#titanium cnc machining parts suppliers

Explore tagged Tumblr posts

Text

🛠️ Aircraft Brackets: Market Expansion to $1.5B by 2034!

Aircraft Brackets Market is projected to expand from $0.9 billion in 2024 to $1.5 billion by 2034, growing at a CAGR of approximately 5.2%. This market is integral to the aerospace industry, encompassing the production and supply of structural components essential for securing various aircraft parts. These brackets play a critical role in ensuring structural integrity and safety, making them indispensable in aircraft assembly and maintenance.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS31475 &utm_source=SnehaPatil&utm_medium=Article

Key Growth Drivers

The market’s growth is driven by:

Technological advancements in materials and manufacturing processes.

An increasing focus on lightweight and fuel-efficient aircraft.

Expanding commercial aviation fleets and defense modernization programs.

The commercial aviation segment leads the market, supported by the rising demand for lightweight, durable components. Military aviation follows as the second-highest performing sub-segment, driven by the acquisition of advanced aircraft and defense upgrades.

Regional Insights

North America dominates the market, benefiting from a strong aerospace industry and continuous innovation in aviation technology. The region is home to leading aircraft manufacturers and suppliers, driving demand for high-performance brackets.

Europe is the second-leading region, with significant contributions from Germany and France, known for their advanced aerospace manufacturing capabilities.

Asia-Pacific is rapidly gaining traction, fueled by increasing air traffic and investments in aviation infrastructure. Countries like China and India are emerging as major players due to growing commercial aviation demand.

Market Segmentation

The Aircraft Brackets Market is segmented by:

Type: Fixed Brackets, Adjustable Brackets, Hinged Brackets

Product: Engine Brackets, Fuselage Brackets, Wing Brackets, Tail Brackets, Landing Gear Brackets

Material Type: Aluminum, Titanium, Stainless Steel, Composite Materials

Technology: Additive Manufacturing, CNC Machining, Casting, Forging

End User: OEMs, Aftermarket, MRO (Maintenance, Repair, and Overhaul)

Competitive Landscape

Key players in this market include Arconic Inc., Precision Castparts Corp., and TriMas Corporation, each holding substantial market shares. Arconic Inc. leads with innovations in lightweight solutions, while Precision Castparts focuses on high-strength components. TriMas Corporation is recognized for its advanced manufacturing processes and extensive product range.

The Aircraft Brackets Market is poised for steady growth, driven by advancements in additive manufacturing, increasing adoption of composite materials, and a growing demand for fuel-efficient aircraft. As aviation technology evolves, the market offers lucrative opportunities for stakeholders, emphasizing innovation and sustainability.

#AircraftBrackets #AerospaceInnovation #AviationTechnology #LightweightComponents #FuelEfficiency #CommercialAviation #MilitaryAviation #AerospaceManufacturing #StructuralIntegrity #AircraftAssembly #AerospaceMaterials #CompositeBrackets #AdditiveManufacturing #CNCMachining #AerospaceComponents #AviationGrowth #AerospaceIndustry #AviationSafety #AerospaceEngineering #FlightEfficiency #AdvancedManufacturing #AerospaceInnovation #AirTrafficGrowth #AviationInfrastructure #AircraftMaintenance #AerospaceOEM #MROIndustry #DefenseAviation #AerospaceTrends #AviationSustainability #FutureOfFlight

0 notes

Text

A Guide to Sourcing CNC Machined Components Effectively

Sourcing CNC machined components can be a crucial aspect of ensuring operational efficiency and maintaining high-quality standards in various industries, from aerospace to automotive and medical. With CNC machining being an integral part of modern manufacturing, identifying the right supplier and understanding the nuances of the industry are vital for businesses aiming to stay competitive.

When seeking a reliable CNC machined components supplier, one must prioritize suppliers who demonstrate precision, consistency, and scalability. CNC machined components are manufactured using advanced computer-controlled systems, enabling the production of intricate parts with exceptional accuracy. This accuracy ensures compatibility and functionality in complex machinery. Therefore, partnering with a supplier who prioritizes cutting-edge technology and adheres to strict quality control measures is essential to meet project requirements.

The first step in effective sourcing involves assessing the capabilities of potential suppliers. This includes evaluating their production capacity, experience, and the industries they serve. A competent CNC machined components supplier will often have a track record of delivering customized solutions tailored to unique specifications. Additionally, their ability to handle large-scale production without compromising on quality is a critical factor to consider.

For businesses in Canada, working with CNC machine manufacturers in Canada provides distinct advantages. Canadian manufacturers are known for their adherence to stringent quality standards and their commitment to innovation. By sourcing components locally, companies can reduce lead times, lower shipping costs, and ensure faster communication with suppliers. Moreover, many CNC machine manufacturers in Canada offer comprehensive support services, including design assistance, prototyping, and post-production maintenance, which further simplifies the sourcing process.

Another crucial factor in effective sourcing is understanding material requirements. The choice of material significantly impacts the performance and durability of CNC machined components. Reputable suppliers will often provide guidance on selecting materials best suited to the application, whether it’s aluminum for lightweight parts, stainless steel for corrosion resistance, or titanium for high strength. Collaborating closely with the supplier to discuss material options ensures optimal results.

In addition to technical capabilities, a supplier’s reputation and reliability play a pivotal role. Customer reviews, case studies, and references can provide valuable insights into their performance and reliability. Timely delivery is critical in today’s fast-paced manufacturing landscape, making it imperative to partner with suppliers who prioritize punctuality without sacrificing quality.

The collaboration between businesses and suppliers extends beyond transactions—it is a partnership built on trust and mutual goals. Establishing clear communication channels and outlining expectations regarding timelines, costs, and specifications can prevent misunderstandings and ensure a seamless process.

Finally, as sustainability becomes a growing concern, sourcing from environmentally conscious suppliers can be a strategic advantage. Many CNC machine manufacturers in Canada are adopting sustainable practices, such as waste reduction and energy-efficient processes, aligning with global sustainability goals while ensuring high-quality production.

