, verdancy, verdantness, verdigris, verdure, vernal, virescence, viridescence, viridity

ORANGE apricot, cantaloupe, carotene, carroty, ochreous, ochroid, pumpkin, saffron, tangerine, terracotta, Titian

PINK carnation, coral, coralline, flesh-pink, incarnadine, peach, primrose, roseate, rosy, salmon

PURPLE amethystine, aubergine, bruise, empurple, fuchsia, lavender, lilac, lividity, magenta, mauve, mulberry, orchid, pansy, plum, puce, purpure, purpureous, raisin, violaceous, violet

RED beet, blowzy, cardinal, carmine, carnation, carnelian, cerise, cherry, copper, crimson, damask, encrimson, erubescence, erythema, erythematous, erythrism, erythroderma, ferruginous, fire, floridity, floridness, flushing, gules, hectic, henna, incarnadine, infrared, laky, lateritious, lobster, lurid, magenta, mantling, maroon, miniate, port, puce, raddle, rose, rosiness, rouge, rubefaction, rubicundity, rubor, rubricity, ruby, ruddiness, rufescence, rufosity, russet, rust, sanguine, scarlet, stammel, vermeil, vermilion, vinaceous

YELLOW aureateness, auric, aurify, banana, begild, bilious, biliousness, cadmium, canary, chartreuse, citreous, citrine, citron, engild, fallowness, flavescent, flaxen, fulvous, gildedness, gilt, goldenness, honey, icteric, icterus, jaundice, lemon, lutescent, luteous, luteolous, mustard, ochroid, old gold, primrose yellow, saffron, sallowness, sandy, straw, sulfur, topaz, xanthism, xanthochroism, xanthoderma

WHITE achromatic, alabaster, albescent, albinic, besnow, blanch, bleach, bone, calcimine, chalk, cream, cretaceous, eggshell, etiolate, ghastly, ivory, lactescent, lily, lime, milk, pearl, sheet, swan, sheep, fleece, flour, foam, marmoreal, niveous, paper, pearl, phantom, silver, snow, driven snow, tallow, teeth, wax, wool

VARIEGATION (diversity of colors) spectrum, rainbow, iris, chameleon, leopard, jaguar, cheetah, ocelot, zebra, barber pole, candy cane, Dalmatian, firedog, peacock, butterfly, mother-of-pearl, nacre, tortoise shell, opal, kaleidoscope, stained glass, serpentine, calico cat, marble, mackerel sky, confetti, crazy quilt, patchwork quilt, shot silk, moire, watered silk, marbled paper, Joseph's coat, harlequin, tapestry; bar code, checkerboard

variegation, multicolor; parti-color; medley or mixture of colors, spectrum, rainbow of colors, riot of color; polychrome, polychromatism; dichromatism, trichromatism; dichroism, trichroism

iridescence, iridization, irisation, opalescence, nacreousness, pearliness, chatoyancy, play of colors or light; light show; moire pattern, tabby; burelé or burelage

spottiness, maculation, freckliness, speckliness, mottledness, mottlement, dappleness, dappledness, stippledness, spottedness, dottedness; fleck, speck, speckle; freckle; spot, dot, polka dot, macula, macule, blotch, splotch, patch, splash; mottle, dapple; brindle; stipple, stippling, pointillism, pointillage

check, checker, checks, checking, checkerboard, chessboard; plaid, tartan; checker-work, variegated pattern, harlequin, colors in patches, crazy-work, patchwork; parquet, parquetry, marquetry, mosaic, tesserae, tessellation; crazy-paving; hound's tooth; inlay, damascene

stripe, striping, candy-stripe, pinstripe; barber pole; streak, streaking; striation, striature, stria; striola, striga; crack, craze, crackle, reticulation; bar, band, belt, list

mottled, motley; pied, piebald, skewbald, pinto; dappled, dapple; calico; marbled; clouded; salt-and-pepper

Source: The Concise Roget's International Thesaurus, Revised & Updated (6th Edition) More: Writing Notes & References ⚜ Writing Resources PDFs

