#china two shot plastic parts factory

Explore tagged Tumblr posts

Text

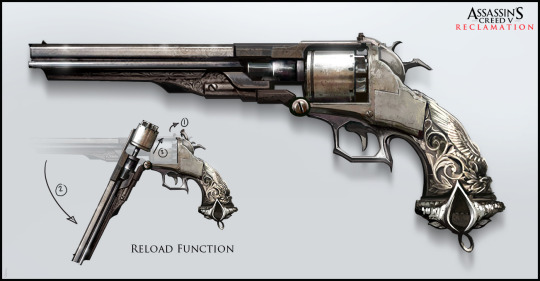

Wait, Zhao Yunlan's gun is actually a...?!

(I've never claimed production meta for @guardianbingo before, but after the amount of time and research I put in on this, I feel like I've earned the "Zhao Yunlan's Gun or Whip" square, haha)

SO. GUYS.

Maybe this is something fandom as a whole figured out back in 2018, but I, who didn't hear of Guardian until 2020, did not realize until now and I need to share the knowledge because when I finally noticed, I made an unholy sound.

I've tracked down where Zhao Yunlan's gun came from -- or at least, what it most likely started as. Not the in-universe dark-energy-maybe-uses-bullets-maybe-doesn't-device-that's-best-not-thought-about-too-long, but rather the actual fake-steampunk-revolver-that-is-best-not-looked-at-too-long-because-it's-awful prop.

Y'know, this disaster:

I was actually working on a different Guardian Bingo fill and needed to look something up for continuity, so I'd flipped through a couple of episodes at super high speed trying to find a scene. As luck would have it, one of my skips forward happened to land on the scene I screencapped above, when ZYL confronts Zhang Shi.

Normally we don't get this clear (or this stationary) a shot of the godawful gun prop. I'd assumed all along they had just taken a plastic gun, glued some extra bits and bobs on it to make it look fancy, and hit it with some dry brushing (fun fact: you can watch the paint flake throughout the series; check out the top of the barrel and the side of the cylinder in the above screenshot!) to make it look #steampunk like the abandoned aesthetic of 25% of the show (as I've said before, I have theories about what happened in preproduction, but that's another post). This sort of thing is exactly what I've done for cheap cosplay weapons or background props for film work that aren't going to be seen at HD detail range.

Anyway, since the detail showed up better here than in other shots, I paused the video to look at the random screws and hex bolts (why??) they'd glued on it, since I recalled that I had the aforementioned gun/whip bingo square to fill.

That's when I noticed a detail that had eluded me before: An inverted V shape at the bottom of the grip.

Only looking more closely, that's not an inverted V. It's a symbol that I've seen a whole series of variations of over the past 15+ years... every time there's a new installment of the Assassin's Creed video game series:

So I started hunting. The principal weapons in each game turned up no matches, but eventually I found a gun that looks almost exactly like ZYL's:

It's not a perfect replica, but the details are certainly all there: The stylized logo; the leaves and swirls on the grip; the feathers up the back; even the Victorian scrollwork beneath the barrel.

Now, what's really interesting is that this gun isn't actually from the AC game series. It's part of an elaborate fan project by artist David Paget that started as a class assignment back in 2014. Even though it gathered a bit of steam in the AC fandom and generated a couple of forum role-play groups, OCs and the like, nothing about this artwork was ever connected to a real Assassin's Creed title. So why would there be a physical version of a gun that was only someone's fanart?

This is where the smoking gun (*rimshot*) goes missing, because I can't prove any of this, and it's been long enough that digging through the archives of the internet to find answers is going to take way more time than I can afford to spend on a project I'm not getting paid for. But there are two likely possibilities:

Scenario A: Some employee in a toy factory somewhere in China got told, "This Assassin's Creed franchise is really big, so we need to be producing replicas from those games to sell. Work up some designs." So the employee Googles "assassin's creed gun," finds David Paget's very professional-looking art, and whips up a replica to mass-injection-mold without realizing it's not actually from a game. Later, someone on the cash-strapped Guardian production team needs a gun to mod, and finds a cheap toy revolver on clearance after several years of sitting in storage because there was little demand for a replica of a gun that was never in a game. They buy several, glue hex bolts on the cylinder for reasons unknown, and poof! Instant pseudo-steampunk!

Scenario B: Other fans were involved in the design. Someone did build a 3D model of David Paget's design that's still available on Sketchfab (screenshot below), and it's not unreasonable to assume that other fans could have thought it looked cool and built 3D printable models. Later, someone on the cash-strapped Guardian production team needs a gun to mod, and acquires the 3D print file of one of those models from the interwebs. They mod the file a bit, print some, glue hex bolts on the cylinder for reasons unknown, and poof! Instant pseudo-steampunk!

Personally, I find Scenario A far more likely than Scenario B, for two reasons: First, the hero prop looks more injection molded than 3D printed, especially given the technical state of 3D printing back in 2017-8. And second... Budget-challenged dramas do have a history of picking up bulk video game replicas and using them as cheap props. I made a post back in 2019 about the WoW Horde shields we spotted in a different drama...

Anyway, no firm answers about the source of the hero prop -- the world may never know! -- but we have now confirmed that in some alternate universe (possibly one of the first eighty?), Zhao Yunlan and/or Zhao Xinci is an Assassin.

Wait, wait, wait... *recalls mechanics of how the whole Assassin's Creed frame story is supposed to work* Uh... so... who wants to write a genetic memory explanation for the whole Kunlun -> [lots of lifetimes] -> Zhao Yunlan thing?

.

(I did actually check the catalogue of a friend of mine who makes replicas of props from various media franchises to see if he'd done a commission of the David Paget design, since a surprising number of his custom pieces actually do end up on film and television, but while he has a gorgeous replica of a revolver that actually appears in an AC game, it appears he has not done the Zhao Yunlan gun. I didn't really think it likely, since he's in the U.S., but you never know.)

#guardian#zhen hun#c-drama#guardian bingo#assassin's creed#tv props#it's always fun when my various hats end up stacked on top of one another

142 notes

·

View notes

Note

I remember the movie basically making the old point about “and there’s no women CEO’s :c” and it was like, are you kidding me? The planet is dying and your solution is to make sure some of the CEO’s destroying it are girlbosses?

Loved the movie mostly, especially the set design, but it felt like the message was an afterthought because it was the weakest part of the movie.

I've walked past the Barbie branded selfie booth, sat through the reel of old commercials that precede the previews, and watched Margot Robbie learn to cry, and I’m still not sure what “doing the thing and subverting the thing,” which Greta Gerwig claimed as the achievement of Barbie in a recent New York Times Magazine profile, could possibly mean. This was the second Gerwig profile the magazine has run. I wrote the first one, in 2017, which in hindsight appears like a warning shot in a publicity campaign that has cemented Gerwig’s reputation as so charming and pure of heart that any choice (we used to call them compromises) she makes is justified, a priori, by her innocence. This is a strange position for an adult to occupy, especially when the two-hour piece of branded content she is currently promoting hinges on a character who discovers that her own innocence is the false product of a fallen world. But—spoiler alert!—the point of Barbie’s “hero’s journey” is less to reconcile Barbie to death than to reconcile the viewer to culture in the age of IP.

