#biodegradable polymers

Explore tagged Tumblr posts

Link

#pioneering marketdigits consulting and advisory private limited#biodegradable polymers market#biodegradable polymers#polymers market

0 notes

Text

Medical Polymer Market Outlook: Trends, Innovations, and Global Dynamics

The medical polymer market has become a pivotal sector, growing due to advancements in healthcare materials. Known for durability, flexibility, and biocompatibility, these polymers are essential across devices, surgical instruments, implants, packaging, and drug delivery systems. The rise in demand reflects industry trends, technological breakthroughs, and growing regulatory standards shaping this market.

The global medical polymer market is valued at USD 41.1 billion in 2024 and is projected to reach USD 60.5 billion by 2029, growing at 8.0% cagr from 2024 to 2029.

Key Market Trends

Biocompatibility Innovations: Biocompatible materials are essential in medical applications where patient safety is paramount. To meet this need, polycarbonate, polypropylene, and polyethylene polymers are engineered to strict medical standards, creating materials that offer safe, effective performance within the body.

Surge in Disposable Devices: Single-use medical products like gloves, syringes, and catheters are gaining traction, especially post-pandemic. Disposable polymers allow manufacturers to produce cost-effective, hygienic products, addressing modern healthcare’s need for cleanliness and infection control.

3D Printing Advancements: Customization has transformed through 3D printing, as tailored prosthetics and surgical tools become accessible. Polymers like PEEK are favored here for strength and adaptability, enabling precise medical solutions suited to individual patient needs.

Sustainability Drives: With heightened environmental awareness, medical manufacturers are focusing on bio-based and recyclable materials. This shift aims to reduce the ecological impact of medical products, reflecting the global push towards sustainable solutions.

Enhanced Drug Delivery Applications: Drug delivery systems require polymers that ensure controlled, sustained release of medication. Bioresorbable polymers are particularly beneficial here, facilitating targeted treatment in chronic and long-term therapies without additional interventions.

Growth Drivers in the Medical Polymer Market

Demand for Minimally Invasive Devices: Polymers are ideal for minimally invasive surgery tools due to their flexibility and durability. As demand for less invasive procedures grows, so does the need for these high-performing materials, making them integral to medical advancements.

Aging Population and Chronic Disease: The global increase in chronic health conditions and an aging population drive demand for medical-grade polymers in implants, devices, and products for ongoing care. This market growth reflects the need for durable, biocompatible materials to improve patient care.

R&D and Technological Investments: Innovations in polymer chemistry and healthcare applications expand the versatility of these materials. Significant R&D investment is pushing the boundaries, enabling entry into new applications and meeting stringent regulatory demands across regions.

Regional Market Insights

The market for medical polymers is expanding globally, with strong growth in North America, Europe, and Asia-Pacific. North America leads due to its advanced healthcare sector and robust R&D focus, while the Asia-Pacific region experiences rapid growth driven by healthcare expansion, population increases, and rising disposable incomes in emerging economies like China and India.

Emerging markets hold considerable growth potential, especially as they build their healthcare infrastructure and address increasing medical needs. Access to quality polymers helps these regions expand their healthcare capabilities, catering to larger populations with advancing healthcare needs.

Challenges and Future Prospects

The medical polymer market faces challenges, such as meeting rigorous regulatory requirements, managing high development costs, and addressing environmental concerns. Compliance with medical standards is necessary but can slow down product development and increase expenses. Additionally, the medical industry’s reliance on single-use polymers prompts a need for eco-friendly, recyclable solutions.

To know more Download PDF Brochure :

The future remains promising. The market’s growth, driven by healthcare demands and technological advances, opens new opportunities in medical material innovation. Companies prioritizing sustainability, compliance, and R&D will be well-positioned to capitalize on the evolving needs of this essential industry.

As materials science and healthcare continue to intersect, medical polymers are set to play a critical role in advancing medical technologies, improving patient outcomes, and meeting global healthcare needs.

#medical polymer market#biocompatible materials#disposable medical devices#3D printing in healthcare#sustainable polymers#biodegradable polymers#drug delivery systems#minimally invasive devices#chronic disease treatment#aging population healthcare#medical-grade polymers

0 notes

Text

Compostable straws and bags made by Good2Go set the green standard

As the world increasingly prioritizes environmental sustainability, there’s a notable shift towards eco-friendly consumer products. One of the most promising advancements in this area is the emergence of compostable plastic straws, eco-friendly t-shirt bags, and eco-friendly plastic bags, offering sustainable alternatives to their polluting counterparts.

Conventional plastic straws and bags have long raised concerns among environmentalists and conscious consumers due to their persistence in landfills, oceans, and natural environments, taking several centuries to decompose, if at all. This accumulation of plastic waste has compromised the marine life, ecosystems, and the overall health of our planet.

However, with Good2Go, these worries can end instantly. It is an organisation committed to meeting customer demands for sustainability and combating plastic pollution at the same time. Good2Go’s compostable plastic straws, eco-friendly t-shirt bags, and eco-friendly plastic bags are crafted from natural materials like cornstarch, PLA, or biodegradable polymers.

Moreover, the adoption of compostable alternatives brings several benefits:

1. Reduced Environmental Impact: Compostable plastics can be broken down by microorganisms, leaving behind only water, carbon dioxide, and organic matter, significantly reducing plastic waste in landfills and oceans.

2. Sustainable Resource Use: Made from renewable, plant-based sources, compostable plastics lessen reliance on fossil fuels and non-renewable resources used in traditional plastic production.

3. Improved Waste Management: Compostable plastics easily integrate into existing composting programs, providing an eco-friendly disposal option.

4. Consumer Empowerment: By opting for compostable plastic straws and bags, consumers actively contribute to a more sustainable future, making a tangible difference in their daily lives.

