#cable stayed bridge construction

Explore tagged Tumblr posts

Text

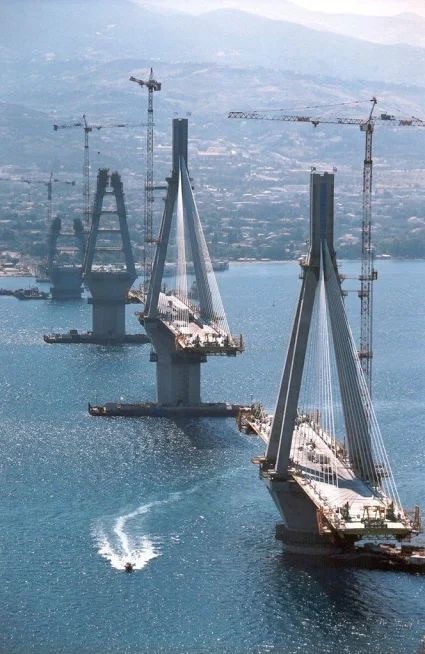

Cable Stayed Bridge - Types, key features and construction

A cable stayed bridge is a modern engineering marvel known for its strength, efficiency, and aesthetic appeal. It uses one or more towers to support the bridge deck through a series of cables, which transfer the load directly to the foundation. Unlike suspension bridges, the cables in a cable stayed bridge connect directly from the deck to the towers in a straight line. This design provides…

#bridges#cable stayed bridge construction#cable stayed bridge design example#cable stayed bridge images#cable stayed bridge surat#cable stayed bridge types#cable stayed railway bridge in india#cable stayed suspension bridge#extradosed bridge vs cable stayed bridge#travel

0 notes

Text

cable stayed

26 notes

·

View notes

Text

Rare Pictures of the Construction of the Brooklyn Bridge

By Carl Seaver

10 December 2024

The Brooklyn Bridge is an iconic structure that connects the boroughs of Manhattan and Brooklyn in New York City.

It stands over the East River. It is a combination of a suspension-style bridge and a cable-stayed bridge.

Talks of building a bridge across the East River began in the early 1800s. The original construction plans and models were created by John A. Roebling (1806-1869).

His son, Washington Roebling (1837-1926), became the chief engineer once the construction plans started moving forward.

Construction officially began in 1870.

Emily Warren Roebling (1843-1903), Washington’s wife, was also an engineer. She ended up playing a pivotal role in the successful completion of the bridge.

The iconic towers sit upon bases known as caissons. These caissons had to be filled be pressurized air to get them to settle deep into their positions in the river.

Many of the workers ended up suffering from what is now know as decompression syndrome (also called the bends).

At the time, it was being called caisson sickness because it was those who worked underwater with the caisson construction who began to suffer from it.

Many workers, including Washington, came down with sever cases of decompression syndrome.

Because Washington was frequently incapacitated, his wife Emily eventually became the main overseer and supervisor of construction.

On top of many workers becoming injured, the bridge also suffered a fire in its early stages of construction.

At its eventual completion, it was the longest suspension bridge of the time.

It is 1,595.5 feet long and stands 127 feet above the water. It was finally completed and opened to the public in 1883.

It has since gone through many restorations to increase safety and repair parts that were becoming worn and dangerous.

In a city full of iconic statues, buildings and entertainment, it stands as one of the most recognizable features in New York City.

