#Junagadh

Explore tagged Tumblr posts

Text

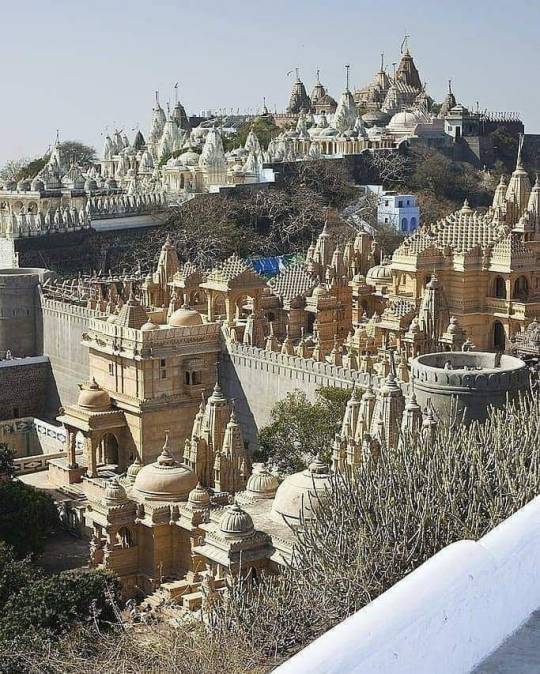

GIRNAR TEMPLE - INDIA

299 notes

·

View notes

Text

PET Bottle Scrap Washing Plant in Gujarat

R Mech Machines LLP is a trusted Manufacturer, Exporter, and Supplier of PET Bottle Scrap Washing Plant in Gujarat, India. Our Manufacturing unit is based in Ahmedabad, Gujarat, India. At R Mech Machines LLP, we manufacture top-quality PET Bottle Scrap Washing Plants designed to process used PET bottles. A PET Bottle Scrap Washing Plant is an industrial machine designed to wash and process used PET bottles into reusable flakes. This machine removes contaminants like labels, glue, dirt, and liquids, ensuring the recycled material is ready for reuse. The plant uses various cleaning systems such as hot water washing, friction washing, and mechanical separation for thorough cleaning. Features: High Efficiency: Designed for maximum throughput while ensuring top-notch cleanliness of PET flakes, ideal for large-scale recycling. Advanced Technology: Equipped with friction washing, hot water washing, and centrifugal drying for thorough cleaning of PET scrap. Energy-Efficient: Optimized for lower operational costs and eco-friendliness, using less energy than traditional washing methods. Low Maintenance: Built for durability with minimal maintenance, ensuring long-term reliability and reduced downtime. Automatic Operation: Fully automated to reduce human intervention, cutting labor costs and boosting efficiency. Customizable: Flexible solutions tailored to meet your specific needs, including capacity, size, and automation level. Eco-Friendly: Minimal water and energy consumption, contributing to sustainability and reducing waste. Applications: Recycling Industry Packaging Industry Textile Industry Automotive Industry Construction Industry FAQs: What is the capacity of a PET Bottle Scrap Washing Plant? The capacity of our PET bottle washing plants ranges from 500kg/hr to 3000kg/hr, depending on the model and customization. You can choose the capacity based on your production requirements. What types of PET bottles can be processed? Our washing plants can process PET bottles of various sizes, ranging from 200ml to 2L, including bottles with labels, caps, and other contaminants. R Mech Machines LLP is Supplier of PET Bottle Scrap Washing Plant in Gujarat, India Including Silvassa, Daman, Vapi, Sarigam, Umargam, Pardi, ValsadAhmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Contact us today to place an order or learn more about our products! Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#BladeSharpeningMachines#Botad#Daman#Deesa#Exporter#Gandhidham#Gandhinagar#Jamnagar#Jetpur#Junagadh#Kalol#ManufacturerofPETBottleScrapWashingPlant#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Pardi#Patan#PetBottleScrapWashingPlant#PETBottleScrapWashingPlantinAhmedabad#PETBottleScrapWashingPlantinGujarat#PETBottleScrapWashingPlantinIndia#PlasticScrapGrinderMachines

