#biodegradablepolymers

Explore tagged Tumblr posts

Text

The PLGA Market: Unlocking Opportunities Across Industries

The Poly(lactic-co-glycolic acid) (PLGA) market is growing steadily, driven by its unique versatility and biocompatibility. As a biodegradable polymer, PLGA has become essential in diverse industries such as healthcare, biotechnology, packaging, textiles, and agriculture. With its ability to degrade at controlled rates and adaptability in formulation, PLGA continues to redefine possibilities across these sectors. Let’s dive deeper into its evolving applications and market potential.

Healthcare: A Breakthrough in Drug Delivery and Medical Devices

In healthcare, PLGA has revolutionized drug delivery systems and medical devices. Thanks to its biocompatibility and FDA approval for medical use, it’s a go-to material for sustained-release drug formulations. By encapsulating drugs within PLGA-based nanoparticles and microparticles, manufacturers can ensure precise, controlled release, reducing side effects. This technology is particularly vital for cancer therapies, vaccines, and chronic disease treatments.

PLGA’s role in tissue engineering and regenerative medicine is equally transformative. As a scaffold material, it facilitates tissue growth and aids in wound healing and artificial organ development. With the rise of personalized medicine and advanced therapies, the demand for PLGA in healthcare is poised for significant growth.

Biotechnology: Driving Innovation and Precision

Biotech firms are leveraging PLGA’s properties to push the boundaries of research and development. Its predictable degradation rates allow the creation of delivery systems that release therapeutic agents with precision. For instance, PLGA carriers play a critical role in gene therapy by effectively delivering DNA and RNA-based treatments.

Furthermore, PLGA is used in developing biosensors and diagnostic tools, where its structural stability enhances accuracy. This polymer continues to enable breakthroughs in biotechnology, empowering researchers to create advanced solutions for global health challenges.

Medical Institutions: Improving Patient Care

PLGA’s applications in drug delivery and medical devices directly benefit medical institutions. PLGA-coated implants and surgical sutures, for example, enhance biocompatibility and reduce post-surgical complications. Biodegradable stents and wound dressings made from PLGA improve recovery times and outcomes for patients.

With minimally invasive procedures becoming the norm, hospitals and clinics increasingly rely on PLGA-based innovations to enhance treatment efficiency. This aligns with broader trends in integrating cutting-edge materials into patient care strategies.

Packaging: Championing Sustainability

The packaging industry is under immense pressure to adopt eco-friendly materials, and PLGA is emerging as a solution. Being fully biodegradable, it addresses the environmental issues associated with conventional plastics. Its ability to form films and coatings makes it ideal for moisture-resistant and antimicrobial packaging, especially for food and pharmaceuticals.

As consumers demand sustainable packaging and governments enforce stricter environmental regulations, businesses investing in PLGA solutions can stay ahead of the curve while building a reputation for environmental responsibility.

Textiles: Redefining Functionality

The textile sector is exploring PLGA for its potential to create smart and functional fabrics. Its compatibility with other materials allows for innovations like controlled-release textiles. Fabrics incorporating PLGA can deliver antimicrobial agents, fragrances, or skincare ingredients over time, enhancing their functionality.

These advancements are particularly impactful in medical textiles, such as wound dressings and compression garments, where PLGA’s properties contribute to improved therapeutic outcomes. As wearable technology gains popularity, the role of PLGA in textiles is expected to expand further.

Agriculture: Enabling Sustainable Farming

In agriculture, PLGA is making strides as a material for controlled-release fertilizers and pesticides. Its biodegradability ensures no harmful residues are left in the soil, supporting sustainable farming practices. By delivering nutrients and agrochemicals precisely where needed, PLGA reduces waste and boosts crop yields.

The potential for PLGA extends to biodegradable films for seed protection and soil enhancement. As the agricultural industry faces the dual challenges of increasing food production and minimizing environmental harm, PLGA offers practical, sustainable solutions.