#Brooklyn Bridge#Manhattan#Brooklyn#New York City#East River#suspension-style bridge#cable-stayed bridge#caissons#decompression syndrome#John A. Roebling#Emily Roebling#Washington Roebling#construction plans#bridge

3 notes

·

View notes

Text

9 notes

·

View notes

Text

How to Differentiate Between Different Types of Bridges

Bridges are not just remarkable feats of engineering but also symbols of human ingenuity and the desire to overcome geographical obstacles. They come in various shapes and sizes, each tailored to specific needs and conditions. From simple beam bridges to awe-inspiring suspension bridges, understanding the different types of bridges is essential for engineers, architects, and anyone fascinated by…

View On WordPress

#arch bridge#beam bridge#bridge#bridge aesthetics#bridge architecture#Bridge Construction#bridge construction materials#Bridge Design#bridge engineering#bridge foundations#bridge infrastructure#bridge innovation#bridge inspection#Bridge Maintenance#bridge materials#bridge safety#bridge stability#bridge technology#cable-stayed bridge#famous bridges#historical bridges#iconic bridges#modern bridges#suspension bridge#truss bridge#types of bridges

1 note

·

View note

Text

Mackenzie River, NWT

The Mackenzie River (French: Fleuve (de) Mackenzie; Slavey: Deh-Cho [tèh tʃʰò], literally big river; Inuvialuktun: Kuukpak [kuːkpɑk], literally great river) is a river in the Canadian boreal forest. It forms, along with the Slave, Peace, and Finlay, the longest river system in Canada, and includes the second largest drainage basin of any North American river after the Mississippi.

The Mackenzie River flows through a vast, thinly populated region of forest and tundra entirely within the Northwest Territories in Canada, although its many tributaries reach into five other Canadian provinces and territories. The river's main stem is 1,738 kilometres (1,080 mi) long, flowing north-northwest from Great Slave Lake into the Arctic Ocean, where it forms a large delta at its mouth. Its extensive watershed drains about 20 percent of Canada. It is the largest river flowing into the Arctic from North America, and including its tributaries has a total length of 4,241 kilometres (2,635 mi), making it the thirteenth longest river system in the world.

The ultimate source of the Mackenzie River is Thutade Lake, in the Northern Interior of British Columbia. The Mackenzie valley is believed to have been the path taken by prehistoric peoples during the initial human migration from Asia to North America over 10,000 years ago, despite sparse evidence.

The Inuvialuit, Gwich'in and other Indigenous peoples lived along the river for thousands of years. The river provided the major route into Canada's northern interior for early European explorers.

Economic development remains limited along the river. During the 19th century, fur trading became a lucrative business, but this was affected by harsh weather conditions. The discovery of oil at Norman Wells in the 1920s began a period of industrialization in the Mackenzie valley. Metallic minerals have been found along the eastern and southern edges of the basin; these include uranium, gold, lead, and zinc. Agriculture remains prevalent along the south, particularly in the Peace River area. Various tributaries and headwaters of the river have been developed for hydroelectricity production, flood control and irrigation.

Source: Wikipedia

The Deh Cho Bridge is a 1.1 km-long (0.68 mi) cable-stayed bridge across a 1.6 km (0.99 mi) span of the Mackenzie River on the Yellowknife Highway (Highway 3) near Fort Providence, Northwest Territories. Construction began in 2008 and was expected to be completed in 2010 but faced delays due to technical and financial difficulties. The bridge officially opened to traffic on November 30, 2012.��The bridge replaced the MV Merv Hardie, the ferry in operation at the time of opening, and ice bridge combination used for river crossing.

Deh Cho (lit. "Big River") is the Slavey language name for the Mackenzie River.

Source: Wikipedia

#Mackenzie River Access Point#Mackenzie River#Deh Cho Bridge by JR Spronken and Associates Ltd#engineering#Northwest Territories#nature#travel#original photography#vacation#tourist attraction#landmark#landscape#Canada#summer 2024#river bank#the North#Fort Providence#South Slave Region#flora#meadow#forest#woods

13 notes

·

View notes

Text

On July 2nd 1971 The Erskine bridge was officially opened.

Construction on the project began in April 1967 at a cost of £10.5m, which is the equivalent of almost £150m today.

The bridge was designed by Freeman Fox & Partners for the Erskine Bridge Joint Committee. Dr Oleg Kerensky was the partner in charge and the chief design engineer was Dr William Brown under the supervision of Sir Gilbert Roberts. The piers and foundations were designed by W. A. Fairhurst & Partners. The consultant architect was R. E. Slater.

