#custom cnc machinery precision steel parts factory

Explore tagged Tumblr posts

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-modifications-for-the-bmw-e60-m5/

Top 8 Best Modifications For The BMW E60 M5

The BMW M5 stands tall as an iconic sports car, renowned globally and possibly the most celebrated BMW ever crafted. Across its generations, this Bavarian masterpiece has captivated the hearts of car enthusiasts, reigning supreme in its segment for years. Notably, the M5 holds a special allure for tuners, inviting passionate modifications and enhancements by enthusiasts worldwide.

Among all iterations, the E60 M5 remains a topic of fervent discussion, whether for its impressive V10 engine or its notorious reliability challenges, constantly making headlines. Despite debates over its advantages and drawbacks, the E60 M5 embodies sheer legend—boasting captivating aesthetics and an exhilarating drive that checks all the boxes. Moreover, it stands out as the most customized M5 to date, offering ample opportunities for personalization.

In its factory form, the E60 sported a divisive V10 engine capable of revving up to 9000 rpm, delivering 500 horsepower and 383 lb-ft of torque—an undeniable testament to its prowess and potential. However, if you sat in or rode in a E60 M5, you will know that BMW left quite a room for improvement. With that being said, here are the 8 Top Performance modifications for the BMW E60 M5.

1. B&B Axle Back Exhaust

Developed for the BMW E60 M5, this Billy Boat Performance Exhaust axle back system is precision crafted using 100% T304 stainless steel. By utilizing the factory mounting locations for an easy installation this system requires a single cut of the factory system on each side for removal and comes with all the necessary mounting hardware.

Billy Boat Performance Exhaust is known for their finely crafted catback systems. Mandrel bent for a smooth and even exhaust flow, their catback exhaust system frees up horsepower and torque that are wasted by the restrictive stock system – resulting in the best possible performance gain and sound quality combination.

Features:

Lifetime Warranty

Utilizing the Purge Resonance Technology (PRT) to have a mild exhaust note at cruising speeds yet a forceful note on aggressive driving

Made of the highest quality T-304 stainless steel

All exhaust tubing is mandrel bent on sophisticated CNC machinery for a precise fit and uninterrupted exhaust flow

Designed as a direct bolt-on replacement for the restrictive factory exhaust and requires absolutely no modifications to the vehicle or the product installation.

Made in USA – Billy Boat Performance Exhaust exhaust systems are crafted in-house with years of racing and street development invested into the design

Part Number: #FBMW-1110

Product Name: B&B Exhaust Axle Back Exhaust System BMW E60 M5 2006-2009

2. CSF Radiators Race-Spec Oil Cooler

The original OE oil cooler from BMW is an all metal design which would make you think it would be fairly robust. However, there are several weak spots in the design that tend to cause leaks. The CSF Race-Spec design reinforces the weak points, especially around the feed and return lines.

CSF’s solid line connection block can handle any abuse thrown at it while the reinforced and braced return tube is rock solid. CSF also upgraded the more fragile Tub/Fin core to a robust and durable Bar/Plate design. The core is 40% larger than the factory unit with 2 additional rows of oil cooling and much thicker core (63mm vs OE 45mm). This offers superior cooling capacity and volume for the oil system. TIG welded end tanks round out the slew of upgrades creating a much stronger connection than the factory brazed construction.

Part Number: #8275

Product Name: CSF Radiators Race-Spec Oil Cooler BMW E60 M5 | E6X M6 2006-2010

Features:

High Efficiency & Rugged Durability Bar/Plate Design

“Aero-Flow” Bar Lightweight Construction for Strength and Maximum Flow

Cast End Tanks with 100% TIG-Welded Construction

Satin Black Finish for Extreme Protection Against Corrosion and Debris

CNC Machined Mounting Brackets and OEM Style Inlet/Outlet Connection

Requires minor trimming of the plastic shroud to install (instructions included)

Individually Leak and Pressure Tested

2-Year Limited Warranty

3. B&B Exhaust Midpipe

Developed for the true enthusiast this center x-pipe section for the BMW E60 M5 is precision crafted from 100% CNC mandrel bent 3″ tubing and is a direct bolt on upgrade to either B&B axle back exhaust. The hand fabricated crossover (x-pipe) helps to even out the exhaust pulses resulting in a deeper, smoother exhaust note as well as increased horsepower and torque.

Part Number: #FBMW-1111

Product Name: B&B Exhaust Midpipe with X-Pipe BMW E60 M5 2006-2009

Features:

Lifetime Warranty

Utilizing the Purge Resonance Technology (PRT) to have a mild exhaust note at cruising speeds yet a forceful note on aggressive driving

Made of the highest quality T-304 stainless steel

All exhaust tubing is mandrel bent on sophisticated CNC machinery for a precise fit and uninterrupted exhaust flow

Designed as a direct bolt-on replacement for the restrictive factory exhaust and requires absolutely no modifications to the vehicle or the product installation.

Made in USA – Billy Boat Performance Exhaust exhaust systems are crafted in-house with years of racing and street development invested into the design

4. Eventuri Black Carbon Intake

The E60/E63 M5/M6 intake system is designed to make a positive impact for the whole driving experience. By taking advantage of aerodynamic principles and using computational fluid dynamics to optimize the airflow, we have engineered an intake system which delivers on all fronts – sharpened throttle response, more torque and power, improving drivability and of course, an amazing V10 induction sound.

The S85 Eventuri system uses our Patent Pending Carbon fiber Housing which provides an aerodynamically efficient airflow path from the filter to the MAF tube. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect.

Part Number: #EVE-E60-CF-INT

Product Name: Eventuri Black Carbon Intake BMW E60 M5| E63 M6 2005-2010

Features:

2 x 100% Pre Preg Carbon Fiber Housings

High Flow Air Filters

2 x CNC Machined and Anodized Aluminum MAF Sensor Housings with Machined Plastic MAF Sensor Mounts

CNC Machined Secondary Air Flow Breather Adapter

Aluminum Intake Cowls

Laser Cut Mounting Brackets

Laser Cut and Neoprene Lined Heat Shields

Coated Aluminum Upper and Lower Air Scoops

OEM Spec Hose Clamps with High Quality Silicon Couplers

OEM Quality Anti Vibration Mounts

5. Recaro Sportster CS Seat

The Recaro Sportster CS seat was developed for all motor sport fans, who do not want to compromise on the functionality and comfort of a sport seat. It cames with the seat backrest tilt setting and the newly developed backrest release for a complete sporty feel in the vehicle.

Features:

Nardo Black | Artista Black Grey Logo

Collapsible/adjustable racing shell in hybrid construction

Made of steel and composite materials

Molded plastic back panel and innovation recliner system

Suitable for 4-point and 3-point belt system

Contoured shoulder support relieves muscle tension when cornering

Defined side bolsters for a firmer sitting position

Fully upholstered headrest

Backrest release integrated into the belt feed for simple and comfortable operation

Built in adapter

Part Number: #414.00.1351

Product Name: Recaro Driver Cross Sportster CS 3 Point Belt Seat Black Nardo | Black Artista with Grey Logo

Part Number: #414.00.2351

Product Name: Recaro Passenger Cross Sportster CS 3 Point Seat Black Nardo | Black Artista with Grey Logo

6. CSF Radiators High-Performance All-Aluminum Radiator

The factory radiator for the E60 M5 and E6X M6 are pretty nice all aluminum units. While they have proven to be fairly robust, age and additional power tend to push them over the edge. Owners who have superchargers tend to have the most issues with their radiators. Between the extra heat produced with forced induction and the heat exchanger mounting in front of the radiator, the factory radiator is working overtime. The E6X models are also getting close to 20 years old and entering the “future classic” stage of life with many owners doing restorations and updates. Anyone who has restored/updated an older car knows the value of having upgraded parts that are as efficient as possible.

