#Forged steel reducer in India

Explore tagged Tumblr posts

Text

Best Forged Steel Reducer in India Online

Shop online for the best forged steel reducers in India. Our premium reducers are known for their durability and strength, making them ideal for high-pressure and heavy-duty applications. Find the perfect fit for your needs at the best prices today.

#Forged steel reducer in India#Forged steel reducer online#Best Forged Reducer Online#Pipe Reducer online#Buttweld Pipe Reducer online

0 notes

Text

Carbon steel threaded flange

It plays a crucial role in the piping system, connecting pipes and other objects. These components are commonly used for plumbing oil and gas, chemical adjustments, construction, and more. They are advantageous for various types of threaded fittings, enhancing the strength and durability of pipe connections. Additionally, you can purchase threaded flange fittings online; their benefits and applications are outlined below.

#Carbon and alloy pipe bends online#Carbon steel slip on flang online in India#Carbon steel threaded flanges online#End lap joint online#Carbon Steel Slip-on Flanges online#Pipe cross online#Pipe Cross online in India#Forged steel reducer online

0 notes

Text

IBR Flanges: Ensuring Safety and Reliability with Tubefit Industries

IBR Flanges: A Comprehensive Guide by Tubefit Industries

IBR flanges are necessary element used in industries requiring high-pressure applications, such as power plants, refineries, and chemical plants. The term "IBR" stands for Indian Boiler Regulations, a set of standards established to ensure the safety, reliability, and efficiency of boiler systems. These flanges are designed and manufactured to meet stringent specifications set by IBR, ensuring they can withstand the most demanding environments.

At Tubefit Industries, we specialize in producing high-quality IBR flanges that cater to various industrial needs. Our IBR flanges are manufactured from superior-grade materials, offering exceptional durability, corrosion resistance, and long-term performance. Whether you're working with steam, water, or other high-pressure fluids, Tubefit Industries provides flanges that comply with IBR standards, ensuring the safety and operational integrity of your system.

Key Features of IBR Flanges by Tubefit Industries:

Compliance with IBR Standards: All flanges are manufactured in strict adherence to the Indian Boiler Regulations, ensuring high safety and quality standards.

Wide Range of Materials: Available in materials like carbon steel, stainless steel, and alloy steel, suitable for various industrial applications.

Precision Engineering: Our flanges are crafted using advanced technology, ensuring precise dimensions and a perfect fit for reliable and leak-proof connections.

Corrosion Resistance: Tubefit Industries' IBR flanges are designed to resist corrosion and maintain their strength even in harsh environments.

Customizable Options: We offer customized IBR flanges based on client specifications, ensuring compatibility with specific system requirements.

If you need top-notch IBR flanges for your high-pressure systems, Tubefit Industries is your trusted partner. Our Dictionary to quality, reliability, and customer contentment ensures that you get the best product for your industrial applications.

Contact us at:

Phone: 9999622266, 9999010233

Email: [email protected]

Website: https://www.tubefitindustries.in/ibr-flanges/

Add: Kila Number 20-21 Pali Nekpur Road Pali Faridabad-121004

#IBR Flanges#IBR Tees#IBR Elbow#IBR Syphon#IBR Reducers#IBR Pipe Fittings Manufacturer in India#IBR Fittings#IBR Pipe Spools#IBR Forgings#IBR Steam Headers Manufacturer#Indian Manufacturers#Industrial Pipe Fittings#IBR Fittings India#Precision Pipe Fittings#Tube Fit Industries#Flanges Manufacturers#Pipe Fittings India#Industria lPipe Components#IBR Standards#Quality Pipe Fittings#Pipe Fitting Solutions#Boiler Components#Flanges#Industrial Flanges#Steel Flanges#Manufacturing#Boiler Manufacturing

0 notes

Text

Incoloy Alloy 800/800HT/825 Forged Fittings

Introduction

In the world of industrial manufacturing and engineering, materials that can withstand extreme environments are crucial. Incoloy alloys, particularly Incoloy 800, 800HT, and 825, are known for their exceptional performance in high-temperature and corrosive environments. These alloys are widely used in various industries, including chemical processing, power generation, and oil and gas. Forged fittings made from these alloys are essential components in these industries due to their superior mechanical properties and resistance to oxidation and carburization. Ranflex Metals, a leading manufacturer in the field, specializes in producing high-quality Incoloy Alloy 800/800HT/825 forged fittings, ensuring reliability and durability in critical applications.

Understanding Incoloy Alloys

Incoloy 800

Incoloy 800 is an iron-nickel-chromium alloy with excellent resistance to oxidation and carburization at high temperatures. It maintains its structural integrity and strength even when exposed to extreme temperatures, making it ideal for applications such as furnace components, heat exchangers, and petrochemical processing equipment. Its composition typically includes 30-35% nickel, 19-23% chromium, and trace amounts of aluminum and titanium, which enhance its stability and resistance to scaling.

