#china cnc machining metal parts suppliers

Explore tagged Tumblr posts

Text

youtube

CNC Lathe Machining, a pinnacle of precision engineering, transforms raw materials into finely crafted components. At the forefront of technological innovation, our CNC Lathe Machining service at China Ming Xiao Manufacturing is dedicated to shaping your ideas into reality. From intricate details to seamless finishes, our advanced machinery ensures unparalleled accuracy, making us the go-to choice for those who demand precision in every turn. Elevate your projects with the excellence of CNC Lathe Machining – where precision meets craftsmanship.

#CNCMachining #PrecisionParts #GlobalManufacturing #cnclathemachining #customparts

#CNC Lathe Machining#CNC Lathe Turning#CNC Turning#mxmparts#china metal parts#china supplier#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#Youtube

0 notes

Text

Excellence Delivered: CNC Machining Suppliers in China by ABCRAPID

ABCRAPID stands out among China CNC machining suppliers, providing end-to-end solutions for intricate components with exceptional accuracy. We cater to diverse industries, offering high-quality parts made from various materials, including metals and plastics. With advanced equipment and a team of skilled technicians, ABCRAPID guarantees consistency and precision in every project. Known for our cost-effectiveness and fast delivery, we are the go-to choice for businesses aiming to streamline manufacturing processes while maintaining international quality standards.

0 notes

Text

Information about laser engraver suppliers

Here is the information about laser engraver suppliers:

Linxuan Laser is a top industrial laser marking and engraving machine manufacturer in China with over 18 years of experience in the laser industry. They offer customizable laser marking and engraving solutions, as well as a variety of automated laser marking accessories. Linxuan Laser specializes in providing leading laser marking solutions for direct part and product marking at affordable prices.

Made-in-China.com provides a directory of manufacturers and suppliers, including companies like Zhejiang Holy Laser Technology Co., Ltd. and Shanghai Yuehua Laser Technology Co., Ltd. These companies offer a range of laser engraving machines, laser marking machines, and laser cutting machines.

Algo Technologies Co., Ltd. is an innovative technology company focused on commercial laser engraving machines, founded by Justin Tan, a renowned expert in the laser engraver industry. They are dedicated to offering innovative laser engraving machine solutions and have a strong professional team.

Hibo Laser is a high-tech enterprise specializing in the application of laser technology, customization, sales, and service of laser equipment. They offer a variety of laser equipment, including laser engraving machines, laser cutting machines, and laser marking machines.

BOGONG® is a CNC machine manufacturer that also provides laser engraving and laser welding machines among other equipment.

laser engraver suppliers offer a wide range of laser engraving machines and services, suitable for engraving and cutting a variety of materials such as metal, wood, plastic, acrylic, and more. You can contact laser engraver suppliers based on your specific needs and budget for further inquiries.

0 notes

Text

An Inside Look at China's Leading Hydraulic CNC Press Brake Factories

China's hydraulic CNC press brake business has actually experienced considerable growth in the last few years, driven through the increasing requirement for high-precision metal construction solutions. At the center of this development are leading manufacturers such as Accurl, JFY, and DMT, whose modern facilities display the nation's capabilities in generating first-rate equipment. However what sets these factories aside from their rivals, and what produces their products a staple in sectors worldwide? A closer examination of their production methods, quality control measures, and sector applications shows a complex interaction of technology, knowledge, and innovation that necessitates more expedition.

Leading Hydraulic Press Brake Producers

Among the several hydraulic press brake makers, many key players attract attention for their cutting-edge innovation, precision engineering, and worldwide market presence. These leading hydraulic press brake suppliers have actually created on their own as leaders in the sector, giving top quality products and innovative solutions to satisfy the diverse necessities of customers worldwide. Companies including Accurl, JFY, and DMT project gamers in the worldwide hydraulic press brake market. Accurl is a well-known maker of SHENCHONG CNC press brake, offering a large range of items that satisfy different business, consisting of automobile, aerospace, and development. JFY is actually yet another leading supplier, understood for its own high-precision press brakes that are actually developed to satisfy the stringent needs of the metal manufacture field.