“Doing the thing and subverting the thing”: I haven’t finished working out the details, but I think the rough translation would be Getting rich and not feeling feel bad about it. (Or, for the viewer: Having a good time and not feeling bad about it.) One must labor under a rather reduced sense of the word “subvert” to be impressed with poking loving fun at product misfires such as Midge (the pregnant Barbie), Tanner (the dog who poops), and the Ken with the earring, especially given that the value of all these collectors’ items has, presumably, not decreased since the film opened. Barbie may feature a sassy tween sternly informing Robbie’s Stereotypical Barbie that the tiny-waisted top-heavy billion-dollar business she represents has made girls “feel bad” about themselves, but if anyone uttered the word “anorexia,” I missed it. (There was a reason Todd Haynes told the story of Karen Carpenter’s life and death with Barbies, and it wasn’t because an uncanny piece of molded plastic has the magical power to resolve the contradictions of girlhood and global capitalism.) There’s a bit about Robbie going back into a box in the Mattel boardroom, but Barbies aren’t made in an executive suite; they come from factories in China. On the one hand, it’s weird for a film about a real-world commodity to unfold wholly in the realm of ideas and feelings, but then again, that’s pretty much the definition of branding. Mattel doesn’t care if we buy Barbie dolls—they’re happy to put the word “Barbie” on sunglasses and T-shirts, or license clips from the movie for an ad for Google. OK, here’s my review: When Gerwig first visited Mattel HQ in October 2019, the company’s stock was trading at less than twelve dollars a share. Today the price is $21.40.

Christine Smallwood, Who Was Barbie?

93 notes

·

View notes

Text

made a great deal

found an Apex 210 ribbon mic, broken jangly ribbon and reeking of cigarette smoke for $40 a couple months ago….

It already had the inner wire mesh layers and any pop filtering fabric removed, and it was missing some screws and had the ribbon screws stripped by the previous owner.

Disassembled it all, washed it, and retensioned the ribbon the day i got it, and it worked but sounded a bit harsh in the highs; likely sounded as good as it ever had up to that point…

The gig bag for this mic smelled disgusting even after multiple washes with TSP substitute and various soap and detergent, so I let that go and replaced it with a padded wine bottle bag but it just isn’t padded enough. Not sure where to find a better padded bag or box that would stow the mic vertically!

Today i got replacement strain relief gland based spirals and they just happen to fit this body, so I added a Neutrik XLR connector and Star quad mic wire with braided shielding to that. Along with some foam and PVC card samples, i was able to deaden the gnarly body resonance that was making the harsh high frequency response. I cut the PVC card samples to make a front and rear rounded-E-shaped wall divider to slot between the magnets and the cup piece of metal that forms the bottom half of the mic. All told, I spent about $10 on the parts used here and wound up with a $50 ribbon mic that performs much better than if I had instantly gone off spending $100 on changing the ribbon thickness and output transformer. I still may give that a shot, but this is suddenly a lot closer to the sound of the AEA R84, whose neodymium magnet and (2”x5mm/2-micron thick) ribbon geometry these Chinese made long ribbons imitate. It is still less sensitive than an RCA type 74b mi-1036G strapped for 250-Ohm output; I believe this Apex output transformer was <200-Ohm impedance from the factory.

This cheap simple change works for any of the yoke-mounted made in China ribbon microphones that may need this, such as the Apex 210 or the improved version model 205, Nady RSM2, Alctron HRM-2, ShinyBox 23, t.Bone R500, SM MC-04, Cascade VinJet, ShinyBox 46, Nady RSM1, Golden Age Project R1 and others may have nearly the same motor and maybe some of the same shortcomings.

Here’s a good article on the subject: http://recordinghacks.com/2008/11/01/chinese-ribbon-microphone-designs/

A note on this PVC card sample stock I used, I have no real clue what I have. It came from a reuse place and they were a steel ring of samples of various colors of this stuff. It doesn’t really bend well and snaps after about 30°. The inside of this stuff is like a closed cell foam while the front and back look the same and form a more solid layer of plastic. Maybe sheets of this stuff were heat pressed from PVC. It’s 1.5-2mm thick and definitely wasn’t meant for this. You could use anything that will fit and stay and where you could fasten two halves with an overlap so that it stays put as a divider between the body and the ribbon motor. I used Ukraine 🇺🇦 colors with yellow on the front side :D

The strain relief was like a PG9 size iirc. Where the original pinch lock passthru strain relief had straight sides, the threads on the new strain relief grab and thread in juuust right, too! Much more like the AEA strain relief, to boot

Further mod ideas:

Replace the yoke with a shockmount like the GAP RSM

Unscrew the yoke flat piece from the piece that threads onto the mic stand and use a post style shockmount more like the one used in the RCA type 44 yoke

Or, replace the thumbscrew thread holes in the frame of the ribbon motor with a threaded insert shockmount bushing

stick some silicone damping instead of the foam

maybe improve sensitivity by using a higher turns ratio transformer

could sew more padding in to the bottle bag

high impedance input circuit or mic pre to pair with these types of things (i already have lots of 150-2200-Ohm inputs, some of which can change)

add a Crown Royal type cloth velvety bag both to pad the mic in the wine bottle bag AND to make the ideal 360° pop filter! They can even be stuffed with some foam and fitted with some fur on the outside to resist wind buffeting, it’s really great for that because it can enclose and keep wind off of the bottom and yoke of the mic as well, even if it is no Rycote zeppelin and dead cat. they even sell some raincoats for the dead cats that don’t make noise as they are hit by raindrops! i just don’t usually do it in the rain

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/this-articollapsible-core/

Collapsible Core

Split pit molds are frequently utilized when the part configuration incorporates complex and undermining outer surfaces. Folding centers are regularly utilized when the part configuration incorporates complex and undermining surfaces on the inside of the part. The plan of a shape which incorporates a folding center is appeared in high precision mould china, which was created to form the top of a doll with an almost uniform divider thickness [12]. The shape depression (14 and 15 together) is framed by two hole embeds 12 and 13, which are burrowed out by a folding center 17. In this plan of automotive mould made in china, the folding center is contained eight sections: 18, 19, 20, 21, 22, 23, 24, and 25. Four of the fragments 18, 19, 20, and 21 are generally three-sided in area and fitted at the corners with a molded external surface in the ideal type of the center. The other four portions 22, 23, 24, and 25 are generally planar in segment and fitted between the corner sections with a shaped external surface to finish the ideal type of the center.

A center pole 37 is situated at the focal point of the center, and forestalls the outspread uprooting of the eight fragments when the folding center is collected. To forestall the pivotal dislodging of the folding center, every one of the eight fragments have a stem 35 with outside strings 35a that draw in the inward strings 39 out of a sleeve 38.

The activity of the folding center depends upon the strings 37b of the center pole 37, and their commitment with the strung way 41 of the sleeve 38. In particular, preceding trim the center bar is turned inside the sleeve so it completely reaches out until its distal (far) end is flush with the finishes of the eight fragments to shape an inflexible center 17. The sleeve with the inflexible center is then positioned in the form cavity and the part is shaped by traditional practice. When the part is hardened, the shape is opened and the formed part is eliminated alongside the center and sleeve. The center pole 37 is then unscrewed from sleeve 38 and eliminated from within the center 17. With no help, the eight portions can implode and be eliminated from within the formed part. The fragments, center bar, and sleeve are then reassembled for the following embellishment cycle.

The folding center plan of oem/odm automotives moulding factory permits complex and undermining highlights to be shaped inside to the formed part. On account of its plan, notwithstanding, a lot of time is needed to collect and dismantle the moving center. To encourage the plan and assembling of molds with folding centers, standard folding center plans have been created and are accessible from various shape base and segment providers. In common plans, the activation of the ejector plate slides the portions along a holding sleeve, which gives a cam activity to implode the center sections during the discharge of the shaped part. This article is from https://www.injectionmouldchina.com/

#automotive mould made in china#carbon fiber cnc manufacturers#china 50 steel mould manufacturers#china cnc machined carbon fiber#china cnc turning and milling metal machining factory work suppliers#china medical device cnc processing suppliers#china mould make services#china mould manufacturer#china precision machining manufacturers#china stainless steel grinding service suppliers#china two shot mold#china two shot plastic parts factory#cnc micro machining brass part manufacturers#cost of injection moulding china#design for injection molding china#high precision mould china#high precision plastic injection mould price#household mould china#injection molded part#injection moulding design china#injection moulding service#moulding company#oem/odm automatives injection overmould factory#oem/odm automotives moulding factory#oem/odm industrial injection mold factory#oem/odm injection mold factory#pipe molds china#precision machined optical components factory#stalinorgel sound#the smithsonian institution39s

0 notes

Text

Steel Industry Import Taxes

At the point when we raised the steel import charge a couple of years prior it hurt many assembling areas who utilized steel in their creation. It additionally hurt more modest organizations, which use steel in their items. US Steel costs have cost our group huge number of additional dollars because of the import burdens that were forced. We told everybody on the off chance that they raise the expense of steel even 100 dollars for each ton we will look to construct the truck beds out of different materials, and when we do we won't ever return to steel. It is weighty, costs gas mileage, rusts, leaving iron oxide streaks on the outside paint. It is by the expense we even still use steel.