Incoloy 800HT

An enhanced version of Incoloy 800, Incoloy 800HT contains higher levels of carbon, aluminum, and titanium, providing improved creep and stress rupture properties. This makes Incoloy 800HT particularly suitable for applications requiring prolonged exposure to high temperatures. Industries that benefit from this alloy include nuclear power plants, where it is used in steam generators and heat exchangers, and petrochemical processing, where it finds applications in high-temperature reaction vessels and catalytic support grids.

Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This unique composition offers outstanding resistance to both reducing and oxidizing acids, as well as to stress-corrosion cracking. It is extensively used in environments where sulfuric and phosphoric acids are present. Typical applications of Incoloy 825 include chemical processing, pollution control equipment, and oil and gas well piping.

The Role of Forged Fittings

Forged fittings are critical components in piping systems, providing secure and leak-proof connections. The forging process involves shaping metal using compressive forces, resulting in a product with a dense and uniform grain structure. This enhances the mechanical properties of the fittings, making them stronger and more reliable than cast or machined fittings.

Ranflex Metals: Excellence in Forged Fittings

At Ranflex Metals, we pride ourselves on producing top-quality Incoloy Alloy 800/800HT/825 forged fittings. Our state-of-the-art manufacturing facility and stringent quality control measures ensure that each fitting meets the highest standards of performance and durability.

Our Product Range

Elbows: Available in various angles, our Incoloy elbows provide smooth directional flow in piping systems, reducing turbulence and pressure drop.

Tees: Our tees are designed to distribute fluid flow evenly, ensuring efficient operation of your piping network.

Reducers: Used to connect pipes of different diameters, our reducers ensure a seamless and secure transition.

Couplings: Our couplings provide a reliable connection between two pipes, ensuring leak-proof performance.

Quality Assurance

Ranflex Metals is committed to delivering products that meet or exceed customer expectations. Our Incoloy forged fittings undergo rigorous testing, including:

Chemical Analysis: Ensuring the precise composition of the alloy.

Mechanical Testing: Verifying tensile strength, hardness, and impact resistance.

Non-Destructive Testing: Detecting any surface or internal defects to ensure the integrity of the fittings.

Conclusion

Incoloy Alloy 800, 800HT, and 825 forged fittings are indispensable in industries where high-temperature and corrosion-resistant materials are required. Ranflex Metals stands out as a trusted supplier, providing high-quality forged fittings that meet the demanding requirements of various applications. Our commitment to excellence and customer satisfaction makes us a preferred choice for Incoloy forged fittings. When it comes to ensuring the reliability and durability of your piping systems, trust Ranflex Metals to deliver the best.

#Incoloy Forged Fittings#Incoloy Alloy 800/800HT/825 Forged Fittings#ASTM B564 Incoloy Alloy UNS N08800/11/25 Forged Fittings#825 Incoloy Alloy reducer#800 Incoloy elbow#800 stainless steel tee#601 Incoloy Alloy cross#825 Incoloy Alloy stub closes#825 Incoloy Alloy channel twist#800 Incoloy Alloy short range elbow Suppliers India