Top Functions and Technical Advantages

The Computer Numerical Control hydraulic press brake's sophisticated design is actually characterized by its own strong steel framework, precision-guided higher ray of light, and high-precision straight resource system, which together give the stability and reliability demanded for sophisticated metal assembly jobs. These components enable the hydraulic Computer Numerical Control press brake machine to provide accurate angle control, minimal deflection, and constant bending outcomes. The hydraulic system of the press brake is made for high performance and integrity, with an adjustable velocity control system that enables smooth and precise activity of the uppermost light beam. The machine's control system is furnished along with advanced program that makes it possible for real-time surveillance and correction of the bending over procedure, ensuring peak outcomes and decreasing inaccuracies.

Manufacturing Facility Tour and Manufacturing Process

youtube

Inside a SHENCHONG CNC press brake factory, the production procedure generally starts with the voucher of raw products, consisting of high-strength steel for the structure and accuracy elements for the machine's several systems. These components undertake rigorous examination to confirm conformity along with industry standards and the factory's quality needs. The creation process includes several phases, featuring machining, assembly, and setting up. The framework and various other structural components are machined to accurate endurances utilizing CNC machining facilities. The machined parts are at that point bonded together making use of sophisticated robotic welding systems to guarantee uniformity and accuracy.

Quality Assurance And Security Measures

Throughout the whole entire production method, stringent quality control and protection solutions are implemented to assure the integrity and functionality of hydraulic CNC press brakes. In China's leading hydraulic Computer Numerical Control press brake factories, an extensive evaluation procedure is actually performed at every stage of production to determine and repair possible problems. The examination process involves visual assessment, dimensional verification, and operational screening to license that the press brakes fulfill global requirements. The manufacturing plants comply with industry-specific safety specifications and regulations to secure a safe functioning setting for staff members. The manufacturing place is furnished along with security attributes like noise decline systems, fire reductions systems, and emergency cessation procedures.

Field Uses and Customer Base

China's hydraulic CNC press brake machine factories deal with a varied customer bottom across different industries, consisting of aerospace, automobile, development, and electronic devices. These manufacturing facilities source Computer Numerical Control press brakes, including SC Shenchong, that are developed to deliver higher preciseness and precision, creating all of them appropriate for applications demanding complicated metal processing making up. In the aerospace industry, hydraulic Computer Numerical Control press brakes are actually utilized to produce plane parts, like segment panels and fuselage components. In the automotive sector, they are utilized to produce body boards and framework components. The building and construction sector uses hydraulic Computer Numerical Control press brakes to create property parts, consisting of metal roofing and covering. The electronic devices sector likewise relies upon these machines to create precision elements, such as metal rooms and cases.

Final Thought

Reliable development of high-precision hydraulic Computer Numerical Control press brakes is guaranteed via stringent quality assurance steps and faithfulness to specialized specs. China's prominent producers, such as Accurl, JFY, and DMT, sustain advanced locations, experienced staffs, and strenuous testing procedures. This leads to reputable press brakes ideal for varied fields. Regular quality and efficiency are actually vital in meeting customer needs, steering development, and keeping competitiveness in the worldwide market. Advanced producing methods permit these manufacturing plants to accommodate progressing field requirements.

Wuxi Shenchong Forging Machine Co., Ltd.

Tianshun Road, Yangshan Industrial Park,

Wuxi, Jiangsu, China 214156

+86-158-9507-5134

0 notes

Text

Sigma Technik Limited

Sigma Technik Limited is a company focused on prototyping and rapid manufacturing, headquartered in Shenzhen, China. The company provides a range of services, including rapid prototyping and small-scale manufacturing of plastic and metal parts, as well as customized manufacturing services such as CNC machining, 3D printing, vacuum casting, rapid machining, and injection molding. The advantage of Sigma Technik Limited lies in its advanced manufacturing technology and highly skilled team, which can provide customers with high-quality and efficient manufacturing services and help them achieve success in all stages of product development.