Market Outlook: A Bright Future

The global PLGA market is on a growth trajectory, fueled by advancements in manufacturing processes and rising environmental consciousness. As production becomes more cost-effective, PLGA’s accessibility across industries will increase, unlocking new applications.

For industries like healthcare, biotechnology, packaging, textiles, and agriculture, PLGA represents a transformative material that bridges functionality with sustainability. Businesses that embrace this versatile polymer can gain a competitive edge and lead their markets.

Download PDF Brochure :

In a world striving for sustainability and innovation, PLGA stands out as a pivotal material. Its wide-ranging applications and eco-friendly nature make it a game-changer for industries aiming to elevate their offerings while reducing environmental impact. By incorporating PLGA into their strategies, companies can pave the way for growth, innovation, and a more sustainable future.

#PLGAMarket#BiodegradablePolymers#HealthcareInnovation#SustainablePackaging#BiotechnologyAdvancements#SmartTextiles#SustainableAgriculture

0 notes

Text

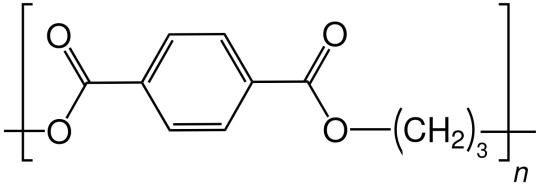

Polytrimethylene Terephthalate Industry Outlook: Growth, Challenges, and Future Prospects

The global polytrimethylene terephthalate market size is predicted to reach USD 1.41 billion by 2030, according to a report by Grand View Research, Inc., growing at a CAGR of 5.4% from 2022 to 2030. The increasing market of textile industries is anticipated to boost the demand for PTT during the forecast period. Furthermore, the rising demand for apparel and automotive carpets is expected to increase the product demand resulting in the growth of the overall industry in the years to come. Many countries have set stringent regulations due to increased environmental concerns for promoting sustainable & innovative PTT demand. Companies are spending heavily on developing adhesives, which are non-ozone depleting and free from harmful compounds (VOCs), solvents, and toxins.

Polytrimethylene Terephthalate Market Report Highlights

Bio-based products witnessed high demand in recent years due to growing usage from major end-use industries, such as automotive, textile, and medical

Fibers is the most common application for PTT owing to its high demand for the manufacturing of carpets, apparels, and engineering plastics globally. It is used to manufacture different automotive interior parts, such as carpets, fabrics, seat belts, and others

The industry is growing owing to the rising product demand from the textile industry. Technological advancements, innovations in plastics, and evolved decontamination devices are boosting the demand further

Major manufacturers have opted for acquisition and merger strategies for expansion of their compounding plants, rather than establishing new plants, to strengthen their position in the global landscape

For More Details or Sample Copy please visit link @: Polytrimethylene Terephthalate Market Report

In June 2020, Teijin Frontier Co., Ltd., a fiber manufacturer, introduced Solotex Eco-Hybrid, a highly stretchable and dyeable product compared to petroleum-derived material. Eco-Hybrid marks a significant line in Teijin Frontier’s PTT fiber Solotex product portfolio. PTT is used across different end-use industries, such as textile, automotive, packaging, building & construction, consumer goods, and the medical industry. It is majorly used in fiber applications like carpet fabrics, automotive fabrics, apparel, and engineering plastics. Bio-based PTT is expected to grow at a significant CAGR over the forecast period owing to its properties, such as resistibility, compressibility, and eco-friendliness.