The CSF radiator features a 2-Row 42mm aluminum core that not only increases the fluid capacity of the radiator, but also improves the cores ability to dissipate heat. CSF’s Exclusive B-Tube Technology increases the heat transfer by approximately 15% over regular oval welded tubes. Between the 6 additional rows of cooling tubes/fins and the thicker 42mm 2 row core, the CSF Radiator will outperform the OEM unit by a significant margin. In addition, the super-efficient multi-louvered fins maximize airflow through the core for the best possible performance. The radiator mounts in the factory location and requires no modifications or cutting.

Part Number: #7218

Product Name: CSF Radiators High-Performance All-Aluminum Radiator BMW E60 M5 | E6X M6 2006-2010

Features:

2-Row, 42mm Ultra-High-Performance Core

Cooling Tubes with CSF’s Exclusive B-Tube Technology

6.5mm Tall Ultra Efficient Fins with a Multi-Louvered Design for Maximum Surface Area Contact

CNC Machined Mounting Brackets and OEM Style “Quick Connect” Inlet/Outlet

100% All Aluminum TIG-Welded Construction

Satin Finish

True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

Individually Leak and Pressure Tested

2-Year Limited Warranty

7. KW Suspension V1 Coilover Bundle Kit

An aging factory suspension stands in the way of the handling and capability of your E60. Many E60 owners upgrate the handling of their cars with tuning suspension upgrades as a priority, this will certainly increase your enjoyment of the car. KW V1 is the ideal system for enthusiasts who like to fine tune the ride height with its preset dampers from for the ultimate balance between sporty driving, comfort and safety. The result is a balanced and sporty feel specific to each vehicle application designed for long lasting driving pleasure. Even after years of use you can easily adjust the ride height thanks to the dirt resistant trapezoid thread and composite Adjustment tollar.

Part Number: #10220082

Product Name: KW Suspension V1 Coilover Bundle Kit BMW M5 E60 w/ EDC Delete 2006-2010

Features:

Composite spring perch made from wear-resistant, frictiontoptimized polyamide composite encompassing a stainless-steel insert. The polyamide composite prevents oxidation while the stainless-steel insert maximizes strength.

Elastomer Bump stop with integrated dust protection system prevents water and dirt particles reaching the piston rod and seals. The highly resilient bump stops act as dynamic load limiters while maintaining ride quality and durability.

Every single damper is dyno tested to ensure functionality and guarantee accuracy before being released for delivery.

Inox-Line Stainless Steel – Truly Permanent Corrosion Resistance. Inox-Line coatings will not wear off while adjusting the suspension making KW coilover struts 100 percent corrosion resistant with an unlimited lifespan.

KW suspensions V1 coilovers are hand built by our expert team and given a uniquely individual serial number at our headquarters in Fichtenberg, Germany.

Limited Lifetime Warranty – Unlimited Mileage

Seamless Ride Height Adjustment – the corrosion resistance of the Inox-line stainless steel and composite perches means easy ride height adjustability to help you dial in your preferred look.

With the preset damping paired with vehicle specific spring rates precisely tuned by our engineers, V1 coilovers provide an optimum balance of sportiness and comfort while driving. KW takes the guess work out of setup for you.

8. VR Tuned ECU Flash Tune

To take the S85 V10 nearer to perfection, the team here at Vivid Racing made a few changes. It started with establishing a baseline and truly testing the limits of the V10, and to our pleasant surprise, it managed to put down 507chp and 384ft/lbs of torque on 91 octane in the arid Arizona heat. However, we knew BMW had left a little bit of room for improvement, and we love improvement. After brunch at the VE table, an otherwise completely factory V10 found an additional 57hp and 43ft/lbs of torque, but that wasn’t all. With our modified ignition mapping and refinement of the throttle response, this E60 felt like a completely different beast. Unfortunately, though, this is as far as we were able to get on our initial session. If you want to pull every last ounce of potential out of your S85 and our VR Tuned Flash Tune, we highly recommend the upgrade to the B&B Axle Back Exhaust and B&B Exhaust Midpipe… but only when you think you can handle it.

Part Number: #VRT-E60-M5

Product Name: VR Tuned ECU Flash Tune BMW M5 E60 E61 V10 2006-2010

Features:

#1 priority is our customer service to you!

Our tuning is used worldwide.

We can tune vehicles for different types of environments.

Most ECU Tuning can be reverted back to stock.

With the VR Tuned ECU Flash, basic bolt-on performance parts will not require a retune of your ECU.

For gasoline vehicles, if you add higher octane fuel, the ECU will adjust accordingly.

Tested and proven files that are safe, reliable, and give you the results you want!

There are dozens of other great ways to modify your E60/E63. Let our performance specialists help you decide what’s right for you by calling 1-480-966-3040 or emailing [email protected].

4 notes

·

View notes

Text

Metal Stamping Market Top Players, Segmentation & Future Trends Analysis till 2034

Metal stamping is a crucial manufacturing process used in various industries to shape metal sheets into desired components. The process involves pressing, bending, punching, and embossing to create high-precision parts. From automotive and aerospace to electronics and industrial machinery, metal stamping supports the production of complex parts with high efficiency and cost-effectiveness.

The global metal stamping market is expected to increase at a compound annual growth rate (CAGR) of 4.2% between 2024 and 2034. Based on an average growth pattern, the market is expected to reach USD 326.38 billion in 2034. It is projected that the worldwide metal stamping market will generate USD 236.83 billion in revenue by 2024.

Get a sample copy of this report: https://wemarketresearch.com/reports/request-free-sample-pdf/metal-stamping-market/1610

Metal Stamping Market Drivers

Rising Demand in the Automotive Sector:

Automotive manufacturers are using metal stamping for parts like frames, brakes, exhaust systems, and fuel delivery systems.

The growing production of electric vehicles (EVs) is driving the demand for customized stamped components, especially for lightweight chassis and battery enclosures.

Industrial Automation Boosting Productivity:

The integration of CNC machines and robotic arms in stamping facilities has significantly improved accuracy and efficiency.

Automated metal stamping systems are particularly advantageous for high-volume production in the automotive and electronics industries.

Miniaturization in Electronics:

Modern electronics, such as smartphones, laptops, and wearables, require highly precise, intricate stamped components.

Innovations like micro-stamping are meeting this demand.

Sustainable Manufacturing Practices:

Metal stamping processes are increasingly being optimized to use recyclable materials and reduce energy consumption.

Metal Stamping Market Emerging Trends

Smart Factories and IoT:

The adoption of Industrial IoT (IIoT) in stamping facilities allows real-time monitoring and predictive maintenance, improving overall productivity.

Smart sensors and analytics are reducing downtime and enhancing the efficiency of stamping operations.