CNC Machining Supplier

1 note

·

View note

Text

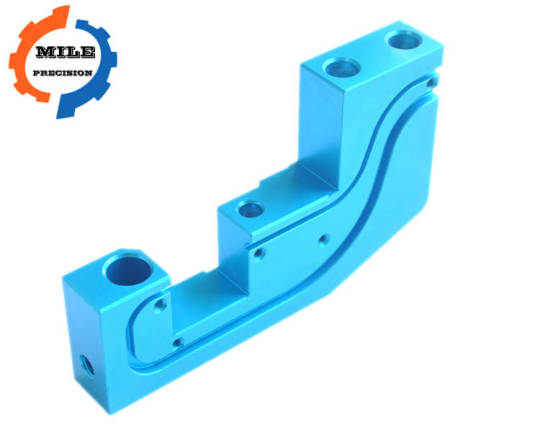

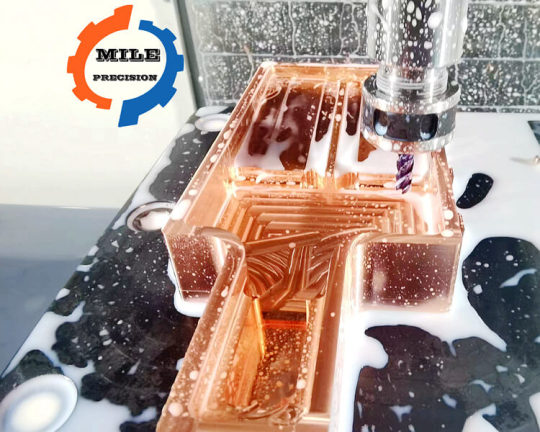

We are an experienced Custom precision machining services supplier, manufacturer in China Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling. Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

Tenral is a metal stamping manufacturer and supplier with many years of experience. Since 2005, we have been manufacturing precision metal stamping parts for customers in the automotive, lighting, construction and other industries, as well as sheet metal fabrication and CNC machining services. With press capacities ranging from 32 tons to 150 tons and hydraulic presses from 80 tons to 200 tons, Tenral can offer a full range of metal stamping services to its customers.

0 notes

Text

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

1. Resistance to dissolution.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

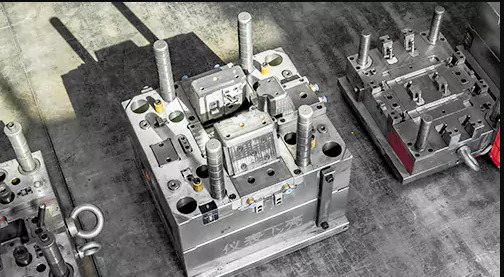

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

China Precision CNC Machining Suppliers

This process is one of the most vital and advanced processes for CNC parts China or CNC Machine China that can be taken into use to control a range of complex machinery that may be from a minor thing like grinders to large ones like mills, routers, and lathes.

0 notes

Text

Infeed Method in CNC Machining

New Post has been published on https://www.cncmachinings.com/infeed-method-in-cnc-machining/

Infeed Method in CNC Machining

Most turning communities have a respective canned stringing cycle that will automatically take progressive string Cutting passes until the apparatus arrives at the string’s root (minor) width. This cycle includes numerous factors to alter the activity for various applications.

Recall that as a “‘”- formed stringing apparatus is progressed into machine work, instrument contact increments enormously When working a manual machine, it was important to gradually decrease the profundity of cut on each pass. This aided continue to cut powers (and volume of material eliminated) steady from pass to pass until finish. When utilizing the stringing canned cycle, the CNC control will automatically calculate the profundity of-cut decrease for each pass. The cycle will likewise keep up planning of the apparatus and the axle position so a similar string groove is unequivocally followed for all passes, even at a lot higher RPM than on manual machines.

Flank Infeed Method

Stringing cycles can be applied with a flank infeed (single-edge) strategy as was appeared in precision machining parts suppler. With this strategy, a 60-degree cutting device is progressed on a 30-degree in-feed point. This aides produce a superior completion and less cutting power, since just one side of the “V” cuts. The disadvantage of this strategy is that the following front line rubs gently as opposed to cutting. Likewise, apparatus life is diminished in light of the fact that the all cutting work is performed by just one of the edges.

Altered Flank Infeed Method

Decreasing the flank infeed point considerably a degree or a full degree will bring about a changed flank infeed as appeared in precision turning titanium parts factory. Here the main edge does the majority of the work, however the following edge will play out a light cut with each pass. This usually delivers the best results for broadly useful work.