#PTTMarket#PolytrimethyleneTerephthalate#PolyesterIndustry#ChemicalMarket#SustainableMaterials#PolymerInnovation#TextileApplications#PolyesterResins#GreenChemistry#GlobalChemicalIndustry#BiodegradablePolymers#MarketAnalysis#RawMaterialsSupply#PolyesterFiber#ManufacturingTrends#PolyesterFilms#PolymerTechnology#MarketInsights#ResinDemand#EcoFriendlyMaterials

0 notes

Text

#biodegradable#biodegradablepackaging#biodegradables#biodegradablepolymers#polymerscience#polymers#biodegradablepolymersmarketgrowth#biodegradablepolymersmarketresearch#biodegradablepolymersmarketsize#biodegradablepolymersmarketreport#biodegradablepolymersmarketanalysis#grandresearchstore

0 notes

Text

Bio-based Emulsion Polymers Market Forecast 2024 to 2032

Bio-based emulsion polymers are types of polymers which are synthesized using bio-based or renewable raw materials. Emulsion polymers are polymers that are dispersed in water to form stable emulsions, and they find applications in various industries such as coatings, adhesives, textiles, and more. The use of bio-based feedstocks in the production of emulsion polymers is driven by the desire to reduce the reliance on fossil fuels and decrease the environmental impact of polymer production.

The Bio-based Emulsion Polymers Market was valued at USD 2583 Million in 2022 and is expected to register CAGR of 4.31% by 2032.

Growing awareness and concern about environmental issues, including climate change and plastic pollution, have led to a greater demand for sustainable and eco-friendly alternatives. Bio-based emulsion polymers, which are derived from renewable resources, are seen as a more environmentally friendly option compared to their petrochemical-based counterparts.

Get a Free Sample Copy

#BioBasedPolymers#EmulsionTechnology#GreenChemistry#SustainableMaterials#RenewablePolymers#EcoFriendlyProducts#BioMaterials#PolymerInnovation#EnvironmentallyFriendly#BiodegradablePolymers#GreenIndustry

0 notes

Text

Super-Absorbent Polymer Tech Market: Projected Growth from $9.8B to $17.5B by 2034

Super-Absorbent Polymer Tech Market is projected to grow significantly, from $9.8 billion in 2024 to $17.5 billion by 2034, reflecting a CAGR of 5.8%. This market focuses on the development and commercialization of polymers that can absorb and retain large quantities of liquids relative to their mass. These advanced materials find applications across various industries, including personal hygiene products, agriculture, medical uses, and industrial applications like spill control. The growth is driven by ongoing innovations in polymer chemistry, with a particular emphasis on enhancing absorption efficiency and developing biodegradable options that align with sustainability trends.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11128 &utm_source=SnehaPatil&utm_medium=Article

The hygiene products segment remains the dominant force in the market, with baby diapers and adult incontinence products playing crucial roles in the personal care sector. As the global population grows, particularly in emerging economies, the demand for such products continues to rise, fueling the market. The agriculture segment is the second-highest performer, driven by the increasing need for moisture retention in water-scarce regions. North America leads the market, supported by strong technological adoption and a large consumer base, while Europe follows with significant contributions from Germany and France, where sustainability regulations drive innovation. The Asia-Pacific region, especially China and India, is witnessing rapid expansion due to growing populations and higher disposable incomes, driving demand for both hygiene and agricultural products.

Key players like BASF SE, Evonik Industries, and Nippon Shokubai Co. Ltd. dominate the market with their innovative product offerings. The market is also shaped by increasing research and development efforts, particularly in the creation of biodegradable polymers and sustainable practices.

#SuperAbsorbentPolymers #HygieneProducts #AgricultureInnovation #SustainableTech #BiodegradablePolymers #PolymerChemistry #WaterRetention #IndustrialAbsorbents #MedicalApplications #PersonalCare #AbsorbentMaterials #SustainableSolutions #PackagingTech #EcoFriendlyProducts #ThickeningAgents #PolymerTechnology #AgriTech #WasteManagement #PolymerResearch #EnergyEfficient #WaterConservation #ChemicalInnovation #SmartManufacturing #FoodPackaging #ConsumerGoods #MarketGrowth #EmergingMarkets

0 notes

Text

Polymerization

Polymerization is a chemical process in which monomers (small molecules) chemically bond together to form long-chain macromolecules known as polymers. This process can occur through various mechanisms, such as addition polymerization (where monomers join without byproducts) or condensation polymerization (where small byproducts like water are released). Polymers produced by these reactions serve as the foundation for a wide range of materials, including plastics, rubbers, fibers, and resins. Innovations in polymerization techniques, such as controlled/living polymerization, ring-opening polymerization, and emulsion polymerization, enable the synthesis of advanced materials for applications in biomedicine, electronics, construction, and environmental sustainability.