0 notes

Text

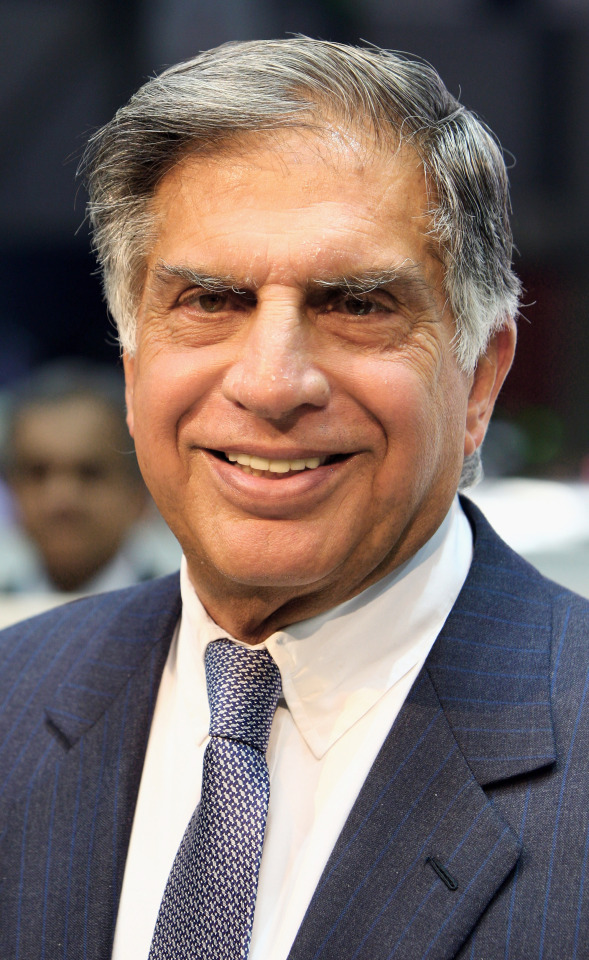

Ratan Tata

Indian business tycoon who turned his family’s Tata Group into a global player, and invested heavily in British industry

Ratan Tata, who has died aged 86, was India’s most celebrated industrialist. He modernised the unwieldy business empire founded by his great grandfather in the 19th century and internationalised it. In the process he spread his interests into western countries, with mixed results.

For the UK, that included the £271m purchase of the Tetley Group in 2000, followed more controversially by the acquisition of the steel company Corus for £6.2bn in 2007. Then, in 2008, Tata, himself a car enthusiast, added the troubled Jaguar Land Rover motor business for a further £1.75bn.

He joined the family firm, Tata Steel, in 1962. Educated in the US, and newly qualified as an architect, the young Tata had, he said, no intention of returning to India. But family ties won out. When his ailing grandmother, Navajbai, who had raised him, asked him to return he did so. He was soon promoted, building his reputation with tough reorganisation, followed by more troubleshooting at the electronics and textile companies.

In 1981, he was made chairman of Tata Industries, and found himself confronting an assortment of separate businesses, with different ownership patterns over which there was little formal control. He made a blueprint for reorganisation, having spent time at the Harvard Business School, but it was rejected after opposition from semi-autonomous bosses.

However, in 1991, the 81-year-old patriarch of the group, JRD Tata, chose him as his successor as the overall chairman. Asked why, he replied: “He has a modern mind.”

Tata soon demonstrated it with a tough programme of reshaping that, against continuing opposition, brought closures, job reductions, and the departure of the heads of the steel, hotel and chemical businesses.

He began to focus more on brands and less on heavy industry, and he benefited from the deregulation of Indian industry championed by Rajiv Gandhi. As part of it, he took the company more heavily into the motor industry. Tata lorries already dominated Indian highways, but now he moved into the car business in line with his own enthusiasms. While always seen as a man of modest habits, he had his own lovingly maintained collection of high-powered and classic cars, and delighted in driving them along Mumbai’s Marine Drive most Sundays.

Tata produced what was called “the first Indian car”, designed by and for Indians, in 1998. Ratan did some of the first drawings himself. The Tata Indica was a success. But when he went further a decade later, and the company conceived the Nano, a tiny saloon described as the world’s most affordable car at a price of about £2,000, the project failed. Such a cheap car was not enticing even to those “on two wheels” whom he hoped to attract.

In 1999 Tata had travelled to Detroit to discuss the sale of the motor business to Ford, only to be asked why his firm had gone into the passenger car business when it clearly knew nothing about it. Later he would turn the tables, buying underperforming Jaguar Land Rover from Ford and reviving it.

With sell-offs and cutbacks, Tata reorganised the group into 98 operating companies from more than 250, reducing the labour force by more than a third. He forged alliances with foreign companies and went into information technology.

He stepped down in 2012, observing the compulsory retirement rule he had himself introduced, but was still regarded as “chairman emeritus” and was brought back unhappily for a few months when his successor was sacked four years later.

His most shocking day came in 2008, when terrorists took over the Tatas’ Taj Mahal hotel on the front at Mumbai with great loss of life. The company has continued to support staff affected and the families of those who died.

Ratan was born in Mumbai, into the large Parsi Tata family, whose wealth came from a scattered collection of businesses including textiles, hotels, engineering, steel and tea. His father, Naval, had been adopted by the son of the founder, Jamsetji Tata. After Naval and his wife, Soonoo, separated when Ratan was seven, the child was brought up with his younger brother, Jimmy, by his grandmother in a grand Tata mansion in central Mumbai.

Aged 17 he was sent to the US to attend Riverdale Country school in New York City, from where he entered Cornell University in Ithaca, New York. He studied engineering before switching to architecture, graduating in 1959. He worked as an architect for a while in Los Angeles before returning to India, and Tata Steel.

In his 20 years at the helm, Tata’s sales grew by 22% annually and its international revenues rose from a quarter to 58% of the total, while Tata Consultancy Services became Asia’s largest software company.

