#carbon fiber cnc manufacturers

Explore tagged Tumblr posts

Text

adventures in QA

(previous post in this series)

My shop in Advanced Midbody - Carbon Wing (AMCW) at Large Aircraft Manufacturer (LAM) is at the very end of the composite fabrication building. Hundreds of people carefully lay up a hundred foot long slab of carbon fiber, cure it, paint it, and then we totally fuck it up with out of spec holes, scrapes, primer damage, etc. The people who write up our many defects are from the Quality Assurance (QA) department.

Every single screw and rivet on a LAM aircraft can be traced back to the mechanic who installed it. Back when even everything was done in pen and pencil, it was joked that the paper used to produce an aircraft outweighed the plane itself. Now that everything is computer-based, of course, the amount of paperwork is free to grow without limit.

(Haunting the factory is endless media coverage of an emergency exit door plug popping out of an Advanced Smallbody - Upengine (ASU) plane during a routine flight a few months ago. Unlike that airframe's notorious problems with MCAS, this was a straightforward paperwork screwup by a line worker: the bolts were supposed to be tightened, and they weren't.

As a result the higher ups have visited hideous tribulations on non-salaried workers. Endless webinars, structured trainings. Here at the Widebody plant we have received a steady flow of refugees from the Narrowbody factory, hair-raising tales of receiving one hundred percent supervision from the moment they clock in to the second they clock out from FAA inspectors who can recommend actual jail time for any lapse in judgement.)

A single hydraulic bracket Installation Plan (IP) is around four brackets. The team leads generally assign two bracket IPs per mechanic, since each bracket set is something like a foot apart, and while working on the plane is bad enough it's much worse to have another mechanic in your lap.

Let me list the order of operations:

One: Find where you're supposed to install these brackets. This is harder than you might think.

Firstly, it's a hundred foot long plank of carbon fiber composite, with longitudinal stringers bonded to it to add stiffness. The stringers are pilot drilled in the trim and drill center, a truly Brobdingnagian CNC mill that trims off the composite flash at the edges and locates and drills part holes for us. But there's a lot of holes, so you must carefully find your set.

A minor difficulty is that the engineering drawings are laid out with the leading edge pointing up, while the wing panels in our cells hang from the trailing edge. Not so bad, you just rotate the paper 180 when orienteering, then rotate it back up to read the printed labels.

A major difficulty is that the drawings are from the perspective from the outside of the panel. But we work on the inside of the wing (obviously, that's where all the parts are installed) so we also flip the drawings and squint through the back of the paper, to make things line up.

Large Aircraft Manufacturer has a market cap of US$110 billion, and we're walking around the wing jig with sheets of paper rotated 180 and flipped turnways trying to find where to put brackets.

Oh well, we're paid by the hour.

Two: Match drill the aluminum brackets to the carbon fiber composite stringer. I can devote an entire post to the subtleties of drilling carbon fiber, but I can already tell that this post is going to be a miserable slog, so I will merrily skip over this step.

Three: Vacuum up all the carbon dust and aluminum swarf created during this process. This step is not optional, as your team lead will remind you, his screaming mouth clouding your safety glasses with spittle at a distance of four inches. LAM is very serious about FOD. Every jet airliner you've ever ridden in is a wet wing design-- each interstitial space is filled with Jet A. There is no fuel bladder or liner-- the fuel washes right over plane structure and wing hardware. Any dirt we leave behind will merrily float into the fuel and be sucked right into the engines, where it can cause millions in damage. No place for metal shavings!

If you are nervous about flying, avoid considering that all the hydraulic lines and engine control cables dip into a lake of a kerosene on their way from the flight deck to the important machines they command. Especially do not consider that we're paid about as much per hour as a McDonalds fry cook to install flight-critical aviation components.

Four: Neatly lay out your brackets on your cart, fight for a position at a Shared Production Workstation (SPW) (of which we have a total of four (4) for a crew of thirty (30) mechanics) and mark your IP for QA inspection as Ready To Apply Seal.

Four: Twiddle your thumbs. Similarly, we have three QA people for thirty mechanics. This is not enough QA people, as I will make enormously clear in the following steps.

Five: Continue waiting. Remember, you must not do anything until a QA person shows up and checks the box. Skipping a QA step is a “process failure” and a disciplinary offense. From the outside, you can observe the numerous QA whistleblowers and say “golly, why would a mechanic ever cut a corner and ignore QA?” Well...

Six: QA shows up. Theoretically, they could choose to pick up the mahrmax you prepared for them and gauge every single hole you've drilled. But since we're three hours into the shift and they're already twenty jobs behind, they just flick their flashlight across the panel and say “looks good" and then sprint away. Can't imagine why our planes keep falling out of the sky.

Seven: Apply the seal to the bracket. P/S 890 is a thick dark gray goop that adheres well to aluminum, carbon fiber, fabric, hair and skin. Once cured, it is completely immune to any chemical attack short of piranha solution, so if you get any on yourself you had better notice quick, otherwise it'll be with you as long as the layer of epidermis it's bonded to. LAM employees who work with fuel tank sealant very quickly get out of the habit of running their hands through their hair.

Eight: Now you wait again. Ha ha, you dumb asshole, you thought you were done with QA? No no, now you put up the job for QA inspection of how well you put the seal on the bracket. Twiddle your thumbs, but now with some urgency. The minute you took the bottle of seal out of the freezer, you started the clock on its "squeeze-out life." For this type of seal, on this job, it's 120 minutes. If QA doesn't get to you before that time expires, you remove your ticket, wipe off the seal, take another bottle out the freezer, and apply a fresh layer.

Nine: Optimistically, QA shows up in time and signs off on the seal. Well, you're 100 minutes into your 120 minute timer. Quickly, you slap the brackets onto the stringer, air hammer the sleeve bolts into position, thread nuts onto the bolts, then torque them down. Shove through the crowd and mark your IP "ready to inspect squeeze out"

Ten: Let out a long breath and relax. All the time sensitive parts are over. The criteria here is "visible and continuous" squeeze out all along the perimeter of the bracket and the fasteners. It is hard to screw this up, just glop on a wild excess of seal before installing it. If you do fail squeezeout, though, the only remedy is to take everything off, throw away the single-use distorted thread locknuts, clean everything up and try again tomorrow.