The central span is 305m (1000ft) flanked by anchor spans of 110m each. The total length including approach spans is 1322m. The aerofoil box-girder deck is supported by fourteen diamond-plan, single-shaft concrete piers at a maximum height of 45m above the river. Two central pylons extend 38m above the level of the deck. A 6x4 cluster of galvanized steel cables passes over the saddle of each pylon in a centralised, single plane.

The dual carriageway has cycle lanes and footpaths with metal safety barriers, renewed in 2012. The underside of the deck carries four water mains pipes and two gas pipes. In 2017 the cables were painted and aluminium lighting columns were installed.

The Bridge was a state-of-the-art infrastructure landmark in Scotland for its time and remains one of the country's most architecturally and technically distinguished bridges of the post-war period and beyond its date of construction. It is the first example of a large-scale cable-stayed bridge in Scotland and is recognised for its structural simplicity, economy of materials and slender appearance.

It was designed and built during a period of substantial development in civil engineering and road infrastructure. It illustrates the aspirations for economic and social progress in Scottish society and is directly associated with the period of ambitious transformation of Scotland's modern infrastructure during the 1960s.

The Erskine Bridge is one of only three road bridges in Scotland with a main span exceeding 300 metres. Its minimalistic single-cable design remains exceptionally rare for large-scale road bridges. On completion, the Erskine Bridge is understood to have had the longest span of this type in the world. The appearance of many bridges on this scale have been altered by later alteration and engineering works. The largely unchanged appearance of the Erskine Bridge contributes to its special interest.

Some of these pics I unearthed are brilliant, my faves are, probably the first person to cross the bridge, no health and safety back then, and the photo with the PS Waverley passing by during construction.

20 notes

·

View notes

Text

Yokohama Bay Bridge: Cable-Stayed Bridge over Port of Yokohama

Location: Honmoku Pier, Naka Ward, Yokohama, Japan Timestamp: 16:30 on Sept. 6, 2023

This shot captures the northwest view from the observation deck of Yokohama Port Symbol Tower.

In this perspective, we can observe the Yokohama Bay Bridge, which serves as the gateway to the Port of Yokohama for ships entering and departing from Tokyo Bay.

The bridge boasts a cable-stayed design, featuring an impressive 860-meter (2,820-foot) span that spans Tokyo Bay. This design allows vehicular traffic to circumvent congestion along the bayshore route, providing faster access to Tokyo and Chiba Prefecture.

Completed in September 1989, the bridge was constructed to accommodate even some of the world's largest ships of that time, including the Queen Elizabeth 2. However, two decades later, the bridge's clearance became insufficient for the newer, taller mega cruise ships, forcing them to dock farther from Yokohama's central piers.

In the foreground, construction equipment is visible, illustrating ongoing efforts to extend the pier's length. This expansion aims to meet the ever-growing demand for berthing container ships.

For convenient navigation and additional information, you can refer to the Pix4Japan blog post, which includes Google Maps links to the tower, parking facilities, and the nearest bus stop. Additionally, the blog post offers curated links to relevant websites for further reading: https://www.pix4japan.com/blog/20230906-symbol-tower

Fujifilm X100V with 5% diffusion filter ISO 400 for 1/250 sec. at ƒ/7.1 Classic Chrome film simulation

#横浜ベイブリッジ#ストリートスナップ#横浜港シンボルタワ#pix4japan#X100V#Fujifilm#street photography#Japan#Yokohama#Yokohama Bay Bridge#Yokohama Port Symbol Tower