In conclusion, sourcing CNC machined components effectively requires a strategic approach that considers supplier capabilities, material selection, and long-term partnership potential. Working with an experienced CNC machined components supplier or trusted CNC machine manufacturers in Canada ensures superior quality, precision, and reliability—key factors for success in today’s competitive manufacturing landscape. By fostering strong relationships with suppliers, businesses can streamline their supply chain and achieve their production goals efficiently.

0 notes

Text

How Round Bars Are Revolutionizing the Manufacturing Industry

The round bar is a forgotten icon at the center of the manufacturing revolution that is taking place in the industry. These versatile cylindrical metal bars have become indispensable across various sectors, driving innovation, efficiency, and superior product quality. Whether you are an industrial designer or a production manager, understanding the pivotal role of round bars can offer insights into their growing demand and impact.

What Are Round Bars?

Round bars are long, cylindrical metal products made from materials such as stainless steel, carbon steel, aluminum, and alloys. They come in a variety of diameters and lengths, making them suitable for diverse applications. Their high tensile strength, durability, and machinability make them a preferred choice in industries such as construction, automotive, aerospace, and manufacturing.

Applications of Round Bars in the Manufacturing Industry

Automotive Sector: Round bars are widely used in the production of axles, engine components, and suspension systems. Their ability to withstand high stress and wear ensures the longevity and reliability of automotive parts.

Construction Industry: From reinforcement in concrete structures to scaffolding and frames, round bars are essential for ensuring stability and strength in construction projects.

Aerospace Engineering: The aerospace industry relies on lightweight yet durable materials. Round bars made of aluminum or titanium alloys are commonly used in manufacturing aircraft components like landing gear and structural frames.

Machine Tools and Equipment: Round bars are indispensable in creating machine shafts, fasteners, and precision tools, facilitating efficient manufacturing processes.

Oil and Gas Sector: In harsh and corrosive environments, round bars made of stainless steel or duplex alloys are used in pipelines, drilling equipment, and valves to ensure durability and safety.

Benefits of Using Round Bars

The growing demand for round bars can be attributed to the numerous advantages they offer:

Strength and Durability: Round bars are known for their robustness, making them ideal for heavy-duty applications.

Corrosion Resistance: Stainless steel round bars, in particular, provide excellent resistance to rust and corrosion, extending their lifespan in challenging environments.

Versatility: With multiple grades and finishes available, round bars can cater to specific industrial requirements.

Cost-Effectiveness: High machinability reduces manufacturing costs and improves production efficiency.

The Role of Round Bar Importers and Suppliers in India

India has emerged as a key player in the global round bar market, thanks to its advanced manufacturing capabilities and quality standards. The country is home to numerous round bar suppliers, including Nippon Alloys Inc, a renowned name in the industry.

Innovations in Round Bar Manufacturing

The advancements in material science and manufacturing technologies have further enhanced the functionality and applications of round bars:

Customized Alloy Compositions: Manufacturers like Nippon Alloys Inc are developing specialized alloy compositions to meet specific industrial demands, such as high-temperature resistance or enhanced machinability.

Precision Engineering: CNC machining and other precision technologies have enabled the production of round bars with exceptional dimensional accuracy.

Sustainability: Eco-friendly manufacturing practices, including recycling and energy-efficient processes, are shaping the future of round bar production.

The Global Impact of Round Bars

The global round bar market is witnessing robust growth, driven by increasing industrialization and infrastructure development. Round bar importers are playing a vital role in bridging the supply-demand gap, ensuring the availability of quality products worldwide. With India emerging as a hub for round bar manufacturing, the country’s exports are contributing significantly to global industrial progress.

Leading Round Bar Importer in India | Quality Materials

Nippon Alloys Inc. stands out as the leading Round Bar Importer in India. With a reputation for excellence, we source premium materials from trusted manufacturers worldwide to ensure our customers receive only the best. Our extensive range of round bars is designed to meet the demands of diverse industries, including construction, manufacturing, and engineering.

As a trusted Round Bar Exporter in India, We take pride in delivering precision-engineered products to clients across the globe. Our round bars are known for their durability, corrosion resistance, and impeccable finish, making them the preferred choice for various applications.

In addition to importing and exporting, We are also a reliable Round Bar Supplier in India. We maintain a vast inventory to meet bulk orders and ensure timely delivery. Our commitment to quality, competitive pricing, and exceptional customer service has solidified our position as a trusted name in the industry.

For More Detail

Website: nipponalloys.com

Product: Round Bar Suppliers

Other Product: Alloy Round Bar Supplier in India, Monel Round Bar Importer in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

Aceforge: A Trusted Name Among Forging Aerospace Parts Suppliers

In the aerospace industry, where safety, precision, and performance are non-negotiable, the quality of the components used is paramount. The forging process is one of the most reliable methods for producing critical aerospace parts, ensuring that they can withstand the extreme conditions encountered in air and space travel. Aceforge, as one of the leading forging aerospace parts suppliers, is committed to providing high-quality, durable components that meet the stringent demands of this high-stakes industry.

The Importance of Forged Parts in Aerospace

Forged parts are critical in the aerospace sector because they provide superior strength, reliability, and resistance to fatigue and stress. Forging enhances the material properties of the part, making it stronger and more resistant to wear, while reducing the chances of defects and failures.

Key components such as turbine blades, engine parts, landing gears, and structural elements are often forged to ensure they can withstand the demands of flight. The forging process also allows for the production of complex geometries that are difficult to achieve through other manufacturing methods, making it a preferred choice for aerospace engineers.

Why Choose Aceforge as Your Forging Aerospace Parts Supplier?

Aceforge has positioned itself as a leader in the forging of aerospace parts, known for its commitment to quality, innovation, and customer satisfaction. Here are some reasons why Aceforge is trusted by aerospace manufacturers around the world:

1. Precision and Expertise

The aerospace industry demands parts with the utmost precision and consistency. Aceforge excels in producing highly accurate, custom-forged components that meet the exact specifications of our clients. Our team of engineers and specialists works closely with clients to understand their unique requirements and ensure that each part is crafted with exceptional attention to detail.