His British investments have been among his less successful. Corus was bought for an over-the-top £6bn just before the global financial crash devastated the industry. Tata claimed it as “the first big step that Indian industry has taken as a global player”. It was later described by a senior Tata executive as “worthless”. The firm is currently negotiating terms of new investment at Port Talbot, which would be accompanied by hundreds of redundancies, while huge plants on Teesside and Scunthorpe have already been closed or sold for a nominal sum.

Jaguar Land Rover was initially a happier story. Tata’s major investment, including in research and development, made the company for a while the largest foreign investor in British industry. But eight years of profits have been followed by losses since 2018.

Surveying the British scene in 2011, Tata told the Times: “Nobody seems to want to exert the effort to make the UK truly competitive. It’s a work ethic issue. In my experience in both Corus and JLR, nobody is willing to go the extra mile.”

He was a major figure in the international business community, close to US politicians as well as the Indian government, advising the former prime ministers Gordon Brown and David Cameron, and sitting on the boards of multinational institutions.

He was also known as a major philanthropist. Many of the Tata companies were owned through trusts he chaired, and huge sums were provided for medical research and university projects both in India and abroad, particularly in the US, where a number of campuses have buildings bearing his name.

A softly spoken man, renowned for his courtesy, he never married, although he described himself as having come close four times. He was known for living modestly, although his recreations included flying his private jet and driving his collection of expensive cars, as well as a speedboat. He was noted for his love of dogs. The Tata headquarters in Mumbai had kennels and made provision for street dogs, and he was a donor to canine charities. In 2014 he was made GBE.

He is survived by Jimmy, by his stepmother, Simone, a half brother, Noel, and two half sisters, Shireen and Deanna.

🔔 Ratan Tata, businessman, born 28 December 1937; died 9 October 2024

Daily inspiration. Discover more photos at Just for Books…?

6 notes

·

View notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Embracing the Future: Virat Special Steels in FY 2024-25 !🌟

As we enter the new fiscal year, Virat Special Steels is poised to navigate the evolving landscape of the steel industry with agility and foresight. Our journey is fueled by innovation, commitment to sustainability, and a relentless pursuit of excellence.

What’s on the Horizon?

Sustainable Practices: We’re doubling down on eco-friendly production methods and reducing our carbon footprint, ensuring a greener tomorrow.

Technological Advancements: Automation and digitalization are at the forefront, enhancing our operational efficiency and product quality.

Global Market Dynamics: We’re adapting to the shifting trade winds, ready to seize opportunities in the global marketplace.

Our Commitment:

Quality and Diversity: Our extensive inventory, including die blocks (DIN 1.2714, DB6) and a wide range of tool steels, is set to meet the dynamic needs of various industries.

Customer-Centric Approach: With over five decades of expertise, we remain dedicated to providing optimal material selection and technical advice.

Looking Ahead The fiscal year 2024-25 is more than just a period; it’s a canvas for us to paint our growth story. With the steel industry projected to grow steadily, Virat Special Steels is ready to forge ahead and contribute to India’s industrial prowess.

Join us as we continue to shape the world with our steel - one innovation at a time.

For more information visit https://www.viratsteels.com/

Any further queries feel free to contact us : Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DB6#db6steel#din2714#din2344#h13steelmanufacturer#h13steelbarexporter#h13toolsteels#h13diesteel#h13steel#h13

2 notes

·

View notes

Text

Specification and Uses of Forged Fittings

Top Quality Forged Fittings Manufacturers in India

Regent Steel Inc is the leading Forged Fittings Manufacturers in India. Our products, which are made in accordance with international standards, are extensively used by the petrochemical, chemical, oil and gas, and other industries. We are the top Molybdenum Rod Manufacturers and Carbon Steel Flanges Manufacturers in India.

Forged Fittings Specification

Material: Stainless steel, carbon steel, alloy steel, etc.

Size Range: 1/8" to 4" or larger

Pressure Ratings: 3000#, 6000#, 9000# or custom

Types: Elbows, tees, couplings, unions, crosses, caps, plugs, reducers, etc.

Design Standards: ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, etc.

Applications of Forged Fittings

Water Treatment Plants

Fertilizers Industry

Marine & Industrial

Oil and Gas Industry

Aircraft Industry

India’s leading Flanges Manufacturer

Regent Steel Inc is a top Forged Fittings Manufacturers in India.We appreciate how crucial having trustworthy and durable flanges are for your piping systems, thus we are committed to offering flanges that adhere to the highest standards of quality and performance. We are the top Flange Manufacturer in Pune and Flange Manufacturer in Kolkata.

Contact us:

Website: forgefittings.com

Mail: [email protected]

Product source: Forged Fittings Manufacturers in India and Carbon Steel Flanges Manufacturers in India.