As consumer awareness of environmental impacts grows, so does the demand for compostable plastic alternatives. Businesses and individuals are embracing this shift, acknowledging the importance of sustainable consumption in creating a greener future.

By transitioning to compostable drinking straws and bags, consumers take a significant step towards reducing their carbon footprint and supporting an eco-friendly lifestyle. This simple change can inspire others, fostering a ripple effect of positive environmental change.

In conclusion, the rise of compostable plastic straws and bags signifies a promising stride toward a more sustainable future. Embracing these eco-conscious consumer products enables us to collectively work towards a cleaner, greener world for future generations.

#eco-friendly t-shirt bags#eco-friendly plastic bags#biodegradable polymers#compostable plastic straws#compostable drinking straws#good2go#good2go bags

1 note

·

View note

Text

First-year MIT students gain hands-on research experience in supportive peer community

New Post has been published on https://thedigitalinsider.com/first-year-mit-students-gain-hands-on-research-experience-in-supportive-peer-community/

First-year MIT students gain hands-on research experience in supportive peer community

During MIT’s Independent Activities Period (IAP) this January, first-year students interested in civil and environmental engineering (CEE) participated in a four-week undergraduate research opportunities program known as the mini-UROP (1.097). The six-unit subject pairs first-year students with a CEE graduate student or postdoc mentor, providing them with an inside look at the interdisciplinary research being conducted in the department. Overall, eight labs in the department opened their doors to the 2024 cohort, who were eager to take advantage of the opportunity to collaborate with current students and build a community around their interests.

“The mini-UROP presents an opportunity for first-year students to experience the diverse climate and sustainability research happening in our department,” says CEE department head and JR East Professor Ali Jadbabaie. “Fostering hands-on experiences in a collaborative, supportive educational environment is central to our mission of preparing students with the skills needed to positively shape the future of our society, systems, and planet.”

The mini-UROP also benefits the graduate students and postdocs who take on the role of mentor. Mentor support is a key component to completing a successful mini-UROP project and requires graduate students and postdocs to hone their leadership and teaching skills.

“I’m always interested in mentoring undergraduate students and to have someone help me with my project,” says postdoc and mentor Yue Hu. “Participating in this project made me excited that my research attracted undergraduates’ interest.”

Guiding students through interactive workshops

Preparation for this year’s mini-UROP began at the end of November, when participants attended the Lightning Lectures, an event that served as an opportunity for the mentors to give lightning-fast pitches on their research projects. First-year students then ranked the projects that they were interested in working on and were matched according to their preferences.

The interdisciplinary nature of the department’s research offered participants a wide range of projects to work on, from redefining autonomous vehicle deployment to mitigating the effects of drought on crops. Once each of the 11 participants were matched to a project, the mini-UROP Kick-off Lunch brought students and mentors together and ensured each group had an open line of communication.

Throughout the duration of the mini-UROP, participants attended three workshops led by Jared Berezin, the manager of the Civil and Environmental Engineering Communication Lab (CEE Comm Lab). The communication lab is a free resource to undergraduates, graduates, and postdocs in the CEE community, providing one-on-one coaching and interactive workshops. Held on Fridays during IAP, the workshops helped students contextualize their research and ensure they were able to explain the scientific concept of their work during presentations.

“Students were fortunate to have research mentors in the lab, and my goal was to provide communication mentorship outside of the lab,” says Berezin. “Our weekly workshops focused on scientific communication strategies, but perhaps more importantly I’d prompt them to talk about their projects, ask questions, and brainstorm together. They really embraced the opportunity to foster a supportive peer community, which I think is a core part of the CEE experience.”

A significant challenge students face while completing the program is condensing their research down to a clear and concise two-minute presentation. To assist with this task, the third workshop featured a presentation by CEE Comm Lab fellow Matthew Goss, providing students with a preview of how their own presentations may take shape. Students also had the option to meet with Comm Lab fellows to practice presenting and get feedback.

“The final talks were impressive, and I was proud of the students for approaching both their research and communication challenges with such curiosity and thoughtfulness,” Berezin remarks.

Reinforcing research interests

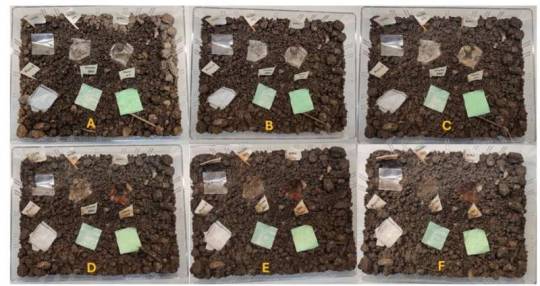

Iraira Rivera Rojas, a first-year student interested in materials science and environmental engineering, worked with Yue Hu, a postdoc in Associate Professor Benedetto Marelli’s lab. Their project used biodegradable polymers, specifically silk fibroin, to make particles that can be used to encapsulate agrochemicals, lessening their negative impact on the environment. Regenerated from silk cocoons, the silk fibroins are used as a building block to revolutionize the agriculture and food industry.

“When I saw the project description, it was a mix of both of my interests,” Rojas says. “I thought it would be a good way to try out both fields.” While she is still deciding which course she will major in, she says that participating in the mini-UROP confirmed her interest in the field.

Working with mentor Jie Yun, a graduate student in Associate Professor David Des Marais’s lab, Sheila Nguyen and Ved Ganesh used biodiversity to increase crop drought resistance. Nguyen and Ganesh studied barely, oat, wheat, and Brachypodium, and compared how these plants grow under conditions of drought stress. Currently, a separate model must be trained for each plant species and type of cell. The project aimed to develop a machine learning model that can generalize to different species of plants and cell types.