2. Advanced Forging Technology

Aceforge invests in the latest forging technologies to deliver the highest quality aerospace parts. We use state-of-the-art equipment, including high-tech presses, CNC machines, and advanced heat treatment facilities, to manufacture components with tight tolerances. Our comprehensive capabilities allow us to produce everything from simple structural parts to complex, intricate components that are essential to modern aerospace designs.

3. Material Selection and Strength

Aerospace parts must be made from materials that can withstand extreme conditions. Aceforge specializes in the forging of high-performance materials such as titanium, aluminum, steel, and Inconel. These materials offer superior strength-to-weight ratios, excellent resistance to heat, and the durability needed for aerospace applications. Whether it's a turbine blade or a structural component, Aceforge ensures the right material is selected to meet performance requirements.

4. Quality Assurance

Quality control is at the core of Aceforge's operations. Every part we produce undergoes rigorous testing to ensure it meets international standards and specifications. We perform comprehensive inspections, including dimensional checks, non-destructive testing (NDT), and material property assessments, to ensure that every component is free from defects and meets the required strength and performance criteria.

Aceforge is also AS9100 certified, demonstrating our commitment to quality and continuous improvement in aerospace manufacturing.

5. Fast Turnaround Times

The aerospace industry often works under tight deadlines, especially for aircraft manufacturers and parts suppliers. Aceforge understands the urgency of timely deliveries and has streamlined its manufacturing processes to ensure fast turnaround times without compromising on quality. Our efficient production and logistics systems allow us to meet our clients’ timelines, whether they are large-scale or time-sensitive projects.

6. Global Reach and Support

Aceforge serves aerospace companies around the globe, providing support from the initial design phase through to large-scale production. Our extensive global network and expertise in international shipping and logistics ensure that we can deliver parts efficiently and cost-effectively to customers worldwide.

Applications of Forged Aerospace Parts

Aceforge's forged aerospace parts are used in a variety of critical applications across the industry, including:

Jet Engine Components: Forged turbine blades, compressor discs, and casings are essential for engine performance and efficiency.

Landing Gear Systems: Structural parts such as struts, support beams, and axles are forged to withstand the high stresses and loads during takeoff and landing.

Aircraft Structural Components: Wing spars, fuselage beams, and other critical components are forged for strength and durability.

Helicopter Parts: Forged components such as rotor hubs and blades ensure smooth and safe operation.

Conclusion

As a leading forging aerospace parts supplier, Aceforge plays a crucial role in ensuring the safety, performance, and reliability of aerospace systems worldwide. Our expertise in precision forging, advanced technology, and commitment to quality make us a trusted partner for aerospace manufacturers looking for high-performance parts. Whether you need custom-designed components or high-volume production, Aceforge is ready to deliver the parts you need, when you need them.

For aerospace companies seeking a reliable supplier of high-quality forged parts, Aceforge stands as a partner you can trust for excellence, innovation, and precision. Let us help you meet the rigorous demands of the aerospace industry with our superior forging solutions.

0 notes

Text

CNC Lathe Machine Supplier in Gujarat

Success Technologies is a Manufacturer, and Supplier of CNC Lathe Machine in Gujarat, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. A CNC lathe machine is a precision tool that uses a rotating workpiece and a stationary cutting tool to shape and cut materials. A computer controls the machine, interpreting a design file and directing the cutting tool's movement to create the desired shape. This technology allows for repeatability, high-quality finishes, and the creation of intricate parts with minimal human intervention. How Does a CNC Lathe Machine Work? CNC lathes work by rotating a workpiece against a stationary cutting tool to remove material and shape it into the desired form. Here's a simplified process: Design Input: The design for the part is input into the CNC lathe using a CAD (Computer-Aided Design) file. Tool Setup: The machine’s controller selects the appropriate cutting tools from the tool turret. Machining Process: The workpiece is clamped securely in the chuck, and the spindle rotates it. The cutting tool then moves along predefined paths to shape the material. Finishing: After completing the necessary cuts, the machine finishes the part with fine-tuned precision to meet the required tolerances and surface finish. Types of CNC Lathe Machines: Horizontal CNC Lathe Vertical CNC Lathe CNC Swiss Lathe CNC Turning Center Features: High-Precision CNC Control Automated Tool Changing Variable Speed Control User-Friendly Interface Robust and Durable Construction Integrated Dust Collection System How accurate are CNC lathe machines? CNC lathes are extremely precise, with accuracy often measured in microns (thousandths of a millimeter). The precision depends on the quality of the machine, tooling, and programming. What materials can be used with a CNC lathe machine? CNC lathe machines can process a wide range of materials, including: Metals (steel, aluminum, brass, titanium) Plastics (PVC, nylon, acrylic) Wood (for specific applications) Composites (carbon fiber, fiberglass) Success Technologies is a CNC Lathe Machine Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CNCLatheMachine#CNCLatheMachineSupplier#CNCLatheMachineSupplierinGujarat#CNCLatheMachineSupplierinIndia#Deesa#ExporterofCNCLatheMachine#Gandhidham#Gandhinagar#India#Jamnagar#Jetpur#Junagadh#Kalol#ManufacturerofCNCLatheMachineinAhmedabad#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar#Rajkot#SupplierofCNCLatheMachine

0 notes

Text

Construct Your Machines with Hobbing Machines

The manufacturing of gear hobs in India has developed into a prominent industry sector that is renowned for its dedication to quality and cutting-edge technology. Indian manufacturers focus on precision, customization, and competitive pricing to meet the demands of industries like heavy engineering, aerospace, and automotive. India is increasingly being recognized as a trustworthy global supplier of high-quality, precision-engineered gear hobs thanks to its commitment to sustainability, adherence to international standards, and investments in cutting-edge machinery.

The Importance of Hobbing Machines:

Gear shaping might be the ideal choice if the gears have unique geometries that necessitate precise cutting procedures or if they need strict tolerances that cannot be reached in any other way. Furthermore, this process is widely used in industries where longevity and dependability are critical, such as aerospace. Engineering sectors where safety regulations are highly stringent because they can produce solid and durable gears because of their uniformity in size and shape without any stress concentration points on them.

What Are The Advantages Of Gear Cutting?

Gear cutting is a method of producing gears, and the process relies on a special type of milling machine with a tool called a gear-cutting machine.