0 notes

Text

Perforated Sheets Supplier in Gujarat

Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider of Perforated Sheets Supplier in Gujarat, India. Our manufacturing unit is in Ahmedabad, Gujarat, India. Perforated sheets are versatile and highly functional materials widely used in various industries for multiple purposes. These sheets are made from metals like stainless steel, aluminum, or mild steel and are perforated with precise holes in different shapes and sizes. Keshar Bhawani Metal & Tubes Pvt. Ltd., a renowned manufacturer and supplier, offers high-quality perforated sheets that cater to the needs of diverse applications such as filtration, ventilation, decorative elements, and structural purposes. At Keshar Bhawani Metal & Tubes Pvt. Ltd., we ensure that our perforated sheets meet the highest industry standards in terms of precision, durability, and performance. Whether you need them for industrial, architectural, or aesthetic purposes, we provide customized solutions to meet your specific needs. Specifications of Perforated Sheets: At Keshar Bhawani Metal & Tubes Pvt. Ltd., we offer perforated sheets with the following specifications: Material: Stainless steel, mild steel, aluminum, and other alloys. Hole Size: Customizable, ranging from 1mm to 100mm. Thickness: Available in thicknesses from 0.5mm to 12mm. Hole Pattern: Round, square, hexagonal, slotted, decorative, and custom patterns. Sheet Size: Customizable according to the project requirements. Finish Options: Powder coating, anodizing, galvanizing, or polished finishes. Corrosion Resistance: Available in corrosion-resistant materials for use in harsh environments. Features: High durability and strength Corrosion and heat resistance Lightweight yet sturdy Aesthetic and decorative appeal Easy to fabricate and install Custom hole sizes, shapes, and patterns available FAQs: What are the main uses of perforated sheets? We use perforated sheets in filtration systems, ventilation, architecture, soundproofing, security fencing, and many other applications. Can perforated sheets be customized? We can customize perforated sheets in terms of hole size, shape, spacing, material, and thickness to suit specific needs. Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider of Perforated Sheets Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Contact us today to discuss your requirements or get a quote. Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Maharashtra#Manufacturer#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#PerforatedSheets#PerforatedSheetsSupplier#PerforatedSheetsSupplierinGujarat#PerforatedSheetsSupplierinIndia#Porbandar#Rajkot

0 notes

Text

IBR Fittings Supplier in Gujarat

Meghmani Metal Industries is a prominent Manufacturer, and Supplier of IBR Fittings in Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. An IBR fitting plays a critical role in constructing and maintaining boiler systems. It refers to fittings regulated under Indian Boiler Regulation (IBR) standards, governing the design, installation, and operation of boilers. IBR fittings withstand high-pressure, high-temperature conditions, ensuring safe boiler operation in industries like power plants, refineries, and chemical processing. These fittings include pipes, valves, flanges, elbows, tees, and reducers designed to meet specific IBR codes and regulations. Meghmani Metal Industries provides durable, reliable IBR fittings that ensure safety, efficiency, and performance in industrial operations. Why Choose Meghmani Metal Industries for IBR Fittings? High-Quality Manufacturing: Meghmani Metal Industries manufactures IBR fittings with premium raw materials and advanced techniques, ensuring durability and performance. Strict Adherence to Standards: All products meet Indian Boiler Regulation (IBR) standards, ensuring safety, reliability, and optimal performance in high-pressure applications. Customized Solutions: We provide tailored IBR fittings to meet your specific project requirements, ensuring flexibility in application. Global Reach: While we specialize in Indian regulations, our IBR fittings are in demand globally, offering international clients access to high-quality industrial components. Competitive Pricing: Meghmani Metal Industries offers cost-effective solutions without compromising on quality, making our IBR fittings highly affordable. Applications: Power Plants Petrochemical Industry Oil & Gas Industry Food and Beverage Industry Pharmaceutical Industry Sugar Mills Frequently Asked Questions (FAQs): What materials are used in manufacturing IBR fittings? Our IBR fittings are typically made from stainless steel, carbon steel, and alloy steel, ensuring they meet the stringent standards required for high-pressure, high-temperature applications. What is the typical lifespan of IBR Fittings? With proper maintenance, IBR fittings can last for many years due to their durable construction and resistance to wear and corrosion, often outlasting other components in high-pressure systems. How do I ensure the proper installation of IBR Fittings? Proper installation of IBR fittings should be carried out by experienced professionals who understand the industry regulations and standards, ensuring the system operates safely and efficiently. Meghmani Metal Industries is an IBR Fittings Supplier in Gujarat, India Including locations Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#ExporterofIBRFittings#Gandhidham#Gandhinagar#Gujarat#IBRFittings#IBRFittingsExporter#IBRFittingsinAhmedabad#IBRFittingsinGujarat#IBRFittingsinIndia#IBRFittingsManufacturer#IBRFittingsSupplier#IBRFittingsSupplierinAhmedabad#IBRFittingsSupplierinGujarat#IBRFittingsSupplierinIndia#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofIBRFittings#MeghmaniMetalIndustries