16 notes

·

View notes

Text

La Paz: Teleferico Adventure

From the central station I took the roja (red) line Teleferico up to the highest point in El Alto, 16 de Julio, since there is a great viewpoint there with La Paz city below and all the snow capped mountains surrounding it. La Paz is just under 3,700m above sea level whereas El Alto is about 4,100m so the gondola ride up definitely made my ears pop. They require masks on the public transit and I had to share the cable car with people on every ride but it’s still the ultimate public transport! I didn’t have any wifi or data once there so I followed directions from a blog I found online to get to the viewpoint. El Alto is definitely a dodgy area, I passed a smoky market that must’ve just closed for the day, crossed a bridge that smelled like piss, and avoided some street dogs as well as dodgy people yelling at me the usual “hey bro, hey you speak English, hey where you from”. It’s so frustrating that so many people do this in South America, and more so that they feel entitled to an actual cordial response or a smile from me like “yes thank you for shouting at me, here is my life story, do you want some money too?” When really they all get ignored and actually deserve to get the middle finger from me too. Approaching the viewpoint there was a police car with two officers which made me feel a little better. It was also deserted around this area except for two ladies sitting in the grass while a fire burned on in a pit beside them. I walked out to the viewpoint, a shoddily constructed railing around a concreted platform with several holes through it large enough to fall through or at least drop a foot into. The pictures however were amazing from here. It was directly under the Teleferico red line so I could see each car passing overhead while I stood there admiring La Paz city. The blog I read had recommended staying for the sunset and then riding back down but as the area was so dodgy I didn’t want to stay there any longer so I headed back down around 4:30pm instead, I had the prime viewing seat for photos of the Cementerio General de La Paz and a little neighbourhood with colourful buildings. The central station was quite cool with a train display and La Paz sign set up for photos so I took some there and then Niki’s caught my eye for dinner. I chose the ribs with chips and coleslaw and also tried a papaya flavoured Fanta. The meal was very average as the pork was super fatty but at least it filled the hole somewhat before buying some water, putting my laundry in with reception, and then going to bed for an early night ready to explore more tomorrow.

2 notes

·

View notes

Text

Trends in Bridge Construction

The bridge construction industry is experiencing a remarkable transformation, driven by technological advancements, sustainable practices, and the growing demands of modern transportation infrastructure. Across continents, engineers and construction experts are pushing the boundaries of what's possible in bridge design and implementation.

In North America, massive projects are redefining infrastructure capabilities. The Gordie Howe International Bridge, spanning the Detroit River between the United States and Canada, represents a pinnacle of modern bridge engineering. With a staggering budget of US$4.8 billion, this groundbreaking project features the longest main span of any cable-stayed bridge in North America, stretching 853 meters. What makes this bridge truly remarkable is its innovative design. It uses no in-water piers for support and incorporates a multi-use path for pedestrians and cyclists, along with advanced security and travel time detection systems.

Across the Pacific, China is making equally impressive strides. The Shiziyang Bridge in Guangzhou will become the world's largest double-deck suspension bridge, with a mind-boggling total length of 35 kilometers. The project showcases cutting-edge construction technology, with manufacturers like Sany and Zoomlion deploying state-of-the-art equipment. Concrete pours involving 25,000 cubic meters and tower cranes with lifting capacities of 20,000 tonnes demonstrate the sheer scale of modern bridge construction.

Sustainability has become a critical focus in bridge development. Engineers are increasingly embracing eco-friendly materials and construction methods that minimize environmental impact. Recycled steel, composite materials, and environmentally friendly concrete mixes are becoming standard. Prefabrication and modular construction techniques are revolutionizing bridge construction, allowing for faster construction times, improved quality control, and reduced carbon footprints.

Smart technology is another game-changing trend. Modern bridges are no longer static structures but intelligent systems with sensors and IoT devices. These technologies enable real-time monitoring of structural health, traffic flow, and potential maintenance needs. By integrating data analytics, engineers can predict and prevent potential issues before they become critical, enhancing safety and efficiency.

The industry is also responding to the challenges of climate change and extreme weather events. Resilient infrastructure has become a key priority, with engineers developing bridges capable of withstanding hurricanes, floods, and earthquakes. This involves utilizing robust materials, creating innovative foundation designs, and building redundancy into structural systems.