Eleven: QA approved squeeze out? Break's over, now we're in a hurry again. By now there's probably only an hour or two left in the shift, and your job now is to clean off all that squeeze out. Here's where you curse your past self for glopping on too much seal. You want to get it off ASAP because if you leave it alone or if it's too late in the shift and your manager does feel like approving overtime it'll cure to a rock hard condition overnight and you'll go through hell chipping it off the next day. You'll go through a hundred or so qtips soaked in MPK cleaning up the bracket and every surface of the panel within three feet.

Twelve: Put it up for final inspection. Put away all your tools. (The large communal toolboxes are lined with kaizen foam precisely cut out to hold each individual tool, which makes it obvious if any tool is missing. When you take a tool out, you stick a tool chit with your name and LAMID printed on it in its place. Lose a tool? Stick your head between your legs and kiss your ass goodbye, pal, because the default assumption is that a lost screwdriver is lurking in a hollow "hat" stringer, waiting to float out and damage some critical component years after the airplane is delivered.)

One tool you'll leave on your cart, however, is the pin protrusion gage. There is a minimum amount of thread that must poke outside of the permanent straight shank fastener's (Hi-Lok) nut, to indicate that the nut is fully engaged. That makes sense. But there's also a maximum protrusion. Why?

Well, it's an airplane. Ounces make pounds. An extra quarter inch of stickout across a thousand fasteners across a 30 year service life means tons of additional fuel burnt. So you can't use a fastener that's too long, because it adds weight.

On aluminum parts, it's hard to mess up. But any given composite part is laid up from many layers of carbon fiber tape. The engineers seemed to have assumed that dimensional variation would be normally distributed. But, unfortunately, we buy miles of carbon fiber at a time, and the size only very gradually changes between lots. When entire batches are several microns oversize, and you're laying up parts from fifty plies and an inch thick, you can have considerable variation of thickness on any given structural component. So you had better hope you had test fit all of your fasteners ahead of time, or else you'll be real sorry!

And, if you're really lucky, QA will show up five minutes before end of shift, pronounce everything within tolerance, then fuck off.

And that's how it takes eight hours to install eight brackets.

174 notes

·

View notes

Text

The baddest wheel in the whole darn town. When Dodge launched the incredible 1025HP Demon 170, they offered an option to equip the vehicle with the most technologically-advanced road wheels ever sold by any automotive manufacturer: The Lacks Carbon Fiber Drag Pack. This same 18x8/17x11 setup is now available here in the LCF205 with fitments available for both the D170 and widebody Hellcat. The lightweight Carbon+Forged LCF205 wheel combines a weight-optimized CNC-machined forged aluminum center with a revolutionary proprietary Lacks Enterprises carbon fiber barrel to deliver the ultimate in technological advancement, exclusive styling, and unparalleled performance. The LCF205 combines its carbon fiber barrel with a unique precision-machined forged 6061-T6 aluminum center featuring lightweight racing-inspired ten spoke design, open-lug hub center, and aggressive I-beam machining to yield a wheel with absolutely impressive performance metrics: very low static mass, very low rotational inertia, minimal deflection, and excellent fatigue strength! Learn more about the LCF205 at: https://www.forgeline.com/lcf205/p410

#forgeline#forgelinewheels#forgedwheels#customwheels#LCF205#ForgelineLCF205#CarbonFiber#carbonforged#lackscarbonfiber#notjustanotherprettywheel#doyourhomework#madeinUSA#carenthusiast#wheelsofinstagram#Dodge#Demon170#D170#Hellcat#DragRacing#🇺🇸

8 notes

·

View notes

Photo

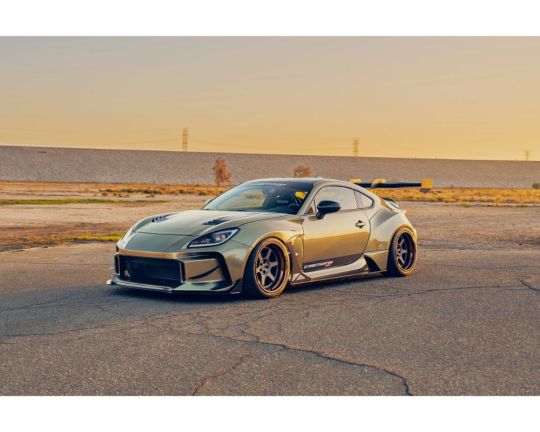

New Post has been published on https://www.vividracing.com/blog/streethunter-designs-wide-body-kit-for-the-toyota-gr86-is-insane/

Streethunter Designs Wide Body Kit for the Toyota GR86 is INSANE

We have some aesthetically pleasing news for owners of BRZ/GR86 from StreetHunter Designs. This U.S. brand utilizes state-of-the-art technologies to design and manufacture carbon fiber body kits, parts, and accessories. Their new BRZ/GR86 wide-body kit is now available in our shop and as seen in the photos below, it is guaranteed to give your ride that unique, aggressive, and muscular look. This widebody kit is high quality like their other products because the brand uses 3D scanning, 3D printing, and precision CNC milling for prototyping.

This widebody kit is the perfect fit for the 2021-2023 Subaru BRZ and the 2022-2023 Toyota GR86, with each of its manufactured parts specifically cut and hand-laid to ensure every part is made with accuracy and quality in mind. Apart from giving your car a sporty appearance, this widebody kit will also revolutionize your car’s;

Resale value – By making your ride more appealing to potential buyers in case you decide to sell it

Weight – This widebody kit is made using carbon fiber materials, which are known for being lightweight. This weight reduction can positively affect acceleration, braking, and overall handling.

Aerodynamics – Widebody kits can also lead to better aerodynamics, reducing drag and potentially improving the vehicle’s performance and fuel efficiency.

Kit Includes:

Front Bumper with lip & canards (full replacement)

Front Fenders (full replacement)

Side skirts with extensions

Rear Flares with gas tank cover

Rear Bumper Extensions

Fitments:

Subaru BRZ 2021-2023

Toyota GR86 2022-2023

Notes:

Front: +58mm – Rear: +75mm

The GT Wing, Rear Trunk Spoiler, and Hood are sold separately.

If you have any questions or if you need new widebody kits for your BRZ/GR86, please do not hesitate to contact us. You can reach us by phone at 1-480-966-3040 or via email at [email protected].