On the off chance that the steel organizations in this nation can't run more proficient and get their trade guilds to perform effectively then one ought not anticipate that the public should uphold that industry or purchase their items. We can construct the truck beds out of fiberglass, plastic or composite. We will actually want to construct uni-body shells and make them all the more austerely satisfying. So the organization and the steel industry better start acting responsibly. The vehicle industry likewise endured a shot and a significant number of the vehicles are moving to lighter materials and they won't return once they do on the grounds that the mileage reserve funds in effectiveness is significant too.

We need Brazil as an exchanging accomplice; we need Japan's economy to get back to development. We ought not give a prop to an industry that isn't imaginative and allows their laborers to kick back and do pretty much nothing if any work. The steel association is solid and they don't have faith in difficult hard working attitude like the opposition in their industry. We ought not help lethargy and give an organization an edge. Parting with free fish makes even awesome of us apathetic. This issue is influencing our group and costing our franchisees cash and return for money invested time, because of expanded expenses in new hardware. That harms their families and their capacity to develop their organizations. The import duty of half on steel, harms the remainder of the economy, it harms my group when we need better costs. This makes an imposing business model on steel for two or three steel organizations who are arranging a consolidation. I'm disturbed that we are assaulting American organizations who have won the market by serving clients and giving them what they need as we as a whole vote with our dollar and afterward the public authority makes syndications simultaneously. So obviously restraining infrastructures are Great as long as the public authority makes them. We are happy to see that these steel organizations are currently ready to create steel since the costs are up, yet a portion of these steel factories are shut to sell their energy agreements to different organizations and stay shut, in this manner who are we making a difference? Absolutely not my group; we will presently see occupations for vehicles and so forth move to Mexico and China this would likewise be intended for farm haulers and weighty industry trucks and trailer makers.

Assuming we help one industry briefly and, part with occupations and processing plant ability to different nations for reasons unknown. We are shifting more than one field by doing this. Indeed we won't represent these increments by any means. Screw that, it influences our group when we are making occupations and we all business people are attempting to uncover ourselves from underneath the downturn. It is great to see that organization had the option to re-view at this issue as right on time as July to bring down the import burden and in the long run dispose of it before long in that first year of expanded tax charges. Then, at that point, we can get the whole South American nations in our group as exchange accomplices, we might require them. Click here : steel buildings

To the extent squeezed orange, we can legitimize limitations for reasons of organic product flies, yet for steel, I don't know we can legitimize this now since we didn't sign the Kyoto Deal and presently we are expressing we can't accepting Brazilian steel because of the strategies for assembling harming the climate, two-faced strategy, we ought not go there. Other than we have innovation, modest innovation to forestall these contaminations in any case, we should simply see they are set up and given them access to the market to keep our steel industry on their feet and from getting lethargic, costing our assembling of truck beds excessively, in this manner harming our capacity to make occupations by giving our group the motivation to understand a reasonable benefit in when many little organizations are leaving business and enormous ones avoiding the annoyance of covering bills in their records payable offices by declaring financial insolvency, Kmart, PG&E, Enron, Worldwide Intersection and others in the news of late. We can't uncover America in case we are consistently driving more expenses on different businesses that need assistance as well. For example, the truck building industry, rail vehicle industry, even waste vehicle development is down 30%, school transports, extensions and framework. Steel is utilized for bunches of things and there is huge volumes; what was the issue with the industry that they couldn't make a benefit in the event that they had a little rivalry? Solid endure and that is a central essential of unrestricted economies. Mull over everything.

1 note

·

View note

Text

Injection molded plastic auto parts

Injection molded plastic auto parts gives various preferences contrasted with different materials or production processes. Has been leading and supporting all engineering departments in various areas: being up to date in parts & process design, mold design, FEA analysis, GD&T and automation. Our team of experienced injection molding professionals works closely with automotive OEMs and Tier 1 clients to evaluate and define all technical requirements and therefore optimize the production of impeccable exterior vehicle components. Plastic injection molding is becoming a very popular technique for manufacturing. Automotive plastic injection molding using plastic is a common method of producing parts because it is sustainable and able to serve the increasing demand. Our expertise in chrome plating and wheel trims, along with our two-shot plastic injection molding capabilities, allow us to provide turnkey solutions that support customers in bringing their products to market successfully. KI automotive partners demand high levels of engineering, quality, and project management. Industry manufacturers are increasingly using plastic molded parts. For each of our products, we develop and maintain a Process Quality Document (PQD) that describes all the critical aspects of running that product.

Whether you are for group or individual sourcing, we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Auto Part Mould Factory list to enhance your sourcing performance in the business line of manufacturing & processing machinery. From the raw material to the finished product, checks are carried out scrupulously and randomly, as scheduled by the customer or according to the complexity of the moulded pieces. Because it is auxiliary equipment, it requires no changes to the injection molding machine. Through our EG TranSpire subsidiary, we've been designing, developing, and manufacturing a wide range of components and sub-assemblies for the automotive market for more than 35 years. Letoplast focuses on co-design and engineering, high quality plastic injection moulding, painting and sub-assembling. A Full-Service Plastic Injection Molding Company. The mold is prepared for production right after the principal testing, which shaves off many weeks. SAC Plastics also helps small start-up companies with small production runs bring new parts to market by making high quality custom molded parts available at competitive rates. Many customers choose to source many electrical components through our electronics division of Cypress Industries. 6. The best advantage that can be gotten from the usage of plastic molding application to the car business is the expenses being driven down; it is an assembling method to bring down overhead costs by the utilization of parts from a few assortments of plastic materials.

Arkal's unique one-stop ‘design-to-manufacturing' approach enables its automotive customers to benefit from optimally cost-effective solutions by integrating Smart Product Design, Efficient Process Design and Automated Production under one roof - enabling our clients to meet and exceed aggressive targets for weight reduction, safety performance and cost reduction. WELCOME TO ELITE PLASTIC PRODUCTS, INC. The latest in equipment, computers, and software along with our greatest asset, trained and experienced personnel, allow Quality Mold Shop to provide injection moldings with shortened lead times, quality designs, made-to-last through production mold demands. We provide custom injection molding solutions, ranging from co-development, mold design and raw material expertise to the final delivery of products and services. Primex Plastics is a leading manufacturer of plastic injection molded components. The tools manufactured here in the UK by our partners are used to produce automotive, electronics, medical, engineering and the construction industries plastic parts, components, fittings and enclosures. After going over some technical innovations in this article, we should make a special mention of one of the main applications of plastic injection moulding: parts and equipment for the automotive industry. We prove that beautiful products can take shape using plastic. The ability to produce plastics in a wide variety of appearances, colours, and textures has made them an irreplaceable part of automotive design. Injection molding involves injecting molten material into a mold or pre-design. Complementing our tooling services are 10 injection molding machines, ranging from 50 to 600 ton capacity. In the automotive industry, injection molding is becoming necessary for manufacturers to keep up with competitors and climbing production rates.