Transportation evolution is also driving bridge innovation. High-speed rail networks and expanding transportation hubs require bridges supporting significant weights and high-speed trains. In the United Kingdom, projects like the HS2 rail expansion demonstrate innovative approaches to bridge construction, including advanced transportation techniques such as massive bridge relocation using modular transporters.

Rehabilitation and maintenance of existing infrastructure are equally important. With many bridges aging, there's an increasing demand for advanced inspection and repair technologies. Drones, robotic systems, and sophisticated monitoring techniques are being employed to assess and extend the lifespan of existing structures without disrupting traffic.

From the intricate modular bridge in Birmingham, England, to the massive suspension bridges of China, the global bridge construction market is experiencing a renaissance. As urban populations grow and transportation needs become more complex, bridge construction will continue to evolve. The bridges of tomorrow will be more than just functional structures; they will be intelligent, sustainable, and resilient monuments to human creativity and technological progress.

0 notes

Text

Designs for New Baltimore Bridge Unveiled Almost a Year After Deadly Collapse

Almost a year after the deadly collapse of Baltimore’s Francis Scott Key Bridge, Maryland officials on Tuesday unveiled their designs for its replacement, which will be taller and better protected against ship strikes. Construction of the state’s first cable-stayed bridge could be completed in 2028 and cost upwards of $1.7 billion. With its graceful outline and delicate design, officials said the…

0 notes

Text

Russky Bridge

15 notes

·

View notes

Text

Turnbuckle: Essential Tool for Tensioning and Securing

Abstract

In various industries, from construction to marine, there is a need for secure and reliable tensioning systems. The device that serves this purpose, often overlooked, is an essential component for a wide range of applications: the tensioning tool. These tools are designed to apply controlled tension to cables, wires, and ropes, ensuring they remain in place without shifting or slackening. They provide a crucial link in securing structures, rigging, and other essential components, making them indispensable for safety and efficiency in several professional fields.

Understanding the Tensioning Mechanism

At its core, a tensioning device operates on a simple mechanical principle. It consists of two threaded bolts with opposing directions, a central body to hold them together, and a mechanism that enables easy adjustment of the tension applied to the connected cables or wires. The device functions by rotating these bolts, which either extend or retract, thus increasing or decreasing the length of the device. This action, in turn, tightens or loosens the cable or wire it is connected to, allowing for precise control over the tension applied.

This method is beneficial in various applications because it ensures that wires and cables maintain their desired tension, which is essential for structural integrity. Whether it’s holding up a fence, securing cables in a rigging system, or stabilizing a marine vessel’s rigging, this tool plays a crucial role in maintaining safety, functionality, and durability.

Applications of the Tensioning Tool

1. Construction

In the construction industry, these devices are essential for ensuring that structures remain stable and safe during and after construction. When setting up scaffolding or securing cables, it is important to control the tension carefully. Too much tension can cause the structure to be overly stiff, potentially leading to stress points and breakage. On the other hand, insufficient tension can cause the cables to slacken, compromising the safety and stability of the structure. These devices are often used to tension cables, support beams, and other key structural components, ensuring that each component is set at the correct tension for maximum safety.

2. Marine Applications

In the marine industry, such devices are particularly useful for rigging sailboats and securing the masts. The tension in the rigging needs to be precise, as it ensures that the sails can be adjusted effectively without causing damage to the structure or the vessel’s stability. Over-tightening can lead to breakage, while too little tension can make the sails ineffective and unmanageable. Whether for larger vessels or smaller sailing boats, these tools are instrumental in setting up the rigging properly. They can also be used in the maintenance of mooring lines or securing ropes that hold boats in place.

3. Fencing and Signage

Tensioning tools are also widely used in fencing applications, particularly when installing wire or chain link fences. The wires need to be kept taut to maintain the structure’s integrity. Without adequate tension, the fence can sag over time, leading to an unattractive appearance and potential security issues. These tools ensure that the wire stays taut, preventing it from loosening or bending and maintaining the fence's overall strength. Similarly, they are useful in securing signage in place, ensuring that banners or other large signs stay securely fastened without the risk of flapping or tearing.