#words#colour#writeblr#writing reference#spilled ink#dark academia#literature#writers on tumblr#writing prompt#poets on tumblr#color#poetry#writing inspiration#creative writing#langblr#linguistics#writing ideas#light academia#lit#writing resources

4K notes

·

View notes

Text

Colour Coated Sheet in Karnatka

In the dynamic landscape of Karnataka's construction industry, where innovation and efficiency are paramount, the adoption of modern building materials plays a pivotal role in shaping the architectural narrative of the state. Among these materials, colour coated sheets have emerged as a versatile and durable solution for roofing and cladding applications across various sectors. This article delves into the significance of colour coated sheets in Karnataka, highlighting their multifaceted benefits and widespread usage in the construction sector, particularly in roofing applications.

The Rise of Colour Coated Sheets in Karnataka:

Colour coated sheets, also referred to as pre-painted or pre-coated sheets, have garnered considerable attention in Karnataka's construction industry due to their exceptional attributes and adaptability to diverse environments. These sheets are typically made from galvanized steel or aluminum substrates, coated with a layer of paint or polymer to enhance their aesthetic appeal and durability.

In Karnataka, the utilization of colour coated sheets has witnessed a steady rise, driven by factors such as rapid urbanization, infrastructural development, and the quest for sustainable building solutions. Builders, architects, and homeowners alike are increasingly turning to colour coated sheets for their roofing needs, recognizing the numerous advantages they offer over traditional roofing materials.

Advantages of Colour Coated Sheets:

The popularity of colour coated sheets in Karnataka can be attributed to several key advantages they offer:

Durability and Weather Resistance: Colour coated sheets are engineered to withstand the vagaries of Karnataka's climatic conditions, including heavy rainfall, intense sunlight, and high humidity. The protective coating acts as a shield against corrosion, rust, and UV radiation, ensuring long-term durability and performance even in the harshest environments.

Aesthetic Versatility: With a wide array of colors, textures, and finishes available, colour coated sheets provide architects and designers with unparalleled creative freedom. Whether it's blending seamlessly with the natural surroundings or making a bold architectural statement, these sheets can be customized to suit the aesthetic preferences of any project, from traditional to contemporary designs.

Ease of Installation: Colour coated sheet in karnataka�� are lightweight and easy to handle, facilitating quick and hassle-free installation. Their modular design and interlocking profiles ensure seamless fitting, reducing labor costs and construction time. This makes them an ideal choice for both new construction projects and renovation endeavors across Karnataka.

Energy Efficiency: Some variants of colour coated sheets come with thermal insulation properties, helping to regulate indoor temperatures and reduce energy consumption. By minimizing heat transfer through the roof, these sheets contribute to enhanced energy efficiency, particularly in regions like Karnataka, where summers can be sweltering.

Low Maintenance: Once installed, colour coated sheets require minimal maintenance compared to traditional roofing materials. Routine cleaning and occasional inspections are usually sufficient to keep them in optimal condition, saving both time and resources over the lifespan of the structure.

Colour Roofing Sheets in Karnataka:

In Karnataka, the demand for reliable and cost-effective roofing solutions has led to the widespread adoption of colour roofing sheets in karnataka across residential, commercial, industrial, and agricultural sectors. These sheets are extensively used in a variety of applications, including:

Residential Roofing: Colour roofing sheets are a popular choice for residential roofing projects in Karnataka, ranging from individual houses and apartments to housing complexes and gated communities. Their durability, aesthetic appeal, and ease of installation make them an attractive option for homeowners looking to enhance the value and longevity of their properties.

Commercial and Industrial Buildings: In urban centers like Bengaluru, Mysuru, and Hubballi, colour roofing sheet in karnataka find extensive usage in commercial and industrial buildings such as warehouses, factories, workshops, and retail outlets. Their ability to provide reliable weather protection and structural integrity makes them well-suited for these applications, where durability and performance are paramount.