Aside from building parts with efficiency and affordability, injection molders have also been instrumental in reducing the cost of heavy metals by opening new material possibilities. Please contact us for more information on the benefits of working with the leading plastic injection mold manufacturers. MVA Stratford is an injection moulding company with a focus on manufacturing and supplying parts to the automotive industry. In addition, our cleanroom allows us to manufacture products for the healthcare industry and we have an ESD room for assembly. Exterior: Plastics are used in many exterior components of the vehicle, including body panels, bumpers, and grilles. Warehousing and engineering at our central U.S. location in Texas, or shipping from our manufacturing facilities in China gives Cypress Industries a unique edge in servicing customers with large custom plastics needs. Injection moulding consists of the high pressure injection of the raw material into a mould which shapes the polymer into the desired shape. Precisely engineered from optimum quality components and using best available technologies, these containers are extensively used in various industries including electrical, automobile and plastic manufacturing industries. Whether you are adopting the injection molding process in your business or seek an understanding of its capabilities, these depictions of how injection molders have shaped the automotive industry will enlighten and inspire you to learn more about this profound technology. Yuval has over 13 years of experience in the Plastic industry, starting in 2005 as a mold designer and project manager at Rimoni Industries. The industry expanded rapidly in the 1940s because World War II created a huge demand for inexpensive, mass-produced products.

Our molds are used to produce plastic and rubber injection molding products in a multitude of applications and industries such as automotive, electronic, and consumer products industries. Custom manufacturer of precision injection molded plastic parts. Our highly experienced staff includes tooling engineers, injection mold designers, programmers, micro and laser welders. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds. Our cutting-edge facilities include much more than injection moulding machinery. KI Industries is a world leader in the contract manufacturing of plastic, decorative parts for the Automotive Industry. KASO's custom automotive capabilities include materials selection to help you evaluate a variety of engineering grade resins. Overmolding can enhance the cosmetic appeal and performance of a product. This greatly improved design flexibility as well as the strength and finish of manufactured parts while reducing production time, cost, weight and waste. We at Quality Mold Shop pride ourselves on Customer Support and providing you, our Customer, with the support to run plastic injection mold production around the clock. As long as we are molding the parts, we will guarantee the molds for the life of the project. Cypress Industries also has additional capabilities including bonding, painting, printing, automotive connector molding, automotive tooling manufacturing and basic assembly of electronic components and plastic products. Welcome to ASPEL, your dedicated global partner for injection molding, complementary manufacturing and logistics solutions.

1 note

·

View note

Text

U.S. Bets On Small, Untested Company to Deliver COVID Vaccine

This undated image provided by ApiJect in July 2020 shows a prototype of their "BFS" prefilled syringe. (ApiJect file photo)

— AP | July 10, 2020 | By Martha Mendoza & Juliet Linderman

This story is part of an ongoing investigation by The Associated Press, FRONTLINE, and The Global Reporting Centre that examines the deadly consequences of the fragmented worldwide medical supply chain.

When precious vats of COVID-19 vaccine are finally ready, jabbing the lifesaving solution into the arms of Americans will require hundreds of millions of injections.

As part of its strategy to administer the vaccine as quickly as possible, the Trump administration has agreed to invest more than half a billion in tax dollars in ApiJect Systems America, a young company whose injector is not approved by federal health authorities and that hasn’t yet set up a factory to manufacture the devices.

The commitment to ApiJect dwarfs the other needle orders the government has placed with a major manufacturer and two other small companies.

“The fact of this matter is, it would be crazy for people to just rely on us. I would be the first to say it,” said ApiJect CEO Jay Walker. “We should be America’s backup at this point, but probably not its primary.”

Trump administration officials would not say why they are investing so heavily in ApiJect’s technology. The company has made only about 1,000 prototypes to date, and it’s not clear whether those devices can deliver the vaccines that are currently in development. So far, the leading candidates are using traditional vials to hold the vaccine, and needles and syringes in their clinical trials.

RELUCTANT SUPPLIER

ApiJect founder Marc Koska never intended to vaccinate the United States. For the past five years, he’s been working on his lifetime mission of creating an ultra low-cost prefilled syringe that would reduce the need to reuse needles in the developing world.

Instead, the company’s biggest customer has become the U.S. government.

ApiJect received a no-bid contract earlier this year from the Defense Department under an exception for “unusual and compelling urgency.” Authorities said the U.S. Department of Health and Human Services, tasked with buying the necessary supplies, “does not have the resources or capacity to conduct procurements necessary to respond to the COVID-19 pandemic,” according to a June 5 military document.

The government promised ApiJect $138 million to produce 100 million of its devices by the end of the year, which will require the company to retrofit new manufacturing lines in existing factories. And it’s offered another $456 million as part of a public-private partnership contract to bring online several new factories to make another 500 million devices to “contain the pandemic spread to minimize the loss of life and impact to the United States economy,” said the document.

These amounts are more than double the per-syringe cost the government is paying other companies for the work.

ApiJect first appeared on the U.S. government’s radar almost two years ago when the company piqued the interest of Admiral Brett P. Giroir, HHS’s assistant secretary for health, at the World Health Organization’s Global Conference on Primary Health Care in Astana, Kazakhstan.

Koska said Giroir was “blown away” by their technology and told them that if a pandemic hit, the strategic national stockpile was going to need a very fast way to get injections filled with vaccines or therapeutics and ready to deliver.

According to Walker, the CEO, ApiJect wasn’t interested in a federal contract — they were aiming to change the developing world with quick, inexpensive injection devices that could save millions of lives.

But at the conference, Walker found himself at a table with Giroir at a luncheon, just two seats apart. The admiral was fascinated by the low-cost injection technology, Walker said, and when Walker showed him the prototype that he always carries in his pocket, Giroir asked how they plan to do this in the U.S.

Walker said he told the admiral that the company wasn’t planning to operate in the U.S. but was struck by Giroir’s enthusiasm.

“He was the first person, if not the only person at the event, who understood the revolutionary nature of this platform,” Walker recalled in an interview with AP. “And he said, ‘Wow this is amazing. You need to do this in the U.S.’”

Walker continued to resist, he said, but Giroir — who is also a doctor specializing in pediatric critical care — “wasn’t big on taking no for an answer,” Walker said.

At Giroir’s urging they presented the prototype injector to U.S. officials. HHS declined to make agency officials available for interviews.

It wasn’t until later, when Walker was introduced by a friend to Col. Matthew Hepburn at the Defense Advanced Research Projects Agency, that a plan for ApiJect to work in the United States began to take shape, he said.

HHS Assistant Secretary for Preparedness and Response Robert Kadlec approved a $10 million contract for ApiJect for research and development in January 2020, according to a document in the federal procurement data system. The company was responsible for securing private investments to create new production lines where the devices would be made over three to five years.

When the pandemic emerged weeks later, officials sounded the alarm about a potential shortage of needles and syringes to deliver a vaccine if and when one became available.

The federal Strategic National Stockpile of medical supplies had only 15 million syringes, according to Dr. Rick Bright, who later left his position at Health and Human Services and filed a whistleblower complaint.

Bright warned White House trade adviser Peter Navarro and his HHS colleagues of a looming needle shortfall, according to a series of emails disclosed in his complaint.

“We are hearing rumblings about the US inventory of needles and syringes … heading to other countries,” wrote Bright. “There is limited inventory in the supply chain, it could take 2+ years to make enough to satisfy the U.S. vaccine needs.”

Navarro said the U.S. would need 850 million needles.

“We may find ourselves in a situation where we have enough vaccine but no way to deliver all of it,” he said in a February memo to the White House coronavirus task force.

He recommended the task force “direct HHS BARDA to initiate a program to identify all alternate vaccine delivery methods and ramp up production.“ BARDA is the Biomedical Advanced Research and Development Authority within HHS.

Suddenly ApiJect’s 5-year plan to mass produce its devices became a sprint measured in months with a new $138 million contract, announced in May, to produce 100 million devices by year’s end.

Jefferies Financial Group is acting as the leader of the public-private partnership with HHS and invested $10 million to help ApiJect build surge production facilities in March. The company said it would try to raise up to $1 billion more. There have been no additional announcements of funding.

Walker said due to nondisclosure agreements with both the government and investors, the company is unable to say what private funding they’ve secured so far.