Rotating Flank Infeed Method

A few machines can substitute the flank scales to and fro between each side of the instrument from pass to pass. This serves to distribute the instrument wear across the two sides of the device and expands the life of the device. Since sides substitute, just each edge is cutting in turn and power is still as light as with the other cutting techniques. Galvanized turning parts manufacturer shows an illustration of exchanging flank cutting.

Outspread Infeed Method

An instrument may likewise be in-taken care of straightforwardly on a 0-degree point so that each flank cuts an equivalent sum simultaneously Since cutting power is higher, this spiral infeed is usually just utilized for fine string pitches where the apparatus isn’t locked in profoundly. Chip arrangement is poor, instrument tip heat is high, and high device contact may cause chattel, so this technique is rarely. attractive. Figure 8.3.47 shows an illustration of an outspread infeed technique.

It is useful to play out the all string computations prior to programming a stringing cycle. Figure 8.3.48 shows a section drawing and program portion for an outer stringing cycle utilized on a Fanuc machine control. Figure 8.3.49 shows a section drawing and program passage for an outside stringing cycle utilized on a Has machine control. cnc machined parts suppliers shows a section drawing and program selection of an inward stringing cycle utilized on a Fanuc machine control. china cnc lathe machine parts manufacturers shows a section drawing and program portion of an internal stringing cycle utilized on a Haas. It is helpful to play out the all string figuring prior to programming a threading cycle.

This article is from http://www.cncmachinings.com/

#auto parts cnc make factory#china automotive machine parts manufacturers#china carbon steel machining parts suppliers#china cnc lathe parts factory#china cnc machining metal parts suppliers#china cnc steel milled mahcining parts manufacturers#china jigs and fixtures factory#china titanium cnc turned part suppliers#cnc machined parts suppliers#cnc milling parts components company#cnc turned pump body china#customized cnc machining titanium parts#galvanized turning parts manufacturer#medical parts machining manufacturers china#metal lathe part manufacturers china#precision brass turned components#precision machining parts suppliers#precision stainless steel cnc lathe parts suppliers#precision turning titanium parts factory#rock machine turns you on cd#steel cnc machining parts china#tight tolerance precision machining factory#Featured Articles

0 notes

Text

CNC Control

In the present requesting and quick moving machining atmosphere, modernized mathematical control (CNC) machines are upsetting the substance of machining. These cutting edge machines can perform things that might have never been envisioned even 10 years prior. Complex tasks can be performed quicker, with more exactness and consistency, thus eagerly that it seems easy. In a cutting edge electronic…

View On WordPress

#auto parts cnc make factory#china 3 aixs cnc machine high precision cnc machining metal parts manufacturers#china bronze custom made parts#china bronze custom made parts manufacturers#china carbon steel machining parts suppliers#china cnc machining metal parts suppliers#china cnc precision machining factory#china cnc stainless steel milling parts manufacturers#china cnc titanium parts suppliers#china large lathe machining parts suppliers#china swiss cnc lathe#cnc lathe turning parts factory#cnc machined parts suppliers#cnc prototyping suppliers china#cnc stainless steel machinery parts china#cnc turning stainless steel parts factory#custom cnc carbon fibre factory#custom cnc machinery precision steel parts factory#fabrication cnc machining parts factory#high precision machining efficiency#machined parts suppliers china#machining aluminum suppliers china#medical parts machining manufacturers china#medical precision machined components factory#metal lathe part manufacturers china#ptfe irregular shaped parts manufacturers china#tight tolerance precision machining factory#titanium cnc machining parts suppliers#turned part

0 notes

Text

Lathe

Posted from 5 axis machining China blog

Lathe

Belt Drive Lathes

A belt drive machine communicates power from the engine to the shaft by methods for belts and what is known as a stage cone pulley. The progression cone pulley has breadths of various sizes that change proportions to accomplish distinctive axle speeds. To change the axle speed of belt-driven machines, first the pressure on the belt must be delivered.

This is generally done by lifting the engine itself upward with a switch. The belt is then moved to the ideal pulley and the belt pressure reapplied. An outline is generally situated on the machine that will show which step to use for a particular RPM setting. China cnc lathe parts factory shows a stage cone pulley.