Speed: In this case, the laser cutting involved in the gear-cutting process can eliminate the need for machinery and the need for additional engineering work. As a result, the gear-cutting machine only requires a little human attention in the manufacturing process. The gear-cutting machines can perform all kinds of cutting tasks promptly and efficiently.

Accuracy: The gear-cutting procedure is performed using a CNC gear-cutting machine. The computer automatically provides odd precision. The gear-cutting method is free from human error, resulting in high-quality gears.

Versatility: Gear cutting permits the exhibition of spur gears and other types of gears, such as worm gears, cycloid gears, and helical gears. There are numerous types of gear, but only one type can meet your needs. In fact, there is a gear for any specific application, providing you with many options to find the gear you require.

Utilization of High-Quality Materials and Coatings:

During cutting operations, gear hobs typically experience significant stress and wear. Indian gear hob manufacturers use high-grade tool steels known for their abrasion resistance and hardness, such as M2 and ASP 2030, to improve performance and durability. TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride) are two additional coating options offered by numerous manufacturers to enhance wear resistance and extend hob life, making them suitable for high-volume production environments.

Gear Cutting Applications:

Gear milling devices can be used to create the following types of concluded gears:

Chain gears

Spur gears

Cycloid gears

Helical gears

Splines

Worm gears

Involution gears

Rackets

Customization Options

Each manufacturing activity has its peculiarities. The best gear-shaving cutter producer should be able to meet your top-end producer with a bonus of special skills in custom cutting. These are different sizes and shapes of the cutter as well as the type of teeth placed on the cutter’s edges. Brief your needs prior to the manufacturing firm and see that it meets them. These benefits can include better cutting and part production as well as better end-product quality when producing goods that are customized to specific clients.

1 note

·

View note

Text

How to Choose the Best Custom CNC Machining Services for Your Needs?

Custom CNC machining services have become essential in today’s manufacturing landscape. cnc precision machiningWith the need for precision, speed, and high-quality production, choosing the right custom CNC machining services is critical for industries ranging from aerospace to automotive. But how do you find the best service provider that meets your specific needs? In this blog, we’ll explore the factors to consider when selecting the right custom CNC machining services for your projects.

1. What Are Custom CNC Machining Services?

Before diving into how to choose the best provider, it's important to understand what custom CNC machining services offer. CNC machining stands for Computer Numerical Control machining, where pre-programmed computer software dictates the movement of machinery and tools. These services allow for the precise manufacturing of complex parts from various materials like metals, plastics, and composites.

The key benefit of custom CNC machining services is the ability to create highly customized parts that meet the exact specifications of your project, all with a high degree of accuracy and consistency.

2. How to Assess the Capabilities of Custom CNC Machining Services

Not all CNC machining providers offer the same range of services or expertise. When evaluating a company, consider the following factors to ensure they can meet your project's requirements.

a) Range of Materials

When selecting custom CNC machining services, it’s crucial to confirm that the provider has experience working with the materials relevant to your project. Whether you need aluminum, steel, brass, titanium, or plastic components, the company should be able to handle various materials effectively.

At Fuson Precision Machining, we specialize in working with a wide array of materials to ensure that we can meet the specific demands of any industry.

b) Precision and Tolerance Levels

Precision is paramount in CNC machining. The tolerance levels—the degree of variation that is acceptable—can make or break the functionality of your part. Always inquire about a company’s tolerance capabilities and their track record in delivering precision-machined parts.

At Fuson Precision Machining, we pride ourselves on maintaining tight tolerances to deliver parts that meet or exceed our clients’ expectations for precision and accuracy.

c) Turnaround Time

The efficiency of custom CNC machining services plays a major role in your project timeline. Fast turnaround times can be crucial for businesses that rely on just-in-time manufacturing or need to meet tight deadlines. Ask potential suppliers about their production schedules and delivery timelines.

Fuson Precision Machining understands the importance of fast and reliable service. We offer flexible scheduling options to accommodate urgent projects and guarantee on-time deliveries for all orders.

3. How to Evaluate the Technology and Equipment of Custom CNC Machining Services

Advanced technology and state-of-the-art equipment are essential for delivering high-quality parts. Here’s how to assess the capabilities of a custom CNC machining services provider:

a) Machinery and Software

Check if the provider uses up-to-date CNC machines and software. Newer machines offer better accuracy, faster production, and more versatility. Also, ask about the types of software they use for designing and programming the CNC machines, as this can impact the complexity of parts they can produce.

At Fuson Precision Machining, we invest in cutting-edge technology to provide clients with the highest level of service. Our advanced CNC machines and software ensure that we can handle even the most intricate designs and complex projects.

b) 3D Prototyping and Design Capabilities

Many custom CNC machining services now offer 3D prototyping and design assistance. This helps streamline the production process, allowing for quick adjustments and reducing the risk of errors. A provider that offers these capabilities will make it easier for you to visualize the final product and make necessary modifications before full production.

Fuson Precision Machining provides 3D prototyping services to help you visualize your part before it goes into production, allowing for fine-tuning and ensuring that the final product matches your expectations.

4. How to Ensure Quality Control in Custom CNC Machining Services

Quality control is a critical component of custom CNC machining services. You need to be sure that the final products meet your specifications and standards, especially if the parts are used in highly regulated industries like aerospace or medical devices.

a) Certifications and Standards

Ask potential providers if they comply with industry standards and certifications such as ISO 9001, AS9100 (for aerospace), or IATF 16949 (for automotive). These certifications indicate that the company follows strict quality control procedures and is committed to delivering high-quality products.

At Fuson Precision Machining, we adhere to stringent quality control processes and hold certifications that ensure our commitment to delivering reliable, high-precision parts.

b) Inspection and Testing

Find out what kind of inspection and testing processes the provider uses to ensure that each part meets specifications. Advanced inspection techniques such as coordinate measuring machines (CMM) or laser scanners help verify the accuracy of parts.

Fuson Precision Machining uses the latest inspection and testing equipment to guarantee that all parts we manufacture meet the highest standards for accuracy and quality.