Focus on Tooling Innovation:

Development of progressive dies and transfer dies that enable multiple operations in a single stamping cycle.

Enhanced durability and precision of stamping tools, reducing the need for frequent replacements.

Customization of Components:

Increasing demand for customized metal stamped parts across sectors like aerospace, healthcare, and energy.

Flexible tooling and modular stamping presses are enabling cost-effective customization.

Expansion into Renewable Energy:

Metal stamping is critical for manufacturing parts in wind turbines, solar panels, and battery systems used in renewable energy projects.

Technological Advancements

Laser Metal Stamping:

Use of laser-assisted stamping to create highly intricate parts with minimal material waste.

Hot Stamping:

Stamping metal at high temperatures, ideal for creating ultra-strong components for automotive and aerospace applications.

3D Printing Integration:

Hybrid manufacturing processes combining additive manufacturing and metal stamping for complex geometries.

Challenges Facing the Metal Stamping Market

Material Availability:

Supply chain disruptions, especially for metals like aluminum and steel, can lead to delays and cost increases.

High Competition:

The presence of numerous local and international players creates intense price competition, especially in cost-sensitive markets.

Labor Shortages:

Skilled labor is critical for managing advanced stamping machinery, and shortages can impact production timelines.

Environmental Regulations:

Strict regulations on waste management and emissions in metalworking facilities are increasing operational costs.

Metal Stamping Market Future Opportunities

Medical Device Manufacturing:

Growing demand for precise and sterile metal parts for surgical instruments, implants, and diagnostic equipment.

Electric Mobility Revolution:

Increased production of lightweight stamped parts for electric cars, scooters, and bikes.

Collaborations and Mergers:

Companies partnering to share technology and expand their reach in global markets.

Investment in R&D:

Opportunities lie in developing innovative stamping processes and materials that reduce costs and improve durability.

Companies Covered: Metal Stamping Market

The Global Metal Stamping Market is dominated by a few large companies, such as

Acro Metal Stamping

Manor Tool & Manufacturing Company

D&H Industries, Inc.

Kenmode, Inc.

Klesk Metal Stamping Co

Clow Stamping Company

Goshen Stamping Company

Tempco Manufacturing Company, Inc

Interplex Holdings Pte. Ltd.

CAPARO

Nissan Motor Co., Ltd

AAPICO Hitech Public Company Limited

Gestamp

Ford Motor Company

These companies have the potential to drive market growth through various strategies. They can focus on offering innovative and high-performance products, taking advantage of advancements in technology. Additionally, expanding their distribution channels to target new customers would be beneficial. Strategic partnerships and collaborations can also be pursued to strengthen market presence and enhance competitiveness.

Global Metal Stamping Market Segmentation

By Process

Blanking

Embossing

Bending

Coining

Flanging

Others

By Press Type

Mechanical Press

Hydraulic Press

Servo Press

Others

By Thickness

Less than & up to 2.5 mm

More than 2.5 mm

By Application

Automotive

Industrial machinery

Consumer electronics

Aerospace

Electrical & Electronics

Telecommunications

Building & Construction

Others

Metal Stamping Market Regional Insights

Forecast for the North American Market

The global market for metal stamping is dominated by North America. In the automobile industry, the United States and Mexico are well-represented, particularly thanks to big businesses like Ford, General Motors, and Fiat Chrysler. Mexico is a major center for the production of stamping components and automobiles due to its affordable labor costs. Precision metal stamped parts are in high demand, particularly for defense equipment, turbines, and aircraft components, thanks to the U.S. aerospace industry, which includes firms like Raytheon, Lockheed Martin, and Boeing. The necessity for metal stamping is further fueled by North America's desire for appliances and electronics.

Forecast for the European Market

Europe has a strong automotive manufacturing sector, including Mercedes-Benz, BMW, Renault, and Volkswagen. Stamped metal components are essential for these vehicles, particularly for the construction of electric vehicles that require lightweight materials. Another significant force behind the metal stamping market is Europe's aerospace sector, which is dominated by firms like Rolls-Royce and Airbus. Stamped metal parts are also in high demand in the industrial machinery sector in nations like Germany. More efficient production techniques like metal stamping have become more popular, especially in the automobile and appliance industries, as a result of the European Union's emphasis on sustainability and environmentally friendly practices.

Forecast for the Asia-Pacific Market

Asia Pacific holds a dominant position in the worldwide industry, with around 48% of the market in 2023. Car manufacturers including Toyota, Honda, Hyundai, and BYD are based in Asia-Pacific, particularly in China, India, Japan, and South Korea. These nations use metal stamping extensively in the production of electric vehicles, body panels, chassis, and automotive parts. The world's manufacturing of electronics is dominated by nations like China, South Korea, and Japan. The production of small, accurate parts for computers, smartphones, consumer electronics, and appliances depends heavily on metal stamping.

The report provides a comprehensive examination of the factors driving growth, constraints, future prospects, and competitive landscape across all regions. The market is segmented by region into North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. Additionally, the report identifies the top countries in each region and provides market forecasts for each one.

Key objectives of this research are:

To explore Global Metal Stamping Market size by respective indicators.

To scrutinize the sum and estimation of the Global Metal Stamping Market, Based on key aspects.

To offer an account of the competitive landscape and investigate their development plans.

To examine the Global Metal Stamping Market for growth possibilities, and strategic growth.

To review the Global Metal Stamping Market size (volume and worth) from the organization, key market regions, items and applications, and statistical data.

To generate competitive learnings and factors analysis, SWOT examination, and business improvement plans for the future.

To scrutinize the range of available and novel organic business growth strategies.

Conclusion

The global metal stamping market is a cornerstone of modern manufacturing, enabling the production of precise, durable, and cost-effective components across industries like automotive, electronics, aerospace, and beyond. With the growing demand for lightweight materials, advancements in automation, and the rise of electric vehicles, the market is poised for substantial growth.

Challenges such as fluctuating raw material costs and stringent environmental regulations present hurdles, but they also open doors for innovation in sustainable practices and advanced technologies. Companies investing in R&D, process optimization, and strategic collaborations will thrive in this competitive landscape.

As industries continue to evolve, the metal stamping market stands as a vital player in shaping the future of manufacturing, driving efficiency, sustainability, and innovation across the globe.

0 notes

Text

Leading Bushes Manufacturer – Reliable Solutions for Your Industrial Needs

As a trusted bushes manufacturer, Dynamic Industries is committed to providing high-quality, durable bushes for a wide range of industrial applications. Our bushes are crucial components used in machinery to reduce friction and enhance performance, ensuring smoother and more efficient operations.

At Dynamic Industries, we specialize in the production of a variety of bushings, such as plain bushes, flanged bushes, and custom bushes for specific needs. Our extensive expertise and state-of-the-art technology allow us to offer both standard and customized solutions to meet the unique demands of different industries, including automotive, construction, and heavy machinery.

Quality Manufacturing with Precision Engineering

As a leading bushes manufacturer, we focus on precision engineering to ensure that every bush we produce adheres to the highest quality standards. Our CNC machining process allows us to manufacture bushes with impeccable accuracy, ensuring a perfect fit and reliable performance. Whether you need metal, plastic, or composite bushes, we have the capabilities to provide the ideal solution for your needs.

