#F316L

Explore tagged Tumblr posts

Text

The forge KB Schmiedetechnik is located in Hagen, Westphalia, with just under 100 employees. It is situated between the historic 'blade and metal' region of Solingen and 'soccer city' Dortmund, near the hilly landscape of the Sauerland.

KB specializes in the small series production of safety-critical closed-die forgings, ranging from 200 g to 130 kg in unit weight, using all steel grades, including duplex stainless steels, nickel-based superalloys, and even titanium.

Depth of Manufacturing

All production processes are carried out in-house, including CAD design, tool construction, closed-die forging, heat treatment, hardening, CNC machining, as well as testing and surface inspection in our own lab.

We process all types of steel, including carbon, alloyed, duplex, as well as nickel-based alloys and titanium.

For 20 years, we have been helping our customers optimize forgings through material flow simulation. We advise on transitioning from assemblies, such as welded structures or cast parts, to forged components with enhanced grain flow. Additionally, material flow simulation facilitates the reduction of excess material, such as flash, allowing for completely flash-free forging (depending on the geometry), which saves both material and energy.

Forged components are often not only more robust and visually appealing (picture above), but also more cost-effective to produce. We assist in transitioning from assemblies, such as welded structures (right) or cast parts, to forged components (left) with enhanced grain flow.

Materials and Case Studies

Nickel (Ni) is used as an alloying element in steels to improve their toughness and ductility at low temperatures. From a nickel content of 9%, steels are considered cold-resistant and free from embrittlement. Besides steel, there are also other alloys with such properties (e.g., superalloys). Examples:

F316x – The standard chromium, nickel, and molybdenum stainless steel for cutlery, power plants, and cryogenics (10-13% Ni). Many sub-varieties with specific properties, such as: 1.4404, 1.4435, 1.4571 exist.

Monel®400 – A nickel-copper superalloy highly resistant to corrosion, particularly suitable for chemical applications, seawater, and high-temperature environments such as rocket engines (63% Ni)

Nitronic®, 1.3964, Alloy 50 – A non-magnetic chromium-nickel alloy (12.5% Ni) specifically for offshore and marine areas.

KB Schmiedetechnik GmbH holds certifications for both ISO_9001 and ISO_14001, along with various additional certifications for demanding sectors such as pressure equipment, nuclear power plants, and even five shipbuilding supplier certifications such as ABS, BV Marine & Offshore, ClassNK, DNV, and LR. Relevant documents can be downloaded from the company's website in the 'Quality' section.

At a glance

Pressure equipment and nuclear power (valves, boilers, piping):

PED 2014/68/EU, AD 2000-W0, ASME, KTA, RCC-M

Shipbuilding and ocean engineering

American Bureau of Shipping (ABS)

Bureau Veritas Marine & Offshore

Det Norske Veritas (DNV)

Lloyds Register (LR)

Nippon Kaiji Kyōkai (ClassNK)

An articles by me on the stability of forged parts of steel (it is the grain flow):

https://www.openpr.com/news/3670898/grain-flow-optimised-forgings-for-maximum-stability-in-critical

0 notes

Text

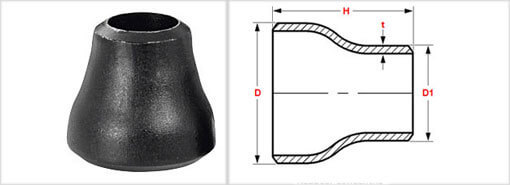

Concentric Reducers Exporters in India

CONCENTRIC REDUCERS

The Concentric Reducers are accessible in assortment of shapes and measurements to suit real pipeline establishment necessities in commercial ventures. This is a standout amongst the most generally utilized modern funnel fitting for adjusting distinctive channel sizes in a pipeline framework. It is fundamentally used to associate two funnels with various widths.

Produced using best grades of stainless steel, these reducers are accessible in an extensive variety of sizes, divider thicknesses and weight evaluations to look over as indicated by the pipeline. Guaranteeing an in-line funnel shaped move between various widths of pressurized channels, these concentric reducers join the pipelines on the same axis.The development of these reducers is finished by joining the little breadths and expansive distances across on inverse closures of cone formed move area. Discover application in petrochemicals, sugar factories and refineries, steel plants and bond and development commercial ventures, the reducer has separate gulf and outlet closes.TECHNICAL SPECIFICATIONSSTANDARD MATERIAL GRADES OF BUTTWELD SS REDUCER

Stainless steel grades:

ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H, WP321, ASTM A815 S31803, S32750, S32760, S32205

Standard material grades in stainless steel:

ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L

Application Areas:

Oil and gas industry

Petrochemical industry

Power stations

Shipbuilding industry

10 notes

·

View notes

Text

Stainless Steel 316 & 316L Flanges

Introduction

Stainless Steel 316 (SS 316) and Stainless Steel 316L (SS 316L) are widely used austenitic stainless steel grades known for their enhanced corrosion resistance, high strength, and excellent durability. These grades are commonly used in marine, chemical processing, food, and pharmaceutical industries due to their superior resistance to chloride and acidic environments.

What is SS 316 & SS 316L?