0 notes

Text

Automatic Milk Bottle Filling Machine in Gujarat

SATV Industries is a Manufacturer and Supplier of Automatic Milk Bottle Filling Machine in Gujarat, India. We are based in Ahmedabad, Gujarat, India. SATV Industries Ltd is a trusted manufacturer and supplier of Automatic Milk Bottle Filling Machines, designed for precision, efficiency, and hygiene. Our advanced filling machines are engineered to meet the highest industry standards, ensuring optimal performance for dairy processing industries. Specifications: Filling Capacity: 200ml to 2L (customizable). Production Speed: 1000-5000 bottles per hour. Material: SS 304 / SS 316. Filling Mechanism: Volumetric, Piston, or Gravity-based. Control System: PLC with touch-screen interface. Power Requirement: 220V/440V, 50Hz. Bottle Types: Glass, PET, HDPE. Features: Fully automated operation. High-speed and accurate filling. Stainless steel construction for hygiene. User-friendly touch-screen controls. Customizable filling volumes. Low maintenance and energy-efficient. Complies with dairy industry standards. Applications: Dairy Industry Food & Beverage Industry Milk Processing Plants Retail & Supermarkets FAQs: What is the production capacity of your automatic milk bottle filling machines? Our machines can fill between 500 to 5,000 bottles per hour, depending on the model and customization options. Can the machine fill different bottle sizes? Yes, our machines are compatible with a wide range of bottle sizes, from 200ml to 5L, with easy adjustments for different bottle types. Is the filling machine hygienic? Yes, the filling machines are constructed from stainless steel and are designed for easy cleaning and maintenance to meet food safety standards. SATV Industries is an Automatic Milk Bottle Filling Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#AutomaticLabelingMachines#AutomaticMilkBottleFillingMachineinAhmedabad#AutomaticMilkBottleFillingMachineinGujarat#AutomaticMilkBottleFillingMachineinIndia#Bharuch#Bhavnagar#Bhuj#Botad#BottleWashingMachines#Deesa#Exporter#ExporterofAutomaticMilkBottleFillingMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur.#Junagadh#Kalol#LiquidFillingMachines#Manufacturer#ManufacturerofAutomaticMilkBottleFillingMachineinAhmedabad#Mehsana#Morbi#Nadiad#Navsari

0 notes

Text

Mahabat Maqbara Palace, Junagadh, Gujarat, INDIA

74 notes

·

View notes

Text

CNC Stone Router Machine in Gujarat

Success Technologies is a Manufacturer and Supplier of CNC Stone Router Machine in Gujarat, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. The CNC Stone Router Machine is a computer-controlled router designed for engraving, cutting, and milling stone. Using a CNC system, the machine precisely follows digital instructions to create complex designs on stone. This machine is ideal for stoneworking professionals who need high-quality, intricate designs on various stones. Specifications: Working Area: Typically ranges from 1300mm x 2500mm to larger custom sizes, depending on the model. Spindle Power: Usually between 3.0kW and 10.0kW for efficient cutting and engraving. Precision: High precision of 0.05mm or better to ensure intricate designs are executed accurately. Axis Configuration: 3-axis, 4-axis, or 5-axis configurations available, depending on the complexity of your projects. Speed: Cutting speed varies, but most machines can operate between 25,000 to 45,000 RPM for detailed cutting. Software Compatibility: Compatible with popular CAD and CAM software like AutoCAD, ArtCAM, and Mastercam. Materials: Capable of handling various stone materials such as granite, marble, limestone, and engineered stone. Applications: Monuments and Headstones Architectural Elements Interior Design and Furniture Signage and Plaques Flooring and Wall Panels Success Technologies is a CNC Stone Router Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information, please feel free to contact us. Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CNCStoneRouterMachine#CNCStoneRouterMachineinAhmedabad#CNCStoneRouterMachineinGujarat#CNCStoneRouterMachineinIndia#Deesa#Exporter#ExporterofCNCStoneRouterMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCNCStoneRouterMachineinAhmedabad#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan

0 notes

Text

Socket Weld Pipe Fitting Supplier in Gujarat

Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider Socket Weld Pipe Fitting Supplier in Gujarat, India. Our manufacturing unit is in Mumbai, Maharashtra, India. We specialize in providing high-quality Socket Weld Pipe Fittings for various industrial applications. The welder inserts the pipe into the socket of the socket weld fitting and welds it in place. Socket weld fittings play an essential role in constructing pipelines by providing a reliable and efficient solution for joining pipes, valves, and other equipment. A Socket Weld Pipe Fitting is a type of pipe fitting designed for pipes with smaller diameters (typically NPS 2 and below). Industries such as oil and gas, power generation, and chemical processing widely use this fitting for its durability and leak-proof performance. Types: Elbows: Used to change the direction of the pipeline. Tees: Used to branch the pipeline. Reducers: Used to connect pipes of different diameters. Caps: Used to seal the end of a pipe. Flanges: Used to connect pipes with bolted connections. Unions: Allow for easy disconnection of pipes. Adapters: Used for changing the size or type of pipe connection. Applications: Oil and Gas Industry Chemical Processing Power Generation Pharmaceutical Industry Food & Beverage Industry Can socket weld fittings be used in high-pressure systems? Designers design socket weld fittings to withstand high-pressure environments, and industries like oil & gas and power generation commonly use them. What materials are socket weld pipe fittings made from? Manufacturers typically make socket weld pipe fittings from stainless steel, carbon steel, and alloy steel, all of which offer excellent strength and corrosion resistance. Keshar Bhawani Metal & Tubes Pvt. Ltd is a Socket Weld Pipe Fitting Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Contact us today to discuss your requirements or get a quote. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#KesharBhawaniMetal&TubesPvt.Ltd#Manufacturer#ManufacturerofSocketWeldPipeFitting#ManufacturerofSocketWeldPipeFittinginGujarat#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar#Rajkot#SocketWeldPipeFitting#SocketWeldPipeFittinginAhmedabad

0 notes

Text

Casing Pipes in Gujarat

Meghmani Metal Industries is a trusted Manufacturer and Supplier of Casing Pipes in Gujarat, India. We are based in Ahmedabad, Gujarat, India. Casing pipes are essential pipes used primarily in the oil and gas industry, mining, and groundwater systems. We design casing pipes to serve as a protective barrier, ensuring the integrity of wells, boreholes, and underground piping systems. Casing pipes prevent the collapse of the borehole and protect the surrounding soil from contamination. Engineers design these pipes to withstand extreme conditions, such as high pressures, temperatures, and corrosive environments, ensuring a safe and durable foundation for industrial operations. We specialize in providing top-tier casing pipes that meet stringent industry standards and offer exceptional durability and performance. Features of Casing Pipes: High Strength and Durability: Casing pipes are designed to withstand high pressures and harsh environmental conditions. Corrosion Resistance: Our casing pipes are resistant to corrosion, ensuring long-lasting performance even in aggressive environments. Customizable Designs: Available in various sizes, thicknesses, and materials to fit specific requirements. Easy to Install: Engineers design casing pipes for easy handling and installation, reducing labor and time costs. Smooth Surface: Our casing pipes feature a smooth internal and external surface to facilitate fluid movement and prevent obstructions. Threaded or Welded Ends: Options for threaded or welded joints, ensuring a secure and leak-proof connection. Durable and Strong: Manufactured from high-strength materials, these pipes can withstand heavy pressures, making them ideal for high-risk applications. Applications of Casing Pipes: Oil and Gas Industry Groundwater Systems Mining Construction Telecommunications and Utilities FAQs: What materials are casing pipes made from? Manufacturers typically make casing pipes from carbon steel, stainless steel, alloy steel, or galvanized steel, depending on the specific requirements of the project. Are casing pipes resistant to corrosion? Yes, casing pipes made from materials like stainless steel or those with galvanized coatings are resistant to corrosion, ensuring long-lasting performance. Meghmani Metal Industries is a Casing Pipes in Gujarat, India Including locations Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CasingPipes#CasingPipesExporter#CasingPipesinAhmedabad#CasingPipesinGujarat#CasingPipesinIndia#CasingPipesManufacturer#CasingPipesSupplier#Deesa#Exporter#ExporterofCasingPipesinGujarat#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCasingPipesinGujarat#MeghmaniMetalIndustries#Mehsana#Morbi