Agricultural Structures: In rural areas of Karnataka, where agriculture forms the backbone of the economy, colour roofing sheets are widely used for roofing agricultural structures such as barns, sheds, poultry farms, and storage facilities. Their resistance to corrosion, moisture, and environmental factors makes them an ideal choice for protecting agricultural assets and livestock.

Conclusion: Advancing Karnataka's Infrastructure with Colour Coated Sheets

In conclusion, colour coated sheets have emerged as a game-changer in Karnataka's construction industry, Roofmyworld, offering a winning combination of durability, aesthetics, and performance that is unmatched by traditional roofing materials. Whether it's enhancing the skyline of Bengaluru with sleek commercial complexes or safeguarding rural farmsteads from the elements, these sheets have become an integral part of the state's architectural landscape.

As Karnataka continues to witness rapid urbanization and infrastructural development, the demand for innovative building materials like colour coated sheets is expected to soar further. With ongoing advancements in technology and manufacturing processes, these sheets will continue to evolve, meeting the evolving needs and aspirations of builders, architects, and homeowners across the state.

In this journey towards progress and prosperity, colour roofing sheet in karnataka are poised to play a pivotal role in shaping Karnataka's infrastructure and skyline, contributing to its growth and development in the years to come. As such, they represent not just a roofing solution but a symbol of Karnataka's unwavering commitment to building a brighter, more resilient future for generations to come.

0 notes

Text

Everything About Colour Coated Sheets & Benefits of Colour Coated Roofing Sheet!

Roofing is a crucial aspect of any structure, be it commercial or residential. It requires a robust, dependable, high-quality roofing material to safeguard the building and its occupants. Among the plethora of options available, colour-coated sheets stand out as a reliable choice. Their durability, flexibility, and high quality not only enhance their functionality but also instill a sense of security in your roofing solution. In this blog explores everything about colour coated sheets and its benefits and why they are a dependable roofing solution.

What are Colour Coated Sheets?

The colour coated profile sheet is essential in modern building construction. These roofing materials offer durability and protection against external elements, regulate temperature, and add to its visual appeal. The colour sheets have a lining of enamel that serves as a protective layer. It is extensively used in different structures like garages, factories, industries, car parking, store rooms, godowns, restaurants, and more places.

Laxmi Enterprise is a leading roofing sheet supplier in Vadodara. We offer premium quality colour coated sheets in 8FT to 24 FT. We also offer customization to meet your requirements. We also provide GC sheets in custom sizes. Contact us to learn about colour coated sheets technical specifications.

Benefits of Colour Coated Roofing Sheet

The coloured coated profile sheets are available in various sizes, shapes and lengths. They offer a wide range of benefits, as listed below.

Advantages of Colour Coated Roofing Sheet

Lightweight: The colour coated sheets are commonly made lightweight material like aluminiium and steel. They are lightweight, sturdy, and exhibit tensile strength.

Durable: The aluminum roofing sheets are durable and long-lasting. It maintains durability and high endurance even in the harshest conditions. They exhibit high tensile strength at low temperatures and can be reused and easily recyclable.

Easy Installation: The colour cooated roofing sheets are are simple and easy to install due to its lightweight. Unlike other sheets, they are not easily bendable and can withstand extreme weather.

Corrosion Resistant: These sheets are highly resistant to corrosion and moisture. Their high resistance makes them a better material for different types of climatic conditions. The anti-corrosion property reduces the chances of deterioration, extends their lifespan, and minimizes maintenance.

Visually Appleaing: The vibrant colours makes these sheets aesthecailly appealing. They are available in different colours that you can choose as per your construction project.

The coloured coated profile sheets are a versatile, durable and flexible roofing material. They offer various benefits as compared to other roofing materials. Laxmi Enterprise is a prominent Mild steel supplier in Vadodara. We provide a range of MS steel products like MS angles, MS pipes, MS TMT bars, MS flat bars, MS channels, GC sheets, colour coated roofing sheet in Vadodara, and more. If you are considering buying MS products or colour coated sheets, contact us for the best quotes.