4. Bridge Construction and Tensioned Cables

For larger infrastructure projects, like bridges and skyscrapers, tensioning devices play a critical role in maintaining the integrity of the cables that hold up such structures. The tension in suspension bridge cables, for example, must be calibrated precisely to ensure that the structure is stable and able to carry loads without putting too much stress on any individual cable. The tensioning device allows for minute adjustments, ensuring the cables are neither too tight nor too loose, creating the necessary balance for structural strength.

Types of Tensioning Tools

Tensioning tools come in several types, each suited to specific tasks and needs. The most common types include:

1. Manual Devices

Manual tensioning tools are the most basic and cost-effective types. These tools often use a screw mechanism or a ratcheting mechanism to adjust the tension applied to the wire or cable. They are usually lightweight and portable, making them ideal for smaller, less heavy-duty applications. These tools are commonly used in smaller construction or rigging projects, such as fencing or securing cables on smaller boats. Despite their simplicity, they offer adequate precision and reliability for most small-scale tasks. For businesses or individuals seeking reliable equipment for tensioning, a turnbuckle equipment supplier in UAE can provide the necessary tools and expertise. When purchasing from a trusted turnbuckle equipment supplier in UAE, you ensure access to high-quality products that meet your specific tensioning needs.

2. Hydraulic Tools

For larger, more heavy-duty projects, hydraulic tensioning tools are often used. These tools apply pressure via hydraulic force, allowing for much greater tensioning force than manual tools can provide. Hydraulic tensioning tools are used in applications where large cables or structures need to be adjusted, such as in bridge construction or large-scale rigging projects. The advantage of hydraulic tools is that they offer a more consistent and powerful tensioning force, making them suitable for heavy-duty applications.

3. Electric Tensioners

Electric tensioners are used in high-volume applications where speed and efficiency are critical. These tools use electric motors to adjust the tension on cables and wires, which can significantly speed up the process when large amounts of wire need to be tensioned quickly and precisely. Electric tensioners are commonly found in industrial settings and are often used in production lines or during large construction projects where rapid installation of tensioned cables is necessary.

Benefits of Proper Tensioning

Using the right tensioning tool for the job brings a variety of benefits, ensuring that each application is performed with precision and reliability.

1. Safety

The most important benefit of using a tensioning tool is safety. Properly tensioned cables and wires reduce the risk of structural failure, which could otherwise lead to accidents, equipment damage, or even injury. Whether in a construction project or when securing a boat’s rigging, ensuring that cables are at the correct tension helps prevent accidents and maintains the stability of the entire system.

2. Durability and Longevity

When tension is applied correctly, the longevity of the materials is extended. Over-tightened cables can become damaged or brittle, while too much slack can lead to wear over time. Proper tensioning minimizes wear and tear on the materials, ensuring they last longer and perform more effectively.

3. Improved Performance

Whether it's the tension in a bridge’s cables or a boat’s rigging, proper tension ensures that each system works as efficiently as possible. Properly tensioned cables help maintain the desired balance and performance, whether it's the stability of a structure or the functionality of a system.

Conclusion

The tensioning tool is a crucial device across a variety of industries, offering control and precision for a wide range of tasks. Whether in construction, marine applications, fencing, or large infrastructure projects, these tools ensure that cables and wires are securely held in place, preventing accidents and wear. Turnbuckles are a key component in many of these applications, providing the necessary tension to secure cables and wires effectively. With options ranging from manual devices to hydraulic and electric tensioners, there is a tool for every application. By understanding the importance of tensioning and selecting the appropriate tool for the job, professionals can ensure that their systems remain stable, safe, and efficient for years to come. The use of turnbuckles in various industries helps maintain proper tension, ensuring structural integrity and safety in all applications.