0 notes

Text

Automatic Glass Bottle Washing Filling and Capping Machine in Gujarat

SATV Industries is a Manufacturer and Supplier of Automatic Glass Bottle Washing Filling and Capping Machine in Gujarat, India. We are based in Ahmedabad, Gujarat, India. We developed the bottled water bottling machine by incorporating advanced technologies, new techniques, and innovative structures, making it one of the leading machines in the industry. Our designed it with a feature where the neck of the bottle clamps between the bottle clamping plate and upper plate, driven by a star wheel. The bottle clamping plate rotates to convey the bottle, ensuring fully automatic bottle washing, filling, and capping. This system offers several benefits, including low wear, easy bottle replacement, accurate and stable conveying, and scientifically designed procedures. Features: High-Quality Materials: We make all parts that come into contact with fluids from imported stainless steel or wear-resistant, ozone-resistant, food-grade engineering plastics. Imported Electrical Components: The electrical systems are made using high-quality imported elements. Sanitation Standards: The machine meets national sanitation standards, ensuring safe and hygienic operation. Stable and Reliable: The performance is stable, with low fault rates, automatic control, and full after-sale support. Wide Application: Suitable for bottling mineral water, purified water, and other soft beverages in various PET bottles of different shapes and capacities. High Production Capacity: Capable of producing between 600 and 42,000 bottles per hour. Bottling Systems: Includes gravity filling and low vacuum filling systems. Machine Components: Automatic Rinsing, Filling & Capping Machine: Includes automatic rinsing, filling, and capping functions, with an AC drive system. Inspection Screen and UV Light: For ensuring proper sanitization and inspection. Air Conveyor for Infeed: Used to transport bottles into the machine. Stainless Steel Housing: We make the entire machine housing from stainless steel with thrust bearings for enhanced durability. Aluminum Close Chamber with Glass Door: Provides easy access for maintenance and inspection. PLC-Based Control: The machine is controlled by a programmable logic controller (PLC). SMPS for Electrical Parts Safety: Ensures safety of electronic and electrical components. Compressed Air Supply: Requires compressed air (buyer’s responsibility). SATV Industries is an Automatic Glass Bottle Washing Filling and Capping Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Feel free to contact us for more information and inquiries. Read the full article

#Ahmedabad#Amreli#Anand#AutomaticGlassBottleWashingFillingandCappingMachine#AutomaticGlassBottleWashingFillingandCappingMachineinAhmedabad#AutomaticGlassBottleWashingFillingandCappingMachineinGujarat#AutomaticGlassBottleWashingFillingandCappingMachineinIndia#AutomaticLabelingMachines#Bharuch#Bhavnagar#Bhuj#Botad#BottleWashingMachines#Deesa#Exporter#ExporterofAutomaticGlassBottleWashingFillingandCappingMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#LiquidFillingMachines#Manufacturer#ManufacturerofAutomaticGlassBottleWashingFillingandCappingMachine#Mehsana#Morbi#Nadiad