Outfitted Head Lathe

As its name infers, an outfitted head machine utilizes a progression of riggings to send power from the engine to the shaft. Bigger machines are normally determined thusly in light of the fact that the riggings can communicate impressive measures of intensity without slipping, as is required during substantial machining activities. To set the speed on an outfitted head machine, switches or handles situated on the facade of the headstock are set to different positions. An outline on the headstock will show the places of these switches expected to set explicit axle speeds. Figure 5.1.9 shows how these switches are utilized to set paces on an average equipped head machine.

Working the machine at an unnecessarily high RPM can harm gear and can be extremely risky. Continuously verify whether a workholding gadget is marked with a greatest RPM rating. Make certain to never surpass that greatest speed or a workpiece might be catapulted from the machine, causing genuine injury or even passing.

Fast Change Gear Box

Simply under the headstock is another apparatus train called the fast switch gear box. The fast switch gear box controls the pace of development of the cutting instrument. This apparatus development is called feed and the pace of the development is known as the feed rate. Feed rates on the machine are estimated by how far the cutting device progresses each time the axle turns one upheaval.

This is called feed per upheaval (FPR). Accessible feed rates on the machine range from about 0.001″ to 0.120″ per upset. An outline will show settings for handles or switches needed to set wanted feed rates. China cnc precision machining factory shows how feed rates are determined to a machine utilizing the fast switch gear box.

Over the top feed rates can make the cutting apparatus break as well as the workpiece to be pulled out of the shaft workholding gadget.

L ATHE BED

The machine bed is situated on the correct side of the headstock and is the establishment of the whole machine. Machine beds are substantial castings intended to both be sufficiently able to deal with weighty machining powers and to guarantee smooth, exact cutting movement. The head of the bed contains accuracy ground level and V-molded rails known as the ways. cnc lathe turning parts factory distinguishes the bed and the methods of a machine. Most machine ways are fire solidified for quality and wear obstruction. Since the ways are so difficult, it is critical to shield them from abrupt stuns that can cause harm and influence machine exactness. Be mindful so as not to drop adornments or apparatuses on the ways. It is a decent propensity to abstain from laying instruments, particularly mallets, wrenches, and records, on the ways. A wooden board can be put on the approaches to fill in as a spot to lay instruments while likewise securing the ways.

This article is from http://www.5axismachiningchina.com/

#auto parts cnc make factory#china bronze custom made parts manufacturers#china cnc lathe machine parts manufacturers#china cnc lathe parts factory#china cnc lathe turning stainless steel parts manufacturers#china cnc machining metal parts suppliers#china cnc precision machining factory#china cnc spare parts factory#china cnc stainless steel milling parts#china cnc stainless steel milling parts manufacturers#china cnc titanium parts suppliers#china jigs and fixtures factory#china metal titanium cnc machining#china swiss cnc lathe#cnc lathe turning parts factory#cnc milling parts components company#cnc prototyping suppliers china#cnc turned parts manufacturer#cnc turning parts aluminum suppliers china#high precision machining efficiency#medical parts machining manufacturers china#ptfe irregular shaped parts manufacturers china#small batches cnc metal parts production manufacturers china

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/this-articollapsible-core/

Collapsible Core

Split pit molds are frequently utilized when the part configuration incorporates complex and undermining outer surfaces. Folding centers are regularly utilized when the part configuration incorporates complex and undermining surfaces on the inside of the part. The plan of a shape which incorporates a folding center is appeared in high precision mould china, which was created to form the top of a doll with an almost uniform divider thickness [12]. The shape depression (14 and 15 together) is framed by two hole embeds 12 and 13, which are burrowed out by a folding center 17. In this plan of automotive mould made in china, the folding center is contained eight sections: 18, 19, 20, 21, 22, 23, 24, and 25. Four of the fragments 18, 19, 20, and 21 are generally three-sided in area and fitted at the corners with a molded external surface in the ideal type of the center. The other four portions 22, 23, 24, and 25 are generally planar in segment and fitted between the corner sections with a shaped external surface to finish the ideal type of the center.