5. How to Compare Costs of Custom CNC Machining Services

Finally, consider the cost of custom CNC machining services, but don’t make your decision based solely on price. While it might be tempting to go with the cheapest option, lower prices can sometimes mean cutting corners on quality or service. Instead, look for a balance between cost-effectiveness and the ability to deliver high-quality parts.

At Fuson Precision Machining, we offer competitive pricing without compromising on quality. We provide transparent quotes and work closely with our clients to deliver cost-effective solutions that meet their budget and production needs.

Conclusion

Choosing the best custom CNC machining services is a critical decision that can impact the success of your project. By assessing the provider’s capabilities, technology, quality control, and costs, you can make an informed choice that ensures the highest quality and precision for your parts.

At Fuson Precision Machining, we take pride in offering top-notch custom CNC machining services to meet the diverse needs of our clients. With advanced technology, skilled technicians, and a commitment to quality, we are your trusted partner in delivering precision-machined parts. Contact us today to learn more about our services and how we can help with your next project!

#custom CNC machining services#cnc precision machining#cnc machine tools#precision cnc machining#cnc machine shop#chinese machine shop#precision machining

0 notes

Text

The forge KB Schmiedetechnik is located in Hagen, Westphalia, with just under 100 employees. It is situated between the historic 'blade and metal' region of Solingen and 'soccer city' Dortmund, near the hilly landscape of the Sauerland.

KB specializes in the small series production of safety-critical closed-die forgings, ranging from 200 g to 130 kg in unit weight, using all steel grades, including duplex stainless steels, nickel-based superalloys, and even titanium.

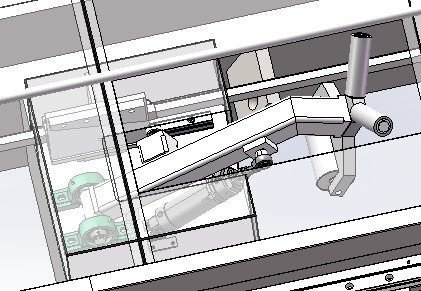

Depth of Manufacturing

All production processes are carried out in-house, including CAD design, tool construction, closed-die forging, heat treatment, hardening, CNC machining, as well as testing and surface inspection in our own lab.

We process all types of steel, including carbon, alloyed, duplex, as well as nickel-based alloys and titanium.

For 20 years, we have been helping our customers optimize forgings through material flow simulation. We advise on transitioning from assemblies, such as welded structures or cast parts, to forged components with enhanced grain flow. Additionally, material flow simulation facilitates the reduction of excess material, such as flash, allowing for completely flash-free forging (depending on the geometry), which saves both material and energy.

Forged components are often not only more robust and visually appealing (picture above), but also more cost-effective to produce. We assist in transitioning from assemblies, such as welded structures (right) or cast parts, to forged components (left) with enhanced grain flow.

Materials and Case Studies

Nickel (Ni) is used as an alloying element in steels to improve their toughness and ductility at low temperatures. From a nickel content of 9%, steels are considered cold-resistant and free from embrittlement. Besides steel, there are also other alloys with such properties (e.g., superalloys). Examples:

F316x – The standard chromium, nickel, and molybdenum stainless steel for cutlery, power plants, and cryogenics (10-13% Ni). Many sub-varieties with specific properties, such as: 1.4404, 1.4435, 1.4571 exist.

Monel®400 – A nickel-copper superalloy highly resistant to corrosion, particularly suitable for chemical applications, seawater, and high-temperature environments such as rocket engines (63% Ni)

Nitronic®, 1.3964, Alloy 50 – A non-magnetic chromium-nickel alloy (12.5% Ni) specifically for offshore and marine areas.

KB Schmiedetechnik GmbH holds certifications for both ISO_9001 and ISO_14001, along with various additional certifications for demanding sectors such as pressure equipment, nuclear power plants, and even five shipbuilding supplier certifications such as ABS, BV Marine & Offshore, ClassNK, DNV, and LR. Relevant documents can be downloaded from the company's website in the 'Quality' section.

At a glance

Pressure equipment and nuclear power (valves, boilers, piping):

PED 2014/68/EU, AD 2000-W0, ASME, KTA, RCC-M

Shipbuilding and ocean engineering

American Bureau of Shipping (ABS)

Bureau Veritas Marine & Offshore

Det Norske Veritas (DNV)

Lloyds Register (LR)

Nippon Kaiji Kyōkai (ClassNK)

An articles by me on the stability of forged parts of steel (it is the grain flow):

https://www.openpr.com/news/3670898/grain-flow-optimised-forgings-for-maximum-stability-in-critical

0 notes

Text

Titanium block Gr5 B348 1860*850*300 sawed in two

Vertical sawing machine sawing material. The main laser alignment is used to ensure the size and tolerance of the product.

Do you know what the green liquid is? Please tell me. thank you.

Sawing this material takes about 28 hours. I like this job...

#Aerospace , #Defense , #Supplier , #aerospace ,#defense , #medical , #titanium, #industrial , #oil , #gas.

0 notes

Text

Custom Micro Screw Manufacturers & Suppliers | Chuanghe Fastener

Among these essential components are micro screws, which play a crucial role in various applications, from electronics and medical devices to aerospace and automotive industries. As their name suggests, micro screws are miniature fasteners designed to hold together tiny parts with exceptional accuracy. Understanding the key players in this niche industry—micro screw manufacturers—can help you find the right supplier for your specific needs. This blog aims to provide an in-depth overview of micro screw manufacturers, exploring their roles, capabilities, and what to consider when choosing the right supplier for your projects.

What Are Micro Screws?

Micro screws are extremely small fasteners, typically with diameters ranging from 0.2 mm to 2.0 mm. They are engineered to provide secure fastening in applications where space is limited and precision is paramount. These screws come in various head types, thread forms, and materials, catering to diverse industry requirements.

The Importance of micro screw manufacturers

Micro screw manufacturers specialize in producing these tiny yet vital components with the utmost precision. The role of these manufacturers extends beyond mere production; they often engage in the design, engineering, and customization of screws to meet specific industry standards and application needs.