International Chemistry Scientist Awards

Website: chemistryscientists.org

Contact us: [email protected]

Nominate now: https://chemistryscientists.org/award-nomination/?ecategory=Awards&rcategory=Awardee

#sciencefather#researchawards#Professor,#Lecturer,#Scientist,#Scholar,#Researcher #Polymerization #Polymers #MaterialScience #Chemistry #SustainableMaterials #Macromolecules #Plastics #BiodegradablePolymers #ChemicalEngineering #InnovationInMaterials #CondensationPolymerization #AdditionPolymerization #SmartMaterials #AdvancedMaterials

1 note

·

View note

Text

#IMIR#BiodegradablePolymersMarket#BiodegradablePolymersMarketresearch#BiodegradablePolymers#Biodegradable

0 notes

Link

#BiodegradablePolymers#BiodegradablePolymersmarket#BiodegradablePolymersmarketforecast#BiodegradablePolymersmarketanalysis#BiodegradablePolymersmarketsize

0 notes

Text

Biodegradable Polymers in Controlled Drug Delivery Systems

Biodegradable Polymers in Controlled Drug Delivery Systems #biodegradablepolymers #drugdelivery #controlledrelease #sustainedrelease #targeteddelivery #chronicdisease #cancertherapy #diabetesmanagement #osteoarthritis #implantabledrugdelivery

Biodegradable polymers have emerged as a promising material for the development of controlled drug delivery systems. These polymers can be degraded by the body’s own enzymes and can be designed to release drugs at a specific rate and location. Photo by MART PRODUCTION on Pexels.com Table of Contents Table of Contents Introduction Importance of controlled drug delivery systemsTypes of…

View On WordPress

0 notes

Text

Global #StarchBlended #BiodegradablePolymer Market growing at a CAGR of 15% during the forecast period 2020-2025. https://bit.ly/2SjLbha Keyplayers: #PlanticTechnologies #BASF #NihonCornstarch #BioGrade #Balson #Novamont #Rodenburg #TryEco #marketresearch #IndustryARC

0 notes

Text

Medical Polymer Market: Trends, Innovations, and Growth

The medical polymer market has seen remarkable growth in recent years, driven by technological advancements, increasing healthcare demands, and a growing preference for lightweight, biocompatible materials in the medical field. As polymers continue to replace traditional materials like metals and ceramics, their role in medical devices, drug delivery systems, and implants is becoming more significant.

Market Overview

Medical polymers, which include resins, fibers, and elastomers, play a crucial role in healthcare. These materials offer a variety of benefits such as flexibility, durability, and biocompatibility, making them suitable for a range of medical applications, including:

Medical devices: Polymers are commonly used in manufacturing surgical instruments, diagnostic equipment, and prosthetics due to their sterilizability and resistance to chemicals.

Implants: Medical-grade polymers are increasingly favored in implants for their biocompatibility, helping to reduce the risk of infection and improving patient recovery time.

Pharmaceuticals: Polymers are utilized in controlled drug delivery systems and packaging, ensuring medication is delivered effectively and safely.

The global medical polymer market was valued at USD 20.2 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of around 8.5% from 2021 to 2028. This growth is primarily driven by the increasing use of minimally invasive procedures, the rising geriatric population, and the ongoing need for advanced medical devices.

Key Trends and Drivers

Growing Demand for Biocompatible and Biodegradable Polymers Biocompatibility is essential in medical devices and implants, where materials must not react negatively with the human body. Biodegradable polymers are gaining traction in wound care, tissue engineering, and drug delivery, as they reduce the need for second surgeries to remove devices, such as stitches or implants.