Our bushes are made from a range of materials, including stainless steel, bronze, and carbon steel, chosen for their strength, corrosion resistance, and durability. This allows us to cater to various applications, from automotive parts to industrial machinery and construction equipment.

Customized Bushes for Diverse Applications

At Dynamic Industries, we understand that each application may require a specific design and material. That’s why we specialize in custom bushes to fit the unique requirements of your machinery. Our team works closely with clients to create tailored solutions, whether it's designing custom flanged bushes, wear-resistant bushes, or high-temperature resistant bushes.

Our commitment to quality ensures that each bush manufactured by Dynamic Industries undergoes rigorous quality checks. This guarantees that our products perform optimally in even the most demanding environments.

Why Choose Dynamic Industries as Your Bushes Manufacturer?

- Precision and Expertise: As a trusted bushes manufacturer, we leverage our years of experience to deliver high-quality products that meet the highest industry standards.

- Durability and Reliability: Our bushes are designed to withstand harsh conditions, offering long-lasting performance and reducing the need for frequent replacements.

- Custom Solutions: We provide tailored bush solutions, ensuring that each component fits perfectly and performs optimally in your machinery.

- Wide Range of Materials: From plastic bushes to metal bushes, we offer a broad selection of materials to suit various industrial applications.

Dynamic Industries is proud to serve a variety of industries, including:

- Automotive: Providing high-performance bushes for vehicles and automotive systems.

- Heavy Machinery: Supplying bushes for construction and mining equipment.

- Industrial Equipment: Offering durable solutions for factory machinery and production lines.

- Aerospace: Providing precise bushings for critical aerospace applications.

Get in Touch with the Leading Bushes Manufacturer

As a top-tier bushes manufacturer, Dynamic Industries is here to fulfill all your bush manufacturing needs. Our commitment to quality, precision, and customer satisfaction sets us apart as a leader in the industry. Whether you require standard bushings or need custom solutions, we are ready to support your business. Contact us today to discuss how we can help optimize your equipment’s performance.

0 notes

Text

Durability Assurance Strategies at Straight Gear Rack Factory

In the realm of mechanical components, the Straight Gear Rack Factory has established itself as a bastion of quality and durability. Gear racks are integral to the smooth operation of machinery in various industries, and their longevity is crucial for maintaining the efficiency and safety of these systems. The Straight Gear Rack Factory is acutely aware of this fact and has implemented a multifaceted approach to ensure the durability of its products.

The Straight Gear Rack Factory begins its commitment to durability with the selection of materials. The factory sources high-quality steel and alloys that are known for their strength and resistance to wear. These materials are chosen not only for their immediate properties but also for their ability to withstand the test of time. The Straight Gear Rack Factory's engineers work closely with material scientists to continually evaluate and improve the materials used in production.

In addition to material selection, the Straight Gear Rack Factory places a strong emphasis on manufacturing processes. The factory employs CNC machines that are capable of producing gear racks with micron-level precision. This level of precision ensures that each tooth on the gear rack is uniformly cut, contributing to the overall durability of the component. The Straight Gear Rack Factory also invests in regular maintenance and upgrades of its machinery to prevent any decline in production quality.

Heat treatment is another critical aspect of the Straight Gear Rack Factory's durability assurance strategy. The factory uses advanced heat treatment processes to enhance the hardness and toughness of the gear racks. This treatment not only improves the wear resistance of the gear racks but also increases their fatigue life. The Straight Gear Rack Factory's heat treatment protocols are meticulously controlled to ensure consistency across all products.

Quality control is a cornerstone of the Straight Gear Rack Factory's operations. Every gear rack that leaves the factory undergoes a rigorous inspection process. This includes visual inspections, dimensional checks, and functional tests to ensure that each product meets the factory's exacting standards. The Straight Gear Rack Factory's quality control team is composed of experienced professionals who are trained to identify even slight deviations from the required specifications.

The Straight Gear Rack Factory also recognizes the importance of continuous improvement. The factory is committed to staying at the forefront of technological advancements in the manufacturing sector. This includes investing in research and development to explore new materials, processes, and coatings that can further enhance the durability of its gear racks. The Straight Gear Rack Factory's R&D team works in close collaboration with production teams to ensure that any new developments are seamlessly integrated into the manufacturing process.

In addition to internal efforts, the Straight Gear Rack Factory also engages with its customers to gather feedback on the performance of its products in real-world applications. This feedback is invaluable in identifying areas for improvement and ensuring that the factory's gear racks continue to meet the evolving needs of its clients. The Straight Gear Rack Factory's customer service team is dedicated to maintaining open lines of communication with customers and addressing any concerns promptly.

Finally, the Straight Gear Rack Factory understands that durability is not just about the initial quality of the product but also about its performance over time. To this end, the factory offers comprehensive after-sales support, including maintenance advice, replacement parts, and technical assistance. This commitment to customer service extends the life of the gear racks and ensures that they continue to perform at their high level after they have left the factory floor.

In conclusion, the Straight Gear Rack Factory's approach to ensuring the durability of its products is a holistic one. It involves careful material selection, precision manufacturing, advanced heat treatment, stringent quality control, continuous improvement, and good customer service. By adhering to these principles, the Straight Gear Rack Factory can produce gear racks that are not only durable but also reliable and long-lasting, meeting the needs of its customers and exceeding their expectations.

0 notes

Text

youtube

Laser cutting/milling/turning wooden cnc machining wood parts

We are cnc machining factory, and we make wood cnc service machining, wood cnc machining service, custom design wooden machinery machining wood cnc, 5 axis wood machining cnc, cnc machining center wood parts etc.

We also can provide the customization services as per customer's drawing or sample, turning milling cnc machining aluminum, cnc machining service custom precision, precision stainless steel cnc machining.

-------------------------------------

https://cncmtf.com

0 notes

Text

CNC Machining Aluminium

Over the past 14 years, Flourish Legend has become a professional CNC precision machining company for aluminum component. Regardless of the precision and complexity of the products, we can provide automated machining processes, comprehensive project management, cutting-edge assembly lines, and logistics services. Our mission has always been to assist customers in manufacturing high-quality parts with competitive prices and fast delivery times. aluminum material is widely used in automotive parts, the aerospace industry, building and construction materials, household appliances, and more. Discover how you and your company can benefit from our services.

Basic Knowledge and Considerations for CNC Machining Aluminium

Aluminum Alloy Basics

The most commonly used material for CNC machining is aluminum alloy. Aluminum alloys are versatile, easy to machine, and can undergo various surface treatments. CNC-machined aluminum finds applications in fields such as machinery, sports equipment, aerospace, automotive, marine, communication optics, medical devices, and robotics. It is one of the most popular materials for machining. Aluminum alloys may seem like a single material to those unfamiliar with them, but in reality, there are hundreds of different types and states.

Commonly used series for customized CNC machining aluminum include 2xxx, 5xxx, 6xxx, and 7xxx, such as 2017, 2024, 5052, 5083, 6061, 6063, 7075, and others. Additionally, the same alloy can have different states, denoted by letters such as F for as-fabricated, O for annealed, H for strain-hardened, W for solution heat-treated, T for heat-treated, such as 2024-T351, 6061-T651, and so on. Different alloy types and states have different applications. For example, 2024 is suitable for aircraft structures, truck hubs, propellers, and other components, while 5052 is commonly used for thin sheets due to its good formability and corrosion resistance, finding applications in aircraft fuel tanks, vehicles, ships, instruments, brackets, medical equipment, and various sheet metal parts. 6061 is the most commonly used alloy due to its high strength, weldability, and corrosion resistance, making it suitable for various fields such as automotive, construction, marine, furniture, machinery parts, robotics, aerospace, and more.