You may also like: Flanges Manufacturers in India

#Forged Fittings Manufacturers in India#Forged Fittings Manufacturers#Carbon Steel Flanges Manufacturers#Carbon Steel Flanges Manufacturers in India#Flanges Manufacturers in India#Molybdenum Rod Manufacturers

3 notes

·

View notes

Text

Mild Steel Pipe Fittings in Uttar Pradesh

Meghmani Metal is a prominent Manufacturer, and Supplier of Mild Steel Pipe Fittings in Uttar Pradesh, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Meghmani Metal is a prominent manufacturer and supplier of MS (Mild Steel) Fittings in India, with a strong focus on maintaining quality and ensuring customer satisfaction. We have the capacity to manufacture a wide range of mild steel fittings, catering to different sectors and client needs. Our product range includes various types of MS fittings such as elbows, tees, reducers, caps, and flanges. As one of the leading MS fittings manufacturers in India, we ensure our products meet or exceed market requirements. MS fittings commonly change the direction of fluid flow, connect pipes of different sizes, and terminate pipes in piping systems. Industries like oil and gas, petrochemicals, power plants, and construction widely use them due to their good mechanical properties and cost-effectiveness. Specifications: Size Range & Type Seamless Butt-Weld Fitting: From 1/2″ - 10″ | Welded ButtWeld Fitting: From 1/2″ - 48″ Dimensions: ASME, ANSI B16.9, ASME B16.28, MSS-SP-43, BS1560, BS4504, BS10 Bending Radius: Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D Thickness of Fitting: SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 Size Ranges: ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. Process of Manufacturing: Push, Press, Cast, Forge. Applications: Plumbing Systems Oil & Gas Industry Construction Chemical Industry Automotive Industry Power Plants FAQS: What is the difference between MS pipe fittings and stainless steel pipe fittings? Manufacturers make MS pipe fittings from mild steel, which is more cost-effective but less resistant to corrosion compared to stainless steel. Stainless steel fittings are more durable and corrosion-resistant but come at a higher cost. Can MS pipe fittings be used for high-temperature applications? MS pipe fittings are suitable for moderate-temperature applications. However, for extreme high-temperature conditions, materials like stainless steel or alloy fittings are recommended. Meghmani Metal is a prominent Manufacturer, and Supplier of Mild Steel Pipe Fittings in Uttar Pradesh, India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Best Forged Steel Reducer in India Online

Shop for the best forged steel reducers in India. Find premium quality reducers for your piping needs at competitive rates.

#Forged steel reducer in India#Forged steel reducer online#Best Forged Reducer Online#Pipe Reducer online#Buttweld Pipe Reducer online

0 notes

Text

Understanding Pipe Bends: Types, Functions, and Their Role in Fluid Transportation Systems

The piping industry requires pipe bends to recirculate gases and liquids. These are available in a wide range of forms, which are made available as per the variety and quality, as well as to ensure that they are free from defects. These are available as per the requirements of the customers, wherein the requirements of the customers can be taken care of as per their needs. These are completely different from elbows, and their function is to reduce pressure drop and wear in the system. These are customized, which works towards reducing the disturbances. We also offer pipe bends online.

#best steel pipe end cap#Carbon Steel Slip-on Flanges online#Pipe cross online#Pipe Cross online in India#Forged steel reducer online#Best forged elbow online in India

0 notes

Text

The Evolution of Alloy Wheel Manufacturing

Alloy wheels are crucial for the modern vehicle as they are aesthetically appreciated and functionally leveraged. Such a variety of wheels improves the car's performance, reduces weight, and improves fuel efficiency for high-performance car lovers and manufacturers. Alloy wheels are typically an amalgamation of many metals, offering better strength and corrosion-resistant characteristics than steel wheels. Alloy wheel manufacturers in India have aptly revolutionized this automotive industry by manufacturing the ultimate, high-quality wheels with accurate, advanced designs. The phenomenon results from an increasing demand for both performance and style. This article explores the driving factors behind the increased number of companies manufacturing alloy wheels. The resultant influence on the automobile market will be studied in this aspect.

The Materials Behind Alloy Wheels

The material used to construct it is at the heart of every alloy wheel. As mentioned above, alloy wheels are generally made from a perfect mixture of metals. This has been a very effective lightweight solution to the needs of the automotive world. The harsh environmental conditions exposed to these wheels make it the ideal choice. Some alloy wheel manufacturers in India even add magnesium into the alloy to give strength without adding weight. This mix of materials enhances wheel performance, providing better acceleration, handling, and braking efficiency, especially for high-performance vehicles.

Innovation in Design and Production

Alloy wheel manufacturers have continually pushed the boundaries of design and technology. The use of new technology and machines has revolutionized the way wheels are designed, giving manufacturers the possibility of creating very intricate, precise, and lightweight structures.