Vinn Nguyen and Diego Del Rio worked with mentor Cameron Hickert, a graduate student in Assistant Professor Cathy Wu’s Lab. Their project focused on making autonomous vehicles safer and more reliable, specifically in areas transitioning on and off highways. As self-driving cars gain popularity, reports of crashes and similar incidents demonstrate deficiencies in the current system. Nguyen and Del Rio sourced satellite imagery and applied computer vision techniques to investigate the safeness of these areas. The goal of their project was to design an infrastructure-supported approach to autonomous vehicles that allows passenger to comfortably work, play, and connect with partial autonomy.

Jordyn Goldson worked in the Terrer Lab with her mentor Kathryn Wheeler, a graduate student in Assistant Professor Cesar Terrer’s lab, on a project focused on plant senescence. As warmer temperatures lengthen plants’ growing period each year, total annual photosynthesis increases along with the amount of carbon plants remove from the atmosphere. Her project investigated if model performance differs between predicting visually assessed timing versus remotely sensed timing. The findings can help advance knowledge of the mechanisms behind forest canopy color change and the ability of forests to capture more carbon by growing longer, mitigating climate change.

Based on the success of her mini-UROP project, Mairin O’Shaughnessy, who worked in Professor Heidi Nepf’s lab with graduate student Ernie Lee, will be continuing her research on “Computer Vision for Plant Density Analysis” in the spring.

“When Heidi and Ernie, the grad student advisor for the project, proposed continuing the project in spring, I was interested in continuing to learn more and explore vision processing for counting real plants,” O’Shaughnessy says.

Jennifer Espinoza, another student who worked in the Nepf Lab, plans to continue her research with graduate student James Brice on “Characterizing Flow Conditions.”

“One of the main things I loved most about working in the lab was the passion that my mentor, James, portrayed for his work, as well as his willingness to teach me anything without complaint,” says Espinoza. “Most of all, though, I became extremely passionate about my work because it has the potential to make an impact in not only society but the natural environment. The significance of my work and the welcoming working environment have prompted me to continue researching at Nepf Lab in the spring.”

#2024#agriculture#Analysis#approach#atmosphere#autonomous vehicles#biodegradable#Biodegradable Polymers#biodiversity#Building#Capture#carbon#Cars#cell#cell types#challenge#change#Civil and environmental engineering#Classes and programs#climate#climate change#collaborate#collaborative#Color#communication#Community#computer#Computer vision#course#crops

0 notes

Text

Modern Technologies and Innovations in Metallurgy: Shaping Industries with Cutting-Edge Metal Advanc

In the ever-evolving world of metallurgy, the fusion of cutting-edge technologies and innovative approaches has led to remarkable advancements in the way we produce, manipulate, and utilize metals. From enhancing material properties to revolutionizing manufacturing processes, modern technologies are reshaping the metallurgical landscape. In this article, we will delve into the exciting realm of metallurgical innovations that are shaping industries across the globe

GET ACCESS FOR MORE INFO

1. Introduction: Unveiling a Metallurgical Revolution

In the past, metallurgy primarily focused on extracting and refining metals. However, the integration of modern technologies has propelled metallurgy into a new era. Today, researchers and engineers are exploring groundbreaking methods that go beyond traditional metallurgical boundaries. This shift has given rise to an era where the properties of metals can be tailored with unparalleled precision, opening doors to a plethora of applications across industries.

The introduction of nanotechnology into metallurgy has heralded a paradigm shift in the understanding and manipulation of materials. At the forefront of this revolution is the ability to harness the power of the nanoscale, where materials exhibit unique and extraordinary properties. Within the realm of metallurgy, nanotechnology has enabled the creation of metals with enhanced strength, improved conductivity, and even self-healing capabilities. These advancements are not simply incremental; they represent a leap into a realm of possibilities that were once relegated to the realm of science fiction.

2. Nanotechnology's Micro Wonders in Metallurgy

Nanotechnology has ushered in a microcosmic revolution in metallurgy. By manipulating materials at the nanoscale, scientists can achieve unprecedented properties in metals, such as enhanced strength, conductivity, and even self-healing capabilities. This ability to engineer materials at such a minuscule level has far-reaching implications, not only for traditional industries but also for cutting-edge technologies like electronics, energy storage, and even medical devices.

The process of alloy design and customization has been redefined by the integration of molecular-level insights. In the past, alloy development was often a trial-and-error process, with researchers relying on experimentation to achieve desired properties. However, with advancements in our understanding of materials at the atomic and molecular levels, metallurgists can now tailor alloys with specific attributes in mind. This level of precision allows for the creation of materials that are optimized for particular applications, whether it's for high-stress environments, extreme temperatures, or specific chemical interactions.

3. Alloy Design and Customization: Metallurgy at the Molecular Level

Advancements in metallurgy are enabling the tailored design of alloys with specific properties. By understanding the molecular composition, researchers can fine-tune metals to exhibit desired characteristics, opening doors to applications in aerospace, automotive, and beyond. This level of control not only enhances the performance of materials but also contributes to the development of more efficient and sustainable technologies.

The influence of 3D printing on metal fabrication cannot be overstated. This innovative manufacturing technique has disrupted traditional production processes by enabling the creation of complex metal structures with unprecedented precision. Unlike conventional subtractive manufacturing methods, which involve cutting away material, 3D printing is an additive process that builds objects layer by layer. This allows for intricate designs that were once inconceivable, reducing material waste and offering the potential for on-demand, customized metal parts.

4. 3D Printing's Influence on Metal Fabrication

The marriage of metallurgy and 3D printing has revolutionized metal fabrication. Additive manufacturing allows intricate designs, reduces material waste, and offers the potential for on-demand, customized metal parts. This level of flexibility and efficiency has far-reaching implications for industries such as aerospace, healthcare, and even fashion, where lightweight yet durable metal components are in high demand.