0 notes

Text

Bolts: The Essential Fasteners for Strong and Secure Connections

Jinnox Bolt is one of the leading Bolt Manufacturers in India. Bolts are one of the most commonly used fasteners in construction, machinery, and many other industries. These versatile, threaded metal components play a vital role in holding parts together securely, ensuring the structural integrity and functionality of countless applications. Whether you're building a skyscraper, assembling furniture, or constructing a vehicle, bolts are essential for creating strong, durable connections. In this blog, we will explore what bolts are, their types, common applications, and why they are such an integral part of various industries.

What Are Bolts?

A bolt is a type of fastener that consists of a threaded shaft, a head, and sometimes a washer. The head of the bolt is typically hexagonal (though it can also be square, round, or other shapes) to allow for easy gripping with a wrench or socket. Bolts are designed to be inserted into a hole and fastened using a nut, which fits onto the threaded shaft. The combination of the bolt and nut forms a strong, secure connection, and the threading ensures that the bolt stays in place even under heavy loads.

Bolts come in a variety of sizes, materials, and strengths, depending on the specific application. The materials commonly used for bolts include steel, stainless steel, titanium, brass, and aluminum, each providing different levels of corrosion resistance, strength, and durability.

Types of Bolts

There are numerous types of bolts, each designed to serve a specific purpose or function. Some of the most common types include:

Hex Bolts: These bolts have a hexagonal head and are widely used in construction and automotive industries. Their versatility makes them suitable for a variety of applications.

Allen Cap Bolt: As a top Allen Cap Bolt Supplier, we take immense pride in manufacturing and supplying premium quality bolts.

Anchor Bolts: These bolts are used to secure structures to concrete or masonry, providing stability in heavy-duty applications.

Square Bolt: every Square Bolt is subjected to thorough testing and inspection, giving you confidence in the dependability and performance of our goods.

U-Bolts: Shaped like the letter "U," these bolts are used to secure pipes, tubes, or round objects to flat surfaces.

Eye Bolts: With a loop at one end, eye bolts are ideal for lifting or securing loads with ropes or cables.

Common Applications of Bolts

Bolt Manufacturer are used in a vast array of applications across multiple industries, from construction to automotive to aerospace. Some of the most common uses include:

Construction: In the construction industry, bolts are used to secure steel beams, reinforce structural elements, and fasten concrete to steel structures. Bolts are crucial for ensuring the safety and stability of buildings, bridges, and other large structures.

Machinery and Equipment: Bolts are used in the assembly of machines, vehicles, and industrial equipment. They help hold parts together, ensuring that machines function smoothly and safely. Automotive engines, for example, rely on bolts to hold components like the cylinder heads, transmission, and exhaust system in place.

Furniture Assembly: Many types of furniture, from bookshelves to office chairs, are assembled using bolts. Carriage bolts and hex bolts are commonly used for securing various parts, providing strong and durable connections.

Electrical and Electronics: Bolts supplier in India are often used in electrical applications to secure components within electrical cabinets, devices, and circuit boards. They are also used to attach electrical panels to walls or ceilings.

Aerospace and Aviation: In the aerospace industry, bolts play a critical role in securing aircraft parts, such as wings, engines, and landing gear. Given the safety and performance demands of the aviation industry, high-strength bolts made from materials like titanium or high-grade steel are used extensively.

Advantages of Using Bolts

Strength and Durability: Bolts suppliers are designed to handle high loads and stresses. Their threaded design ensures a tight, secure hold, making them ideal for applications that require long-term durability.

Easy to Install and Remove: Unlike some other fasteners, bolts can be easily installed and removed with standard tools like wrenches or sockets. This makes them ideal for applications that require periodic maintenance or repairs.

Versatility: Bolts come in a wide variety of sizes, materials, and types, making them suitable for a vast range of applications, from light-duty to heavy-duty tasks.

Corrosion Resistance: Bolts made from stainless steel or coated with anti-corrosion materials can withstand exposure to moisture, chemicals, and harsh environments. This makes them perfect for use in industries like marine, automotive, and construction.