OPERATION WARP SPEED

On a warm mid-May day in the White House Rose Garden, President Donald Trump introduced “a massive scientific, industrial and logistical endeavor” dubbed Operation Warp Speed.

The idea, he said, was to be ready to distribute a COVID-19 vaccine as soon as it was developed.

“We must not be caught short on our capacity to deliver emergency drugs to Americans in need,” said HHS Secretary Alex Azar.

An estimated 700 million injections may be needed to inoculate the nation — at least two shots for every person, according to the military document.

In early May, the government put in two orders, to Retractable Technologies in Little Elm, Texas, and Marathon Medical in Aurora, Colorado, totaling 320 million needles and syringes.

Later in May, the government announced plans for ApiJect to manufacture more than 500 million all-in-one devices that would come pre-loaded with the vaccine.

On Wednesday, the largest domestic manufacturer of needles and syringes, Becton Dickinson, announced the first U.S. order of $11.7 million for 50 million needles and syringes by the end of this year. It plans to ramp up manufacturing over the next year.

And earlier this month Retractable entered into a second contract with the government, this one for $53 million meant to boost domestic manufacturing.

Together that sounds like enough injection devices.

But Retractable, which was worried enough about its financial future that earlier this year it received a $1.36 million loan from the Paycheck Protection Program, has been doing about 80% of its manufacturing in China. And Marathon is a medical supply distributor, and there is no indication on its web site that it manufactures needles and syringes at all. The company did not respond to repeated requests for comment.

Despite the race to replenish the domestic needle and syringe supply, about 400 shipping containers of syringes have left the U.S. for countries including Germany, Colombia, Australia, Brazil and Italy this year, according to Panjiva Inc., a service that independently tracks global trade. That’s the same, on average, as syringe exports over the past five years.

Experts acknowledge that a mass vaccination campaign is going to be complicated.

“There are a lot of moving parts to this,” said Dr. Bruce Gellin, the Sabin Vaccine Institute’s president of global immunization.

Darin Zehrung, who studied medical devices at PATH, a nonprofit advocating for health equity, said it’s wise to invest in new injection technologies. But that only works if there are plenty of basic syringes and needles stocked up.

“Hedging bets is the best approach, but plan for the worst case scenario and hope for the best case scenario,” said Zehrung.

AWAITING APPROVAL

ApiJect’s devices are self-contained, with soft plastic blisters that are squeezed, like a nose spray or eye drop, to push the vaccine through an attached needle and into the patient.

The device includes a little computer chip — like the ones in credit cards — that can transmit information about the drug, dose, location and time of administration.

Other injection devices Koska designed have been used in the developing world, but this ApiJect technology has not.

The company said they have started discussions with the U.S. Food and Drug Administration to review the device on a priority basis while the company moves ahead fitting factories to make their injectors. The agency wouldn’t confirm this, citing its policy against discussing products involved in clinical trials.

Testing different vaccine candidates in the ApiJect devices will be critical before injecting the public.

Plastic could interact differently with the liquid than the glass vials currently used in trials, experts say. And there are strict temperature requirements. ApiJect’s planned process is to pour vaccine doses into the warm plastic blisters as they come off the production line, the company says. ApiJect says they can instantly cool the devices as they are made.

Walker, the ApiJect CEO, who founded the online travel agency Priceline, acknowledges that the government’s decision to rely on “an emergency plan of refitting established pharmaceutical manufacturing facilities is risky. But we feel good about it.”

NO COMMENT

The Associated Press asked the Health and Human Services department over many weeks to explain the government’s approach. The agency didn’t allow an official to speak on the record for this story.

A senior administration official, speaking on condition of anonymity because the agency declined to allow him to identified by name, told AP he wasn’t familiar with ApiJect or the contract. But he said the government was buying a range of devices to deliver the vaccine because they don’t know what they need. And, he said, the Trump administration is looking to boost domestic manufacturing.

When AP reached out directly to Trump’s vaccine czar, Moncef Slaoui, to discuss the new technology, a spokesperson said the query was inappropriate.

“If this continues, we will make no one else available either,” Natalie Baldassarre, a special assistant at HHS, wrote in an email.

Last week, HHS Assistant Secretary of Public Affairs Michael Caputo wrote that the agency has “lost interest in assisting your story” and offered no further comment.

— Mendoza reported from San Francisco. Linderman reported from Baltimore. Lauran Neergaard and Stephen Braun in Washington contributed.

0 notes

Text

PHONELESS IN BERLIN

Words: Kirsty Allison

All photographs by Martyn Goodacre, except images of Danielle De Picciotto’s art, and Alexander Hacke’s studio…and the portrait of Morgan, by Kirsty.

Clouds’ shadows camouflage the sea. Sardine boats dodge the lifeboat wind farms. I jet-trash over last night’s cab, and the phone left on the back seat.

SCHONEFIELD AIRPORT

“Yes,” with an ‘of course’-face, “It has all the streets on it.” The tourist board office give me a map with the VisitBerlin travel card – 41E for 6 days, generous. I like free travel, and I like maps. Not Maps that rhyme with apps. I see the island of West Berlin – I put all the streets in my long black woollen notebook pocket.

U-BAHN/S-BAHN

Map in a glass cage – no index – I’ll take a photo – look at it when I’m moving – I can’t take a photo. My cogs shift from the cybernet dimension.

Alone. Letting go of my infatuation with being monitored, I feel an analogue glitch, a slip of fortune as I enter the low-rise city, uninterrupted with pings.

A watch. I could buy a watch – to tell the time.

I could walk rather than do the connection.

THE HORRORS / Synästhesie Festival / Volksbühne

“The people putting this festival together told me this granite floor was from Hitler’s Bunker,” says Anton Newcombe of the Brian Jonestown Massacre and A Records, DJing in the green room, two floors of sweeping staircases up in the People’s Theatre of Mitte’s Rosa-Luxemburg Platz – once the centre of East Berlin’s GDR.

“Do you believe them?” I ask, of the 8MM Bar promoters who put the festival together. We consider the plausibility, the Nazi star, in dirty creams and blood reds.

Mark Reeder later confirms it to be from the Nazi Vice Chancellor office. And of the cenotaphs stashed beneath the KuDamm – the Nazi spikes. Close enough. Anton is a hero – DIG! the film he stars in aside spars, The Dandy Warhols – an essential on the rock n roll rites-of-passage Reading List. Between his selection of classic psychedelia: “I was born in 1967, in California, of course I’m psychedelic”, with highlights such as Fabio Viscollios 7”, he sets the record straight on all kindsa connections that zip around my references of the night – the stars that guide us, the magnets who form us.

Arrival in Neukölln

So 90s, no blue arrow locator. Without the digital psychographic veils of my screen, the meaning of wrong direction changes – I love to travel, to feel on top of the globe, wherever you walk, with only the weight of the identifiers you carry.

Natural order leads me to Stroke Order – my faux-god-sista, of the Sacred Sound Club – her haus is pink. Y3 shoes, high ceilings, dribble shower, CK mirror. She’s a costume designer for films, but has been hiding out here for a year. Making minimal techno – using autonomous sensory meridian response samples – sounds that turn us on.

Our mothers are pretend godmothers to me and her. She grew up in Vancouver. Dad is a motorcycle racer and ballet dancer in Japan.

Synästhesie Festival / Volksbühne

CAMERA take to the main stage of seated theatre hall. Brutalist fractal collage films of matrix shifting cities, juddering with intent. Projections of you watching me watching you – perhaps being shot live in the auditorium – full scope. Beaming around the physical force of a standing drummer triballing out for a 20 minute set on a bass drum, snare and cymbal. The centre-piece. Astral simulacrum to The Egg who I played with earlier this year. The standing drummer keels in sweat, throws a death white sheet over the drums as though he has beaten them dead, only to dampen their noise, and continue hitting and hitting. Keys, 2 x guitar, sitar bass, different genereration radical on sax – elf dancing.