Advances in 3D Printing Technology 3D printing, or additive manufacturing, has revolutionized the medical polymer market by allowing for customized, patient-specific medical devices and implants. This technology facilitates the creation of complex structures that were previously impossible with traditional manufacturing methods. Polymers used in 3D printing include polyether ether ketone (PEEK) and polylactic acid (PLA), both of which are biocompatible and ideal for producing precise medical parts.

Rise in the Use of Polymeric Nanomaterials Nanotechnology is reshaping healthcare, particularly in drug delivery and diagnostics. Polymeric nanoparticles are used to create more efficient drug delivery systems, improving the bioavailability and targeting of medications. These nanomaterials enable the delivery of drugs directly to diseased tissues, minimizing side effects and enhancing patient outcomes.

Increased Focus on Sustainable Healthcare Solutions As the world becomes more focused on sustainability, the healthcare industry is no exception. There is a growing interest in developing eco-friendly medical polymers that not only meet regulatory standards but also minimize environmental impact. Companies are exploring alternatives to petroleum-based polymers, including bio-based plastics and recycling initiatives, to reduce waste in the medical sector.

Key Players in the Market

Some of the leading companies in the medical polymer market include:

BASF SE: A global leader in chemical manufacturing, BASF offers a wide range of medical polymers, including biocompatible and biodegradable materials.

Dow Inc.: Known for its extensive polymer portfolio, Dow provides medical-grade polymers that meet stringent regulatory requirements.

Celanese Corporation: A key player in the development of high-performance medical polymers, Celanese focuses on creating materials that are resistant to heat and chemicals, making them ideal for surgical instruments.

Eastman Chemical Company: With a focus on innovation, Eastman develops advanced polymers for medical devices and packaging, particularly those that prioritize patient safety and hygiene.

These companies are investing heavily in research and development (R&D) to create next-generation medical polymers that can address the evolving needs of the healthcare industry.

Challenges Facing the Medical Polymer Market

While the medical polymer market is growing rapidly, it also faces certain challenges:

Stringent Regulatory Approvals: Medical polymers must meet rigorous safety and performance standards set by regulatory bodies such as the FDA and EMA. This can slow down the introduction of new materials into the market.

High Production Costs: The manufacturing process for medical-grade polymers is often complex and costly. Companies must balance the need for innovative materials with cost-effective production methods to remain competitive.

Environmental Concerns: The medical industry generates significant amounts of plastic waste, particularly from disposable medical devices. Finding sustainable solutions while maintaining product safety and efficacy is a pressing concern for manufacturers.

Future Outlook

The future of the medical polymer market looks promising, with several factors contributing to its continued expansion. Technological innovations, such as 4D printing (which allows materials to change shape in response to stimuli) and smart polymers (that can respond to changes in their environment), are set to revolutionize the industry. Moreover, the increasing demand for personalized medicine will drive the need for custom-made medical devices and implants, further fueling the growth of 3D printing in healthcare.

Additionally, as healthcare providers seek to improve patient outcomes while reducing costs, medical polymers will continue to be a preferred choice due to their versatility, cost-effectiveness, and ability to meet the stringent requirements of the medical industry.

Download PDF Brochure :

The medical polymer market is poised for robust growth, driven by advances in technology, an aging population, and the rising demand for biocompatible materials in healthcare. Industry experts should pay close attention to the developments in biodegradable polymers, 3D printing, and nanotechnology, as these trends will shape the future of the market. With the right balance of innovation and sustainability, the medical polymer industry will continue to play a vital role in improving healthcare outcomes worldwide.

#MedicalPolymers#HealthcareInnovation#BiocompatibleMaterials#MedicalDevices#3DPrinting#SustainableHealthcare#MedicalPolymerMarket#Nanotechnology#BiodegradablePolymers#MedicalImplants#DrugDelivery#HealthcareTrends#MedicalMaterialScience#MedicalPolymerIndustry#MedicalGradePolymers

0 notes