#colour coated roofing sheet in Vadodara#about colour coated sheets#roofing sheet supplier in Vadodara#colour coated profile sheet

0 notes

Text

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

When it comes to construction materials, color-coated steel is quickly becoming a popular choice for its unique blend of aesthetics and sustainability. Available in a wide range of vibrant hues, color coated sheets and roofing sheets can instantly transform the look of any building, from residential homes to commercial properties.

The PPGI (pre-painted galvanized steel) roofing sheets and PPGL (pre-painted galvalume steel) coils used in these color-coated products not only provide a beautiful finish, but also offer superior durability and corrosion resistance. Prepainted galvanized steel coil and color coated galvalume sheets are among the top choices for PPGI steel coil manufacturers looking to meet the growing demand for visually appealing yet environmentally-friendly building materials.

As sustainability becomes an increasingly important factor in construction, color-coated steel provides the perfect solution that blends form and function.

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

Color-coated steel has emerged as a standout material in the construction industry, offering a perfect blend of aesthetics and sustainability. Its popularity is driven by a combination of visual appeal, durability, and environmental benefits. We’ll explore why color coated sheets are becoming the go-to choice for architects, builders, and homeowners alike.

Vibrant and Versatile Roofing Sheet Colors

One of the primary reasons for the growing popularity of color-coated steel is the wide variety of roofing sheet colors available. Whether you are looking for bold, vibrant shades or more subtle, earthy tones, there is a color coated roofing sheet to match any design vision. These sheets add a modern and stylish look to buildings, enhancing their curb appeal and value.

Durable and Long-Lasting PPGI Roofing Sheets

PPGI (Pre-Painted Galvanized Iron) roofing sheets are a popular type of color coated sheet. They are made by applying a layer of paint over galvanized steel, resulting in a product that is both aesthetically pleasing and highly durable. PPGI roofing sheets are resistant to corrosion, weathering, and UV radiation, ensuring they maintain their appearance and functionality over time. This makes them an excellent investment for any building project.

High-Quality Prepainted Galvanized Steel Coil

Prepainted galvanized steel coils are the raw material used to produce various color coated sheets. These coils undergo a thorough manufacturing process that includes cleaning, pre-treatment, painting, and curing, resulting in a high-quality product that meets stringent standards. PPGI steel coil manufacturers are dedicated to producing coils that offer superior performance, ensuring that the end products, like roofing sheets, are of the highest quality.

Sustainable Building Material

Color-coated steel is not only about aesthetics and durability; it is also a sustainable choice. The steel used in these products is often recycled, reducing the demand for virgin materials and minimizing environmental impact. Additionally, the coatings used on these sheets are designed to be environmentally friendly, with minimal VOC (Volatile Organic Compounds) emissions. Choosing color coated roofing sheets can contribute to greener building practices and a more sustainable future.

Versatility of Color Coated Galvalume Sheets

Color coated galvalume sheets offer another excellent option for construction projects. Galvalume is a steel sheet coated with a zinc-aluminum alloy, which provides enhanced corrosion resistance. When combined with a color coating, these sheets offer both superior durability and a stylish appearance. They are ideal for a wide range of applications, from residential roofing to commercial and industrial buildings.

Innovative PPGL Solutions

PPGL (Pre-Painted Galvalume) is similar to PPGI but uses a galvalume substrate instead of galvanized steel. This combination of galvalume’s corrosion resistance and the aesthetic benefits of pre-painting results in a product that is perfect for demanding environments. PPGL sheets are particularly well-suited for coastal areas and regions with harsh weather conditions, providing long-lasting protection and beauty.

Reliable PPGI Steel Coil Manufacturers

The quality of color coated sheets depends heavily on the manufacturers producing the raw materials. Reputable PPGI steel coil manufacturers ensure that their products meet high standards of quality and performance. They invest in advanced technology and rigorous quality control processes to produce coils that offer excellent consistency and reliability. Choosing products from these manufacturers guarantees that your color coated roofing sheets will meet or exceed your expectations.