I’m reminded of the need for parameters – the ones we invent to live inside. The significance of numbers plays on the screens – another hallucination. A replacement for seeing everything through snapshot Insagram lens. Abandoning our digital religion – is so FKK (freikörperkultur – the GDR East Berliners act of rebellion was to strip on Sundays around the lakes – to rip off the communist soaked nylons of identikit clothing*). So naked.

TANGERINE DREAM

A violinist in black – modular synth Memotron on one side – a bank of other buttons on the other side. One life. One nerve shatters and then rest follow. First they twitch, and glitch the matrix…

I catch a bit of THE PINS – all girls – superhot, riot grrrrl electronica.

THE HORRORS

Violent Lenin Uber Alles track shatters across the increased scale of the stage for this headline performance – punk anger of East Berlin, red deco chandeliers of alles Ku-damm Cabaret glory. Waiting for Faris Badwan, the singer who I first interviewed for Dazed and Confused, making a film about his illustration – and exhibition, I wonder about the symbolism of genre/sound/music/art as signs of the times – about resonance – of what we are creating and producing – of X Factor sounds as the capitalist panacea – of our art resonating our environment – or us gravitating towards it. Stroke Order making techno in Berlin.

The futurism of white noise perfection – the dystopian values, four albums in from when I first met Faris – he was maybe 23 then. Unsure if he was going to carry on at St Martins art school. By the time I interviewed him again for Vogue, he was not going back.

And here, seated in the very front row – I witness the evocation of destiny – he’s become less of the shy frontman, but someone who is commanding the respect of the universe – he violently whips the mic lead – he hails the pulses of front row screamers, bonding their necks with rubber wire – he in black PVC – guitarist in red lipstick – beautiful rockstar boys. Lyrics are lost in the Elritch reverb – Faris is crown stealing. Volatile black energy of goth industrial – contemporised by Tom Furse – and his techno pyramid synths. Ice sweat dripping Hackney vampire bassist Rhys Webb. Faris has become storming iconic balearic, striding over theatre seats, in smart city shoes. It’s cosmic goth, it is power – it is owning the depth of Poe hell to Blakean heavens. From voyeurs to submission, the audience leave satisfied.

WEDDING/NW multi-cultural reaches of the city.

Fire station studio. Danielle De Picciotto walks us across a courtyard in twilight. Pyramid of flowers, split by stairs to a below-sea-level, waiting buddha, draped with beads. Left and right basement of Californian security doors, co-joined studios, His and Hers. Drums on the male side, Alexander Hacke, Einsturzende Neubatten – poles of metal to hit. Next door: paintings of black and white folklore S+M dolls with tripped out wings, and photograph reflections. Hers. With tea. Laughter. Discussion. Love. She is love.

***

Lost – ghetto kid guides me and Stroke Order to the ambient dinner in a bar beneath a block in Wedding: soundproof triangles of three-tone pastel shaved hardwood. Clean vegetables, and a series of performances from three post-Akai-ists. Poetry, soundscapes layering paranoic schizophrenic voices – a DJ girl in from Seattle. The residents, ex-pats, from across Germany, and the world – carrying less ego than London. A wholesome intellect carries through, it gets lost in the whirl of London survival. I think back to hanging with the man commonly known as Rodent, the Sex Pistols’ sound tech – he was saying everything is lost in our digital times – the lack of ability to hang out together, they had to live frugally, himself in the studio of The Clash. The intensity of art. It’s easier here. To get involved in your creativity – away from the grab.

SUNDAY

Home jukebox, coffee, and Okay Cafe cinnamon swirls at Jason McGlade and Anne-Cathrin Saure’s (the art director/photographer, and designer of Cold Lips II, and co-createurs of the Shedville font). They moved back here recently – but Jason’s back and forth to London, working on an incredible analogue Polaroid project.

Stroke Order and I head out to Berghain – but instead collide with a very old friend who’s been living in Thailand for 14 years – Martyn Goodacre. He took the most iconic picture of Kurt Cobain, and many more. We tried doing music together when we worked on magazines. We go to a bar, meet with a midwife – talk about the horror show of birth, the guidance into the world, policed by the womb and the channel to birth and the rejection from the vulvic eye. The propulsion.

MONDAY MORNING COMING DOWN FROM AN EMAIL THAT IS CHANGING MY LIFE

Space, China – coffee with Mark Reeder. His vinyl of Mauderstadt is out now. I’ve just run a trilogy of stories on him in DJ Mag, explaining his part in Berlin, from being the Factory rep in Berlin in Joy Division days, through to putting on punk gigs in East Berlin, recording the music in gay bars to play to New Order – thus Blue Monday – and since, from inventing trance music with his label MfS – getting Paul van Dyk on the map – he’s the man. His uniforms. Rare light.

“Danielle [De Picciotto] and Katia – Love Parade would never have started without them.”

[Love Parade was the street party that began in the ecstatic reunification of East and West Berlin. The wall came down in 1990. The old GDR was a wild land. Read Danielle De Picciotto’s Beauty of Transgression for more…or watch Mark Reeder’s B-Movie…and his forthcoming E-Movie.]

He realises he’s late for his lunch…

Alone, back on the Neukölln streets, I look into the door of a Moroccan cafe – get called in by a round-faced Muslim woman, grey jumper, jeans – trainers – Tangiers market vibes, enter – beans – good – no English – point at a box – I don’t know if she knows I don’t want a tagine but takeaway – they waterfall me mint tea – the door slams shut. There are stickers on the wall tiles – plastic table cloths. Am I about to be drugged? Locked in – I have few Euros and no phone to be stolen.

I sit, read the Unspoken Berlin I’ve picked up – and wait for either the drugs to kick in, or to relax. Oh, some brot on the table – no it ain’t Gucci Bloom sea hedgehog fennel and jerusalem artichoke, chestnut puree and scallop, purple watercress like the exquisite experience of Lokal where local ingredients will dance on plates for us later – nor is is it as refined as the Techno sauna we’ll meditate in around the bar – but it is E2.50 and beautifully wholesome – the chickpeas are larger than London.

—-

Neurotitan have taken Cold Lips and my last 3 copies of Unedited. Stefi there is lovely. It’s somewhere that’s always called me on previous trips to Berlin. Many putting a film together that became impossible, about Manuel Gottching, of Ash Ra Tempel – and E2:E4 – the most sampled record – inventor of ambient – before Eno, before the HANSA recordings of Iggy and Bowie. I tell Stefi of my gig last night with Whisky and Words at the Keith bar – where Stroke Order – her pals – and Jason McGlade come by – and Mark Reeder. And Rasp Thorne [post coming to Cold Lips soon, or buy the second edition for total spread]- the consumate performer – lighter over here – my lips are still red from the wine. Stephen Crane. Rasp’s performance of Crane. He’s so good.

Everytime I get on a train here the stasi black jacket ticket checkers are on the same carriage. It’s happened to Morgan 3 times in her year here – and 3 times with me in as many days. I am able to fight my usual paranoias from the top of my Maslow pyramid – the email from a publisher – saying he wants to publish my novel – the one I have had two agents hawk around in 11 years – during which time, I have changed, and so has the story. It is the best email I’ve ever had. Here, lying in bed on the Monday morning after meeting with Anton Newcombe and front row for Faris – Faris frow.Two days later, I’m still flying, as I hit EchoBucher, back in Wedding – they’re taking some Cold Lips…I drop into Potsdamer – meeting… No fucking way. Ticket checkers.

Zug Fallt aus!

You have amazing eyes – you look like Madonna said the guy from Milano – I’m hoping he means old skool hot Madz. En route to the airport – delays – nerves shot / triggering towards Parkinsons and spiked dreams. He calmed me – so did the guy who was also travelling to Stansted – as we ran for the plane, and vice versa. Detoxed from the phone, train home, to the temple – travelling with Alice A Bailey. Nanobotic karmic overide. More ticket inspectors – haunted by the stasi – on plane now – could do with some extra O2 from the overhead locker after running in a coat I just bought which I think I may be allergic to. But it’s so warm.