As we continue our journey through the captivating landscape of modern metallurgical innovations, we will explore the pivotal roles of artificial intelligence, sustainable practices, and remarkable materials that are poised to shape the future of industries around the world. The fusion of science, technology, and imagination is propelling metallurgy to heights previously deemed unattainable, and the story is just beginning to unfold.

5. The Role of Machine Learning and AI in Metallurgical Research

Machine learning and AI are accelerating metallurgical research by swiftly analyzing vast datasets and predicting material behaviors. This synergy expedites alloy discovery, process optimization, and quality control.

Eco-Friendly Metallurgy: Sustainable Practices and Green Materials In an era marked by environmental consciousness and sustainable practices, the metallurgical industry is undergoing a transformative shift towards eco-friendliness. This shift is not only driven by regulatory pressures but also by a collective commitment to minimize the ecological footprint of metallurgical processes while maintaining and even enhancing material performance.

Traditional metallurgical processes have often been associated with resource-intensive practices, including energy consumption and the generation of waste products. However, advancements in technology and a growing awareness of environmental concerns have prompted metallurgists to seek innovative solutions that align with sustainable development goals.

One significant aspect of eco-friendly metallurgy is the development of green materials. These materials are characterized by their reduced environmental impact throughout their lifecycle, from extraction and production to eventual disposal. Researchers are exploring alternative sources of raw materials, such as recycling scrap metal and utilizing bio-based feedstocks, which not only conserve resources but also reduces the need for environmentally taxing mining operations.

Furthermore, energy-efficient processes are being integrated into metallurgical operations. Technologies like electric arc furnaces, which use electricity instead of fossil fuels, are gaining prominence due to their reduced carbon emissions and enhanced energy efficiency. These eco-friendly practices not only reduce the industry's carbon footprint but also contribute to cost savings in the long run.

"Shaping metals, shaping industries: A journey through the forefront of metallurgical advancements." - [METNMAT RESEARCH AND INNOVATION]

In the pursuit of sustainability, metallurgical research is focusing on minimizing waste generation and pollution. Efforts are being made to develop closed-loop systems that recycle and reuse process byproducts, thereby minimizing the environmental impact. Additionally, advanced filtration and treatment techniques are being implemented to reduce the release of harmful substances into the environment. Eco-friendly metallurgy extends beyond the production phase. The design of products for end-of-life considerations is gaining traction. Metallurgists are exploring ways to make products more easily recyclable, ensuring that valuable metals can be reclaimed and repurposed, reducing the demand for virgin resources. This circular economy approach not only conserves resources but also reduces waste and promotes a more sustainable future.

7. High-Temperature Superconductors:

Paving the Way for Future Applications Imagine a world where electricity could flow without resistance, leading to unparalleled energy efficiency and transformative technological advancements. High-temperature superconductors are poised to make this vision a reality. These remarkable materials exhibit zero electrical resistance at temperatures higher than conventional superconductors, which typically require extremely low temperatures to function.

The discovery and understanding of high-temperature superconductors have opened up a realm of possibilities for various industries. One of the most significant applications is in power transmission and distribution. Currently, a substantial amount of energy is lost during long-distance electricity transmission due to resistance in the wires. High-temperature superconductors could revolutionize this process by allowing electricity to flow without loss, leading to more efficient and reliable power grids.

In the field of medicine, high-temperature superconductors have the potential to advance magnetic resonance imaging (MRI) technology. These materials can create powerful and compact magnets, enabling the development of more portable and higher-resolution MRI machines. This could lead to improved diagnostic capabilities and enhanced patient care. Furthermore, high-temperature superconductors have implications for transportation systems. The development of superconducting magnets could lead to more efficient and faster train systems, known as maglev trains, which use magnetic levitation to eliminate friction and increase speeds. This technology could revolutionize the way we travel and transform urban transportation networks.

As researchers continue to delve into the properties and applications of high-temperature superconductors, the potential for innovation seems boundless. From energy to healthcare to transportation, these materials have the power to reshape industries and pave the way for a more efficient and technologically advanced future.

8. The Fascinating World of Shape Memory Alloys

Shape memory alloys (SMAs) are a captivating class of materials that possess the extraordinary ability to "remember" and recover their original shape after undergoing deformation. This unique property is a result of a reversible phase transformation that occurs within the material's atomic structure.

The concept of SMAs was first introduced in the 1960s, and since then, they have found diverse and remarkable applications across various industries. One of the most prominent applications is in the field of medicine, particularly in the development of stents. Stents made from SMAs can be compressed to a smaller size, allowing for minimally invasive procedures during insertion. Once in place, the stent can recover its original shape, providing support and improving blood flow in narrowed or blocked arteries.

SMAs are also making waves in the aerospace and automotive industries. In aerospace, these alloys are used in components that require precise shape changes, such as deployable structures and adaptive wings. In the automotive sector, SMAs are being explored for use in smart materials that respond to changes in temperature, which could lead to innovations in fuel efficiency and safety.

Another fascinating application of SMAs is in robotics. These alloys enable the creation of robotic components that can change shape in response to external stimuli. This opens up possibilities for soft robotics and wearable technologies that can adapt to different tasks and environments.

The allure of shape memory alloys lies in their ability to seamlessly combine mechanics with materials science. As researchers continue to unravel the intricacies of these materials, new applications and innovations are likely to emerge, further expanding the boundaries of what is possible in fields ranging from healthcare to engineering.

9. Metallurgy in Medicine:

From Biodegradable Implants to Drug Delivery The convergence of metallurgy and medicine has given rise to groundbreaking innovations that are transforming healthcare practices and patient outcomes. The use of metals in medical applications is not a recent development; however, recent advancements are pushing the boundaries of what metals can achieve within the realm of medicine.

One notable area of innovation is the development of biodegradable metal implants. Traditional implants, such as those made from titanium or stainless steel, often require a second surgery for removal once the healing process is complete. Biodegradable implants, on the other hand, gradually dissolve over time, eliminating the need for a second procedure. These implants are particularly advantageous in pediatric patients, as they eliminate the need for invasive procedures as the child grows.