We are supplier in various cities

Bolt Supplier in Mumbai

Bolt Supplier in Pune

Bolt Supplier in Ludhiana

Bolt Supplier in Rajkot

Bolt Supplier in Ahmedabad

0 notes

Text

youtube

The Insane Future of Bridge Construction Explore the incredible process behind constructing modern-day bridges! In this video, we uncover the advanced engineering, cutting-edge technology, and meticulous planning that goes into building these architectural marvels. From designing and laying foundations to assembling and finishing, learn how these structures connect the world in the most efficient and durable ways possible. Whether it's suspension bridges, cable-stayed designs, or massive overwater constructions, discover the techniques that make them withstand time and the elements. This is a must-watch for engineering enthusiasts, aspiring architects, and anyone curious about modern infrastructure. What’s your favorite bridge in the world? Let us know in the comments below! If you enjoyed this video, give it a thumbs up 👍, share it with your friends, and subscribe to our channel for more fascinating insights into modern construction. Don’t forget to hit the bell 🔔 to stay updated on our latest content! #HowBridgesAreMade #ModernBridges #BridgeEngineering #ConstructionTechnology #EngineeringMarvels #Infrastructure #CivilEngineering #BridgeConstruction #ModernArchitecture #StructuralEngineering Disclaimer: This video is for informational and entertainment purposes only and does not constitute professional advice. via ManufacTour https://www.youtube.com/channel/UC7jM-HeXkReUyl3y6oSU-3w December 21, 2024 at 06:00AM

#digitalmanufacturing#ai#manufactour#techinnovation#manufacturing#materialsscience#automotive#futuretech#Youtube

0 notes

Text

youtube

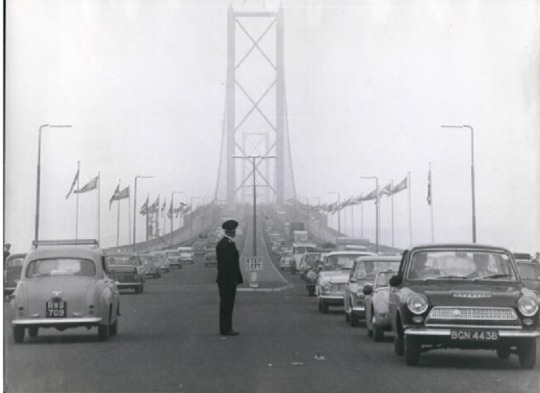

On September 4th 1964 the Forth Road bridge was officially opened to the public.

Soldiers of Lowland regiments from the south linked up symbolically with a Highland brigade from the north to mark the opening of the new crossing, which cuts more than an hour off the journey-time by road.

The Forth Road Bridge at the time the fourth longest in the world. The opening of the Forth Road Bridge marked end of the Ferries across the Forth an 800-year-old service.

At its peak, the service was running 40,000 trips a year, carrying 1.5m people. The four ferryboats have been run by 70 men only 30 of whom were be re-employed on the new bridge collecting tolls. Up to 400 men have worked on the bridge sometimes in very dangerous conditions with winds up to 100mph. Seven men lost their lives - others were saved by the terylene safety nets suspended beneath them. It took 39,000 tons of steel, 30,800 miles of wire in the suspension cables, and is 163ft above the river at its highest point. Tragically 7 workers died during the construction, although another source says only 3 died.

53 years later, to the day the official opening of The new Queensferry Crossing takes place today. The structure spans 1.7 miles (2.7km) making it the longest three-tower, cable-stayed bridge in the world. Another record was set when in 2013 they had the largest continuous underwater concrete pour over 14 days the 24-hour non-stop operation successfully poured 16,869 cubic metres of concrete into the water-filled south tower caisson.The building work was also hit by tragedy with the death of one worker..

While we remember the building of these bridges we also remember those who died on three structures that cross the Firth of Forth.

13 notes

·

View notes