SS 316: A molybdenum-bearing stainless steel that offers superior resistance to pitting and crevice corrosion.

SS 316L: A low-carbon variant of SS 316, designed for improved weldability and corrosion resistance, especially in high-temperature environments.

SS 316 Flange Material & Specifications

SS 316 and SS 316L flanges are manufactured under ASTM A182 standards and are suitable for various industrial applications requiring high strength and corrosion resistance.

SS 316 Flange Specifications

Material Standard: ASTM A182 F316 / F316L

Pressure Ratings: ANSI Class 150, 300, 600, 900, 1500, 2500

Flange Types: Slip-on, Weld Neck, Blind, Threaded, Socket Weld, Lap Joint, Spectacle Blind, SORF (Slip-On Raised Face)

Face Type: Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ)

SS 316 Flange Dimensions & Weight Charts

Stainless Steel Flange Dimensions Chart (PDF)

To view the complete SS 316 flange dimensions chart, refer to manufacturer datasheets or download ASME B16.5 / B16.47 standards.

SS 316 Class 150 Flange Dimensions

Size (inches)Outside Diameter (OD)Bolt Circle DiameterBolt Hole SizeNumber of Bolts1/2"3.50"2.38"0.62"41"4.25"3.12"0.62"42"6.00"4.75"0.75"44"9.00"7.50"0.75"8

SS 316L Flange Weight Chart

Flange Size (Inches)Weight (kg)1/2"1.51"2.52"5.84"12.0

316 Stainless Steel Flange Pressure Rating

SS 316 and SS 316L flanges are available in different pressure classes ranging from 150 to 2500 ANSI ratings.

Class 150: Suitable for pressures up to 285 psi at 100°F.

Class 300: Can withstand pressures up to 740 psi at 100°F.

Class 600: Rated for 1,480 psi at 100°F.

ASTM A182 SS 316 & F316 PDF

ASTM A182 defines the standard specifications for forged or rolled alloy and stainless steel pipe flanges, fittings, valves, and parts. The F316 and F316L variants offer superior properties for high-pressure and high-temperature applications.

FAQs

1. What is the difference between SS 316 and SS 316L?

SS 316L has a lower carbon content than SS 316, which enhances its weldability and corrosion resistance in chloride-rich environments.

2. What is a 316L flange made of?

SS 316L flanges are made of low-carbon stainless steel, which improves weldability and corrosion resistance.

3. What is the ASTM standard for SS 316 flanges?

The standard specification is ASTM A182 F316 / F316L.

4. What is SS 316 commonly called?

SS 316 is also referred to as marine-grade stainless steel due to its excellent resistance to seawater and chloride environments.

5. What are the standard SS 316 flange dimensions?

SS 316 flange dimensions follow ASME B16.5 and ASME B16.47 standards.

6. What is the pressure rating of a 316 stainless steel flange?

SS 316 flanges are available in ANSI 150 to 2500 pressure ratings, with Class 150 rated for 285 psi at 100°F.

7. What is the function of a SORF flange?

SORF (Slip-On Raised Face) flanges are used for easy installation and cost-effective piping connections in moderate pressure applications.

8. Where can I get the SS 316 flange weight chart?

You can find the SS 316 and SS 316L flange weight charts in manufacturer catalogs or ASME B16.5 datasheets.

9. What is the difference between F316 and F316L?

F316L has lower carbon content than F316, making it more resistant to intergranular corrosion after welding.

10. What are the typical applications of SS 316 flanges?

SS 316 flanges are widely used in oil & gas, marine, food processing, pharmaceuticals, and high-pressure piping systems.

0 notes

Text

Forged steel check valve supplier in Dubai

Forged steel check valve supplier in Dubai UAE Valve is the reputed Forged steel check valve supplier in Dubai. A forged steel check valve works to avoid backflow and it also ensures the effective and secure functioning of fluids in commercial, industrial, and residential functions. forged steel check valves are an important part of many piping devices. These valves are also good at providing outstanding support, durability, and dependability even in high-pressure and high-temperature settings because they are built of selected forged steel. These are some of the features and benefits of forged steel check valves. ● various Designs: forged steel check valves come in swing, lift, and dual-plate designs, making it simple to integrate them into a variety of devices. They are appropriate for installations with restricted areas because of their small design. ● Corrosion Resistance: To ensure a longer lifespan and lower maintenance costs, many forged steel check valves are available with specific coatings or manufactured from alloys that resist corrosion. ● Low Leakage: Forged steel check valves' precise engineering decreases the possibility of leaks, boosting system security and effectiveness. ● Ease of Maintenance: Forged steel check valves have fewer moving parts than other valve varieties, making maintenance simpler and saving downtime and operating costs. Applications of forged steel check valve ● Oil and Gas Industry for Forged Steel Check Valves: These valves are essential for preserving flow direction and stopping backflow in pipelines and are used in both upstream and downstream activities. ● Water treatment plants are necessary to ensure a clean and safe supply of water by preventing reverse flow in sewage and water treatment operations. ● Power Generation: Used in cooling and steam systems where backflow could compromise security and functionality. ● Chemical processing mitigates the risk of contamination and dangerous conditions while preventing backflow and ensuring the safe transportation of chemicals. We Forged steel check valve supplier in Dubai helps to select Appropriate Forged Steel Check Valve ● Check the valve's ratings for pressure and temperature to be sure it can withstand the unique circumstances of your system. ● Size and Type of Connection: Select the right fitting and size to go with the pipes you already have. ● Material Compatibility: Make sure the valve material is appropriate for the fluids you are handling. ● Flow Characteristics: Assess if a dual-plate, swing, or lift design better suits your operational requirements. Industries: •Oil and Gas Industry •Pipeline Industry •Marine Industry •Power Industry •Nuclear Industry •Chemical Industry •Petrochemical Industry Description: Body Material: A105, F22, F304L, F316L, A105, F22, F6, F304 Size: 1”-3/4” Nominal Diameter: DN15 to DN50 Nominal Pressure: Class800 to Class2500 End Connections: Buttweld, Socketweld, Flanged