Metals are also being harnessed for their unique properties in drug delivery systems. Nanoparticles made from metals can be engineered to carry and release drugs with remarkable precision. These nanoparticles can target specific cells or tissues, increasing the efficacy of treatments while minimizing side effects. Additionally, metals like gold and iron are being explored for their potential in hyperthermia therapy,

where targeted heating of cancer cells using metal nanoparticles enhances the effectiveness of treatments like chemotherapy.

In the realm of diagnostics, metallurgy plays a crucial role in the development of medical devices. Metals are integral components of medical imaging technologies, such as X-ray machines and MRI scanners. These devices rely on the interactions between metals and electromagnetic fields to create detailed images of the body's internal structures, aiding in the diagnosis and treatment of various medical conditions.

"From nanoscale wonders to eco-conscious practices, metallurgy's evolution knows no bounds." - [METNMAT RESEARCH AND INNOVATION]

As metallurgical research continues to intersect with medical science, the potential for transformative advancements is immense. From regenerative medicine to personalized treatments, the collaboration between metallurgy and medicine is poised to reshape the landscape of healthcare, improving patient outcomes and enhancing quality of life.

12. Conclusion: Where Innovation and Metal Converge

In the dynamic realm of metallurgy, innovation is the driving force. The fusion of modern technologies with traditional metalworking practices has unlocked a realm of possibilities, from life-changing medical applications to eco-friendly industrial processes.

FAQs (Frequently Asked Questions)

1. How has nanotechnology impacted metallurgy?

Nanotechnology has revolutionized metallurgy by enabling precise manipulation of materials at the nanoscale, resulting in metals with extraordinary properties.

2. What are high-temperature superconductors, and how do they work?

High-temperature superconductors are materials that can conduct electricity without resistance at higher temperatures than conventional superconductors, holding potential for various technological advancements.

3. Can you explain the concept of shape memory alloys?

Shape memory alloys can "remember" their original shape and return to it after deformation, making them valuable for applications requiring repeated shape changes.

4. How is metallurgy contributing to sustainable practices?

Metallurgy is adopting sustainable practices through the development of eco-friendly materials and energy-efficient processes that reduce its environmental impact.

5. What role does AI play in modern metallurgical research?

AI accelerates metallurgical research by analyzing large datasets, predicting material behaviors, and facilitating tasks like alloy discovery and process optimization.

FIX YOUR MEETING NOW

#Alloy Manufacturing#Alloysfuture trends#Future Trends#Biodegradable Polymers#Manufacturing#Innovations in New Materials

0 notes

Text

Durable supramolecular plastic is fully ocean-degradable and doesn't generate microplastics

Researchers led by Takuzo Aida at the RIKEN Center for Emergent Matter Science (CEMS) have developed a new durable plastic that won't pollute our oceans. The new material is as strong as conventional plastics and biodegradable, but what makes it special is that it breaks down in seawater. The new plastic is therefore expected to help reduce harmful microplastic pollution that accumulates in oceans and soil and eventually enters the food chain. The experimental findings are published Nov 22 in Science. Scientists have been trying to develop safe and sustainable materials that can replace traditional plastics, which are non-sustainable and harm the environment. While some recyclable and biodegradable plastics exist, one big problem remains. Current biodegradable plastics like PLA often find their way into the ocean where they cannot be degraded because they are water insoluble. As a result, microplastics—plastic bits smaller than 5 mm—are harming aquatic life and finding their way into the food chain, including our own bodies.

Read more.

#Materials Science#Science#Supramolecular#Plastics#Polymers#Environment#Pollutants#Cross linking#Biodegradable

40 notes

·

View notes

Text

Coronary stents have evolved the treatment of coronary artery disease, with life-saving support from keeping blocked arteries open.

0 notes

Text

god that one tweet shitting on indie artist shops for making charms is so annoying to me

#like ok. why are we picking this one fuckin thing#get mad at plastic waste all around the world ?????? the fact we made a biodegradable mlp and people got mad bc it was TOO LOUD?#IT CRINKLED TOO LOUD SO THEY DIDNT USE IT . SO NOW WE USE MORE SHIT THAT WILL NEVER DEGRADE#a company thats laser cutting fucken . acrylic in reasonable quantities that serves a wide variety of artists who are#probably pre order manufacturing most of their stuff is the weirdest thing ever to get mad about#like ok. yes. as a person who believes in communism this would not be cool under communism . obviously. but can we not understand#the nuance of the transition from capitalism to communism and how its not really a solid argument to say stuff like#well artists are the petite bourgeoise for ordering 30 farcille charms from a chinese manufacturer#does that not seem . MAYBE blwon out of proportion to you. just maybe . and the alternative would be? buying from companies? is that better#or should we just not have art in our lives like im just wondering. then we should cut out all plastics? good luck buying Anything Ever the#its probably just for shock value and interactions (the og tweet) but im still like dear god . this is such a stupid thing take#and people were like 'omg yes i want more handmade goods at cons' OK PAY $60 FOR THEM. NOW !!!!!!!!!! PSYCHIC BEAM . no one wants to pay fo#art anyway everyones just morality jerking each other off at the idea that polymer will be erased forever and artists magicallyget paid wel#d.txt#anyway. yeah can u tell im abnormal about manufacturing i really like this stuff bc theres a whole world to learn about#and comfortingly- not all of it is bad! there's a lot of things that are very sustainable in manufacturing! <3

0 notes

Text

Global biodegradable bone graft polymers market size was valued at US$ 326.12 Mn in 2019 and is expected to reach US$ 365.45 Mn by 2027, at a CAGR of 7.24% during a forecast period.