#BRZ/GR86#BRZ/GR86 widebody kits#streethunter designs#streethunter designs body kits for Subaru BRZ 2021-2023#streethunter designs body kits for Toyota GR86 2022-2023

2 notes

·

View notes

Text

The Precision Craftsmanship of Surgical Instruments: Tools That Heal

Introduction

In the world of modern medicine, the art of surgery relies heavily on the precision and efficacy of surgical instruments. These remarkable tools, crafted with painstaking attention to detail, play a crucial role in the hands of skilled surgeons. They are the silent heroes in the operating room, helping to save lives and improve the quality of life for countless patients worldwide. In this article, we will delve into the fascinating world of surgical instruments, exploring their history, types, materials, and the importance of their design and maintenance.

A Brief History

The history of surgical instruments dates back thousands of years. Early examples of rudimentary surgical tools have been found in archaeological digs from ancient civilizations such as Egypt, Greece, and Rome. These early instruments were often made of materials like bronze and iron and were limited in their functionality.

It wasn't until the Renaissance that surgical instruments began to evolve into more specialized and effective tools. The works of pioneering surgeons like Ambroise Paré and Andreas Vesalius paved the way for the development of instruments tailored to specific surgical procedures. The Industrial Revolution further accelerated the production of surgical instruments, with advancements in metallurgy and manufacturing techniques.

Types of Surgical Instruments

Surgical instruments are incredibly diverse, designed to serve a wide range of medical needs. They can be broadly categorized into several groups:

Cutting and Dissecting Instruments: These instruments are used to cut through tissues, such as scalpels, scissors, and dissectors. Scalpels, in particular, come in various shapes and sizes to accommodate different surgical tasks.

Grasping and Holding Instruments: Forceps and clamps fall into this category, allowing surgeons to grasp and manipulate tissues, sutures, or other objects within the surgical field.

Hemostatic Instruments: Hemostasis is the control of bleeding during surgery. Instruments like hemostatic forceps and clamps help clamp blood vessels and prevent excessive bleeding.

Retractors: Retractors are used to hold tissues or organs aside, providing better visibility and access to the surgical area. Common retractors include wound retractors and self-retaining retractors.

Suturing and Stapling Instruments: These tools are essential for closing incisions or wounds. They include needle holders, suture scissors, and skin staplers.

Materials and Manufacturing

The materials used in surgical instrument production have evolved significantly over time. Stainless steel, due to its corrosion resistance and strength, is the most common material in modern surgical instruments. Some specialized instruments, such as those used in minimally invasive surgeries, are made from materials like titanium and carbon fiber, which offer unique advantages like reduced weight and enhanced durability.

Crafting surgical instruments is a meticulous process that demands precision and attention to detail. Manufacturers utilize advanced techniques such as CNC machining, laser cutting, and electro-polishing to ensure the instruments are of the highest quality. These instruments must meet strict regulatory standards to ensure patient safety and maintain their sterile condition.

Design and Ergonomics

Surgical instruments are designed with the utmost care to enhance the surgeon's performance. Ergonomics play a significant role in their design, as they must be comfortable to use for long periods. Grips, handles, and the arrangement of controls are carefully considered to minimize hand fatigue and improve maneuverability.

Maintenance and Sterilization

Proper maintenance and sterilization are paramount to the functionality and safety of surgical instruments. They undergo rigorous cleaning and sterilization processes to ensure they are free from contaminants and pathogens. Many instruments are designed for repeated use after thorough sterilization.

Conclusion

Surgical instruments are marvels of modern engineering and craftsmanship. Their evolution from basic tools to highly specialized, precision instruments has revolutionized the field of medicine. Surgeons rely on these instruments every day to perform life-saving procedures and improve the quality of life for patients around the world. As technology continues to advance, we can expect further innovations in the design and manufacturing of surgical instruments, enhancing their effectiveness and improving patient outcomes.

4 notes

·

View notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

0 notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

#artificial intelligence#machine learning#business#lasercutting#precision machining#writers on tumblr#blog

0 notes

Text

Tube Laser Cutting Machine Manufacturers – Precision, Speed & Innovation

Looking for high-performance tube laser cutting machines manufacturers? Whether you need precision cuts, fast processing, or complex designs, choosing the right manufacturer ensures efficiency, accuracy, and cost savings for your business.

Why Choose Our Tube Laser Cutting Machines?

✅ High-Speed & Precision – Achieve clean, burr-free cuts with advanced laser technology. ✅ Automated CNC Control – Enhance productivity with fully programmable cutting systems. ✅ Versatile Material Compatibility – Perfect for stainless steel, aluminum, carbon steel, and more. ✅ Minimal Material Wastage – Laser technology ensures efficient and precise cutting.✅ Ideal for Complex Designs – Cut intricate patterns and customized shapes effortlessly.

Our Cutting Solutions

🔹 CNC Tube Laser Cutting Machines – Precision cutting with automated efficiency.🔹 Fiber Laser Tube Cutting – High-speed, low-maintenance laser technology. 🔹 Heavy-Duty Tube Cutting Machines – Perfect for industrial metal fabrication.

Industries We Serve

✔ Metal Fabrication ✔ Automotive & Aerospace ✔ Furniture & Structural Engineering ✔ Pipe & Tube Processing

🚀 Upgrade to Cutting-Edge Tube Laser Technology Today! 🚀 Maximize efficiency, reduce production time, and achieve unmatched accuracy with our tube laser cutting machines.

#LaserCutting#FiberLaser#CNCPrecision#MetalCutting#IndustrialLaser#HighPrecisionCutting#LaserTechnology#SheetMetalFabrication#AutomatedCutting#ManufacturingSolutions