*German born LA-resident, Benedikt Taschen, the art collector and publisher, has directed the content of the new EAST GERMAN HANDBOOK. An encyclopedic collab with Wende Museum, a place of Cold War artefacts in Culver City. It’s a compendium of communist porn – picture-led, masonically-charged graphics of the whole nine yards of life behind the wall – from ideal weaponary to food, fags, appalling vodka, and the requisite communist shit shoes. It’s got 50s utopian vision written all over it.

#berlin#Travel#Writing#New Writing#Kirsty Allison#Zine#Magazine#Art#Music#Fashion#Film#Video#Poetry#Culture#Counterculture#Subculture#Punk#Grunge#Underground#Literature#Photography#Independent#Indie#London#COLD LIPS

1 note

·

View note

Text

The Price of Recycling Old Laptops: Toxic Fumes in Thailand’s Lungs

KOH KHANUN, Thailand — Crouched on the ground in a dimly lit factory, the women picked through the discarded innards of the modern world: batteries, circuit boards and bundles of wires.They broke down the scrap — known as e-waste — with hammers and raw hands. Men, some with faces wrapped in rags to repel the fumes, shoveled the refuse into a clanking machine that salvages usable metal.As they toiled, smoke spewed over nearby villages and farms. Residents have no idea what is in the smoke: plastic, metal, who knows? All they know is that it stinks and they feel sick.The factory, New Sky Metal, is part of a thriving e-waste industry across Southeast Asia, born of China’s decision to stop accepting the world’s electronic refuse, which was poisoning its land and people. Thailand in particular has become a center of the industry even as activists push back and its government wrestles to balance competing interests of public safety with the profits to be made from the lucrative trade.Last year, Thailand banned the import of foreign e-waste. Yet new factories are opening across the country, and tons of e-waste are being processed, environmental monitors and industry experts say.“E-waste has to go somewhere,” said Jim Puckett, the executive director of the Basel Action Network, which campaigns against trash dumping in poor countries, “and the Chinese are simply moving their entire operations to Southeast Asia.”“The only way to make money is to get huge volume with cheap, illegal labor and pollute the hell out of the environment,” he added.Each year, 50 million tons of electronic waste are produced globally, according to the United Nations, as consumers grow accustomed to throwing away last year’s model and acquiring the next new thing.The notion of recycling these gadgets sounds virtuous: an infinite loop of technological utility. But it is dirty and dangerous work to extract the tiny quantities of precious metals — like gold, silver and copper — from castoff phones, computers and televisions.For years, China took in much of the world’s electronic refuse. Then in 2018, Beijing closed its borders to foreign e-waste. Thailand and other countries in Southeast Asia — with their lax enforcement of environmental laws, easily exploited labor force and cozy nexus between business and government — saw an opportunity.“Every circuit and every cable is very lucrative, especially if there is no concern for the environment or for workers,” said Penchom Saetang, the head of Ecological Alert and Recovery Thailand, an environmental watchdog.While Southeast Asian nations like Indonesia, Malaysia and the Philippines have rejected individual shipments of waste from Western countries, Thailand was the first to push back more systematically against the electronic refuse deluging its ports.In June of last year, the Thai Ministry of Industry announced with great fanfare the ban on foreign e-waste. The police made a series of high-profile raids on at least 10 factories, including New Sky Metal.“New Sky is closed now, totally closed,” Yutthana Poolpipat, the head of the Laem Chabang Port customs bureau, said in September. “There is no electronic waste coming into Thailand, zero.”But a recent visit to the hamlet of Koh Khanun showed that the factory was still up and running, as are many others, a reflection of the weak regulatory system and corruption that has tainted the country. Despite the headlines about the police raid, New Sky Metal was fined a maximum of only $650 for each of its licensing infractions. Since the e-waste ban, 28 new recycling factories, most dealing with electronic refuse, began operations in one province east of Bangkok, Chachoengsao, where Koh Khanun is located, according to provincial statistics. This year, 14 businesses in that province were granted licenses to process electronic waste. Most of the new factories are in central Thailand between Bangkok and Laem Chabang, the nation’s biggest port, but more provinces are allowing the businesses. Thai officials say that some incinerators may still be burning because factories are working through old stockpiles. Plants may also be processing domestic rather than foreign refuse, they say.But neither explanation is likely, according to industry experts. Hoards of imported waste wouldn’t last this long. And the amount of electronic trash that Thailand produces is far outpaced by the number of new factories.Foreign e-waste might be smuggled into the country mislabeled as scrap, said Banjong Sukreeta, the deputy director general of the Department of Industrial Works.“Ask customs about falsified declarations,” he said. “Rules are not enough if the people who implement them are not up to it.”But Mr. Yutthana, of the customs bureau, said every box that landed at his port was inspected thoroughly.“We are 100 percent careful,” he said.In October of this year, the Thai legislature unveiled loosened labor and environmental regulations for all factories, a move that has benefited the e-waste industry. Under one provision, small companies are no longer subject to pollution monitoring. At the same time, a draft bill that would ensure tighter control over Thailand’s electronic waste industry has languished in legislative purgatory. “Thailand is welcoming environmental degradation with its own laws,” said Somnuck Jongmeewasin, a lecturer in environmental management at Silpakorn University International College. “There are so many loopholes and ways to escape punishment.”The consequences are frightening. If some types of electronic waste aren’t incinerated at a high enough temperature, dioxins, which can cause cancer and developmental problems, infiltrate the food supply. Without proper safeguarding, toxic heavy metals seep into the soil and groundwater.Locals who fought against the deluge of trash have been attacked. “Why don’t you in the West recycle your own waste?” said Phayao Jaroonwong, a farmer east of Bangkok, who said her crops had withered after an electronic waste factory moved in next door.“Thailand can’t take it anymore,” she said. “We shouldn’t be the world’s dumping ground.”Phra Chayaphat Kuntaweera, a Buddhist abbot, has watched as several waste-processing factories opened around his temple. Two more are under construction.First, the monks began to cough, he said. Then they vomited. When the incinerators burned, their headaches raged.“Monks are people, too,” he said. “We get sick from the fumes just like anyone else.”Earlier this year, the abbot put a sign in front of his temple in Khao Hin Sorn, east of Bangkok.“Cheap temple for sale,” the banner read, blaming “fumes from burning factories” for the desperate measure.At King Aibo Electronics Scrap Treatment Center, one of the factories near the temple, schedules written in Chinese note the dates that shipments will be arriving. The three workers in the office on a recent visit were all Chinese.“We know that Chinese people set up factories in Thailand,” said Mr. Banjong of the industrial works department. But he said that since the ban on electronic waste was instituted, “we are more strict.” King Aibo is one of the factories that began operations this year. Other factories never shut down, despite repeated infractions. One, Set Metal, was ordered to shut in April 2018, officials said. It never had a license to import electronic waste, and locals complained about the stench. But on a recent visit, a Thai-Chinese interpreter, speaking through a gate, said the company was open for business, even if some operations had moved to a nearby village. Behind him, containers overflowed with electronic waste. About 100 Burmese workers live on the factory’s grounds.Even in cases in which wrongdoing is acknowledged, follow-through is weak. This year, officials admitted that 2,900 tons of electronic waste seized in last year’s raids had gone missing. The police had left the stockpile in the care of the Chinese manager, who later skipped the country.In September, Sumate Rianpongnam, an activist, campaigned against the e-waste industry’s polluting his hometown, Kabinburi. That night, men on motorcycles shot bullets into the air near his home and raced off.Shortly afterward, men in a pickup truck tossed small grenades, known as Ping-Pong bombs, at his friend’s house. The grenades exploded, but the friend was not injured.Others weren’t as fortunate. In 2013, a village chief spoke out about the illegal dumping of toxic waste. He was shot four times in broad daylight. The man charged with ordering the killing, an official in the local Department of Industrial Works, was acquitted in September.Mr. Sumate and his friend were campaigning against a landfill that illegally mixes electronic waste and household rubbish. On a visit to private land adjacent to the landfill, muscled men packed in a pickup truck tried to block the path out.“I’ve chosen to do this work,” Mr. Sumate said. “I am not scared of death.”In the shadow of the corroded smokestack at New Sky Metal, Metta Maihala surveyed her eucalyptus plantation. The lake that waters the farm has clouded over, and the smell is nauseating.Suddenly, through the rows of trees, a pair of Burmese workers emerged. The man showed burns on his arms from his work at New Sky Metal but said he had no idea what liquid had caused his wounds.The woman, Ei Thazin, said she received $10 a day for sorting metal. “I didn’t know this was dangerous work,” she said.In Thailand, millions of undocumented workers from poorer countries like Myanmar and Cambodia are vulnerable to abuse, environmental watchdogs say, adding that the need for such laborers will only intensify. Of the 14 factories granted licenses to process e-waste this year in Chachoengsao Province, six are in Koh Khanun. Five are linked to the man whose name is associated with New Sky Metal, or with his wife.“We can’t choose the air we breathe,” said Ms. Metta, the eucalyptus farmer. “Now there will be even more factories. We are all going to die a slow death.” Source link Read the full article