Key Features of Leading Micro Screw Manufacturers

Precision Engineering

Top micro screw manufacturers utilize advanced machinery and technology to achieve unparalleled precision. This includes CNC (Computer Numerical Control) machines, micro-threading equipment, and automated inspection systems to ensure each screw meets stringent quality standards.

Material Selection

Quality manufacturers offer a range of materials suited to various applications, including stainless steel, brass, titanium, and plastic. The choice of material affects not only the screw's durability but also its performance in different environments, such as high temperatures or corrosive conditions.

Customization Capabilities

Given the diverse applications for micro screws, leading manufacturers often provide customization services. This includes producing screws with specific thread patterns, lengths, or coatings to meet the unique requirements of a project or industry.

Quality Control

Rigorous quality control processes are essential in micro screw manufacturing. Reputable manufacturers conduct extensive testing and inspection to ensure each batch of screws adheres to international standards and performs reliably under various conditions.

Top Applications for Micro Screws

Electronics

In electronics, micro screws secure delicate components like circuit boards and connectors. Precision is critical to avoid damage to sensitive electronic parts and ensure the reliable operation of devices.

Medical Devices

Medical devices often require micro screws for assembling intricate instruments and implants. These screws must meet stringent hygiene and reliability standards, making precision and material choice vital.

Aerospace

The aerospace industry demands micro screws for their lightweight yet robust properties. These fasteners must withstand extreme conditions and contribute to the overall safety and performance of aerospace components.

Automotive

In the automotive sector, micro screws are used in various components, from dashboards to engine parts. They play a role in ensuring parts are securely fastened and function correctly.

Choosing the Right Micro Screw Manufacturer

Selecting the right micro screw manufacturer involves several considerations:

Industry Experience

Manufacturers with extensive experience in your specific industry are often better equipped to meet your needs and understand the nuances of your application.

Technical Support

A manufacturer that offers technical support can assist in optimizing your screw selection and customization, ensuring that you achieve the best performance for your application.

Reputation and Reviews

Researching a manufacturer’s reputation and reading reviews from other clients can provide insights into their reliability, quality of products, and customer service.

Lead Times and Delivery

Ensure that the manufacturer can meet your delivery timelines and has a track record of timely fulfillment, as delays can impact your project schedules.

Conclusion

Micro screw manufacturers are pivotal in providing the tiny yet critical components needed for modern technology and innovation. By understanding their capabilities and carefully selecting a supplier that meets your specific needs, you can ensure the reliability and performance of your products. Whether you require standard micro screws or custom solutions, partnering with a reputable manufacturer can significantly enhance the quality and success of your projects.

1 note

·

View note

Text

A Guide to Selecting the Right Materials for CNC Machining

Material selection is a critical factor in determining a project's success and efficiency in the field of CNC machining. Selecting the appropriate materials influences a number of variables, including machining time, cost, and overall performance, in addition to guaranteeing the final product's quality and longevity. This is a thorough guide that will help you choose the best materials for CNC machining:

Understand Machinability: It's important to recognize the machinability of several materials before choosing one. The term "machinability" describes a material's ease of shaping, cutting, and finishing using CNC machining techniques. Machinability is influenced by properties including hardness, ductility, and heat conductivity.

Consider Material Properties: Consider the particular qualities, including strength, durability, conductivity, and resistance to corrosion that are necessary for your project. These qualities can be found in various combinations in different materials. For instance, aluminium is perfect for automotive and aerospace applications since it is lightweight and has great corrosion resistance.

Assess Cost: When choosing a material, cost is an important factor. specific materials could be too expensive for specific tasks, even though they might have better qualities. Choose the most economical choice without sacrificing quality by establishing a balance between the qualities you want and financial limitations.

Review Application Requirements: Examine the environmental conditions and application requirements that the finished product will face. Will it be subjected to adverse weather conditions, wetness, substances, or normal wear & tear? Choose materials that will function over time and can tolerate these circumstances.

Evaluate Machining Complexity: Evaluate the complexity of the design and what is required for machining. Certain materials need a greater amount of money and effort to deal with, increasing the manufacturing time and cost of the parts. Select materials that are easy to work with while maintaining high quality.

Consult with Machining Experts: Consult with material suppliers or CNC machining experts at HLH for guidance. Our knowledge and experience can offer valuable insights. In order to ensure the best outcomes, they can suggest appropriate materials based on the details of your project.

Explore Material Options: Learn about the many different types of materials that may be used for CNC machining. These materials include composites (like carbon fibre, fibreglass), metals (like aluminium, stainless steel, and titanium), and polymers (like ABS, acrylic, and nylon). Every substance has special qualities and uses.

Prototype and Test: Consider testing and prototyping several materials to assess their appropriateness and performance before moving on with full-scale manufacturing. This enables you to see any problems early and make the required corrections.

The efficiency and success of a project are greatly impacted by the choice of material in CNC machining. It's important to understand machinability, considering how simple a material is to shape and finish. Strength, durability, and conductivity of the material must match the requirements of the project. Affordability and quality should be balanced because cost is important. Analyze the product's exposure to the environment. Assess machining difficulty and select materials that facilitate manufacture. Seeking advice from machining specialists yields priceless insights. Look at the various material possibilities, such as metals, plastics, and composites. Suitability is ensured via testing and prototyping different materials. To sum up, careful evaluation of machinability, characteristics, cost, application, complexity, professional guidance, and research results in the best CNC machining results.

Check out also the details about CNC Prototype Machining and when you can use it here: https://hlhrapid.com/blog/what-is-cnc-prototype-machining/

For questions about CNC Machining, send us an email at [email protected]

0 notes

Text

Battery Cover, a precision-engineered accessory designed to protect and secure your device's power source. Crafted from high-quality, durable materials, this sleek and stylish cover ensures a snug fit, while providing easy access for battery replacement. Enhance your gadget's longevity and performance with this reliable safeguard.

Functions and Importance of Battery Terminal Covers in Vehicles

Protection: Battery caps are designed to protect the battery from external elements such as dust, dirt, moisture, and road debris. They shield the battery from physical damage and prevent contaminants from entering the battery compartment. This protection is crucial for maintaining the battery's integrity and preventing potential malfunctions or short circuits.