0 notes

Text

Trunnion Ball Valve Manufacturers

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturers in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valves and How They Work? Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints. Key Components: Body: The main housing of the valve, providing structural support. Ball: Spherical disk within the valve body, rotates to control fluid flow. Trunnion: Shaft supporting the ball from below, ensuring secure attachment. Seat: Machined surface where the ball makes contact to regulate flow. Stem: Connects the actuator to the ball, facilitating its rotation. Disk: Another term for the ball, referring to its spherical shape. Actuator: Mechanism for operating the valve, such as handwheel or gear. Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

We are Trunnion Ball Valve Manufacturers in India our valve give following advantages:

Long Service Life: Built to withstand wear and tear, ensuring durability. High Pressure and Temperature Handling: Capable of operating in demanding conditions. Wide Range of Materials: Available in various materials to suit diverse applications. Tight Shutoff: Ensures minimal leakage for precise flow control. Easy Operation: User-friendly design for seamless valve operation. Customizable: Can be tailored to specific requirements for optimal performance. Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries: Oil and Gas Industry: Used in upstream, midstream, and downstream operations. Petrochemical Industry: Essential for handling chemicals and petrochemical products. Chemical Industry: Suitable for controlling the flow of various chemicals and solvents. Power Generation Industry: Employed in power plants for fluid control applications. Water and Wastewater Treatment Plants: Ensures efficient management of water resources. Mining Industry: Used in mining operations for slurry and fluid control. Hydrocarbon Industry: Critical for handling hydrocarbons and related fluids.

Product Description: Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy (Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/5A, A352 LCC/LCB (Casting) Class: 150-2500, PN25 – PN450. Size: 2” to 48”. Ends: Buttweld, Socket weld, Threaded, Flanged Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

Address:- Corporate Office, Specialityvalve, 37 NGR Street, P.N Palayam, Coimbatore, Tamil Nadu – 641037

0 notes

Text

BRANCH OUTLET FITTINGS – WELDING, SOCKET WELD, THREADED OUTLETS MANUFACTURER, EXPORTERS IN INDIA

Montex Forge Industries is a Dominant manufacturer of buttweld pipe outlets, socket weld, and threaded pipe outlets in all material grades and wall thicknesses and in compliance with international standard MSS-SP-97. Our forged pipe outlet products are available in various grades including carbon steel conforming to ASTM A105/SA105N and NACE MR-01-75 and stainless steel to ASTM A182 F304, F304L, F316, and F316L. Upon request, we can also manufacture pipe outlet fittings in special materials such as 904L, 347H, Duplex, Super Duplex, Inconel, Monel, Incoloy and Hastelloy series of metals. Branch outlet fittings are widely used in processing plant for sulphuric, phosphoric and acetic acids, pulp and paper processing, components in gas scrubbing plants, seawater cooling equipment, oil refinery components, petrochemical plants, and various other industries.

#pipe outlet fittings online#Carbon steel slip on flang online in India#Best forged tee fitting near me#Forged steel reducer in India#Carbon Steel Socket weld Pipe Fittings online

0 notes

Text

JUAL STEAM TRAP BOILER-GESTRA

Kami perusahaan penyedia steam trap untuk boiler dengan mrek gestra yang memiliki type ukuran beragam sesuai kebutuhan konsumen, beberapa type gestra yang tersedia akan kami bahas di bawah ini. Kesempurnaan Steam Trap Gestra Pada Boiler Dalam industri, salah satu tugas terpenting steam adalah menyediakan energi panas melalui kondensasi, dan memanaskan berbagai media dalam penukar panas. Selama proses ini, uap mengalir melalui pipa dan semakin dingin dalam perjalanan, sehingga kondensat juga terbentuk di sini. Kondensat mencegah perpindahan panas secara optimal, namun juga, khususnya, menyebabkan erosi dan palu air. Untuk memungkinkan sistem uap bekerja dengan andal dan efisien, steam traps membuang kondensat yang menumpuk, sambil mempertahankan uap yang berharga semaksimal mungkin sejauh mungkin. Seberapa baik kinerja steam traps mempunyai pengaruh yang besar terhadap: keandalan sistem ketersediaan dan efisiensi biaya. Untuk mencapai hasil terbaik di sini, diperlukan katup yang memenuhi semua persyaratan berbeda dalam segala hal,