0 notes

Text

INSERT MOLDING VS COATING MOLDING

Injection molding of inserts is similar to other molding methods, but there are some differences in each process. Injection molding involves injecting one or more molten plastics into a mold to form a single finished product.

Coating molding

What is the coating molding? Simply put, the coating process can be plastic, flexible or flexible.

There are physical and chemical methods to realize the coating moulding (including overmolding). The former, for example, relies on snap design, surface tapping threads, and then coated with the second material to achieve the coating forming. The physical joints have strong adhesion, while the parts outside the physical joints have little adhesion.

Chemical method is based on the molecular affinity between two materials and the bonding force of chemical bonds. The two materials are bonded together to form a single component, two or even many kinds.

china mold factory

Insert molding

Inserts for plastic inserts are usually made of brass, steel or stainless steel and have threaded surfaces to provide better adhesion to plastics. Injection molding inserts are placed in the molds manually or vertically by a machine.

This position allows gravity to keep the plug-in in place when the mold is closed. As the molten plastic is slowly poured into the mold, it helps to fix the insert in a fixed position.

About JasonMould Industrial Company Limited

Jasonmould is a China mold maker of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer, mold manufacturer China– plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

Contact: Person: James Yuan Company: JasonMould Industrial Company Limited Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China Tel: 86-752-6682869 Email: [email protected]

0 notes

Text

March update part two: Plastics, Pollution, and Programming

TL;DR: Plastic parts are looking good; Wooden parts are looking good; Raw material costs in China are skyrocketing; Open source is amazing.

Hello from Oakland!

This is part two of our March 2017 update. If you missed part one last week, you can read it on Kickstarter.

Baseplates

One of the ongoing problems we've had with our manufacturer is the quality of the plastic baseplates being produced for us.

First, here's a recap of the saga of the baseplates up to now.

When we started this process, we'd specified metal baseplates. We'd also specified press-fit nuts and standoffs for anchoring the keyplates and wooden enclosures to the baseplate.

The factory proposed swapping out the metal for plastic. While we were a little bit nervous about this, plastic has the dual advantages of weighing less and better fitting our design. With the plastic baseplates, the factory was able to mold in features to help protect the RJ45 and Type C jacks. They were able to mold the metal tripod mounts right into the plastic.

And back when we thought there were going to be flip-out feet on the bottom of the keyboard, they were going to be able to hide the feet inside baseplates.

Well, it turned out that the flip-out feet just weren't going to work. The factory took a gamble and had their partner start on the baseplate injection molding tooling before we signed off on this part of the design.

The first versions of the baseplates came back with numerous "hot points" where you could see sinking due to the plastic cooling at a different rate. That's not great, but is entirely normal for a first (called a "T0") injection sample.

Entirely aside from the issue with the feet, the quality of the baseplates provided by the factory's partner was not up to snuff. There were many issues, both small and large. The biggest issues centered around the quality of the tooling. The internal "ribbing" on the parts looked like they'd been hand-cut by a CNC operator. The lines were too thin and not quite in the right place. There were places that two of the ribs were supposed to touch, but instead they were about a millimeter apart. Because the structural stability of the part depends on those ribs being fused together, this was less than ideal.

We asked them to try again.

The injection factory blew their self-imposed deadline by a week or two. The parts they came back with looked a little better, but as we looked at the details, we found that the structural lines hadn't really been made thicker. They'd just cut new lines next to them which… almost lined up.

This is right about when the factory read them the riot act. They told the injection supplier they had one more chance to fix things.

The injection factory blew their self-imposed deadline by a week or two. The next version was a little better, but still just didn't match the design files sent to them in a number of places. What's worse was that the injection factory thought they'd done a decent job.

By now, it was early January and we were at T5 or T6. We were pretty frustrated.

The factory relented and asked the injection molding factory to take one more shot at things.

The injection factory blew their self-imposed deadline by a week or two. The samples they came out with were ok, but still not production quality.

This was the point at which our factory started shopping for a new injection molding partner in earnest. Just before Chinese New Year, the factory told us which of the three bids for the baseplates they thought we should accept. The only real details we had were the pricing and the factory's opinion, so we ran with it.

They told us that the new factory expected to finish tooling the week of March 5, with samples sometime that week.

Once Jesse got to China, the factory took Jesse to visit the new baseplate supplier. They confirmed that tooling and "T0" injection samples would be ready on March 8.

The tooling supplier showed us the work-in-progress injection molds, as well as their fancy test equipment.

Well, March 8 rolled around and the injection factory asked if we could delay our visit until the afternoon. With a little bit of trepidation, we agreed. When we showed up sometime after lunch, we were brought straight to one of their injection machines. The factory manager, in a suit, was pulling out baseplates, "hot off the presses."

The first "T0" sample of the left baseplate from the new supplier

We took them upstairs to the injection shop's offices, pulled out our sharpies and started marking up issues as we found them. There were a reasonable number of "hot point" sinkholes, but that's very much part for the course as molds get dialed in.

The first samples didn’t have tripod mounts on the bottom. To add them, it was just a matter of adding tripod mount inserts into the tool as it made each sample. We then found that the tripod screw inserts, while exactly as long as we'd specified, were missing a bit of headroom above them. The problem with this is that longer tripod screws wouldn't be able to screw all the way into the baseplates, leaving them extra wobbly. We'd picked a depth of 6mm because that's what the ISO standard for camera tripod mounts says. Perhaps unsurprisingly, some of our test commercially available camera tripods actually have screws as long as 7 or 8mm. After talking things through with the injection supplier, we decided to switch to 10mm long threaded inserts. There was a little bit of stress because the injection factory's supplier claimed they couldn't actually do 10mm inserts while still making them from stainless steel. We'd have to switch to brass or galvanized iron. This seemed a little bit nutty to us. We agreed that brass was the better of the two choices. (While it might deform a little bit, it's unlikely to start rusting after repeated use wears it down.) The next day, with help from our friends at HWTrek, we got the injection factory to recant and switch back to stainless steel. We're still not quite sure what happened, but we're happy with the result.

Back to the baseplate inspection. These samples looked good. Surprisingly good. The baseplate supplier agreed to run the samples through their fancy 3D measurement machine to compare them to the CAD designs. We handed them our marked-up samples showing off the issues we'd found.

A report showing how well the first version of the new baseplates matched the CAD designs

At that point, it was again time to talk about texture. The injection factory pulled out their texture sample card. We settled on texture number 48, which is a moderately dense texture we found both attractive and a little bit "grippy."

After that, the factory's R&D manager marked up samples with a white paint pen to show the surfaces that should have the texture applied. The injection molding factory said they expected to be able to turn new samples fixing the substantive issues by the time Jesse left China four days later. They warned that we shouldn't expect the texture to be applied yet.