0 notes

Text

Fiber Laser Metal Cutting Machine in Gujarat

Success Technologies is a Manufacturer, and Supplier of Fiber Laser Metal Cutting Machine in Gujarat, India Our Manufacturer unit is located in Ahmedabad, Gujarat, India. Success Technologies Is a Manufacturer, Exporter, and Supplier of CNC Wood Router Machine, CNC Stone Router Machine, CNC Metal Engraving Machine, Co2 Laser Machine, Fiber Laser Metal Cutting Machine, CNC Lathe Machine, Welding Machine, Channel Letter Bending Machine, Fiber Laser Marking Machine, Printer. Fiber Laser Metal Cutting Machines have revolutionized the manufacturing industry by offering exceptional precision, speed, and versatility in metal cutting. At Success Technologies, we provide high-quality fiber laser cutting machines that deliver optimal performance for various industries. These machines are designed to cut through metals like stainless steel, carbon steel, aluminum, brass, and copper with unparalleled accuracy. Specifications: Laser Power: 500W to 12kW (depending on the machine model) Cutting Thickness: Can cut metal plates from thin sheets (0.5 mm) to thick plates (up to 30 mm or more). Cutting Speed: Up to 35 m/min (depending on material and thickness). Accuracy: ±0.02 mm for intricate and precise cuts. Material Types: Compatible with stainless steel, carbon steel, aluminum, copper, and more. Cooling System: Water or air-cooled system to maintain optimal operating temperatures. FAQs: What are the key features of fiber laser metal cutting machines? High Precision: Achieve intricate cuts with micron-level accuracy. Speed: Rapid cutting speeds to optimize production efficiency. Versatility: Cut a wide range of metals including stainless steel, aluminum, and brass. Low Maintenance: Minimal downtime and reduced operating costs. Automation: Integrated CNC systems for precise control and automation. What are the applications of fiber laser metal cutting machines? Fiber laser machines are indispensable in industries such as: Automotive manufacturing Aerospace engineering Electronics and semiconductor production Architectural metalwork Medical device fabrication Success Technologies is a Fiber Laser Metal Cutting Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Exporter#ExporterofFiberLaserMetalCuttingMachine#FiberLaserMetalCuttingMachine#FiberLaserMetalCuttingMachineinAhmedabad#FiberLaserMetalCuttingMachineinExporter#FiberLaserMetalCuttingMachineinGujarat#FiberLaserMetalCuttingMachineinIndia#FiberLaserMetalCuttingMachineManufacturer#FiberLaserMetalCuttingMachineSupplier#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofFiberLaserMetalCuttingMachine#Mehsana#Morbi#Nadiad

0 notes

Text

5 Axis Water Jet Cutting Machine

In the realm of precision cutting technologies, the 5 axis water jet cutting machine stands out as a versatile and powerful tool. This comprehensive guide will explore the features, benefits, applications, and considerations for purchasing a 5 axis water jet cutting machine.

5 Axis Water Jet Cutting Machine

A 5 axis water jet cutting machine utilizes a high-pressure stream of water, often mixed with an abrasive substance, to cut through various materials. The “5 axis” designation refers to the machine’s ability to move the cutting head along five different axes: X, Y, Z, A, and B. This multi-axis capability allows for intricate and precise cuts on complex geometries.

Unlike other cutting methods, such as laser or plasma cutting, water jet cutting does not generate heat. This means there is no heat-affected zone (HAZ), which can alter the material properties and cause warping or distortion.

Water jet cutting is an environmentally friendly process. It does not produce harmful fumes or gases, and the water used in the process can be recycled. Additionally, the absence of heat means there is no risk of fire or explosion.

Water Jet Cutting Machine Key Features:

High-Pressure Water Jet: Uses a high-pressure stream of water mixed with an abrasive material to cut through materials. The pressure can reach up to 60,000 psi or more.

Versatility: Capable of cutting a variety of materials, including metals, glass, stone, ceramics, composites, and even food products.

Precision Cutting: Provides high accuracy and smooth edges without the need for secondary finishing processes.

Cold Cutting Process: As there is no heat-affected zone, it prevents material warping or changes in material properties due to heat.

Eco-Friendly: Uses water and natural abrasives, making it a cleaner alternative compared to other cutting methods.

User-Friendly Interface: Often equipped with advanced software for easy programming and operation, allowing for the import of CAD/CAM files.

Applications of a 5 Axis Water Jet Cutting Machine

Water Jet Cutting Machine Applications:

Metal Fabrication: Cutting intricate metal parts for automotive, aerospace, and manufacturing industries.

Stone and Tile Cutting: Creating detailed designs and shapes for countertops, flooring, and decorative stone pieces.

Glass Cutting: Producing precise cuts for architectural glass, mirrors, and other glass products.

Composite Materials: Cutting carbon fiber, fiberglass, and other composite materials used in various industries.

Prototyping: Creating accurate prototypes and models for various engineering and design applications.

Art and Sculpture: Producing detailed and intricate art pieces from various materials.

Aerospace Industry

In the aerospace industry, the 5 axis water jet cutting machine is used to cut complex shapes and components from high-strength materials. Its precision and ability to cut without generating heat make it ideal for aerospace applications.

Automotive Industry

The automotive industry benefits from the versatility and precision of the 5 axis water jet cutting machine. It is used to cut various components, including body panels, interior parts, and engine components.

Architecture and Construction

In architecture and construction, the 5 axis water jet cutting machine is used to create intricate designs and patterns in materials such as stone, glass, and metal. It is also used for cutting custom tiles, countertops, and decorative elements.

Manufacturing

Manufacturing industries use the 5 axis water jet cutting machine for cutting parts and components from a wide range of materials. Its precision and ability to handle complex geometries make it a valuable tool for producing high-quality products.

CNC Water Jet Cutting Machine Advantages:

Versatility: Can cut almost any material with high precision.

No Heat Distortion: Ideal for materials sensitive to heat.

Precision: High degree of accuracy and detail.

Clean Cutting Process: Minimal dust and fumes, making it safer and more environmentally friendly.

0 notes

Text

3Dプリンターは生物を模倣する / 3D printers that mimic life forms

最新のスーパーカーと呼ばれる少量生産の高額車両で、金属用の3Dプリンターで製作した部品がこぞって採用されているという話題です。 The latest supercars, low-volume, high-value vehicles, are all using parts made with 3D printers for metal. ************* sources : Life in the FAST LANE

記事では、マクラーレンW1やフェラーリF80、ブガッティ・トゥールビヨンで、3Dプリンターでサスペンション用の構造部品が製造されている事が画像と併せて紹介されています。そして、最も興味深い事は、そのどれもが有機体・生物の骨格の様な形状をしている事です。これは、使用されている部位からも判る通り、スタイリングを優先した結果ではなく、AIを使った設計で、より少ない材料で軽量に仕上げ、より高い強度や優れたエアロダイナミクスを追及した結果だと事。まるで、何十億年もかけて進化してきた生物の骨格そっくりな点に最も注目しています。 更に、3Dプリンターを使えば、内部にトラス構造の中空部品さえ製造可能で、正に少量生産で高性能で高額な車両に採用するのに最適な製造方法と言えるでしょう。 しかし、近い将来、AIの利用技術は一般的になる事は間違いないので、3Dプリンターを使った同様な部品の製造が可能になるでしょう。少なくとも、マニングセンタやCNCフライスなどを駆使して作られた特殊な部品よりも、3Dプリンターで作られた最適形状の部品の方が評価が高くなるでしょう。更に、カーボンファイバーなどの複合素材用の3Dプリンターが��発されれば、圧倒的な優位性を持つ部品が F1等の車両に広く利用されるでしょう。オートバイだと、スイングアームに最初に採用されるでしょう。高剛性で軽量、しかも最適なエアロダイナミクスを持つ、チーターの骨格を思わせる様なスイングアームです。夢が広がる技術です。