0 notes

Text

Polymers have many of the characteristics of an ideal biomaterial; they are lightweight and strong, are inert or biodegradable (depending on their chemical structure) and have physical properties (softness, rigidity and elasticity) that are easily tailored to match those of natural tissues.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quote#chemistry#nonfiction#textbook#polymers#biomaterials#lightweight#strong#inert#biodegradable#chemical structure#softness#rigidity#elasticity#natural tissues

0 notes

Text

#biodegradable#biodegradablepackaging#biodegradables#biodegradablepolymers#polymerscience#polymers#biodegradablepolymersmarketgrowth#biodegradablepolymersmarketresearch#biodegradablepolymersmarketsize#biodegradablepolymersmarketreport#biodegradablepolymersmarketanalysis#grandresearchstore

0 notes

Link

#adroit market research#biodegradable polymer#biodegradable polymer market#biodegradable polymer industry

0 notes

Text

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

New Post has been published on https://thedigitalinsider.com/the-next-frontier-how-3d-printing-is-revolutionizing-manufacturing-technology-org/

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

3D printing, also known as additive manufacturing, has gained significant popularity in recent years, revolutionizing the manufacturing industry. The concept of 3D printing dates back to the 1980s when it was first introduced as a rapid prototyping technology. However, it is only in the past decade that 3D printing has gained widespread recognition and adoption in various industries.

The growing popularity of 3D printing can be attributed to its ability to create complex and customized objects with ease. Traditional manufacturing methods often involve multiple steps and processes, which can be time-consuming and costly. 3D printing simplifies the manufacturing process by directly creating objects layer by layer from a digital design, eliminating the need for molds or tooling.

The central piece of a 3D printer – illustrative photo. Image credit: Christian Englmeier via Unsplash, free license

The History of 3D Pringting

The concept of additive manufacturing has existed since the 1940s. In 1945, sci-fi author Murray Leinster described a machine that could “make drawings in the air” and output plastic parts layer-by-layer in his short story “A Logic Named Joe.” However, it took a few more decades for this vision to become reality.

1980s: Early Prototyping

In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute invented one of the first working rapid prototyping systems. It used photopolymers that could be cured by UV light to build parts additively.

In 1984, Charles “Chuck” Hull filed a patent for stereolithography (SLA), which described an additive manufacturing process using photopolymers cured layer-by-layer by UV lasers. He later co-founded the company 3D Systems to commercialize SLA 3D printers.

In 1986, Carl Deckard, an undergraduate at the University of Texas, filed a patent for selective laser sintering (SLS), another 3D printing process that used a laser to fuse powder material. Deckard’s patent was licensed by DTM corporation, which released the Sinterstation 2000, the first SLS machine, in 1992.

In 1989, S. Scott Crump invented fused deposition modeling (FDM) and patented the technology. This process used a heated nozzle to extrude thermoplastic filament material layer by layer. Crump later commercialized it through the company Stratasys, which he co-founded.

1990s: Industry Growth

In 1992, 3D Systems released the SLA-250, which was the first commercially available 3D printer. Meanwhile, Stratasys introduced their first commercial FDM 3D printer in 1992 as well.

Through the 1990s and 2000s, the industry saw rising adoption and usage of additive manufacturing for rapid prototyping across automotive, aerospace, medical, consumer goods and other industries. Both established corporations and startups expanded the capabilities of 3D printing during this period.

2000s: Patent Expiration, Desktop 3D Printers

A significant milestone came in 2009 when key SLA patents expired, opening up the technology. This allowed for the rise of desktop SLA 3D printers like the Form 1, developed by startup Formlabs in 2012.

The expiration of FDM patents around 2010 similarly saw a wave of open source FDM/FFF desktop 3D printers like the RepRap, inspiring companies like MakerBot. This drove increased adoption of desktop 3D printing.

The Basics of 3D Printing: How it Works and its Advantages

The process of 3D printing involves several steps. First, a digital design of the object is created using computer-aided design (CAD) software. This design is then converted into a format that can be read by the 3D printer. The printer then builds the object layer by layer using various materials such as plastic, metal, or even biological materials.

One of the key advantages of 3D printing is its ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. Traditional methods often involve subtractive processes, where material is removed from a larger block to create the desired shape. In contrast, 3D printing is an additive process, where material is added layer by layer to create the final object.

Another advantage of 3D printing is its ability to create customized products. With traditional manufacturing methods, producing customized products can be expensive and time-consuming. However, with 3D printing, each object can be easily customized by simply modifying the digital design before printing.

From Prototyping to Production: How 3D Printing is Changing the Manufacturing Process

One of the key roles of 3D printing in manufacturing is in the prototyping stage. Traditionally, prototyping involved creating molds or tooling, which can be expensive and time-consuming. With 3D printing, prototypes can be created quickly and cost-effectively, allowing for faster iteration and refinement of designs.

However, 3D printing is not limited to prototyping alone. It has the potential to replace traditional manufacturing methods in certain applications. For example, in industries such as aerospace and automotive, where complex geometries are often required, 3D printing can offer significant advantages over traditional methods. By eliminating the need for molds or tooling, 3D printing can reduce costs and lead times while enabling the production of lightweight and optimized components.

Customization and Personalization: The Power of 3D Printing in Meeting Customer Demands

One of the key advantages of 3D printing is its ability to create customized products. Traditional manufacturing methods often involve producing large quantities of identical products, which may not meet the specific needs or preferences of individual customers. With 3D printing, each product can be easily customized to meet the unique requirements of each customer.

This ability to create customized products has a significant impact on the customer experience. Customers today are increasingly looking for personalized products that reflect their individual tastes and preferences. By offering customized products, companies can differentiate themselves from their competitors and build stronger relationships with their customers.