0 notes

Text

Supplier of ABA Blown Film Machine in Gujarat

Adroit Extrusion is a trusted Manufacturer, Exporter, and Supplier of ABA Blown Film Machine in Gujarat. Our Manufacturing unit is located in Ahmedabad, Gujarat, India. Our ABA Blown Film Machine are designed to deliver superior performance, reduce raw material costs, and ensure exceptional film quality. Features of ABA & AB Blown Film Machines: Efficient Design for Cost Savings: A single, smaller extruder produces both A-layers using only 30–40% new plastic resins per minute, operating at a slower pace for efficiency. The second extruder forms the intermediate layer using recycled plastic resins and CaCO₃, significantly lowering material costs. Enhanced Film Quality: Produces three-layer film that is 30% stronger than monolayer film, ensuring durability and strength. Both sides of the film provide a smooth printing surface, ideal for applications like shopping bags. Flexible Layer Configurations: A simple modification in the die block design allows for a traditional two-layer co-extrusion line to produce three-layer films. Depending on application requirements, the machine can switch between A/B/A co-extrusion and A/B co-extrusion. Technical Specifications: Model Name: Duoflex ABA Three Layer & AB Two Layer Co-Extrusion Blown Film Plant Materials Used: LDPE, LLDPE, HDPE, CaCO₃, Virgin Raw Materials Output Range: 60–200 kg/hr Screw Diameter: 35/45/55/65/75 (Customized) Screw L/D Ratio: 30:1 (Customized) Layflat Film Width: 500–3000 mm Thickness Range: 20 microns to 150 microns Applications of ABA & AB Blown Film Machines: Our machines are suitable for producing various films: General-purpose PE Film HDPE Pick-Up Bags Shade-Net Film PE Lamination Film Mulch Film Courier Film Stretch & Cling Film Shrink Film Anti-Rust Film Tarpaulin Film FAQs. Q1: Can the machine produce both two-layer and three-layer films? A1: The machine can switch between A/B and A/B/A co-extrusion configurations with a simple die block adjustment. Q2: What materials can be processed in these machines? A2: Our machines are compatible with LDPE, LLDPE, HDPE, CaCO₃, and virgin raw materials. Q3: What are the typical applications for the films produced? A3: These machines produce films for various uses, including general-purpose films, pick-up bags, lamination films, mulch films, courier films, and more. Adroit Extrusion is a Supplier of ABA Blown Film Machine in Gujarat including locations Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Sachin, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad. For more details or to inquire about our ABA & AB Blown Film Machines, contact Adroit Extrusion today! View Product: Click here Read the full article

#ABABlownFilmMachineinGujarat#ABABlownFilmMachineManufacturerinAhmedabad#AdroitExtrusion#Ahmedabad#Amreli#Anand#Ankleshwar#Balasinor#Bhachau#Bharuch#Bhavnagar#Bhuj#Chotila#Dahod#Dhandhuka#Dholka#Dwarka#Exporter#Gandharpur#Gandhidham#Gandhinagar#Godhra#Gujarat#Halol#Halvad#India#Jamnagar#Jetpur#Jhagadia#Junagadh