The article shows, with images, that suspension structural parts are being made with 3D printers in the McLaren W1, Ferrari F80, and Bugatti Tourbillon. And the most interesting thing is that all of them are shaped like the skeleton of an organism or living thing. As you can see from the parts they are used in, this is not the result of prioritizing styling, but rather the result of designing using AI to make them lighter with less material, and to pursue higher strength and better aerodynamics. The most notable thing is that they look just like the skeletons of organisms that have evolved over billions of years. In addition, with a 3D printer, it is even possible to manufacture hollow parts with truss structures inside, making it the perfect manufacturing method for low-volume, high-performance, high-value vehicles. However, it is certain that AI technology will become commonplace in the near future, so it will be possible to manufacture similar parts using 3D printers. At the very least, parts with optimal shapes made by 3D printers will be more highly rated than special parts made using machining centers, CNC milling cutters, etc. Furthermore, if 3D printers for composite materials such as carbon fiber are developed, parts with overwhelming advantages will be widely used in vehicles such as F1 cars. For motorcycles, it will probably be first used in swingarms. High rigidity, light weight, and with optimal aerodynamics, the swingarm resembles the skeleton of a cheetah. It is a technology that expands dreams.

0 notes

Text

Metal Laser Cutting: Exploring its Benefits for Industrial Applications

In the fast-paced world of industrial manufacturing, precision and efficiency are paramount. One of the technologies that have revolutionized the way industries process metals is metal laser cutting. This advanced technique has become a staple in various sectors, from automotive to aerospace, construction, and electronics, thanks to its versatility and accuracy. Whether you are a manufacturer looking to optimize your production line or a business owner seeking custom metal parts, metal laser cutting offers a range of benefits that can significantly improve your operations.

What is Metal Laser Cutting?

Metal laser cutting is a precise and highly efficient process that uses a focused laser beam to cut through metal materials. The laser is typically generated from a CO2, fiber, or Nd (neodymium-doped yttrium aluminum garnet) source. The focused light beam melts, burns, or vaporizes the material, leaving behind smooth, clean cuts without the need for physical contact with the metal surface. This method offers high accuracy, minimal material waste, and the ability to handle complex designs, making it an essential tool in modern manufacturing.

Key Benefits of Metal Laser Cutting in Industrial Applications

Precision and Accuracy

One of the most significant advantages of metal laser cutting is its unparalleled precision. The focused laser beam allows for cuts with tolerances as low as +/- 0.1mm, which is far superior to traditional cutting methods. This high level of accuracy makes metal laser cutting ideal for applications requiring intricate designs and detailed shapes, such as in the aerospace and electronics industries. The precision also reduces the need for post-processing, saving both time and resources.

Versatility

Metal laser cutting is incredibly versatile, capable of cutting a wide variety of metals including stainless steel, aluminum, carbon steel, copper, and titanium. This versatility makes it suitable for multiple industries, from automotive parts production to custom metal signage. Additionally, laser cutting can handle varying thicknesses of metal sheets, providing flexibility in design and production.

High Speed and Efficiency

Compared to traditional cutting methods, metal laser cutting is significantly faster. The speed of the laser, combined with its precision, allows manufacturers to produce large quantities of components in a shorter amount of time. This increased productivity leads to reduced production costs, making it a cost-effective solution for both small and large-scale projects.

Minimal Material Waste

In conventional cutting methods, such as mechanical cutting or sawing, there is often a considerable amount of material waste due to the larger kerf (cut width) and imprecision. Metal laser cutting, on the other hand, produces a very narrow kerf and requires less material removal, resulting in minimal waste. This not only reduces the overall cost of materials but also makes the process more environmentally friendly by optimizing material usage.

Non-Contact Process

Metal laser cutting is a non-contact process, meaning the cutting tool (laser beam) does not physically touch the material. This eliminates the risk of tool wear and tear, which is a common issue in traditional cutting methods like mechanical sawing or milling. The absence of mechanical stress on the material also prevents deformation, ensuring that the final product maintains its structural integrity and dimensional accuracy.

Automation and Customization

Many metal laser cutting machines are integrated with advanced CNC (Computer Numerical Control) systems, allowing for automated and highly customized cutting processes. This automation ensures consistency and repeatability in large production runs while reducing the likelihood of human error. Additionally, the flexibility of CNC programming allows for the production of highly detailed and customized designs, even in complex geometries, without the need for tool changes or manual intervention.

Reduced Energy Consumption

Despite its high power and efficiency, metal laser cutting is relatively energy-efficient when compared to other cutting methods like plasma cutting. The laser’s focused energy ensures that only the required amount of energy is used for each cut, reducing overall power consumption. For industries seeking to reduce their carbon footprint, this is an added advantage.

Improved Edge Quality

One of the standout benefits of metal laser cutting is the smooth and clean edges it produces. The focused laser beam ensures that cuts are precise and free from burrs, jagged edges, or other imperfections typically found with traditional cutting methods. This high-quality edge finish reduces the need for secondary finishing processes, saving time and labor costs in the manufacturing process.

Common Industrial Applications of Metal Laser Cutting

Metal laser cutting is used across a wide range of industries, thanks to its versatility and efficiency. Some common applications include:

Automotive Industry: Laser cutting is widely used to produce precision automotive parts such as gears, body panels, and custom components.

Aerospace Industry: The need for accuracy and high-quality metal components makes laser cutting an ideal solution for manufacturing aerospace parts.

Construction and Architecture: Metal laser cutting is often used to create intricate architectural designs, custom metal structures, and decorative elements.

Electronics: In the electronics industry, laser cutting is used to produce small, precise metal components for circuit boards, connectors, and heat sinks.

Signage and Metal Art: Laser cutting allows for the creation of customized signs, logos, and artistic metalwork with intricate details.

Conclusion

Metal laser cutting is a powerful and versatile technology that offers numerous benefits for industrial applications. From its high precision and efficiency to its ability to handle complex designs and materials, this method is transforming the manufacturing landscape. Whether you need custom parts for your business or are looking to improve production efficiency, metal laser cutting is an excellent solution.