Reducing Costs and Waste: The Economic Benefits of 3D Printing in Manufacturing

One of the key advantages of 3D printing is its potential to reduce manufacturing costs. Traditional manufacturing methods often involve multiple steps and processes, each adding to the overall cost of production. In contrast, 3D printing simplifies the manufacturing process by directly creating objects from a digital design, eliminating the need for molds or tooling.

By reducing the number of steps and processes involved in manufacturing, 3D printing can significantly reduce costs. This is particularly beneficial for small and medium-sized enterprises (SMEs) that may not have the resources to invest in expensive molds or tooling. With 3D printing, SMEs can compete with larger companies by offering customized products at a lower cost.

In addition to reducing costs, 3D printing also has the potential to reduce waste. Traditional manufacturing methods often result in significant material waste, as excess material is removed during the production process. With 3D printing, only the required amount of material is used, minimizing waste and reducing environmental impact.

Sustainability and Environmental Impact: How 3D Printing is Helping to Reduce Carbon Footprint

In addition to reducing waste, 3D printing also has the potential to reduce carbon footprint. Traditional manufacturing methods often involve transporting raw materials and finished products over long distances, resulting in significant carbon emissions. With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering carbon emissions.

Furthermore, 3D printing enables the use of more sustainable materials. For example, bio-based materials can be used in 3D printing, reducing reliance on fossil fuels and minimizing environmental impact. Additionally, 3D printing allows for the optimization of designs, resulting in lighter and more efficient products that require less energy to produce and use.

The Role of 3D Printing in Industry

The impact of 3D printing on various industries is significant. In the healthcare industry, 3D printing has revolutionized medical device manufacturing by enabling the production of customized implants and prosthetics. In the aerospace industry, 3D printing has been used to create lightweight components that improve fuel efficiency and reduce emissions.

The potential for 3D printing to disrupt traditional manufacturing industries is also significant. For example, in the automotive industry, 3D printing has the potential to transform the production of spare parts. Instead of maintaining large inventories of spare parts, manufacturers can simply 3D print the required parts on demand, reducing costs and lead times.

The Future of Manufacturing

The potential for 3D printing to revolutionize the manufacturing industry is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in various industries. The ability to create complex and customized objects with ease will continue to drive the growth of 3D printing in manufacturing.

However, there are also challenges and opportunities associated with 3D printing in manufacturing. One of the key challenges is the need for skilled operators who can design and operate 3D printers effectively. Additionally, there are regulatory challenges that need to be addressed, particularly in industries such as healthcare where safety and quality standards are critical.

The Challenges of 3D Printing in Manufacturing: Overcoming Technical and Regulatory Hurdles

One of the key technical challenges of 3D printing in manufacturing is the limited range of materials that can be used. While 3D printing has made significant advancements in recent years, there are still limitations in terms of the types of materials that can be used. For example, metals such as titanium and aluminum are commonly used in traditional manufacturing methods but are more challenging to 3D print.

Another technical challenge is the need for post-processing and finishing. While 3D printing can create complex geometries with ease, the surface finish of 3D printed objects is often rough and requires additional processing to achieve the desired quality. This can add time and cost to the manufacturing process.

In addition to technical challenges, there are also regulatory challenges associated with 3D printing in manufacturing. In industries such as healthcare, where safety and quality standards are critical, there is a need for regulatory frameworks to ensure that 3D printed products meet the required standards. This includes the need for validation and certification processes to ensure the safety and efficacy of 3D printed medical devices.

The Impact of 3D Printing on Supply Chain Management: Opportunities and Challenges

The potential for 3D printing to disrupt supply chain management is significant. With traditional manufacturing methods, products are often manufactured in one location and then transported to various distribution centers or retail stores. This can result in long lead times and high transportation costs.

With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering lead times. This has the potential to transform supply chain management by enabling companies to produce products on demand, reducing inventory costs and improving responsiveness to customer demands.

However, integrating 3D printing into supply chain management also presents challenges. For example, companies will need to invest in 3D printing infrastructure and develop new processes and workflows to support on-demand manufacturing. Additionally, there may be challenges in terms of intellectual property protection and ensuring product quality and consistency across different manufacturing locations.

The Future of 3D Printing in Manufacturing: Emerging Trends and Technologies

The future of 3D printing in manufacturing is promising, with several emerging trends and technologies driving its growth. One of the key trends is the development of new materials that can be used in 3D printing. Researchers are exploring the use of materials such as graphene, carbon fiber, and biodegradable polymers, which offer improved strength, durability, and sustainability.

Another emerging trend is the development of multi-material and multi-color 3D printing technologies. Currently, most 3D printers can only print objects using a single material or color. However, researchers are working on developing printers that can print objects using multiple materials or colors simultaneously, opening up new possibilities for complex and customized designs.

The Promise of 3D Printing in Revolutionizing Manufacturing

3D printing has the potential to revolutionize the manufacturing industry. Its ability to create complex and customized objects with ease, reduce costs and waste, and promote sustainability makes it an attractive option for manufacturers across various industries.

While there are challenges and opportunities associated with 3D printing in manufacturing, the promise of this technology is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in manufacturing, leading to a more efficient, sustainable, and customer-centric manufacturing industry.

3D printing is transforming manufacturing across industries in revolutionary ways. Its ability to rapidly prototype designs, create complex geometries, enable mass customization, reduce waste, and distribute production is disrupting traditional processes. Companies are adopting 3D printing to accelerate product development, unlock new design possibilities, produce specialized components, and manufacture goods on-demand. While the technology does have some limitations currently, advancements around speed, materials, and costs are helping address these.

Overall, 3D printing provides unmatched flexibility that is spurring a manufacturing revolution. It allows for more sustainable production methods with less waste and emissions. As the capabilities of 3D printing continue to advance, its applications will expand even further. Forward-thinking companies that leverage this technology now will gain key competitive advantages. Adoption is still in early phases, signaling immense room for growth. 3D printing is undoubtedly redefining manufacturing as we know it and enabling the factories of the future.