This alloy wheel is good-looking, and alloy wheels companies in India are now producing them with new-age manufacturing technologies like casting, forging, and flow-forming. Casting gives the capability to make a considerable volume while keeping costs low, and forged alloy wheels possess superior strength to regular alloy wheels. Flow-forming is the newer technology and combines the virtues of casting and forging, thereby delivering a light but strong wheel. It is sought after by those who prefer a high-performance car.

Customization and Aftermarket Demand

The demand for alloy wheels extends beyond factory-fitted options, with many vehicle owners opting for aftermarket modifications. Alloy wheel companies carry a variety of custom designs, sizes, and finishes to match the requirements of the different vehicle types and individual preferences. This trend also gave life to a flourishing aftermarket market, where car enthusiasts pursue uniqueness and superior, high-performance wheels for their vehicles.

The alloy wheels companies in India are developing wheels that can be used with various tires and vehicle models. This helps the companies offer customization to cater to a broader market, from average drivers to racing enthusiasts. The variety of options available in finishes, like matte, gloss, and chrome, adds to the allure of alloy wheels.

The Future of Wheel Manufacturing

It is safe to say that the future of manufacturing wheels looks bright and is driven by continuous advancements in materials, design, and production techniques. As this technology advances, manufacturers will add even lighter, and more durable, materials to their designs. High-performance wheels are expected to increase in demand because of the growth of electric and hybrid cars. Alloy wheels will continue to be an essential part of the current revolution in the automobile industry, characterized by the compatibility of strength, reduced weight, and aesthetic appeal.

Conclusion

Alloy wheel companies and manufacturers like Advantec Wheels have recently shaped the modern automotive landscape. Innovation, sustainability, and customization have set aside mere functional purposes for alloy wheels and have instead positioned them as intelligent, stylish features for contemporary vehicles. Indeed, alloy wheel manufacturing will hardly be left out of the game as soon as the needs of performance enthusiasts and everyday drivers become relevant to be addressed through high-quality products.

0 notes

Text

Top Industrial Valve Manufacturers in India

We are trusted and leading industrial valve manufacturers in India and global exporters of industrial applications. Headquartered in Coimbatore, India, and established in 2013 by an industry specialist, our company has achieved a higher position as a top valve manufacturer in India with high quality, durability, and versatility apart from buying the finest industrial valves at the global level.

1. Control Valve - We are one of the top control valve manufacturers in India. It fluid flow or pressure by varying the size of the flow passage based on signals from a controller. It is essential in maintaining the desired process conditions in industries like chemical and oil & gas.

We provide valves in the following description

1. Available Materials: Ductile Iron, Cast iron (WCB, WCC, WC6), LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55).

2. Class: 150 to 2500.

3. Nominal Pressure: PN10 to PN450.

4. Medium: Air, Water, Chemical, Steam, Oil.

5. Operations: Electric Actuated and Pneumatic Operated.

6. Size: 1/2”- 24”.

7. Ends: Flanged, butt weld, socket weld, threaded.

Electric Actuator Details:

1. Torque: 3 – 9 nm.

2. Operating pressure: 8 Bar.

3. Port Connection: NPT1.4”.

4. Mounting Base: ISO5211.

5.Temperature: -20°C to +80°C.

Pneumatic Actuator Configuration:

1.4-20 amp.

2. Pneumatic single-acting actuators.

3. Pneumatic double-acting actuators.

4. Pneumatic rotary actuators.

5. Pneumatic Scotch and Yoke actuators.

6. Pressure: 228 bar.

Temperature Ranges:

1.Standard: -4°F to 200°F (-20°C to 93°C).

2.Low: -40°F to 176°F (-40°C to 80°C).

3.High: 0°F to 300°F (-18°C to 149°C).

2. Cryogenic Valve - We are famous for our design and the best cryogenic valve manufacturers in India. It is designed to operate at extremely low temperatures and is used in the transport and storage of liquefied gases like nitrogen, oxygen, and LNG. They ensure safe control and isolation in cryogenic systems.

We supply valves in the following description:

1.Materials: SS304, SS316, CF8M, CF8, F51, F55, F53, WCB, WC6, WCC, LCB, LCC.