Aluminum alloys can also undergo various surface treatments to enhance wear resistance, corrosion resistance, and aesthetics. Therefore, due to its superior performance and affordable price, aluminum is widely used in CNC machining. At Flourish Legend, we not only specialize in machining aluminum alloys but also work with various other metal materials like steel, stainless steel, copper, iron, magnesium alloys, zinc alloys, titanium alloys, nickel alloys, etc. Just let us know the application field and required performance of your product, and we can suggest the most suitable material.

0 notes

Text

Tapping in CNC Machining

New Post has been published on http://www.cncmachinings.com/tapping-in-cnc-machining/

Tapping in CNC Machining

A few machines are not equipped for organizing the feed and shaft pivot precisely enough to forestall tap breakage. These machines require the utilization of a coasting tap holder. (See medical precision machined components factory, A floating tap bewilder permit pivotal (in and out) buoy of the tap to make up for little coordination blunders between the axle revolution and feed.

At the point when a coasting tap holder is utilized, tapping is modified with a G32 code while the shaft is already running at the ideal RPM. At least two G32 blocks are normally expected, one to propel the tap and one to withdraw it. In the event that utilizing a coasting tap holder, the feed. rate ought to be customized about 0.001″ per upset not exactly the hypothetical feed rate. Thusly, the tap will be step by step pulled from the characteristic loosened up situation of the drifting holder. This permits the tap holder buoy to adapt to blunder when the tap is switched. When utilizing a G32, the shaft should be modified to turn around after the tap has arrived at its profundity. The full determined feed rate ought to be utilized while withdrawing.

The tap will keep on being pulled in as the shaft coasts to a stop, so use alert when programming the profundity of the tap so it doesn’t base in the opening.

Anticipating how far the tap will be pulled in during deceleration is difficult in light of the fact that each machine is extraordinary. lt might be ideal to diminish the hypothetical tap profundity by 6 *PITCH in the program. This should bring about a string profundity that is excessively shallow. After an initial segment is run, the string profundity can be gagged and afterward the program profundity adapted to the following part. It isn’t prudent to rerun a G32 cycle in a formerly cut string in light of the fact that there could be a following mistake. With the goal that the initial segment isn’t squandered, its string profundity can usually be tapped further by hand.

Both Fanuc and Haas machines utilize a similar organization for G32 tapping. Custom cnc machinery precision steel parts factory shows a section drawing and program for tapping utilizing a skimming tap holder.

Unbending Tapping Canned Cycles (G84) Some machines can facilitate the feed and revolution of a tap precisely. This allows for unbending tapping, where the tap is held firmly in a holder without the capacity to skim. When programming inflexible tapping, the developer doesn’t have to lessen the passage feed and there ought to be no critical synchronization mistake. Inflexible tapping was an uncommon choice on numerous more seasoned machines, however today is regularly standard.

On numerous Fanuc machines, an aaditional block is needed before the G84 block. This extra square requires a M29 code to enact the unbending tapping mode, and a rehash of the axle speed order. China machining service shows a Fanuc program passage for inflexible tapping. The table underneath shows the arrangements for each tapping cycle referenced.

Few out of every odd string pitch computation will bring about a number with an ending decimal. Since the exactness of the feed rate is critical, non-ending numbers ought to be adjusted to the same number of decimal spots as the control will permit (usually four is sufficient). This article is from http://www.cncmachinings.com

#4 axis cnc milling machine china#carbon fibre cnc service suppliers#carbon steel grinding rod suppliers china#china carbon fibre cnc mill#china cheap cnc machining service manufacturers#china custom made metal cnc machining parts manufacturers#china machining service#china titanium cnc turned part suppliers#cnc machining aluminum factory#cnc turning and milling metal machining factory work factory#custom cnc machinery precision steel parts factory#high precision cnc machining auto titanium parts china#machined carbon fibre factory#medical precision machined components factory#precision cnc machining china#precision machining china#precison cnc turning parts suppliers#steel turning parts suppliers#titanium machining components factory#Featured Articles

1 note

·

View note

Text

CNC Control

In the present requesting and quick moving machining atmosphere, modernized mathematical control (CNC) machines are upsetting the substance of machining. These cutting edge machines can perform things that might have never been envisioned even 10 years prior. Complex tasks can be performed quicker, with more exactness and consistency, thus eagerly that it seems easy. In a cutting edge electronic…

View On WordPress

#auto parts cnc make factory#china 3 aixs cnc machine high precision cnc machining metal parts manufacturers#china bronze custom made parts#china bronze custom made parts manufacturers#china carbon steel machining parts suppliers#china cnc machining metal parts suppliers#china cnc precision machining factory#china cnc stainless steel milling parts manufacturers#china cnc titanium parts suppliers#china large lathe machining parts suppliers#china swiss cnc lathe#cnc lathe turning parts factory#cnc machined parts suppliers#cnc prototyping suppliers china#cnc stainless steel machinery parts china#cnc turning stainless steel parts factory#custom cnc carbon fibre factory#custom cnc machinery precision steel parts factory#fabrication cnc machining parts factory#high precision machining efficiency#machined parts suppliers china#machining aluminum suppliers china#medical parts machining manufacturers china#medical precision machined components factory#metal lathe part manufacturers china#ptfe irregular shaped parts manufacturers china#tight tolerance precision machining factory#titanium cnc machining parts suppliers#turned part

0 notes

Text

Spot Drilling

Posted from 5 axis machining China blog

Spot Drilling

SPOT DRILLING

After the workpiece is situated and safely clasped, a middle drill (mix drill and subset) or spot drill is normally used to make a more certain beginning stage for a bend drill. This activity is in some cases called spotting, and the imprint made can be known as a spot. Select a drillwith a pilot distance across that is marginally bigger than the flawlessly focused of the wind drill to be utilized. The diagram shows sizes of focus drills and their pilots. On the off chance that utilizing a spot drill, the detect drill’s width isn’t as basic, however on the off chance that china cnc precision machining factory utilizing a spot drill bigger than the ideal opening breadth, make certain to abstain from penetrating excessively profound and making a measurement bigger than the ideal gap size. While figuring axle speed for a spot drill, utilize the drill distance across. Hypothetically, while computing axle speed for a middle drill, the pilot width ought to be utilized. Notwithstanding, this regularly brings about an illogical shaft speed for littler focus drills, so some judgment must be utilized to set a reasonable speed.

A decent guideline for spot profundity is to bore to a profundity that is equivalent to around 1/2 the length of the purpose of the bend drill to be utilized. At this profundity, if there is an area mistake, steps can be taken to alter the opening area. On the off chance that the profundity of the spot is equivalent to or more prominent than the length of the bend drill point, an area mistake is extremely hard to address. The length of a drill point relies upon the included edge of the tip.

China carbon steel machining parts suppliers Just utilize these speedy recipes as appraisals. Since they do no record for the level on the drill point made by its right on target, the length of the point will really be somewhat not exactly the speedy count.