For more information on how metal laser cutting can benefit your business, visit https://www.qatarsteelfactory.com/product/laser-cutting to explore their comprehensive metal laser cutting services.

0 notes

Text

The Power of CNC Fiber Laser Cutting Machines in Modern Manufacturing

CNC fiber laser cutting machines have altered the assembling industry, giving unrivaled accuracy, speed, and versatility in metal creation. Enterprises, for example, automotive, aerospace, construction, and electronics are progressively embracing these high level machines to improve productivity and decrease operational costs. This blog investigates the innovation behind CNC fiber laser cutting machines, their key benefits, and how they are forming the eventual fate of assembling.

What is CNC Fiber Laser Cutting?

CNC (Computer Numerical Control) fiber laser cutting machines use laser innovation to slice through various materials, primarily metals. The "fiber" in the machine alludes to the utilization of optical fibers as a medium to concentrate the laser bar, considering higher accuracy and effectiveness. The laser shaft is coordinated by computer-controlled instruments, which guarantee reliable, precise cuts even on multifaceted plans.

These machines can cut many materials, including stainless steel, aluminum, brass, copper, and gentle steel, making them incredibly flexible for various enterprises. In contrast to conventional cutting techniques, negligible material wastage, higher exactness, and faster production times.

Key Benefits of CNC Fiber Laser Cutting Machines

1. Unequaled Accuracy

One of the main benefits of CNC fiber laser cutting machines is their accuracy. The engaged laser shaft takes into account very tight cuts, which lessens material waste and guarantees high precision. This degree of accuracy is particularly helpful for businesses that require tight resistances and unpredictable plans, like aerospace and electronics.

Also, the absence of direct contact between the cutting instrument and the material diminishes the gamble of deformation, guaranteeing the honesty of the finished product.

2. Faster Production Times

Speed is one more significant benefit of CNC fiber laser cutting machines. These machines can slice through materials at a lot faster rate contrasted with conventional strategies like mechanical cutting or plasma cutting. Rapid cutting prompts more limited production cycles, permitting makers to fulfill tight time constraints without settling on quality.

The faster cutting times, joined with accuracy, imply that CNC fiber laser cutting machines are great for high-volume production conditions where effectiveness is vital.

3. Versatility Across Materials

CNC fiber laser cutting machines can handle various materials, including metals like steel, aluminum, and copper, as well as non-metallic materials like plastics and earthenware production. This versatility makes them reasonable for a large number of uses across various ventures.

For instance, in the automotive industry, CNC fiber lasers are utilized to cut body boards, motor parts, and other multifaceted parts. In the construction area, they are utilized to cut underlying steel and modified plans for structures and foundation projects.

4. Lower Operational Costs

While the underlying interest in CNC fiber laser cutting machines might be higher than a few conventional cutting strategies, the drawn out operational costs are essentially lower. These machines require less consumables, have low support necessities, and result in less material waste. This implies producers can save money on both material costs and work costs, working on their general benefit.

Also, the expanded proficiency and diminished production times convert into higher result, permitting makers to successfully take on additional ventures and scale their activities.

5. Eco-Friendly and Energy Efficient

CNC fiber laser cutting machines are more energy-efficient contrasted with other laser types, like CO2 lasers. They consume less power, which diminishes operational costs and makes them an eco-friendly choice for organizations hoping to decrease their carbon impression.

Furthermore, since fiber lasers produce cleaner cuts with less waste, they add to more economical assembling rehearses. This is becoming progressively significant as ventures endeavor to take on greener innovations and diminish their ecological effect.

Utilizations of CNC Fiber Laser Cutting Machines

1. Automotive Industry

In the automotive industry, accuracy and speed are basic. CNC fiber laser cutting machines are utilized to create various parts, including motor parts, skeleton parts, and body boards. These machines permit makers to make excellent parts with negligible material waste, further developing both production proficiency and product quality.

2. Aerospace Industry

The aerospace industry demands accuracy and unwavering quality, with parts frequently expected to meet severe resiliences. CNC fiber laser cutting machines are great for creating lightweight, high-strength parts that are fundamental for airplane construction. The accuracy and versatility of these machines make them a significant resource in delivering parts for both business and military airplane.

3. Construction Industry

CNC fiber laser cutting machines assume a critical part in the construction industry by creating primary steel parts, lines, and custom compositional plans. Their capacity to slice through thick materials rapidly and precisely makes them basic in making all that from building structures to decorative components in present day compositional plans.

4. Electronics Industry

In the electronics area, accuracy is of most extreme significance. CNC fiber laser cutting machines are utilized to cut little, complicated parts, for example, circuit sheets, connectors, and nooks. The machines' capacity to handle slight and fragile materials guarantees that electronic gadgets satisfy the fundamental quality guidelines.

Future Patterns in CNC Fiber Laser Cutting

As ventures keep on developing, so too do the innovations that drive producing. CNC fiber laser cutting machines are continually being improved to fulfill the developing needs of the market. A portion representing things to come drifts that are probably going to shape the industry include:

1. Automation and Robotics

The mix of automation and robotics with CNC fiber laser cutting machines will additionally upgrade productivity. Computerized frameworks can handle material stacking and dumping, diminishing the requirement for manual mediation and speeding up. This will permit producers to zero in on additional complicated errands while the machine handles routine cutting activities.

2. Higher Laser Power

As demand for faster and more efficient cutting develops, producers are creating CNC fiber laser cutting machines with higher laser power. This takes into consideration cutting thicker materials without forfeiting accuracy or speed, opening up additional opportunities for ventures that work with uncompromising materials.

3. Customization and Flexibility

The capacity to modify CNC fiber laser cutting machines to meet explicit production needs will become progressively significant. Makers will look for machines that offer more prominent flexibility, permitting them to switch between various materials and plans effortlessly. This pattern will drive advancement in machine plan and programming coordination.

Conclusion

CNC fiber laser cutting machines are changing the manner in which ventures approach metal creation. Their accuracy, speed, and versatility make them key apparatuses for producers in automotive, aerospace, construction, and electronics areas. As innovation keeps on propelling, these machines will assume a significantly more basic part in driving proficiency and development in assembling.