2. Class: 150 to 800.

3. Nominal Pressure: PN25 to PN100.

4. Size: 1/2” to 24”.

5. Operations: Lever Operated, Gear Operated, Handwheel Operated, Electric Actuated, and Pneumatic Actuated.

6. End Connection: Buttweld, Threaded or welded, lug, and wafer

3. Pressure Reducing Valve - It is one of the largest pressure-reducing valve manufacturers in India. It automatically lowers incoming pressure to a desired downstream level, ensuring safe and consistent pressure for sensitive equipment. It is widely used in water distribution and gas systems

Description:

1. Materials: Ductile Iron, WCB, WCC, WC6, LCB, LCC, SS304, SS316, Cast iron

2. Size: 1/2″ to 24″.

3. Nominal Pressure: PN10 to PN100.

4. Class: 150 to 600.

5. Ends: Threaded, Buttweld, Socket weld, Flanged

4. Safety Valve - The leading Safety Valve Manufacturers in India. It opens to release pressure when it exceeds a preset limit, protecting equipment from overpressure damage. It is commonly used in steam boilers, pressure vessels, and pipelines.

Description:

1. Body Material: Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] , WCB, WC6, SS304, SS316, DUPLEX STEEL.

2. Class – 150 – 2500

3. PN 10 – PN 450

4. Size – ½ – 24”

5. Ends- Butt welded, Socket welded, Flanged, Threaded

5. Check Valve - We are the largest check valve manufacturers in India that allow liquid to flow in one direction and prevent backflow, protecting systems from damage caused by reverse flow. It is used in applications like water systems, oil pipelines, and pumps.

Description:

1. Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), Duplex and Super duplex steel [F51, F53, F55] Forged Steel A105, A105N, F11, F22, F304, F316, F91] Alloy20, Hastelloy, ALBR.

2. Size- ½” – 80”

3. Class-150 – 2500; PN10 – PN-450

4. Ends-threaded, socket weld, butt weld, flanged, lug, wafer

#industrial valve manufacturer#gate valve manufacturers#control valve manufacturers in India#cryogenic valve manufacturers in India#pressure-reducing valve manufacturers in India#Safety Valve Manufacturers in India#check valve manufacturers in India

0 notes

Text

Pioneering Excellence in Industrial Valve Manufacturing Since 1977

Introduction

Prime Industrial Valves Mfg. Co., established in 1977, is a premier manufacturer of industrial valves, headquartered in Ahmedabad, India. Over the years, the company has emerged as a leader in the industrial valve sector, known for its commitment to quality, innovation, and customer satisfaction. With a robust infrastructure, dedicated R&D capabilities, and a highly skilled workforce, Prime Industrial Valves Mfg. Co. continues to set benchmarks in the industry.

Vision and Mission

Vision: To be a globally recognized leader in the industrial valve manufacturing industry, delivering innovative solutions tailored to the evolving needs of our clients.

Mission: To provide high-quality, cost-effective, and timely solutions while ensuring superior customer satisfaction and environmental sustainability.

Infrastructure and Certifications

Prime Industrial Valves Mfg. Co. operates a state-of-the-art manufacturing facility in Ahmedabad, equipped with cutting-edge technology. The facility boasts an in-house casting unit renowned for its precision and excellence. A dedicated R&D unit drives innovation and continuous improvement, enabling the company to stay ahead in the competitive market.

The company’s commitment to quality and efficiency is validated by prestigious certifications, including:

ISO 9001: For adhering to international quality management standards.

NSIC Certification: Demonstrating our capabilities as a trusted MSME partner.

IBR Certification: Ensuring compliance with the Indian Boiler Regulations.

Product Portfolio

Prime Industrial Valves Mfg. Co. offers a comprehensive range of valves and related products, tailored to meet the diverse needs of industries worldwide. Each product is manufactured from high-quality materials such as Forged Steel, Alloy Steel, Stainless Steel Valve, and Duplex Steel. Here’s an overview of the product range:

1. Gate Valves

Used in water and sewage systems, oil and gas industries, and various industrial processes, gate valves ensure reliable flow control.

2. Globe Valves

Ideal for water and wastewater systems, chemical processing, oil and gas applications, and power plants. Globe valves are designed to regulate flow effectively and withstand challenging environments.

3. Ball Valves

Widely used in water and wastewater treatment, HVAC systems, oil and gas industries, and chemical processing, Ball valves offer durability and precise control. With advanced sealing technologies, they ensure leak-proof operation.

4. Butterfly Valves

Designed for water and wastewater treatment, industrial processes, and pipelines, Butterfly Valves provide efficient flow regulation and are available in various configurations to meet specific needs.

5. Check Valves

Preventing backflow, Check valves are essential for water distribution systems, pumping stations, and fire protection systems. Their robust design ensures long-term reliability.

6. Strainers

Used in water systems, HVAC systems, industrial processes, marine applications, and petrochemicals, strainers ensure the removal of debris and particles, protecting downstream equipment.

7. Needle Valves

Perfect for laboratories, hydraulic systems, fuel systems, and aerospace industries, needle valves provide precise flow control, ensuring accuracy in critical operations.