This outcomes in a marginally more profound outcome than anticipated. On the off chance that a more exact drill point length is wanted, one approach to gauge its length is by precision machining parts suppliers utilizing an optical comparator.

The profundity stop on the drill press plume can be utilized to set the profundity of the spot.

Adjust the profundity stop with the goal that the tip of the spot drill almost contacts the outside of the workpiece. A bit of paper can be utilized as a sensor measure to set up the separation between the workpiece and the drill tip if there is no punch blemish on the workpiece.

Retract the plume.

Move the stop the measure of the ideal spot profundity.

Start the axle and set the suitable speed.

5 axis Milling Machine

Use the feed handle to take care of the drill to the ideal profundity. Apply an adequate measure of a proper cutting liquid while boring and feed focus bores gently to keep the pilot from being severed in the work.

●Retract the plume often to clear chips from the point. This substituting boring and withdrawing movement is called pecking, or peck penetrating. This article is from http://www.5axismachiningchina.com.

#buy brass cnc turning components#carbon fiber cnc service manufacturers#china cnc lathe machine parts manufacturers#china cnc precision machining factory#china cnc stainless steel milling parts manufacturers#china cnc titanium milled machining parts#china large lathe machining parts suppliers#china milling mild steel suppliers#china steel machining#cnc machined parts suppliers#cnc milling parts components company#cnc prototyping suppliers china#cnc stainless steel machinery parts china#custom cnc carbon fibre factory#customized cnc machining titanium parts#fabrication cnc machining parts factory#galvanized turning parts manufacturer#precision machining parts suppliers#precision turning titanium parts factory#ptfe irregular shaped parts manufacturers china#steel cnc machining parts china#titanium cnc machining parts factory

0 notes

Text

NagualMetal Precision Manufacturing Limited.

CNC Sheet Metal NPM is specialist manufacturer of CNC sheet metal in China for many consumer and industrial products. We provide a complete turnkey solution for your CNC sheet metal requirements.

Some of the CNC sheet metal services we provide include:

CNC turret punching Laser cutting Guillotining CNC Folding and Bending Metal Rolling Band Sawing Tube Bending Product Assembly

NPM is committed to producing high quality CNC sheet metal components and providing excellent service and support to our customers. Our dedicated and highly experienced staff and constantly updated processes and machinery have enabled NagualMetal to grow and remain competitive in China’s CNC sheet metal industry. Each member of our company

NagualMetal CNC Machining in china Branch of NagualMetal is a specialist China manufacturer and supplier offering the full range of CNC/EDM engineering services, comprising CNC Machining, CNC Milling, CNC Lathe Turning, EDM Wire Cutting and EDM Eroding. Computer Assisted Manufacturing (CAM) programs are run on customer 2D or 3D CAD data files. CAM programs are then directly downloaded to one of our CNC machines for automated machining.

Our lead times are fast, depending on the nature and volume of work. Automatic tool changers, high speed spindles, and fast feed rates allow us to machine components efficiently and accurately.

A wide range of materials such as aluminium, steel, hardened tool steel, stainless steel cast iron, brass, copper, polycarbonate, ABS, acrylic, PET, nylon and more can be machined to suit your needs.

NagualMetal is an experienced Precision Manufacturer specializing in precision tooling, automated manufacturing equipment, and prototypes requiring close tolerance. Our wire cut EDM services are perfect for tooling assemblies and EDM intensive component parts. Along with top quality services, our operation offers quick turn delivery, and can assist you with every aspect of your project, from design to manufacturing.

Our staff of experienced machining professionals can assist you in solving the most challenging CNC machining and manufacturing tasks. From complex 3-D machining to simple hole drilling, we can be your first choice for CNC and EDM. Email RFQ and Drawings to:

[email protected] Follow are the informations about our precision parts by CNC machining.

--------------------

● Materials for CNC Precision machining parts

We can process product materials are:

An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from 1050-7475), commonly used are: 2011,5052,6061,7075, etc.

(2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000

(3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades (JIS grade corresponds to the basic, together with the SUS can): 201,301,303,304,314,316,420,430,630

Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15)

● CNC Precision machining parts accuracy

Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm

● Maximum size of Precision parts suit to CNC machining

Lathe parts (turning parts , such as axes, coupling,bushing, thread rod , etc.) following the outer diameter of 300mm, length less than 150mm

Milling parts (box, cylinder, etc.) 800mm long, 330mm wide, 120mm high

Branch of NagualMetal is specialized in making various springs parts,including disc springs,extension springs,compression springs,snap springs,wave springs,flat spiral springs,drum springs,leaf springs,pagoda springs,spring lamination and kinds of stamping parts etc. With powerful technology,good producing equipment and pretty quality,the factory passed ISO9000:2008 quality system and obtained good public praise in this field. Following the concepts of development born of innovation and quality based of constant. The company is dedicating to be internationally competitive and to be the world-known spring supplier.

#stamping cnc machining cnc lather#cnc milling#Branch of NagualMetal is specialized in making various springs parts

1 note

·

View note

Text

We are the leading investment casting foundry for various metal components in 1997. And we have started our exporting business all over the world.Such as American, Japan, German,Australia, UK, Canada,ect.

Currently, our investment casting company has 2 units: one is foundry,Another one is CNC Machining Factory.There are total 310 workers in our factory, with 265 workers, 7 engineers, 23 QC man, 10 sales person, and 5 management.Via many years’ hard working,we are now have become one of the largest investment casting manufacturer and supplier.

Our company can cast a variety of materials: Alloy Steel, Carbon Steel, Stainless Steel, Aluminum, ect. With great capabilities of design, molding, casting, machining, and heat treatment.With automatic lost wax investment casting process, we can make custom investment castings for various industries, such as agricultural castings, construction castings, railway castings, valve castings, food machinery castings, and other industrial applications.We are committed to producing Quality Investment Castings at the lowest possible price and on time delivery. In addition, we offer engineering consultancy services, to assist in the development of new products for best application.

Located in Dongying,Shandong, China. 2.5hours trip to Qingdao Seaport. That will greatly reduce the transportation cost for our customers.As a direct investment casting manufacturer and supplier, we provide a project management service, from initial design to delivery of finished components or assemblies. Pls do not hesitate to contact us when you need investment casting solution.

Investment Casting Methods in Our Company

Silica Sol Casting: Medium temperture lost-wax casting process with gereral tolerance CT5-CT6. Most Widely used for stainless steel products. Also could be used for precision carbon steel parts. This investment casting method allows to cast products range from 0.1kgs to 50kgs.

Water Glass Casting: Low temperature lost-wax casting process with general tolerance CT7-CT8. More suitable to produce carbon steel and alloy steel products. The capacity of water glass casting is to cast products range from 0.05kg to 70kgs.

Lost Foam Casting: Another investment casting technic different from lost wax casting. This kind of casting process can achieve casting tolerance CT8-CT9. Weight of products range from 0.5kgs to 50kgs. The usually used materials are ductile iron, gray iron, high chrome iron, etc.