Spesifikasi Steam Trap Gestra Untuk memanaskan air dengan menggunakan uap, terkadang sejumlah besar kondensat harus dibuang secepat mungkin, sehingga drainase tanpa penimbunan dapat terjamin walaupun terdapat beban dan tekanan berfluktuasi. Jika turbin atau pipa dengan uap super panas dikuras, hanya terjadi laju aliran kondensat yang rendah selama operasi. Lebih banyak kondensat hanya terbentuk saat start-up. Di sini, tuntutannya adalah ketahanan, keramahan perawatan, daya tahan, dan pengatur yang menutup dengan andal bahkan pada tekanan di atas 200 barg. Type Materials, body, cover AK 45 1.0460 / SA105 BK 15 1.0460 / SA105 BK 27N 1.5415 BK 28 1.5415 BK 28-ASME 1.7335 / SA182-F12-2 BK 29 1.7335 / SA182-F12-2 BK 29-ASME 1.7335 / SA182-F12-2 BK 36A-7 1.4408 / SA351-CF8M BK 37 1.5415 BK 37-ASME A182-F12 BK 45 1.0460 / SA105 BK 45-LT SA350-LF2 BK 46 1.5415 BK 212 1.7383 / A182-F22-3 BK 212-F91 1.4903 / SA182-F91 BK 212-1.4901 1.4901 (F92) BK 212-ASME 1.7383 / A182-F22-3 DK 36A-7 1.4408 / SA351-CF8M DK 45 1.0460 / SA105 DK 47-L A743 CA40 DK 47-H A743 CA40 DK 57-L AISI 420 DK 57-H AISI 420 GK 11 5.1301 GK 21 5.1301 IB 16A-7 SA240-304L MK 20 5.4202 MK 25/2 1.0460, 1.0619 / SA105, SA216-WCB MK 25/2 S 1.0460, 1.0619 / SA105, SA216-WCB MK 35/31 1.0460 / SA105 MK 35/32 1.0460 / SA105 MK 35/2S 1.0460 / SA105 MK 35/2S3 1.0460 / SA105 MK 36A-71 1.4408 / SA351-CF8M MK 36A-72 1.4408 / SA351-CF8M MK 36/51 1.4301 / SA479-F304 MK 36/52 1.4301 / SA479-F304 MK 45-1 1.0460 / SA105 MK 45-2 1.0460 / SA105 MK 45 A-1 1.4404 / A182-F316L MK 45 A-2 1.4404 / A182-F316L SMK 22 1.4435 SMK 22-51 1.4404 SMK 22-81 1.4404 SMK 22-82 1.4404 TK 23 5.1301 TK 24 1.0619 / SA216-WCB TS 36 1.4408 / SA351-CF8M UBK 46 1.0460 / SA105 UC 36, UCY 36 1.4408 / SA351-CF8M UNA 14 5.3103 UNA 14P 5.3103 UNA 16 1.0460, 1.0619 / SA105, SA216-WCB UNA 16A 1.4404, 1.4408 / A182-316L, SA351-CF8M UNA 25-PK 5.3103 UNA 25-PS 5.3103 UNA 27h 1.5419 UNA 43 5.1301 / A126-B UNA 45 1.0460, 5.3103 / SA105, (A395) UNA 45 MAX 1.0460, 5.3103 / SA105, (A395) UNA 46 1.0460, 1.0619 / SA105, SA216-WCB UNA 46 MAX 1.0460, 1.0619 / SA105, SA216-WCB UNA 46A 1.4404, 1.4408 / A182-316L, SA351-CF8M UNA 46A MAX 1.4404, 1.4408 / A182-316L, SA351-CF8M UNA 38 1.5415, 1.7357 UNA 39 1.7335 / SA182-F12 UNA-Special Typ 62-B 1.0425 UNA PN 25 1.0619 / SA216-WCB UNA-Special PN 63 1.5419 Kelebihan Steam Trap Gestra Bagi operator sistem uap, biaya produksi energi merupakan faktor pendorong utama. Uap yang tahan lama perangkap yang bekerja tanpa kehilangan uap membantu menekan biaya serendah mungkin. Apa terlebih lagi, mereka memastikan pengoperasian yang andal dan aman. Selama beberapa dekade, steam trap GESTRA telah melambangkan efisiensi energi dan efisiensi energi yang optimal keandalan mutlak. Mereka memenuhi persyaratan kualitas yang paling menuntut, dan kompak dan desain modular membuatnya mengesankan di lapangan. Selain itu, mereka sangat ramah perawatan dan sangat mudah serta nyaman digunakan. PT Indira Mitra Boiler Jln. LoveBird blok D19/21 RT12 RW005 Permata Sepatan,Pisangan jaya ,Sepatan, Kab. Tangerang, Banten-15520 ZAENAL ARIFIN Sales Engineer Phone : (021) 59375021 Mobile : 081385776935 Whatshap : 081385776935 Email : [email protected] Email : [email protected] Website: https://jualthermaloil.com Read the full article

0 notes

Text

Trunnion Ball Valve Manufacturer in India

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturer in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valve and working?

Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints. Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

Key Components:

Body: The main housing of the valve, providing structural support.

Ball: Spherical disk within the valve body, rotates to control fluid flow.

Trunnion: Shaft supporting the ball from below, ensuring secure attachment.

Seat: Machined surface where the ball makes contact to regulate flow.

Stem: Connects the actuator to the ball, facilitating its rotation.

Disk: Another term for the ball, referring to its spherical shape.

Actuator: Mechanism for operating the valve, such as handwheel or gear.

Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Advantages of Our Trunnion Ball Valves

Long Service Life: Built to withstand wear and tear, ensuring durability.

High Pressure and Temperature Handling: Capable of operating in demanding conditions.

Wide Range of Materials: Available in various materials to suit diverse applications.

Tight Shutoff: Ensures minimal leakage for precise flow control.

Easy Operation: User-friendly design for seamless valve operation.

Customizable: Can be tailored to specific requirements for optimal performance.

Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries:

Oil and Gas Industry

Petrochemical Industry

Chemical Industry

Power Generation Industry

Water and Wastewater Treatment Plants

Mining Industry

Description :

Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy(Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/ 5A, A352 LCC/ LCB (Casting)

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Threaded, Flanged

Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

0 notes

Text

Expander Flanges Stockists in India

ASME B16.5 Expander Flanges is such a welding neck pipe Flanges used to make pipe size at the Flanges connection. On the off chance that you have confined space or on an exceptionally fundamental level need to chat with more central line size, it gives an obliging system to mechanical party, siphons, and valves. The Stainless Steel expander Flanges can keep the use from getting a Flanges and minimizer. The Strain evaluations and appraisals are as shown by ANSI/ASME B16.5. This Expander Weld Neck Flanges has a raised face.

Nutech Overseas Expander Flanges. We are passing on Hastelloy Expander Flanges, ASME B16.5 Expander Flanges, ANSI B16.5 Class 150 Expander Flanges and ASTM A105 Expander Flanges acceptably by morals of sensible power hours in India and dumbfounding wellspring of top notch ASTM A182 SS Expander Flanges, most very smart arrangement, cost open in Mumbai, India. We are Programming interface expander Flanges supplierss in India, Check expander Flanges assessments and Weight Diagrams. We are merchant of smoke Flanges expander in Mumbai.

Expander Flanges Manufacturers, Expander Flanges Suppliers, Expander Flanges Stockists, Expander Flanges Exporters

We can obviously ASME B16.47 Series b Expander Flanges, most very smart arrangement, cost as we are one of the most dumbfounding suppliers and judge of Clamor 86029 PN10 Expander Flanges in India. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our Carbon Steel Expander Flanges cost going prior to purchasing SS Expander Flanges from India or China. similarly mail for our live deftly of Stainless Steel Expander Flanges to check types and sizes with our set up stock we can give you best cost of MSS SP-44 Copper Nickel Expander Flanges.

We can in like manner give free portrayal of Duplex Steel Expander Flange,Nutech Overseas is having our Seller and Merchant in Bangalore, Karnataka, Chennai (Madras), Tamil Nadu, Ahmedabad, Gujarat, Delhi, Pune, Maharashtra, Rajkot, Ghaziabad, Uttar-Pradesh, Bhosari, Ludhiana, Punjab, Vadodara, Aurangabad, Faridabad, Gurgaon, Haryana, Indore, Madhya Pradesh, Jaipur, Rajasthan, Kolkata, West-Bengal, Khopoli, Karnataka, Kolhapur, Nagpur, Raipur, Chhattisgarh.. So tolerating you are searching for best cost of Programming interface Expander Flanges or Expander weld neck Flanges, A182 F316L Expander Flanges close to you with most confined time transport or free event of Stainless Steel Expander Flanges.

0 notes

Text

Specialityvalve is a top Forged steel ball valve manufacturer in India. We supply to France, Australia, Mexico and Turkey. A forged steel ball valve is a type of valve used to control the flow of fluids (liquids or gases) in pipelines and industrial processes.

Description:

Available materials: F55, F51, F53, F11, F22, A105, A105, F304 F316, F316L, F91, F904, F44

Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Lever Operated, gear operated, Electric Actuated and Pneumatic Actuated.

End Connection: Threaded, Buttweld, Socketweld

Medium LNG, Cryogenic application, Water, Air, Steam

0 notes

Text

C’est en forgeant qu’on devient forgeron !

Estampage, Matriçage et Usinage : Pièces forgées en tous types d'aciers et superalliages à base de nickel, produites en petites séries.

La Forge KB est située à Hagen (Westphalie), en Allemagne de l'Ouest, entre Solingen (la région historique des couteaux) et Dortmund (la ville du football), à deux heures de route des frontières belge et néerlandaise.

Pour découvrir les détails de la région, cliquez sur « ALT » sur la carte !

KB est spécialisée dans les pièces forgées pour équipements sous pression et ainsi que pour les applications maritimes, nucléaires et industrielles, certifiée selon des normes strictes.

Spécialisée dans le forgeage à chaud par estampage et matriçage en matrice fermée, KB fabrique des pièces forgées en petites séries à partir de matériaux de qualité européenne.