#1980s#250#3d#3D printing#additive manufacturing#aerospace#aerospace industry#air#aluminum#applications#automotive#automotive industry#biodegradable#Biodegradable Polymers#carbon#carbon emissions#carbon fiber#carbon footprint#certification#challenge#Chemistry & materials science news#Color#colors#Companies#computer#customer experience#dates#Design#desktop#development

0 notes

Text

Biomimetic Materials: Nature-Inspired Innovations

Innovation has always been driven by the marvels of nature, and biomimetic materials stand as a testament to this dynamic interplay between science and the natural world. With an ingenious blend of cutting-edge technology and insights from Mother Earth, biomimetic materials have revolutionized industries across the spectrum, from architecture to medicine. In this article, we delve into the fascinating realm of biomimetic materials, exploring their origins, applications, and the awe-inspiring potential they hold for the future.

Metnmat Research and Innovation

Introduction

Nature has perfected its designs over millions of years, leading scientists and innovators to draw inspiration from its intricate patterns and ingenious mechanisms. Biomimetic materials are the remarkable result of these endeavors, mimicking nature's principles to create materials that can outperform traditional ones in various ways.

"From architecture to medicine, biomimetic materials rewrite the rules of design."

The Inspiration from Nature

Biomimicry, the process of imitating natural processes and structures, has led to some of the most groundbreaking inventions. From Velcro, inspired by burdock burrs, to the Shinkansen bullet train, designed after the kingfisher's beak, nature's influence is far-reaching. Scientists study the lotus effect to create self-cleaning surfaces and spider silk to engineer lightweight, strong fabrics.

Biomimetic Materials in Architecture and Design

Architects and designers are harnessing biomimetic materials to create sustainable and energy-efficient structures. The Eastgate Centre in Zimbabwe, inspired by termite mounds, regulates temperature without conventional heating or cooling systems. The development of adaptive facades and self-healing concrete showcases nature's elegance and efficiency in the built environment.

Medical Marvels: Biomimetics in Healthcare

The medical field benefits immensely from biomimetic materials. Prosthetics, inspired by the movement of muscles and tendons, offer greater functionality and comfort. Biomimetic nanoparticles can precisely deliver drugs to targeted cells, enhancing treatment efficiency while reducing side effects. The potential for growing replacement organs through tissue engineering is also a tantalizing possibility.

Industrial Applications and Sustainability

Industries like manufacturing and transportation are embracing biomimetic solutions for enhanced efficiency and sustainability. The study of sharkskin has led to aircraft designs that reduce drag, improving fuel efficiency. Biomimetic adhesives find use in robotics and construction, offering robustness and flexibility. By emulating nature's circular systems, biomimetic materials contribute to a more sustainable future.

Advancements in Biomimetic Research

The field of biomimetic materials is constantly evolving, driven by innovative research. Nanotechnology and biotechnology converge to create materials with unprecedented properties. Researchers are exploring the potential of artificial photosynthesis to harness solar energy efficiently. As our understanding of nature deepens, so too does our ability to translate its brilliance into groundbreaking technologies.

Challenges and Future Prospects

While biomimetic materials hold immense promise, challenges persist. The complexity of natural systems can be difficult to replicate, and ethical considerations arise when extracting resources from the environment. However, as technology advances and interdisciplinary collaboration flourishes, these hurdles are likely to be surmounted, opening doors to unimaginable possibilities.

Conclusion-

Biomimetic materials have ignited a revolution by channeling the genius of nature into human innovation. By emulating the intricacies of the natural world, we have unlocked a treasure trove of possibilities that span across industries and hold the potential to reshape our world for the better. As we stand on the cusp of a new era, guided by nature's wisdom, the journey of biomimetic materials continues to unfold, captivating our imaginations and driving us toward a brighter future.

"Nature's blueprints inspire innovation, and biomimetic materials bring these blueprints to life." - Metnmat Research and Innovation

FAQs-

Q1: What are biomimetic materials?

A: Biomimetic materials are innovative substances inspired by nature, designed to mimic biological structures and processes for improved performance.

Q2: How do biomimetic materials differ from traditional ones?

A: Biomimetic materials draw inspiration from nature's efficiency, resulting in enhanced properties and functionalities compared to conventional materials.

Q3: Where are biomimetic materials applied?

A: They find applications in diverse fields such as architecture, medicine, manufacturing, and transportation, revolutionizing industries with their unique capabilities.

Q4: Are biomimetic materials sustainable?

A: Yes, biomimetic materials often promote sustainability by emulating nature's circular systems and reducing environmental impact.

Q5: What challenges does biomimetic research face?

A: Complexities in replicating nature's intricacies and ethical concerns regarding resource extraction are challenges that researchers strive to overcome.

Fix Your Meeting Today!

#Metallurgy#Alloy Manufacturing#Biodegradable Polymers#future trends#Innovations in New Materials#Heat Treatment

0 notes

Text

Researchers invent 100% biodegradable 'barley plastic'

A biofriendly new material made from barley starch blended with fiber from sugarbeet waste—a strong material that turns into compost should it end up in nature—has been created at the University of Copenhagen. In the long term, the researchers hope that their invention can help put the brakes on plastic pollution while reducing the climate footprint of plastic production. Enormous islands of plastic float in our oceans and microscopic particles of it are in our bodies. The durability, malleability and low cost of plastics has made them ubiquitous, from packaging to clothing to aircraft parts. But plastics have a downside. Plastics contaminate nature, are tough to recycle and their production emits more CO2 than all air traffic combined. Now, researchers at the University of Copenhagen's Department of Plant and Environmental Sciences have invented a new material made from modified starch that can completely decompose in nature—and do so within only two months. The material is made using natural plant material from crops and could be used for food packaging, among many other things.

Read more.

31 notes

·

View notes