1 note

·

View note

Text

Everything depending on the aspect of equipment or tools that are required

When it comes to specialty brass or other metal components for armed forces, medical, or other specialty industries, the use of CNC Machined ferrous materials and equipment to design the products is single way to make certain the quality grade, and fine workmanship in elements. From aerospace design, to military instruments, the items use for surgical operations, with ferrous materials, and the best rating metal, the reputed company can design any item for specialty and niche industries. So, when we deciding on which professionals to turn to when CNC machined ferrous materials are required, the particular industry has to decide, they get the most reliable and reputable designers, with the top of the line machinery and tools, to create any parts or components that needed, when well design and quality are vital in design and operation.

Everything depending on the aspect of equipment or tools that are required, the true CNC machined device and production line can manufacture a wide range of items. From grinding down the instruments for definite designs, to using built forms to generate a steady and quality look for a particular product that has to be fully perfect each time, the top designers will have the correct equipment to do any job, at the superior quality and level. From a usual prototype design, to a specific shape or casing, no matter what steel, metal, or brass parts have to be designed, for any specialty industry, the renowned companies are going to use the exact tools, layout, and prototype, in order to build the perfect items anytime. Before selecting a supplier to provide the CNC machined ferrous materials and employment ensuring they are a reputable provider, for a number of specialty industries in the way of work that your company offers, is something to certify of earlier to relying on the business for any design or prototype.

However, it is a specific part in military operations for certain weapons, or whether it is a form or covering design to make the complete surgical rating tools and equipment for a healthcare office, the true service provider has to be hired for the work, to ensure the quality, the China Precision Assembly of assemblies Factory similar design each time, and the accuracy with each tool, part, or component which is designed to meet positive specifications and instructions. During the dealing with these scientific designs, and specific role industries where quality, consistency and accuracy have to be accurate every time, ensure, you hire the most reliable services provider to do the CNC machined work is something that has to be completed. Not only will this build for the same design and same quality look for all components, but it is also going to make certain you are going to obtain the same quality grade material, metal, and module design for the items being ordered which have to be custom made. From surgical tools to aerospace and tools, when quality and the faithful design have to be found every time, spinning to the true services provider for CNC machined ferrous metal work is something that has to be done.

0 notes

Text

Leading Bushes Manufacturer — Reliable Solutions for Your Industrial Needs

As a trusted bushes manufacturer, Dynamic Industries is committed to providing high-quality, durable bushes for a wide range of industrial applications. Our bushes are crucial components used in machinery to reduce friction and enhance performance, ensuring smoother and more efficient operations.

At Dynamic Industries, we specialize in the production of a variety of bushings, such as plain bushes, flanged bushes, and custom bushes for specific needs. Our extensive expertise and state-of-the-art technology allow us to offer both standard and customized solutions to meet the unique demands of different industries, including automotive, construction, and heavy machinery.

Quality Manufacturing with Precision Engineering

As a leading bushes manufacturer, we focus on precision engineering to ensure that every bush we produce adheres to the highest quality standards. Our CNC machining process allows us to manufacture bushes with impeccable accuracy, ensuring a perfect fit and reliable performance. Whether you need metal, plastic, or composite bushes, we have the capabilities to provide the ideal solution for your needs.

Our bushes are made from a range of materials, including stainless steel, bronze, and carbon steel, chosen for their strength, corrosion resistance, and durability. This allows us to cater to various applications, from automotive parts to industrial machinery and construction equipment.

Customized Bushes for Diverse Applications

At Dynamic Industries, we understand that each application may require a specific design and material. That’s why we specialize in custom bushes to fit the unique requirements of your machinery. Our team works closely with clients to create tailored solutions, whether it’s designing custom flanged bushes, wear-resistant bushes, or high-temperature resistant bushes.

Our commitment to quality ensures that each bush manufactured by Dynamic Industries undergoes rigorous quality checks. This guarantees that our products perform optimally in even the most demanding environments.

Why Choose Dynamic Industries as Your Bushes Manufacturer?

Precision and Expertise: As a trusted bushes manufacturer, we leverage our years of experience to deliver high-quality products that meet the highest industry standards.

Durability and Reliability: Our bushes are designed to withstand harsh conditions, offering long-lasting performance and reducing the need for frequent replacements.

Custom Solutions: We provide tailored bush solutions, ensuring that each component fits perfectly and performs optimally in your machinery.

Wide Range of Materials: From plastic bushes to metal bushes, we offer a broad selection of materials to suit various industrial applications.

Dynamic Industries is proud to serve a variety of industries, including:

Automotive: Providing high-performance bushes for vehicles and automotive systems.

Heavy Machinery: Supplying bushes for construction and mining equipment.

Industrial Equipment: Offering durable solutions for factory machinery and production lines.

Aerospace: Providing precise bushings for critical aerospace applications.

Get in Touch with the Leading Bushes Manufacturer

As a top-tier bushes manufacturer, Dynamic Industries is here to fulfill all your bush manufacturing needs. Our commitment to quality, precision, and customer satisfaction sets us apart as a leader in the industry. Whether you require standard bushings or need custom solutions, we are ready to support your business. Contact us today to discuss how we can help optimize your equipment’s performance.

0 notes

Text

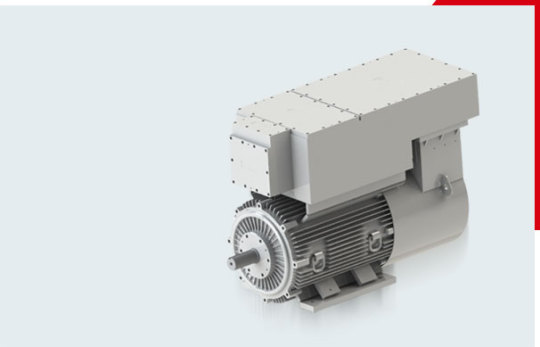

ELECTRICAL TRANSMISSION & POWER CONTROL EQUIPMENT IN CCS ELECTRIC

https://www.ccs-motors.com/products/

We at CCS can provide customers with a variety of electrical transmission equipment and electrical control solutions, which can meet the needs of various working conditions. We strictly control the quality, from raw material procurement to factory test, and all is in accordance with IEC standards.

As a professional power control equipment company, CCS has been providing mining with highly reliable electrical transmission equipment for more than 10 years. Recently, our customers have gradually expanded to oil and gas, port, steel, and other fields.

Types of Electrical Transmission & Power Control Devices

Why Choose Electrical Transmission & Power Control Equipments in CCS Electric

Professional Manfacturer

The company, with a complete system for R&D, design, manufacturing, marketing, and maintenance service, is professional in the manufacturing of high-quality electrical transmission equipment & electrical control equipment.

Well-equipped Production Facilities

We have a large-scale motor assembly machine, motor automatic assembly machine, intelligent CNC winding machine, iron core automatic stacking equipment, solid insulation vacuum casting equipment, inverter production line, vertical machining center, and other production equipment.

Complete Test Platform

CCS has an advanced 12MW loading test platform, high-precision power analyzer, power frequency, and turn to turn to withstand voltage tester, torque tester, and other facilities of the test and inspection center, and has obtained ISO9001 quality management system certification.

Good Development Prospect

With the increasing demand for electrification and intelligence in the industrial field, CCS electrical control devices have a broad market prospect in the industries of engineering, port, shipping, metallurgy, cement and other industries.

FAQs about Electrical Transmission & Power Control Equipments

Q.

What is electrical transmission equipment?

A.