Schmiedetechnik [prononciation : Chmyd(e)technique] est le mot allemand pour désigner la technologie de forgeage. « Schmied » signifie « forgeron » en français.

L'entreprise fabrique des composants pesant entre 200 g et 130 kg par unité, avec une longueur maximale de 600 mm, dans toutes les nuances d'acier.

Température | Corrosion | Pression | Fragilisation

Cela inclut les aciers inoxydables tels que le F316L et le duplex, ainsi que les alliages à base de nickel, notamment les superalliages Monel®, Incoloy®, Inconel® et Hastelloy®, sans oublier le titane.

Profondeur de Fabrication

KB maîtrise en interne tous les processus : conception, ingénierie, simulation, fabrication d'outillages, forgeage, traitement thermique et trempe, ainsi que les essais destructifs en laboratoire, contrôle des fissures, usinage mécanique et contrôle dimensionnel.

Applications dans des Secteurs Critiques

Robinetterie industrielle, notamment des corps de vannes cryogéniques, hydrogéniques et nucléaires, des raccords et brides de tuyauterie pour la chaudronnerie et la construction navale, des ébauches d’engrenages, ainsi que des supports et crochets forgés, destinés également aux secteurs agricole, maritime et de la défense.

Toutes les productions sont conformes aux normes, standards et certifications suivants :

ISO 9001 et ISO 14001

Equipements sous pression et énergie nucléaire :

DESP 2014/68/UE, AD 2000-W0, ASME, KTA, RCC-M

Chaudronnerie : Alstom, Babcock, CNIM, MHPS

Construction navale et génie océanique :

American Bureau of Shipping (ABS)

Bureau Veritas Marine & Offshore

Nippon Kaiji Kyōkai (ClassNK)

Det Norske Veritas (DNV)

Lloyd’s Register (LR)

Source (sous-marin): DCNS - Free Media Kit

Les certificats de qualité peuvent être téléchargés ici (en anglais) :

https://kb-schmiedetechnik.de/quality.html

Article Info

Un de mes articles sur le flux de grains et la stabilité des pièces forgées. « Fibrage » n'est pas le terme exact, mais il illustre bien le concept (EN: grain flow) !

Des photos, des textes complémentaires et des vidéos sont hébergés sur le site suisse suivant :

https://waisch.ch/firma/la-forge-kb-schmiedetechnik-gmbh-hagen-nrw

0 notes

Text

Threadolets Manufacturers

We supply Threadolets (3000#, 6000 #) in pressure grade of 3000LBSCH40, SCH80, STD, XS, 6000LBSCH160, XXS etc., and carbon steel of A182 A105 and in stainless steel of A182 F304, A182 F304L, A182 F316, A182 F316L, A182 F321 respectively. These Threadolet Fittings are available in sizes ranging from 1/8" ~ 20".

0 notes

Text

Pneumatic Actuated Ball Valve manufacturer in USA

SVR Global is the top Pneumatic actuated ball valve manufacturer in USA supplying good quality valves to chemical industries, petroleum industries and oil and gas industries in Alabama, Nashville and Miami. The Pneumatic Ball Valve, which regulates the flow of liquid or gas through a ball with a bore, is a robust valve that shuts off perfectly. Its exceptional safety features ensure quick and secure shutdown, making it a popular choice in various industrial applications. Its efficient performance makes it even more appealing.

Parts

Valve body: The valve body is the main housing that contains the ball and the ports through which the fluid flows.

Ball: The ball is a spherical component inside the valve body that rotates to open and close the valve.

Seat: The seat is a ring-shaped component that fits around the ball and provides a seal when the valve is closed.

Stem: The stem is a component that connects the ball to the actuator and is used to rotate the ball.

Actuator: The actuator is the device that converts compressed air into mechanical force to rotate the ball.

Mounting bracket or coupling: The mounting bracket or coupling is used to connect the actuator to the valve body.

Control system: The control system is a set of components that allow the valve to be operated remotely, such as a solenoid valve or control panel.

Accessories: Additional components may include limit switches, positioners, or other accessories that provide additional control or feedback for the valve.

TYPES

Pneumatic Actuated two-piece ball valve

Pneumatic Actuated Three-piece ball valve

Pneumatic Actuated Flanged ball valve

Pneumatic Actuated Three-way ball valve

Industry

Oil and Gas Industry

Chemical Industry

Textile industry

Petrochemical Industry

Mining Industry

Marine Industry

Features of Pneumatic Actuated Ball Valve: • Provides tight and safe shutoff. •It has a quick opening and shutting capabilities. •It is compact and simple to use.

Applications:

Chemical processing: Pneumatic actuated ball valves are commonly used in chemical processing applications to control the flow of chemicals and other fluids.

Water treatment: used in water treatment applications to control the flow of water and other liquids.

Oil and gas industry: used in the oil and gas industry to control the flow of oil and gas through pipelines and other equipment.

Advantages:

Fast operation: Pneumatic actuated ball valves are capable of fast and efficient operation, making them suitable for applications that require quick response times.

Reliable: These valves are known for their high reliability and durability, which makes them suitable for use in a wide range of industrial applications.