For organizations hoping to remain serious in a speedy market, putting resources into CNC fiber laser cutting machines is a shrewd move. With their capacity to convey great outcomes, decrease operational costs, and further develop productivity, these machines are set to shape the eventual fate of assembling into the indefinite future.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturer#metweld#cncfiberlasercuttingmachine#industrialcncfiberlasercutter#manufacturer#fiberlasercutter

0 notes

Text

Opt For Transformative Building Designs With Cladding Spcialists

Within the field of modern architecture, innovative, sustainable, and aesthetically pleasing building designs are becoming more and more prevalent. Specialists in cladding are essential to the realization of revolutionary architectural concepts because they provide knowledge of materials, methods, and creative solutions that improve the built environment. Cladding experts help create iconic structures that define cityscapes and inspire generations, from famous skyscrapers to sustainable residential developments. This article examines the various ways that experts in cladding contribute to innovative architectural ideas.

MATERIAL INNOVATION:

In order to push the limits of architectural design, cladding professionals are at the forefront of material innovation. They are continuously investigating new materials and technologies. Cladding experts use a broad range of materials to accomplish a variety of aesthetically pleasing and useful goals, from conventional materials like stone and brick to cutting edge materials like glass-reinforced concrete (GRC) and carbon fiber composites.

For instance, elegant and sophisticated modern facades that radiate elegance and sophistication can be created through the use of lightweight and resilient materials like aluminum composite panels. The Cladding Specialists Newcastle incorporates sustainable materials, such recycled glass cladding or recovered wood, also helps to promote sustainability and ecologically conscious design by lowering the project’s carbon impact.

Cladding specialists work with manufacturers, suppliers of building materials, and architects to promote the use of cutting edge materials that improve building designs’ aesthetic appeal, functionality, and sustainability.

CUSTOMIZATION AND PERSONALIZATION:

Cladding specialists’ capacity to personalize and customize facades in accordance with project specifications and the client’s vision is one of their main contributions to transformative building designs. Cladding professionals are able to produce custom cladding solutions that are made to fit the specific requirements of each project by using sophisticated fabrication techniques like digital modeling, computer numerical control (CNC) machining, and parametric design.

Experts in cladding collaborate closely with architects and designers to transform the abstract concepts into concrete architectural aspects, such as dynamic textures, complex geometric patterns, or custom branding elements. Along with giving the building more visual appeal and personality, this degree of personalization also strengthens the building’s identification and brand recognition in the city.

Cladding experts may also maximize material utilization, reduce waste, and improve fabrication process efficiency by using parametric design tools, which helps produce design solutions that are both affordable and environmentally friendly.

INTEGRATION OF BUILDING PERFORMANCE SYSTEMS:

Cladding experts are in charge of incorporating building performance systems into the façade design in addition to aesthetic concerns. The optimization of a building’s energy efficiency, comfort, and environmental performance is contingent upon the incorporation of several technologies, including but not limited to thermal insulation, moisture management, noise control, and passive solar shading.

To improve indoor air quality and lessen the demand for mechanical cooling systems, ventilated façade systems, for example, can be incorporated to allow for natural ventilation and airflow. A building’s total energy performance and occupant comfort are improved when high-performance insulation materials and air barrier technologies are integrated to reduce heat loss and thermal bridging.

In order to create integrated façade solutions that combine performance, functionality, and aesthetic criteria, cladding professionals of Cladding Specialists Newcastle work in conjunction with engineers, sustainability consultants, and building scientist. Buildings that are not only aesthetically pleasing but also robust, sustainable, and efficient are created by cladding professionals through their emphasis on holistic design techniques.

EMBRACING DIGITAL FABRICATION TECHNOLOGIES:

The design and production of cladding have been completely transformed by developments in digital fabrication technologies, which have made it possible to achieve previously unheard-of levels of accuracy, intricacy and efficiency. Cladding experts use technologies like robotic manufacturing, 3D printing, and parametric modeling to shorten lead times, expedite the fabrication process, and maximize the use of available resources.

For instance, complex geometric forms and patterns can be automatically produced by robotic fabrication, opening the door to the development of extremely expressive and sculptural facades. Similarly, rapid prototyping and customization of cladding components are made possible by 3D printing technologies, which facilitate iterative designs processes and increase design flexibility.

Cladding specialists push the limits of architectural innovation and creativity by enabling architects and designers to experiment with new formal expressions and design possibilities through the adoption of digital fabrication technology.

SUSTAINABLE DESIGN PRACTICES:

Modern architecture now places a strong emphasis on sustainable design techniques in an era of growing environmental consciousness and resource scarcity. Specialists in cladding contribute significantly to the advancement of sustainability in the built environment by encouraging the use of ecologically friendly materials, systems, and building techniques.

Cladding experts work in tandem with architects and engineers to include sustainable elements into building facades, such as living walls, green roofs, and passive solar design methods, which in turn promote resilience, biodiversity, and energy efficiency. Recycled, recyclable, and low-impact materials are also used in building projects to lessen their environmental impact, which adds to the built environments overall sustainability.

In addition, Cladding Specialists Newcastle experts in cladding give precedence to methods like prefabrication, modular building, and adaptive reuse since they reduce waste production, construction duration, and interference with the site. Cladding experts aid in the creation of structures that improve the urban fabric while also promoting the community vitality, health, and well-being by advocating for sustainable design principles.

To sum up, experts in the cladding are very essential in creating an innovative construction concept that reshape the city and stimulate creativity. Cladding professionals help create buildings that are not only aesthetically pleasing but also practical, efficient, and sustainable through the use of innovative materials, personalization, performance integration, digital fabrication, and sustainable design. Cladding experts are positioned to take the lead in creating a built environment that is more resilient, inclusive, and sustainable by pushing the bounds of architectural expression and utilizing cutting edge technologies.

Disclaimer: This is generic Information & post; content about the services can be changed from time to time as per your requirements and contract. This is written for only SEO purposes; we are not claiming it is 100% accurate as it's general content. The images we use in this context have been taken from the official website of Newcastle Frame & Truss. To get the latest and updated information, contact us today or visit our website.

0 notes

Text

How CNC Machining Supports Customization of Automotive Parts?

In automotive design and manufacturing, customization is very important. Whether you want to improve a car's performance, change its look, or make it stand out, CNC machining is a great method for customizing car parts.

But what is CNC machining, and how does it help with customization? Let’s explain it in simple terms.

What is CNC Machining?

CNC stands for Computer Numerical Control. It’s a technology that uses computers to control machines that cut, shape, and finish materials. In CNC machining, a computer program directs a machine to perform precise cutting tasks on materials like metal, plastic, and wood. This allows for incredibly accurate and complex shapes to be made, which is essential for customizing automotive parts.