8. Piston Valves

Used in hydraulic and pneumatic systems, chemical processing, and water treatment, Piston valves are known for their reliability and ability to handle high-pressure environments.

9. Pressure Reducing Valves

Designed for water, gas, steam, and hydraulic systems, Pressure Reducing valves regulate pressure effectively, enhancing system efficiency and safety.

10. Knife Edge Gate Valves

Ideal for wastewater treatment, mining, pulp and paper, and chemical processing, Knife Edge Gate Valves are built for rugged environments and can handle slurry and viscous media efficiently.

11. Specialized Products

Moisture Separators: For steam systems and compressed air applications, ensuring dryness and efficiency.

Blow Down Valves: For boilers and pressure vessels, helping in the effective removal of impurities.

Flush Bottom Valves: Facilitating cleaning and maintenance in industrial processes, ideal for reactors and tanks.

Steam Traps: Enhancing efficiency in heating systems, steam boilers, and autoclaves.

2-3 Way Motorized, Cylinder & Pneumatic Control Valves: Offering precision control in automation systems, designed for advanced industrial needs.

Industries Served

Prime Industrial Valves Mfg. Co. caters to a wide array of industries, ensuring customized solutions for each sector’s unique requirements. Key industries include:

Oil and Gas: Valves designed to handle high pressure and corrosive environments.

Chemical Processing: Specialized valves for handling aggressive chemicals and high temperatures.

Water and Wastewater: Solutions for efficient water management and distribution systems.

Power Generation: High-performance valves for power plants and energy systems.

HVAC Systems: Components ensuring optimal flow and temperature control.

Food and Beverage: Hygienic and durable valves for stringent industry standards.

Marine and Petrochemicals: Robust valves designed for challenging environments.

Operational Philosophy

Prime Industrial Valves Mfg. Co. operates on the philosophy of "QUALITY, COST, and DELIVERY." This ensures that every product not only meets stringent quality standards but is also cost-efficient and delivered on time to exceed customer expectations. The focus on maintaining high standards across all operations has solidified the company’s reputation for excellence.

Research and Development

Innovation is the cornerstone of Prime Industrial Valves Mfg. Co. The R&D unit is equipped with the latest technology and software tools, enabling the design and development of advanced valve solutions. Recent innovations include high-efficiency sealing systems, corrosion-resistant materials, and automation-compatible valves. Continuous research helps the company introduce new products and improve existing ones, ensuring alignment with global industry trends.

Commitment to Sustainability

As a socially responsible organization, Prime Industrial Valves Mfg. Co. is committed to environmental sustainability. The company employs eco-friendly manufacturing practices and materials, minimizing its environmental footprint while maximizing operational efficiency. Initiatives such as energy-efficient production processes and recycling programs reflect the company’s dedication to a greener future.

Global Reach and Export Capabilities

Prime Industrial Valves Mfg. Co. has established a strong presence in both domestic and international markets. Key export regions include the Middle East, Southeast Asia, Africa, and Europe. By maintaining high-quality standards and offering competitive pricing, the company has successfully built lasting relationships with clients worldwide. Customized solutions and efficient logistics ensure timely delivery, enhancing customer satisfaction.

Conclusion

Prime Industrial Valves Mfg. Co. stands as a testament to excellence in the industrial valve manufacturing industry. With a legacy of over four decades, the company has consistently demonstrated its expertise in delivering high-quality, innovative, and cost-effective solutions. Guided by its core values of quality, efficiency, and customer focus, Prime Industrial Valves Mfg. Co. is poised to continue its journey of excellence and innovation in the years to come.

youtube

0 notes

Text

Top Quality Flanges Manufacturer In India

Metalica Forging Inc. is a leading Flanges Manufacturer in India. Flanges are essential components in piping systems, widely used to connect pipes, valves, pumps, and other equipment to form a secure and leak-proof structure. Made from materials like stainless steel, carbon steel, and alloy steel, flanges come in various types, including slip-on, weld neck, blind, and threaded, each designed for specific applications and pressure ratings.

Flange Supplier various industrial pipe flanges from 12″NB to 48″NB. Flanges are used as connectors in piping systems to join pipes to other piping systems, such as tees, elbows, reducers, valves, and other piping equipment. is one of the largest Flange Suppliers in India.

We cater to our clients’ vast global demand, spread across 5 continents and around 80 countries. Our BS 4504 Carbon Steel Forged Flange is reputed and well-known across the globe for its reliability and quality. We treat our clients as partners by providing them with our products and services. Flanges Manufacturers are used in various parts of India. Other Product: JIS Flanges Manufacturer in India

0 notes