Easy to maintain: Pneumatic actuated ball valves are relatively simple to maintain, which can help to reduce downtime and maintenance costs.

Versatile: These valves can be used with a wide range of fluids, including gases, liquids, and slurries.

Good flow control: The design of the ball valve allows for good flow control, which can help to improve the efficiency of a system.

SVR Global is thepremium Pneumatic actuated ball valve manufacturer in USA is used in throttling applications for smooth flow of mediums.

Body: cast iron, cast steel (WCB, WCC, WC6, LCC, LCB), carbon steel (CF8, CF8M), titanium, stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L). Class: 150-2500, PN 10 – PN450. Size: ½” to 48” Ends: socket weld, butt weld, flanged, threaded Operation: pneumatic actuated

Visit our website for more information-https://svrglobal.net/products/pneumatic-actuated-ball-valve/

0 notes

Text

Floating Ball Valve Supplier in UAE

UAE valve is the top-most Floating Ball valve supplier in UAE. A floating ball valve is an important part of many fluid control systems. In this post, we examine what they are, how they function, and their attributes as well as the benefits of each type — to know which one is best suited for your application. Floating ball valves are quarter-turn valves used in industrial scenarios to control the flow of gases or liquids through a pipe. The pneumatic actuation due to the ball float can easily and quickly open or close.

Floating Ball Valve Working Process

Construction: A floating ball valve consists of a hollowed-out valve body, having the inlet and outlet ports in it alongside spherical-shaped metallic or plastic-covered balls. Fluid flows through this chamber by passing over the ball. It typically consists of a stem to a cage-guided setup configuration. The ball in a full-bore valve has a central hole (or bore) that, when open, allows fluid to flow. It can be a stainless steel or other material ball to match the type of fluid being controlled.

How They Work: Pressure from fluid forces the ball against the valve seat, sealing it and blocking pressure. To divert the valve, a 90-degree rotation is necessary, which implies a quarter-turn ball. It consequently aligns the hole in the ball with the flow path, allowing the passage of fluid.

Ball Valve Types Floating Design: In the case of a floating ball valve, it is designed rather than being held by any trunnion, so that otherwise comprises most top bottom ends available for this type, which means they have the connection between only two tips . This design ensures total rotated rotation across either end, with another side joined from below the base level, allowing screw-type rotation among the highest rotating participants.

Components of Floating Ball valve supplier in UAE

Valve Body: The valve body is typically made from carbon steel, stainless and alloy steel, or cast iron. Material selection depends on the chemical compatibility of a fluid, operating temperature range, and pressure rating.

Ball: A ball-type component that restricts the flow of fluids being controlled. It is normally made from robust, rust-resistant metals such as bronze or brass — sometimes stainless steel. On the surface, wear resistance and sealing performance can be improved by coatings or specific treatments.

Seats: The valve seats form the sealing surfaces for the ball when the valve is closed. Most often, they are built from Viton or EPDM resilient high-performance polymers, semi-rigid elastomers, and rigid resins like Polytetrafluoroethylene.

Actuator: The actuator handles the opening and closing of the valve. It can be automatic. The desired amount of control and the particular application determine the type of actuator.

Industries Using Floating Ball Valves

Oil and Gas Petrochemical Chemical Processing Power Generation Water and Wastewater

Description:

Body Material: Stainless steel, brass, or other metals, Cast Steel (WCB, WCC, WC6, WC9), Cast Iron, SS316, SS304, Forged Steel (F22, F51, LF2, F304, F304L, F316, F316L)

Size: 1/4'' to 48''

Class: 150-2500; PN 10-PN 450

Ends: Buttweld, Flanged, Socketweld, Threaded

Operation: Gear operated, Electric actuated, Lever-operated, Pneumatic actuated.

Visit our website: https://www.uaevalves.com/product-category/floating-ball-valve/

0 notes

Text

Pneumatic Actuated Ball Valve manufacturer in USA

SVR Global is the top Pneumatic actuated ball valve manufacturer in USA. We make high quality products as per international standards with our team of experts.

The Pneumatic Actuated Ball Valve Actuator is a double-piston actuator, specifically designed for operating ball valves and flaps. This actuator comes in two versions, namely the double-acting and single-acting models. The Pneumatic Ball Valve, which regulates the flow of liquid or gas through a ball with a bore, is a robust valve that shuts off perfectly. Its exceptional safety features ensure quick and secure shutdown, making it a popular choice in various industrial applications. Its efficient performance makes it even more appealing.

SVR Global is thepremium Pneumatic actuated ball valve manufacturer in USA and is used in throttling applications for smooth flow of mediums.

Parts

Valve body: The valve body is the main housing that contains the ball and the ports through which the fluid flows.

Ball: The ball is a spherical component inside the valve body that rotates to open and close the valve.

Seat: The seat is a ring-shaped component that fits around the ball and provides a seal when the valve is closed.

Stem: The stem is a component that connects the ball to the actuator and is used to rotate the ball.

Actuator: The actuator is the device that converts compressed air into mechanical force to rotate the ball.

Mounting bracket or coupling: The mounting bracket or coupling is used to connect the actuator to the valve body.