Cost-Effective and Low Maintenance

In addition to their aesthetic and environmental benefits, color-coated steel sheets are also cost-effective and require minimal maintenance. Their durability means they need fewer repairs and replacements over time, saving money in the long run. Furthermore, the coatings on these sheets are designed to withstand the elements, reducing the need for frequent painting or cleaning. This makes them a practical choice for both residential and commercial buildings.

Easy Installation and Customization

Color-coated steel sheets are lightweight and easy to install, which can significantly reduce construction time and labor costs. They can be customized to fit specific design requirements, offering flexibility in architectural design. Whether you need sheets cut to size or specific shapes, manufacturers can provide products tailored to your project’s needs. This versatility makes color-coated steel an attractive option for a wide range of building applications.

Enhancing Energy Efficiency

Many color-coated steel products come with reflective coatings that can help improve a building’s energy efficiency. These coatings reflect more sunlight, reducing heat absorption and helping to maintain a cooler indoor environment. This can lead to lower energy costs for cooling, making color-coated roofing sheets a smart choice for energy-conscious builders and homeowners.

Color-coated steel represents a perfect blend of aesthetics and sustainability, offering a range of benefits that make it an excellent choice for modern construction projects. By choosing color-coated steel, you are investing in a product that enhances the visual appeal of your building, supports sustainable practices, and offers long-term cost savings. Whether for residential, commercial, or industrial applications, color-coated steel is a superior choice for today’s construction needs of aesthetics and sustainability.

Conclusion

As the construction industry continues to evolve, the demand for building materials that merge stunning aesthetics with eco-friendly credentials is higher than ever before.

Color-coated steel, with its vibrant color options, superior durability, and impressive sustainability, is perfectly positioned to meet this growing need. From PPGI roofing sheets and color coated roofing sheets to PPGI color coated sheets and color coated galvalume sheets, the versatility of this material allows it to be seamlessly integrated into a wide range of architectural styles.

PPGI steel coil manufacturers are further enhancing the appeal of color-coated steel by continuously improving their production processes to reduce the environmental impact. As homeowners and businesses prioritize sustainability alongside visual appeal, color-coated steel emerges as the ideal solution - a perfect blend of form and function that is poised to transform the future of the built environment.

0 notes

Text

instagram

Discover the best in thermal insulated roofing sheets with METAhybrid® roofing sheets – lightweight, eco-friendly, and noise-reducing. Stay cool, save big, and enhance your space. Visit us at www.metahybrid.in or contact us at 8550995556 | [email protected]. . . . . #thermalinsulatedroofingsheet #roof #sheet #insulatedroof #soundproofing #soundproof #heatinsulation #architecture #interiordesign #insulatedroofing #insulatedpanels #insulatedpanel #thermalinsulation #metahybrid #roofinsulation #geometric #steels

#heat insulated roof sheets#heat insulation for metal roof#insulated cladding sheets#insulated metal sheet#insulated profile sheet#insulated steel sheets#metal sheet with insulation#thermal insulated roofing sheets#thermal insulation metal sheet#thermal roof sheets#insulated thermal roofing#Colour coated thermal insulated roofing sheets#heat insulated sheet for roof#Aluminum Thermal insulated roofing sheets#Instagram

0 notes

Text

How Aluminium Colour Coated Sheets Are Transforming Modern Construction

Aluminium colour coated sheets have become a popular choice in the construction and industrial sectors due to their durability, aesthetic appeal, and versatility. Used in everything from roofing to cladding, these sheets are a preferred material for architects and builders alike. In this blog, we’ll explore the benefits of aluminium colour coated sheets and why choosing the right manufacturer is key.

Why Choose Aluminium Colour Coated Sheets?

Aluminium colour coated sheets offer a range of advantages over traditional materials, making them ideal for modern construction projects. Here’s why they stand out:

Aesthetic Variety: These sheets come in a wide range of colours and finishes, allowing architects and builders to create visually appealing designs that enhance the look of buildings.