Electrical power transmission equipment refers to various components that allow for internal parts to operate properly in machinery. These items typically include belts, chains, couplings, pulleys, sprockets, bushings, hubs, bearings, linear actuators, slide rails, bevel gears, worm gears, and various other components.

Q.

What are the types of power transmission system?

A.

4 Types of Power Transmission – Mechanical, Electrical, Hydraulic, and Pneumatic (Pros & Cons) The transmission method is an engineering method that matches the power machine and the working part of the machine in terms of energy configuration, movement speed, and motion form.

Q.

What material is used for electrical transmissions?

A.

Copper, aluminum, and steel are the primary conductor materials used in electrical power systems. Other types of conductors such as silver and gold are actually better conductors of electricity; however, cost prohibits wide use of these materials.

0 notes

Text

How Does CNC Machining Function?

CNC machineries allow manufacturing equipment and tools to be controlled by software. This allows for more complex factory processes. Common cnc machinist types include but aren't only limited to three-dimensional cutting instruments routers, lathes grinders and mills. CNC is a shorthand for computer numerical control. Learn more about CNC manufacturing in Michigan.

The main components of a CNC machine comprise the machine itself, the computer that controls the machine and computer-aided production (CAM) software. You may choose to use separate computers or an onboard controller. This is for more complicated CNC processing.

In order to prompt the machine to carry out specific automated tasks, the digitized information is entered into the CAM program. The software commands the drive and motor components to drive machine wheels. A feedback system tracks speed and position.

What Are the Advantages of CNC Machining?

CNC machinery is used to automate tasks across various industries, including auto, manufacturing, metal fabrication, electronics, agriculture and electrical CNC machining. This technology has many benefits:

Cost reduction

Flexibility

Quality and consistency, with results

Increased productivity and decreased downtime

Accuracy increased

Smart use of cnc milling machine can allow businesses to reduce the need for human intervention in repetitive tasks to allow operators to focus on the tasks that require skilled work. This allows for a predictable workflow , which reduces fatigue among workers. Also, it eliminates human error which ultimately streamlines and enhances the process of manufacturing.

T.M. is the expert in repairs to CNC machines and spare parts in Michigan. Smith Tool International Corporation. Our company has been operating in this field for more than six years. We offer a variety of high-quality tool holding systems, customized and standard systems for various industries as well as small and large operations.

CNC Milling: Some Benefits

CNC milling machines have higher precision and accuracy when in comparison to other modern manufacturing techniques.

Multi-axis CNC machines can produce extremely complex geometries and meet tolerance requirements as tight as +/-0.004mm.

The CNC machines can be used with a variety of materials, including composites, plastics metals, metals and various metals.

Conclusion

CNC machines can be used for producing complex geometries and have very precise tolerances. But like with other machining techniques the achievement of your CNC milling endeavor will largely depend on your CNC milling machine technicians, operators and engineers. This is why you need to choose the right manufacturer for your particular project.

DieSandManufacturing is a leader in the world in steel fabricators near me services, is readily available. Our engineers and technicians are highly skilled to assist you in creating the parts you need.

0 notes

Text

Pocket Milling

New Post has been published on http://www.cncmachinings.com/pocket-milling/

Pocket Milling

A pocket is an inward part highlight machined into the outside of a workpiece. An open pocket gets through at any rate one edge of the workpiece while a shut pocket is totally contained inside the external edges of the workpiece. china 3 aixs cnc machine high precision cnc machining metal parts manufacturers shows a couple of instances of open and shut pockets. Rectangular-molded pockets can be machined on the vertical factory. Pocket area and size can be constrained by utilizing the micrometer collars or DRO to screen table and seat developments. Profundity is regularly controlled with the knee. It isn’t unexpected to unpleasant with a bigger breadth endmill in light of the fact that it can eliminate material more rapidly than a more modest width endmill. At that point a more modest breadth can be utilized to complete the pocket and make more modest required corner radi.

Follow these means to machine a rectangular pocket:

If wanted, spread out the pocket limit to help give a visual reference.

Select the roughing and additionally completing endmil diameter(s).

Create an organize map. This can be a basic hand sketch demonstrating the X-and Y-pivot directions of the middle point areas for the cutting apparatus. Utilize the focal point of the pocket for the machined parts suppliers china. The sweep of the endmill should be mulled over while ascertaining these directions. Two arrangements of directions should be determined if two distinctive measurement endmills will be utilized. high precision cnc machining auto titanium parts china for an illustration of how to decide these qualities.

Establish a reference”0″ position in the focal point of the pocket.

Mount the ideal endmill and position the device in the focal point of the pocket.

Set the apparatus around 1/16″ over the part surface with the plume and lock plume set up.

Calculate and set proper shaft RPM.

Start the axle and ignite the top surface of the workpiece by raising the knee.

Set the collar on the knee to “0”.

Feed with the knee for the main profundity cut. Regardless of whether the pocket is sufficiently shallow to be machined in one profundity pass, it is as yet a smart thought to leave about 0.005″ to 0.010″ on the base for a completing pass.

Mill roughing passes outward from the middle a clockwise way to utilize ordinary processing. Step over about %2 to 34 of the endmill width. Lock the hub not being taken care of to forestall undesirable development.

Plan to leave some material on each mass of the pocket by halting about 0.020″short of each position on the organize map. On the off chance that utilizing a roughing endmill, more material may should be left on the dividers so a satisfactory completion cut can be made.

Return to the beginning stage at the pocket place and continue roughing passes to inside 0.005″ to 0.010″ of definite profundity.

Climb plant around the external limit, removing just enough material to make smooth surfaces that can be utilized to gauge sizes. Keep on remaining shy of the last facilitates from the guide by about 0.020″.

Return to the pocket place.

Withdraw the endmill from the pocket and shut off the axle.

Measure profundity, size, and position of the pocket.

Feed the knee steadily until definite profundity is reached, causing acclimations to the areas on the facilitate map varying to change the size and position of the pocket.

Mill ordinary passes around the limit inside about 0.005″ of definite directions.

Mill a last traditional pass around the limit at the last facilitates.

Machine a trip processing spring pass around the limit at the last arranges.

Return to stash focus, pull out instrument from the pocket, and check measurements. Try not to eliminate the workpiece from the workholding gadget until all pocket measurements are confirmed on the grounds that it very well may be hard to restore the facilitate areas if the workpiece is repositioned. This article is from http://www.cncmachinings.com

#china 3 aixs cnc machine high precision cnc machining metal parts manufacturers#china carbon fiber electric hotline#china carbon fibre cnc mill#china cheap cnc machining service manufacturers#china cnc precision lathe machine parts manufacturers#china cnc steel milled mahcining parts manufacturers#china metal lathe turning service#china plastic tapping parts and service suppliers#china titanium cnc turned part suppliers#china turning machining suppliers#cnc machining aluminum factory#cnc machining quotation#cnc turned pump body china#custom carbon fibre parts cnc suppliers#custom cnc machinery precision steel parts factory#high precision cnc machining auto titanium parts china#machined parts suppliers china#machining aluminum suppliers china#medical precision machined components factory#metal lathe part manufacturers china#precision brass turned components#steel turning parts suppliers#tight tolerance precision machining factory#toolmaker's microscope#turning steel parts companies#Featured Articles

0 notes