Precision and Accuracy

One of the biggest advantages of CNC machining is its precision. When you want to customize a part of your car, such as a new intake manifold or custom wheels, the parts need to fit perfectly. CNC machines can create parts with extremely tight tolerances, meaning the parts will be exactly as designed. This precision ensures that all customized parts fit perfectly and function as intended.

Creating Complex Designs

Cars often need parts with intricate designs. For example, you might want a custom grille or a specialized bracket for a performance upgrade. CNC machining can handle these complex designs with ease. The computer controls allow the machine to make detailed cuts and shapes that would be very difficult or impossible to achieve by hand. This means that custom designs can be brought to life with high accuracy.

Speed and Efficiency

CNC machines are fast. Once a design is programmed into the computer, the machine can produce parts quickly and consistently. This is especially useful when you need multiple parts, such as for a limited edition vehicle or a small batch of custom accessories. CNC machining can produce these parts faster than traditional methods, saving time and making the customization process more efficient.

Flexibility in Design Changes

Sometimes, a design needs to be adjusted or refined. With CNC machining, making changes to a part’s design is relatively easy. Since the design is controlled by a computer program, you can quickly update the program to reflect any changes. This flexibility means you can experiment with different designs and make adjustments without having to start from scratch each time.

High-Quality Finishes

Custom automotive parts often require a high-quality finish to look great and perform well. CNC machining can achieve smooth, precise finishes on a variety of materials. Whether it’s a custom aluminum wheel or a carbon fiber component, CNC machines can provide the surface quality needed for both functional and aesthetic purposes. This ensures that custom parts not only fit well but also look polished and professional.

Cost-Effective Customization

Although CNC machining may seem expensive at first, it can be cost-effective in the long run. For custom parts, the cost of setting up the machine and programming can be offset by the precision and efficiency of the machining process. Additionally, CNC machining reduces waste material, which helps keep costs down. For custom parts that need to be produced in small quantities, CNC machining can be a cost-effective solution.

Supporting Innovation

The automotive industry is constantly evolving, with new technologies and designs emerging all the time. CNC machining supports innovation by allowing designers and engineers to create and test new ideas quickly. Whether it’s a new engine component, a unique body part, or an innovative accessory, CNC machining provides the flexibility and precision needed to explore and implement new concepts.

In Summary

CNC machining is really important for customizing car parts. It's precise, can handle complex designs, works quickly, and is flexible, making it perfect for creating custom parts. Whether you want to boost your car's performance or change its look, CNC machining can help make your ideas a reality with accuracy and speed. Knowing how to use CNC machining can help you get the best results when customizing your car.

#hlhrapid #rapidprototyping #cncmachining

0 notes

Text

Moulding Tolerances and Surface Finish: Expectations in On-Demand Production

In on-demand production, moulding tolerances and surface finish play a crucial role in determining the quality and performance of the final product. For manufacturers, designers, and engineers, understanding these aspects is key to ensuring smooth and successful project outcomes.

Exploring Moulding in On-Demand Manufacturing

On-demand manufacturing has transformed the moulding landscape, providing unmatched flexibility, speed, and precision. This method allows for the rapid creation of moulded components without the need for extensive tooling or large inventories.

Advantages of On-Demand Moulding

With on-demand manufacturing, moulds can be created swiftly, reducing lead times from weeks to mere days. This rapid process accelerates production cycles and offers the flexibility to modify or iterate designs without incurring hefty tooling costs. The process minimizes the need for large-scale tooling investments and eliminates the burden of storing large inventories. Advanced technologies and precise tooling used in moulding ensure the consistent production of high-quality, reliable parts. Moreover, production levels can be adjusted easily, scaling up or down as demand fluctuates, leading to efficient use of resources.

Common Moulding Techniques in On-Demand Manufacturing

Injection Moulding: Ideal for mass-producing complex parts with stringent tolerances.

CNC Machining: Suitable for creating small to medium-sized components with detailed geometries.

3D Printing: Facilitates rapid prototyping and the production of intricate, custom parts.

Reaction Injection Moulding (RIM): Best suited for producing large, lightweight parts with smooth surfaces.

Materials Used in On-Demand Moulding

Plastics: Including thermoplastics, thermosets, and elastomers for diverse applications.

Metals: Such as aluminum and steel for creating strong, durable components.

Composites: Including carbon fiber and glass fiber for high-performance needs.

Applications of On-Demand Moulding

Aerospace: Creation of lightweight, high-performance components for aircraft and spacecraft.

Automotive: Facilitating rapid prototyping and the production of complex automotive parts.

Medical: Producing precise, customized parts for medical devices and equipment.

Consumer Products: Enabling the quick production of customized components for various industries.

By embracing on-demand manufacturing for moulding, businesses can enhance their production efficiency, lower costs, and expedite the introduction of innovative products to the market.

Moulding Tolerances: Defining the Precision

Moulding tolerances refer to the permissible deviations in the dimensions of parts produced through processes like injection moulding. These tolerances are critical for ensuring that components fit, function, and assemble correctly. On-demand production often delivers tighter tolerances compared to traditional methods, thanks to the use of advanced technologies and precise tooling.

Surface Finish: Balancing Aesthetics and Functionality

Surface finish is a crucial element in moulding that affects both the look and performance of the final product. On-demand manufacturing provides a range of surface finish options, including textured, smooth, or matte finishes. The selected finish can influence the product’s durability, resistance to corrosion, and overall user experience.

Key Factors Impacting Moulding Tolerances and Surface Finish

Several factors play a role in determining moulding tolerances and surface finish in on-demand production:

Material Choice: Different materials shrink at different rates, affecting tolerances and finish.

Tooling Quality: High-quality tooling ensures accurate dimensions and superior surface finishes.

Manufacturing Process: Techniques like injection moulding, CNC machining, and 3D printing each offer unique capabilities in terms of tolerance and surface finish.

Design Complexity: More intricate designs can sometimes challenge the achievement of precise tolerances and surface finishes.

Best Practices for Optimal Moulding Results

To achieve the best possible moulding tolerances and surface finishes in on-demand production:

Collaborate with Experienced Partners: Work with skilled manufacturers and designers to optimize design and material selection.

Set Clear Expectations: Define tolerance and surface finish requirements upfront.

Choose Compatible Materials: Select materials that meet the desired tolerance and finish standards.

Mechkonnect Industrial Solutions Pvt Ltd: Your Trusted Partner