Control system: The control system is a set of components that allow the valve to be operated remotely, such as a solenoid valve or control panel.

Accessories: Additional components may include limit switches, positioners, or other accessories that provide additional control or feedback for the valve.

TYPES

Pneumatic Actuated two-piece ball valve

Pneumatic Actuated Three-piece ball valve

Pneumatic Actuated Flanged ball valve

Pneumatic Actuated Three-way ball valve

Industry

Oil and Gas Industry

Chemical Industry

Textile industry

Petrochemical Industry

Mining Industry

Marine Industry

Features of Pneumatic Actuated Ball Valve: • Provides tight and safe shutoff. •It has a quick opening and shutting capabilities. •It is compact and simple to use.

Applications:

Chemical processing: Pneumatic actuated ball valves are commonly used in chemical processing applications to control the flow of chemicals and other fluids.

Water treatment: used in water treatment applications to control the flow of water and other liquids.

Oil and gas industry: used in the oil and gas industry to control the flow of oil and gas through pipelines and other equipment.

Advantages:

Fast operation: Pneumatic actuated ball valves are capable of fast and efficient operation, making them suitable for applications that require quick response times.

Reliable: These valves are known for their high reliability and durability, which makes them suitable for use in a wide range of industrial applications.

Easy to maintain: Pneumatic actuated ball valves are relatively simple to maintain, which can help to reduce downtime and maintenance costs.

Versatile: These valves can be used with a wide range of fluids, including gases, liquids, and slurries.

Good flow control: The design of the ball valve allows for good flow control, which can help to improve the efficiency of a system.

Body: cast iron, cast steel (WCB, WCC, WC6, LCC, LCB), carbon steel (CF8, CF8M), titanium, stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L). Class: 150-2500, PN 10 – PN450. Size: ½” to 48” Ends: socket weld, butt weld, flanged, threaded Operation: pneumatic actuated

Visit our website for more information-

https://svrglobal.net/products/pneumatic-actuated-ball-valve/

0 notes

Text

Forged Steel Gate Valve Manufacturer in India

Speciality Valve, renowned for its precision engineering, is Forged Steel Gate Valve manufacturer in India, crafted to meet rigorous industry standards. With a commitment to excellence, we ensure reliable performance and durability in every valve supplied to Maharashtra, Gujarat, and Tamil Nadu.

What are Forged Steel gate Valves?

Forged steel gate valves are industrial valves designed to control the flow of fluids in pipelines by either fully opening or fully closing the passage. They are manufactured through forging, a process that involves shaping metal using compressive forces, resulting in a stronger and more durable valve compared to those made by casting. These valves consist of a gate or wedge that moves perpendicular to the flow of the fluid to either block or allow passage, providing efficient shut-off capability in high-pressure and high-temperature applications.

What does Forged means? Forged refers to a manufacturing process in which metal is shaped using compressive forces, typically under high pressure and heat. In forging, the metal is heated to a high temperature to make it more malleable, then subjected to mechanical force, often applied using a hammer or press, to deform it into the desired shape.

Advantages:

Strength and Durability

Resistance to Corrosion

Reliability

High-Pressure and High-Temperature Capability

They are available in various designs

Long Service Life

Safety

Easy to Maintain

Wide Range of Applications

Industry:

Oil and Gas Industry: Forged steel gate valve are vital components in oil and gas operations, ensuring reliable flow control in pipelines and refineries.

Petrochemical Industry: These valves play a crucial role in petrochemical plants, facilitating safe and efficient fluid handling in various processes such as refining and chemical production.

Power Generation Industry: In power plants, forged steel gate valves help regulate the flow of steam and other fluids in high-pressure and high-temperature environments, ensuring smooth operation of turbines and boilers.

Chemical Processing Industry: Forged steel gate valves are used in chemical plants to control the flow of corrosive chemicals and other fluids, offering durability and resistance to harsh operating conditions.

Refining Industry: Refineries rely on forged steel gate valves to manage the flow of crude oil and refined products, ensuring optimal performance and safety in refining processes.

Water and Wastewater Treatment Plants: These valves are employed in water treatment facilities to regulate the flow of water and chemicals, contributing to efficient treatment processes and maintaining water quality standards.

Pulp and Paper Industry: Forged steel gate valves are utilized in pulp and paper mills to control the flow of various liquids, including chemicals and pulp slurries, supporting the production of paper products.

Mining Industry: In mining operations, these valves are used to control the flow of water, chemicals, and slurries in processing plants, providing reliable performance in demanding mining environments.

Marine Industry: These valves find applications in marine systems and vessels for controlling the flow of seawater, fuels, and other fluids, ensuring safe and efficient operation at sea.

We are Forged Steel Gate Valve manufacturer in India supplying valve in following Description:

Available materials: F55, F51, F53, F11, F22, A105, A105, F304 F316, F316L, F91, F904, F44

Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Lever Operated, gear operated, Electric Actuated and Pneumatic Actuated.

End Connection: Threaded, Buttweld, Socketweld, Flanged, Wafer, Lug

To explore our range of valves, visit our website at: https://www.specialityvalve.com/product-category/forged-steel-gate-valve/

0 notes