Durability and Corrosion Resistance: Aluminium is naturally resistant to corrosion, and when coated with high-quality paint, these sheets become even more durable. They are perfect for use in environments exposed to harsh weather conditions.

Lightweight Yet Strong: Aluminium sheets are much lighter than steel, making them easier to transport and install. Despite their light weight, they offer excellent strength and structural integrity, making them ideal for roofing, cladding, and façades.

Applications of Aluminium Colour Coated Sheets

The versatility of aluminium colour coated sheets makes them suitable for various applications across different industries. Some common uses include:

Roofing and Cladding: One of the most popular uses of aluminium colour coated sheets is in roofing and cladding for both commercial and residential buildings. Their lightweight nature makes installation easier, and the wide variety of colour options allows for greater design flexibility.

Architectural Façades: These sheets are often used to create modern and sleek façades for office buildings, shopping centres, and industrial complexes. The vibrant colours and durable coatings add to the aesthetic value while ensuring long-term protection.

Interior Design: Aluminium colour coated sheets are also used in interior design for creating partitions, ceilings, and decorative panels in offices, homes, and commercial spaces.

Choosing the Right Manufacturer

When selecting aluminium colour coated sheets, it’s crucial to choose a reputable manufacturer to ensure high-quality products. Look for manufacturers who use advanced coating technology and provide sheets that meet industry standards for strength, durability, and weather resistance. A reliable manufacturer will also offer a variety of colour and finish options to suit your specific project needs.

A Game Changer for Construction and Design

Aluminium colour coated sheets have revolutionized the construction industry with their combination of strength, lightweight design, and aesthetic appeal. From roofing to interior design, these sheets provide durability and versatility, making them a top choice for builders and architects. Choosing the right manufacturer ensures you get high-quality sheets that will stand the test of time while adding a modern touch to any project.

#Aluminium Colour Coated sheet manufacturers#Aluminium Colour Coated sheet supplier#Aluminium Colour Coated sheet

0 notes

Note

hi! i was just wondering if you’re getting a piece of this pie. https://www.kickstarter.com/projects/voidrealmminis/rise-of-the-eldertubbies?ref=profile_saved_projects_live

Oh my goodness! Haha thanks for showing me! And no, of course, this guy is still selling my dream while claiming it’s totally nothing to do with me. I hadn’t heard about it so thank you.

For those just joining us, here is the saga of the elder teletubbies:

1. in 2017 I posted a dream I had on Tumblr. In the dream I discovered that the childish teletubbies shown on BBC’s Teletubbies are merely the children of a species that grows up to be forest cryptids as adults. The post contained a detailed character description explaining how the children’s simple antennae become more complex antlers; their coats become thicker hair; their eldritch screens are unknowable; here, look:

The adult Teletubbies have more branching, complex antlers and shaggy coats. They are less brightly coloured. They are terrifyingly large. Their strangely human faces, emerging from the thick fur, are unquestionably adult; remote, serene, reproachful. Their television screens are glitchy, esoteric and unknowable. They are cryptids whose public exploitation has undermined their rarity and their strange, alien dignity.

That’s a pretty clear description.

2. The post quickly gained attention and many people drew art, made sculptures, designed in-depth character concepts, and even made DnD character sheets and entries with detailed notes. It was 2017. The post got over 90k notes. It had an extremely clear description of the cryptid in it. This wasn’t at all obscure.

3. The post and four pieces of the concept art, including the first piece by were screencapped and posted on r/tumblr. The post included this art by the now-deactivated @finoliatav which is, I think, the first piece of art. Most screencaps don’t show that it’s animated! Once you see it you can no longer pretend that any more work needs to be done in designing these characters, really - they’re all variations on a very clear theme.