0 notes

Text

Co2 Laser Machine in Gujarat

Success Technologies is a Manufacturer, and Supplier of Co2 Laser Machine in Gujarat, India. Our Manufacturer unit is located in Ahmedabad, Gujarat, India. A CO2 Laser Machine uses a carbon dioxide laser to deliver a highly focused laser beam that cuts, engraves, or marks materials. It operates by directing the laser beam through a series of mirrors and lenses to focus it onto the workpiece. The focused beam generates enough heat to vaporize, melt, or burn through the material, depending on the application. CO2 Laser Machines are widely used in industries ranging from manufacturing and textiles to advertising and automotive. These machines are ideal for industrial applications where high-quality results are needed, with exceptional accuracy, repeatability, and flexibility. Advanced CO2 laser machines deliver superior performance, speed, and precision for cutting wood, acrylic, leather, and metals. Features: High-Speed Cutting and Engraving: The machines are designed to operate at high speeds while maintaining precision, improving workflow efficiency. Precise Focus and Beam Control: The focused laser beam enables intricate cuts and engravings, ensuring precision on small and detailed projects. Automatic Focusing: Some models have automatic focusing, adjusting for material thickness to ensure optimal laser cutting quality. Advanced Cooling System: The water-cooled laser prevents overheating, ensures consistent performance, and extends the laser tube’s lifespan during production. Reliable DSP Control System: The Digital Signal Processor ensures stable operation, and software compatibility, and enables offline operation for efficient performance. Safety Features: Built-in safety protocols, such as emergency stop buttons and protective covers, ensure that the machine operates safely for both operators and the environment. Applications: Laser Cutting Laser Engraving Marking Signage and Advertising Textile and Apparel Industry Woodworking FAQs: How long does a CO2 Laser Machine last? The lifespan of a CO2 Laser Machine depends on usage and maintenance, but the laser tubes typically last between 2,000 and 3,000 hours of operation. What software can I use with a CO2 Laser Machine? CO2 Laser Machines are compatible with popular design software such as AutoCAD, CorelDRAW, Illustrator, and other CAD/CAM programs. Are CO2 Laser Machines safe to use? Yes, CO2 Laser Machines come with multiple safety features, including protective enclosures, emergency stop buttons, and cooling systems to prevent overheating, ensuring operator safety. Success Technologies is a Co2 Laser Machine in Gujarat, India Including locations like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Co2LaserMachine#Co2LaserMachineExporter#CO2LaserMachineinAhmedabad#CO2LaserMachineinGujarat#CO2LaserMachineinIndia#Co2LaserMachineManufacturer#Co2LaserMachineSupplier#Deesa#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCo2LaserMachine#ManufacturerofCo2LaserMachineinGujarat#Mehsana#Morbi#Nadiad#Navsari

0 notes

Text

#art#absolutely amazing#absolutely beautiful#absolutely breathtaking#absolutely perfect#deep thoughts#love#peace#junagadh#mountains#clouds

0 notes

Text

The Byke Suraj Club - Best Pure Veg Hotel in Junagadh

Experience the perfect blend of comfort and culinary excellence at The Byke Suraj Club, Junagadh's favorite pure veg hotel. Enjoy beautifully designed rooms, top-notch facilities, and delectable vegetarian dishes in a serene environment. Whether for work or leisure, our hotel promises a stay that’s both relaxing and rejuvenating.

0 notes

Text

Perforated Sheets Supplier in Gujarat

Company Overview: Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider of Perforated Sheets Supplier in Gujarat, India. Our manufacturer unit is in Ahmedabad, Gujarat, India. Our stainless steel perforated sheets are made in accordance with both national and international industry standards, utilizing premium raw materials. We design them in accordance with ASTM A240 requirements. We conduct stringent quality checks on all our perforated sheets before packaging and delivering them to customers. Stainless Steel TP403 perforated sheets in a range of sizes and shapes, customised to satisfy client needs, are readily available in our inventory. Our offer customized perforated sheets to meet the specific needs of our clients, ensuring versatile solutions for various industrial applications. Specifications Of Perforated Sheet: Size: 3′ X 8′ AND 4′ X 8′ Material: MS, SS, AND GI Application: INDUSTRIAL AND DECORATIVE Hole Diameter: 0.5MM TO 40MM Hole Shape: ROUND HOLE, LONG HOLE, SQUARE HOLE Width: UPTO 4′ WIDTH Applications Of Perforated Sheet: Textile Machinery Oil and Gas Industry Medical Gas Pipeline Systems the Pharmaceutical Processing Industry Fluid Piping Modern Architecture Water Waste Projects What materials are available for perforated sheets? We offer stainless steel, mild steel, aluminum, and other alloys to suit diverse applications. Can perforated sheets be customized? Yes, we provide customized perforated sheets with specific hole sizes, patterns, and dimensions. Are these sheets suitable for outdoor use? Absolutely! Our corrosion-resistant materials, such as stainless steel, are ideal for outdoor environments. Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider Perforated Sheets Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Gandhidham#Gandhinagar#Gujarat#Jamnagar#Jetpur#Junagadh#Kalol#ManufacturerofPerforatedSheets#ManufacturerofPerforatedSheetsinAhmedabad#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#PerforatedSheets#PerforatedSheetsSupplier#PerforatedSheetsSupplierinGujarat#PerforatedSheetsSupplierinIndia#Porbandar#Rajkot#StockiestofPerforatedSheets

0 notes