A center pole 37 is situated at the focal point of the center, and forestalls the outspread uprooting of the eight fragments when the folding center is collected. To forestall the pivotal dislodging of the folding center, every one of the eight fragments have a stem 35 with outside strings 35a that draw in the inward strings 39 out of a sleeve 38.

The activity of the folding center depends upon the strings 37b of the center pole 37, and their commitment with the strung way 41 of the sleeve 38. In particular, preceding trim the center bar is turned inside the sleeve so it completely reaches out until its distal (far) end is flush with the finishes of the eight fragments to shape an inflexible center 17. The sleeve with the inflexible center is then positioned in the form cavity and the part is shaped by traditional practice. When the part is hardened, the shape is opened and the formed part is eliminated alongside the center and sleeve. The center pole 37 is then unscrewed from sleeve 38 and eliminated from within the center 17. With no help, the eight portions can implode and be eliminated from within the formed part. The fragments, center bar, and sleeve are then reassembled for the following embellishment cycle.

The folding center plan of oem/odm automotives moulding factory permits complex and undermining highlights to be shaped inside to the formed part. On account of its plan, notwithstanding, a lot of time is needed to collect and dismantle the moving center. To encourage the plan and assembling of molds with folding centers, standard folding center plans have been created and are accessible from various shape base and segment providers. In common plans, the activation of the ejector plate slides the portions along a holding sleeve, which gives a cam activity to implode the center sections during the discharge of the shaped part. This article is from https://www.injectionmouldchina.com/

#automotive mould made in china#carbon fiber cnc manufacturers#china 50 steel mould manufacturers#china cnc machined carbon fiber#china cnc turning and milling metal machining factory work suppliers#china medical device cnc processing suppliers#china mould make services#china mould manufacturer#china precision machining manufacturers#china stainless steel grinding service suppliers#china two shot mold#china two shot plastic parts factory#cnc micro machining brass part manufacturers#cost of injection moulding china#design for injection molding china#high precision mould china#high precision plastic injection mould price#household mould china#injection molded part#injection moulding design china#injection moulding service#moulding company#oem/odm automatives injection overmould factory#oem/odm automotives moulding factory#oem/odm industrial injection mold factory#oem/odm injection mold factory#pipe molds china#precision machined optical components factory#stalinorgel sound#the smithsonian institution39s

0 notes

Text

Water jet cutting lends itself perfectly to low volume

Partwell have been engineering bespoke components for over 30 years, since 1979 using a wide range of technology, our Lancashire based machine shop offers: CNC routers, including 5 axis technology for the production of 3D plastic parts; Lathes for the machining of plastic rod material; Also can be used for the cost effective machining of metals, plastics and synthetics.

Here's one more example of how Partwell China Rapid Prototyping Machine Group uses their experience.

The client is looking for a local alternative to an imported injection moulded plastic tension block, the application is for a jack. The plastic tension blocks were injection moulded with intricate detail.

As with most injection moulded plastic parts, they were imported from the Far East. The client was looking for a local supplier that could provide a cost effective cutting solution for low volume production runs as an infill to their main bulk injection moulded orders.

Water jet cutting lends itself perfectly to low volume production runs, the quick machine set up, easy programming and dual head cutting function enables cost effective locally produced parts. It is known that there is a level of intricate detail on the injection moulded components, it is not commonly known that waterjet cutting can also achieve this detail. The fine nozzles allow a tight cutting tolerance of up to 0.1mm.

This means the criteria of a cost effective fast production turnaround with high detail are fulfilled, the next issue we addressed with the customer was a more economical base material. As a sheet stockist of open and closed cell rubbers, the engineering department were able to provide the client with a range of samples for trial in different hardnesses of material. The final product was water jet cut from a closed cell vulcanised rubber material. Having the sheet material in stock also contributed to minimised lead times.

Water jet cutting offers a quick and economical approach to cutting a range of different materials. The tight nesting techniques minimises waste to save money. Partwell’s water jet cutting machine is very quickly set up and operates with two cutting heads, both heads will cut simultaneously for fast production times; again this provides cost savings as less labour and machine time is charged.

The machine is just as quick to set up and will just as quickly cut both thin and delicate materials and thick, more difficult materials. Water jet cutting can be carried out on felts, foams, rubbers, metals, gasket material etc.

1 note

·

View note