Thermal Management: Batteries generate heat during operation, especially during charging and discharging cycles. Battery covers often have built-in insulation and ventilation features to manage the battery's temperature. They help dissipate heat and maintain optimal operating conditions for the battery, enhancing its performance and extending its lifespan.

Safety: Battery covers play a significant role in ensuring the safety of both the vehicle and its occupants. They help contain any potential acid leaks or spills from the battery, preventing them from coming into contact with other components or causing harm. Battery covers also act as a barrier between the battery terminals and any conductive material, reducing the risk of electrical shorts or accidental contact.

Noise Reduction: In electric vehicles (EVs) and hybrid vehicles, battery covers can contribute to reducing noise levels. They act as sound barriers, minimizing the transmission of noise and vibrations generated by the battery, thereby enhancing the overall driving experience for passengers.

Aesthetics and Integration: Battery covers are designed to integrate seamlessly with the vehicle's overall design and aesthetics. They provide a neat and finished appearance to the battery compartment, contributing to the overall visual appeal of the vehicle.

Specification of Battery Terminal Cap

Material

Iron, stainless steel, brass, copper, galvanized steel, titanium, Aluminium, etc.

Surface treatment

Zinc/Nickel/Tin/Ag-Plated/Au-Plated, etc.

Type

High-Precision nonstandard parts

(OEM Service)

Process

Stamping/Punching/Pressing, CNC machining/Turning/Milling, Deep Drawing and other process.

Certificate

IATF16949 2016;I SO9001 2015; ISO14001:2015;RoHS&REACH, etc.

Usage

Automotive/ Car Thermostat, Switch, Electric Heating, Aerospace, New energy, etc.

Factors to Consider in Choosing the Right Battery Cover for Your Vehicle

When choosing the right battery cover for your vehicle, there are several factors to consider. These factors can help ensure that the battery cover is compatible with your vehicle's specifications and provides the necessary protection and functionality. Here are some key factors to consider:

Vehicle Make and Model

Material and Construction of Battery covers

The ventilation and thermal management features of the battery cover

The level of protection and safety features provided by the battery cover

Ensure that the battery cover is easy to install and remove

Manufacturer Reputation and Warranty

Budget.

0 notes

Text

Diverse Product Range: Industrial parts manufacturing encompasses a wide array of products, ranging from simple nuts, bolts, and fasteners to intricate components like gears, bearings, valves, and specialized machinery parts. These products serve as building blocks for the assembly and functioning of complex systems.

Materials and Technologies: Manufacturers in this sector work with an extensive range of materials, including metals (such as steel, aluminum, and titanium), plastics, ceramics, and composites. Advanced manufacturing technologies like CNC machining, additive manufacturing (3D printing), casting, forging, stamping, and precision cutting are employed to shape and create these parts with high precision and quality.

Quality and Precision: Precision is paramount in industrial parts manufacturing, as even the smallest deviations can lead to equipment malfunction, safety hazards, or inefficiencies. Manufacturers invest in advanced quality control processes, inspection techniques, and measurement tools to ensure that parts meet exact specifications.

Customization and Prototyping: Many industrial parts need to be customized to meet the specific requirements of different applications. Manufacturers often work closely with clients to design and prototype components that fit their exact needs, sometimes utilizing rapid prototyping techniques to expedite the development process.

Supply Chain Integration: Industrial parts manufacturing is often part of an intricate global supply chain. Manufacturers collaborate with suppliers of raw materials, tooling, and equipment to ensure a seamless flow of resources. Just-in-time production and lean manufacturing principles are often employed to minimize waste and optimize efficiency.

Industry Standards and Regulations: The manufacturing of industrial parts is subject to various industry standards and regulations that ensure safety, quality, and compatibility. Manufacturers must adhere to these standards to produce parts that meet the requirements of their intended applications.

Innovation and Research: To remain competitive and relevant, industrial parts manufacturers constantly seek innovations in materials, processes, and design. Research and development efforts may focus on creating more durable, lightweight, or energy-efficient components, as well as exploring new manufacturing technologies.

Global Reach: Industrial parts manufacturing is a global endeavor, with manufacturers located in various countries to serve both local and international markets. This interconnectedness allows for the exchange of knowledge, expertise, and resources, contributing to the growth of the sector

0 notes

Text

About-Cast & Alloys | Aluminum Forging and Castings Supplier

ABOUT

Cast & Alloys is a leading provider of integrated solutions for Aluminum Forging and Aluminum Castings (GDC & HPDC) to the industry, backed by 30+ years of experience. Our capability to provide END to END Solution sets us apart from the competition. We believe in creating value for our customers by meeting their product requirements on QCDIP -Quality, Cost and Delivery, Innovation and Productivity, which has helped us provide complex part development and cost saving engineering solutions.

Due to our strong commitment, our products are exported across the globe directly to OEMS meeting their supply chain challenges in today’s complex global environment.

Who We Are?

Cast & Alloys is committed to providing Complete Aluminum Solutions to its customers. We strive to become the PREFFERED development and supply partner with our customers, by supplying complete engineering solutions for their Aluminium Casting and Forging needs across Industry Segments. We make commitments we fully understand and believe we can meet.

We support our customers Just – In – Time delivery requirements and this is all possible through the sheer dedication and commitment of our team of professionals and highly motivated work force.

We will be commissioning our new 1000 Ton Direct Drive CNC Screw Press with automatic die spray system by January 2023. We have on follow up order 1600 Ton

Direct Drive CNC Screw Press, Reduce Roll Mill, 200 Ton Hydraulic Trimming Press and Billet Heating Furnace to complete our fully autonomous Forging Line. This line will be further integrated with 2 Robots, one each at forging and trimming station. With the commissioning of this new line by end 2023, we would have achieved capability to forge even more complex parts both in Aluminum and Titanium with better yield leading to savings for our customers.

Company is conscious about its EHS responsibilities, towards the environment and its employees. We employ manufacturing practices and processes that are environment friendly and place top priority on providing a safe and comfortable working environment.