4. A guy called Jars started drawing the BBC Teletubbies as adult Teletubbies. He noted on Reddit that his inspiration for the first one was the r/tumblr post but after that, he considered it entirely his own creative work. He drew each of the 4 BBC Teletubbies as adults using my character description and wrote a little story about how his character had stumbled upon them in the woods. He’s a good artist and his work went viral on Reddit and instagram. Those places being separate from Tumblr by the walls of the enclosure, they quickly believed the Jars was being highly original and praised him for it.

5. jars got carried away by his fame and started merchandising for all he’s worth. He’s selling elder teletubbies placemats. He got a collaborator to help him make and sell plushies.

6. Plushies of my character design applied to BBC characters. Jars sells them. To people. Who buy them. He sells these.

7. I think this is like… his job.

8. It has been years of this. I don’t think he has actually come up with anything else to sell by himself. But given that he now has millions upon millions of views on platforms I don’t use, let alone dominate (Instagram, YouTube, Reddit, TikTok) he seems to have fully subscribed to the idea that this is his THING.

9. After a while I wrote him a friendly email expressing that since my original dream was very much about discomfort with how the teletubbies were being exploited, I didn’t mind him selling his own art but that I wasn’t happy with him selling plushes based on my writing.

10. He wrote back along the lines of it all being his original intellectual property and absolutely nothing to do with me, etc, so jog on and don’t interfere.

11. I’m not entirely sure where the original intellectual property is when taking BBC characters and drawing them according to someone else’s detailed description of how to “evolve” them (branching antlers, shaggy coats, eldritch screens, serene adult human faces) especially having drawn them after seeing four separate detailed reference photos to base your own drawings on; especially when they’re the existing BBC characters from the show and not even your own. Like, Jars, you were given an entire detailed brief, several sets of references, an entire concept and a television show: the only artistic choices made here were to pick up your own personal pen and do the drawing. You have never deviated from my description, which you did not come up with yourself in any way. But okay Jars. You did some real intellectual heavy lifting here, this is Intellectual Property suddenly, and I guess this is your day job!

12. I myself actually have a day job, am capable of generating lots of other original material just for funsies, have never asked you guys for money, and I’m not generally huge jerk I don’t think. Also, I’m uncomfortable but have never been clear on how to stop him - I don’t think I can. So I don’t do much about this, apart from occasionally scream with hilarity with you guys about it.

13. Like this is the opposite of Goncharov. This is a guy making his wage on a 2017 tumblr collaborative shitpost insisting that this is the beautiful fruit of his only brain. And millions of people believe him.

14. There are now YouTube documentaries with millions of views and TikTok lore about Jars, and his lore, the Elder Teletubbies, which apparently he invented. People are making their wage talking about the history of Jars and his teletubbies lore. These documentaries are, if you can’t tell, not especially well-researched, as it is not difficult to find the original elder teletubbies art on the internet, which is all timestamped. Occasionally hilarious people from Tumblr point this out in the comments (thank you, you guys are hilarious) but the juggernaut is unstoppable!

15. Jars is now, apparently, doing a kickstarter to raise money for some kind of DnD sheets using the grown up BBC teletubbies.

16. I will point out that tumblr made and played with DnD teletubbies in 2017 for free and nobody had to pay $3000, but again. The juggernaut is unstoppable.

I have never, ever known what to do about this guy.

I have always been open to advice but genuinely never been able to articulate how it “damages” me, apart from ethical discomfort about how much I hate my writing being monetised by other people, especially when it was about my discomfort with exploitation. The juggernaut is unstoppable though. He fully intends to get thousands of dollars from this. He almost certainly will!

4K notes

·

View notes

Text

5 Factors to Consider When Buying Roofing Sheets.

Some factors you need to know before buying colour coated roofing sheet in Vadodara. Roofing Sheets Thickness, Square Feet Vs. Kilograms, Beware of Poor-quality Roofing Sheets, etc. Always Purchase from authorized and trusted roofing sheet supplier in Vadodara, like Laxmi Enterprise.

#colour coated roofing sheet in Vadodara#colour coated roofing sheets supplier in Vadodara#roofing sheet supplier in Vadodara#roofing sheet distributor in Vadodara

0 notes