Cast & Alloys has adopted best in Quality Management Systems and have numerous accreditations to its credit. . . ISO 9001 : 2015, IATF 16949 : 2016, ISO 14001 : 2015 & ISO 45001 : 2015.

Corporate Ideology

The company believes in:

Maintaining and enhancing Product Quality.

Being efficient and adhering to committed Time Schedules.

Being Cost Effective.

To ensure effective achievement of the corporate goals, all members of the company passionately believe in the concept of Teamwork. Active participation in the form of discussions and suggestions from one and all are encouraged to create a congenial and a productive environment in the company. Such an interaction leads to analyse the work required for a project, thereby enabling the work force to prepare for each operation in advance, thus optimizing the process, hence attaining better quality.

To ensure this, the operators on every machine have been selected on the criteria of.

Experience and Exposure

Dedication to Quality

Technical Ingenuity

So that they can perform their functions with a greater degree of independence.

Vision

To become the PREFFERED development and supply partner with our customers, by providing complete engineering solutions for their Aluminium Casting and Forging needs across Industry Segments.

Mission

Providing our customers a customized approach that suits each individual customer needs, through High Quality, High Flexibility, Low Cost and Low Risk business model.

1 note

·

View note

Text

Aceforge: Leading the Way as Forging Aerospace Parts Suppliers

In the highly demanding aerospace industry, precision, durability, and reliability are paramount. Whether it's aircraft components, engine parts, or structural elements, the quality of materials and manufacturing processes directly impacts safety, performance, and efficiency. This is where Aceforge stands out as a trusted name among forging aerospace parts suppliers.

The Importance of Forged Aerospace Parts

Forged parts play a critical role in the aerospace sector, offering superior strength, resistance to wear, and reliability compared to cast or machined components. Through a process of shaping metal using compressive forces, forging ensures that parts have superior mechanical properties, essential for the extreme conditions aerospace parts endure.

From jet engines to landing gears, forging aerospace parts involves creating components that can withstand high temperatures, stress, and fatigue while maintaining structural integrity. As aerospace designs become more complex and materials advance, the need for precision forging has never been greater.

Aceforge: A Leader in Aerospace Forging

Aceforge has positioned itself at the forefront of the aerospace forging industry, catering to manufacturers, OEMs (Original Equipment Manufacturers), and Tier-1 suppliers across the globe. With years of expertise, advanced technology, and a commitment to quality, Aceforge offers an array of forged components that meet or exceed industry standards.

Key Features of Aceforge’s Aerospace Forging Capabilities:

Precision and Customization: Aceforge understands the unique demands of the aerospace industry. Our forging capabilities ensure that every part is created with exceptional accuracy. Whether you need high-tolerance parts or customized components for specific aircraft models, Aceforge can deliver precision-forged aerospace parts tailored to your needs.

Material Expertise: The aerospace industry requires materials that can endure extreme conditions. Aceforge uses advanced forging techniques with high-quality metals such as titanium, aluminum, steel, and Inconel. These materials are known for their strength-to-weight ratios and resistance to heat and corrosion, ensuring that each part meets the demanding requirements of aerospace applications.

Advanced Technology and Innovation: At Aceforge, we invest in the latest forging technology, including state-of-the-art CNC machinery, die design systems, and heat treatment processes. This commitment to innovation enables us to offer solutions that optimize performance, reduce weight, and enhance the lifespan of aerospace components.

Rigorous Quality Control: Quality assurance is the cornerstone of Aceforge’s operations. Every aerospace component undergoes stringent testing to ensure it meets international aerospace standards, including AS9100 certification. From visual inspections to non-destructive testing (NDT), we ensure that every part performs at its best.

Efficient Lead Times: We understand that the aerospace industry operates on tight schedules and high production volumes. Aceforge has refined its processes to offer quick turnarounds without compromising on quality. Our streamlined production capabilities allow us to deliver high-volume orders with fast lead times, ensuring that you meet your project deadlines.

Sustainability and Safety: Aceforge not only focuses on performance but also sustainability. We adopt eco-friendly practices throughout the manufacturing process, from material sourcing to waste management, ensuring that our forging practices are environmentally responsible. Additionally, we prioritize safety in all aspects of our operations, adhering to the highest industry safety standards.

Applications of Forged Aerospace Parts

The aerospace sector covers a broad range of applications, and forged parts from Aceforge can be found in various critical systems, including:

Jet Engines: Components such as turbine blades, shafts, and casings need to withstand extreme temperatures and mechanical stresses. Aceforge produces forged parts that enhance engine efficiency and safety.

Landing Gear: Forged parts like struts, wheels, and support frames are essential for the safe takeoff and landing of aircraft. These parts must be strong and reliable, even in harsh environments.

Aircraft Structural Components: Parts like wing spars, fuselage beams, and engine mounts require forged precision to ensure the structural integrity of the aircraft during flight.

Why Choose Aceforge as Your Forging Aerospace Parts Supplier?

Aceforge’s reputation as a trusted forging aerospace parts supplier stems from our dedication to quality, innovation, and customer satisfaction. Here’s why aerospace companies choose Aceforge:

Expertise in Aerospace Forging: With a dedicated focus on the aerospace industry, Aceforge brings specialized knowledge and experience to every project.

End-to-End Solutions: From design and prototyping to large-scale production, Aceforge offers complete solutions for aerospace forging needs.

Global Reach: Serving clients around the world, Aceforge has the infrastructure and logistics to meet the needs of both large-scale manufacturers and niche aerospace applications.

Proven Track Record: Over the years, we have forged strong partnerships with aerospace giants, providing them with high-quality, high-performance components that keep aircraft flying safely and efficiently.

Conclusion

In an industry where precision, safety, and performance are non-negotiable, Aceforge stands as a trusted partner for forging aerospace parts suppliers. With our advanced forging technology, expert team, and commitment to quality, we continue to play a key role in ensuring that aerospace components meet the highest standards of excellence. Whether you are looking for custom parts or high-volume production, Aceforge is ready to support your aerospace manufacturing needs with unparalleled expertise and reliability.

If you��re seeking a supplier that understands the complexities of aerospace forging and can deliver superior parts for your critical applications, look no further than Aceforge.

0 notes

Text

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes