#Metal fabrication for industrial applications

Explore tagged Tumblr posts

Text

Industrial Metal Fabrication Services

Metalman Auto Ltd. provides industrial metal fabrication services, catering to diverse sectors with precision and quality. Our integrated approach includes sheet metal work, tubular fabrication, and assembly, all since 1986. For more information, contact +91 240 665 2444 (Ext. 500) or email [email protected].

#Metal fabrication for industrial applications#Industrial steel fabrication services#Custom metal fabrication for industries#Precision metal fabrication for industrial parts#Heavy-duty metal fabrication services#Large-scale industrial metal fabrication#Sheet metal fabrication for industrial use#Industrial-grade metal forming services#car accessories#automotive parts#automotive industry#electric vehicles#manufacturer#fabricationservices#metal fabrication#automotive#oem manufacturing

1 note

·

View note

Text

Premier SS Angle Manufacturer: High-Quality Stainless Steel Angles

Elevate your structural projects with top-tier SS angle manufacturer, stainless steel angles, structural steel, corrosion-resistant angles, high-quality SS products, durable metal angles, precision engineering, structural fabrication, stainless steel fabrication, industrial applicationsfrom our leading company. Crafted with precision and durability in mind, our SS angles offer superior strength and corrosion resistance, ensuring long-lasting performance in diverse applications.

#SS angle manufacturer#stainless steel angles#structural steel#corrosion-resistant angles#high-quality SS products#durable metal angles#precision engineering#structural fabrication#stainless steel fabrication#industrial applications

0 notes

Text

Beryllium Copper Sheets & Plates Exporters

#Stainless steel#metal fabrication#corrosion-resistant#kitchenware#appliances#construction materials#durable#rust-proof#industrial applications#stainless steel grades#maintenance#cleaning#sustainable materials#architectural design#cookware#utensils#sanitary equipment#marine applications#automotive components#aerospace materials

0 notes

Text

Metal Fabrication Market Will Touch USD 27.4 Billion in 2030

The metal fabrication market was USD 21.8 billion in 2023, which will rise to USD 27.4 billion, progressing at a 3.4% compound annual growth rate, by 2030. Automation comprises the usage of digital platforms and technologies and helps in improving the workflow and preserving the necessitated efficiency, precision, safety of workers, and quality standards. Therefore, a large amount of workflow…

View On WordPress

#cutting-edge technologies#fabrication applications#industry excellence#Key players#Market dynamics#market trends#Metal Fabrication Market#precision manufacturing#raw material shaping#technological advancements

0 notes

Text

Exploring the Three Types of Metal Fabrication

When it comes to metal fabrication, there's no shortage of options available. Whether you're in the manufacturing industry, construction, or simply looking to customize metal products, understanding the different types of metal fabrication is crucial. In this article, we will explore the three primary types of metal fabrication and shed light on the importance of metal fabrication powder coating in Ohio.

I. Sheet Metal Fabrication

Sheet metal fabrication is one of the most common forms of metal processing. It involves taking flat metal sheets and transforming them into various shapes and sizes using cutting, bending, and assembling techniques. The key advantage of sheet metal fabrication is its versatility. From creating intricate designs for architectural purposes to producing precision parts for industrial machinery, sheet metal fabrication is a cornerstone of many industries.

In Ohio, metal fabrication powder coating has become an integral part of the sheet metal fabrication process. Powder coating is a method of applying a durable and attractive finish to metal products. It not only enhances the aesthetics of the fabricated metal but also provides a protective layer against corrosion, making it ideal for products exposed to various environmental conditions.

II. Structural Metal Fabrication

Structural metal fabrication involves the creation of large and complex structures, such as bridges, buildings, and industrial facilities. This type of fabrication requires meticulous planning and precise execution, as the structural integrity of the final product is paramount.

In Ohio, where structural steel is widely used in construction, metal fabrication powder coating plays a crucial role in ensuring the longevity and durability of these structures. The powder coating process not only adds an extra layer of protection but also enhances the visual appeal of structural components, making them more resistant to wear and tear.

Also read about, How Do Solid Lubricants Work?

III. Custom Metal Fabrication

For those seeking unique and tailored metal products, custom metal fabrication is the way to go. Whether it's designing ornate metal gates, specialized vehicle parts, or one-of-a-kind art installations, custom metal fabrication allows for limitless creativity.

In Ohio, metal fabrication powder coating is also extensively applied to custom metal products. This ensures that each piece not only meets the desired specifications but also boasts a finish that stands the test of time. From intricate patterns to solid colors, powder coating adds a touch of personalization to your custom metal creations.

Why Metal Fabrication Powder Coating Ohio Matters

Ohio, with its diverse industrial landscape, relies heavily on metal fabrication for economic growth. To maintain the integrity and longevity of metal products, metal fabrication powder coating is indispensable. Here's why it matters:

Corrosion Resistance: Ohio experiences a wide range of weather conditions, from hot summers to cold winters. Powder coating provides a robust defense against rust and corrosion, ensuring that your metal products endure the test of time.

Aesthetics: The visual appeal of metal products matters. Powder coating offers a broad spectrum of colors and finishes, allowing you to customize the look of your metal creations.

Environmental Benefits: Powder coating is an eco-friendly method, as it produces no harmful emissions, making it a responsible choice for preserving Ohio's environment.

Cost-Effective: While it provides exceptional protection and aesthetics, metal fabrication powder coating is a cost-effective solution, ensuring that you get the most value for your investment.

Euclid Refinishing Company: Your Metal Fabrication Solution in Ohio

When it comes to top-quality metal fabrication and powder coating in Ohio, look no further than Euclid Refinishing Company. With a commitment to excellence and a focus on precision, they are your go-to source for all your metal fabrication needs. Their team of experts, armed with state-of-the-art equipment, ensures that every project meets the highest standards of quality and craftsmanship.

To get started on your next metal fabrication project, contact Euclid Refinishing Company, Inc. at (440) 275-3356. Experience the difference that professional metal fabrication and powder coating can make.

Resource URL: https://bit.ly/3MkA2W6

#metal fabrication powder coating in Ohio#industrial powder coating ohio#industrial powder coating services ohio#Cleveland custom powder coating ohio#Industrial coating applicator ohio

0 notes

Text

Commission for @pixlemonade

Grian “Big Boss” Xelqua Aka The Legendary Poultry Man.

CR 17 N Medium Humanoid Strix

XP 102,400 (if used as npc for encounter)Strix Cleric 10 Evangelist 7

Neutral Medium humanoid, Strix Init +2; Senses Perception +29

AC 31, touch 13, flat-footed 29 (+2 Dex, +10 Armor, +4 Shield, +1 Intuition, +4 Natural) hp 115 (16d8+34)

Fort +11, Ref +19, Will +12

Speed 60 ft. Flying, Land speed 30ft. Melee Returning shortspear+16/11/6 1D8+4 RangedRanged Spell+14, Returning shortspear+17/12/7 1D8+4

Racial Dayguard, Suspicious, Darkvision 60ft, Low light vision 60ft, Hatred, Fly speed 60ft, Land speed 30ft.

Traits Obsession(Buttons, etc), Spark of creation.

Class features Aura, Channel Energy 9D6, Domains Artifice, Air), Divine obedience,Skilled (Use magic device, Fly), Protective grace +2, Aligned class (Cleric), Divine boons (Strategic warrior, Sensibility of crafting), Creator’s touch, Material transformation, Gift of tongues(Ignan, Auran), Multitude of talents(+4 sacred bonus on untrained skills).

Spellcasting CL17 DC17 spells per day

4/6+1/6+1/6+1/5+1/5+1/5+1/5+1/3+1/2+1/1+1

Str 12, Dex 14, Con 14, Int 12, Wis 24, Cha 10

Base Atk +12/7/2; CMB +13; CMD +25

Feats Brew potions, Deific obedience, Extend spell, Craft magic weapons and armors, Craft wondrous magic items, Empower spells, Quicken spells, Maximize spells, Master crafter.

Skills Appraise +5, Craft(Metal) +20, Craft(Stone) +14, Diplomacy +4, Fly +21, Heal +10, Knowledge (arcana, history, religion) +14, engineering +9 (nobility, the planes,) +5, Linguistics +5, Perception +19, Profession(architect) +19, (engineer)+14, Sense motive +14, Spellcraft +14, Use magic device +13.

Languages Common, Draconic, Strix, Ignan, Auran.

Combat gear Manual of understanding+3(used), Returning shortspear+3, Mithral catskin breastplate+4, Caster shield(greater), Amulet of natural armor+4, Dusty rose ion stone, Headband of aerial agility+6(Wis), Rainbow lenses, Eagle cape, Belt of goat strength, Rod of thunder and lighting, Robe of useful items, Arrow magnet, Band of the colorful(pride) flight (ring of feather falling+Ring of flying improved+Colored flight), 4 Potions of cure critical wounds, Cleric kit, MWK tools(stone mason), 105GP.

Spells per day 0- All. 1-Animate ropes, Bless, Command, Divine favor, Sanctuary, Shield of faith, Summon monster I 2-Wind wall, Bear’s endurance, Sonic boom, Cat’s grace, Summon monster 2, Aid, Make whole. 3-Gaseous form, Dispel magic, Summon monster 3, Remove blindness/deafness, Blindness/deafness, Remove curse, Protection from energy. 4-Airwalk, Summon minor planar ally, Summon monster 4, Divine power, Freedom of movement, Divination. 5-Fabricate, Flamestrike, Summon monster 5, Spell resistance, Truesight, Reanimate dead. 6-Major creation, Planar ally, Animate objects, Dispel magic major, Word of return, Blade wall, Mass bull strength. 7-Elemental body(air), Regeneration, Destruction, Resurrection. 8-Whirlwind, Planar ally major, Summon monster VIII. 9-Miracle, Prismatic sphere.

Mumbo Jumbo Aka Bumbo Baggins the Mustache Man.

CR 17 N Humanoid, Dwarf

XP 102,400 (if used as npc for encounter)Dwarf Wizard (Conjurer, Creation school)15 Lore master 2

Neutral Medium humanoid Init +2; Senses Perception +20

AC 22, touch 17, flat-footed 20 (+2 Dex, +5 Deflection, +5Mage armor) Hp 135 (17d6+51)

Fort +13, Ref +13, Will +17

Speed 20 ft. Melee Father’s forgehammer+11/6 1d8+31 RangedRanged Spell+10

Racial Speed 20ft, Defensive training, Unstoppable, Stone cunning, Craftsman, Industrious urbanite, Stability, Darkvision 60ft, Weapon familiarity.

Traits Spark of creation, Socially awkward.

Class features Summon familiar (archetype Valet), Arcane bond (Familiar Cat), Create gear, Creator’s will, Summoner’s charm, Scribe scroll, Specialization school (Conjuration), Arcane discoveries: Arcane builder(wondrous magic items), Fast study, Golem constructor(Iron), Lore, Secret of health, Applicable knowledge(Forge ring).

Spellcasting CL17 DC18 spells per day 4/6/6/6/6/5/5/4/3/1

Str 12, Dex 14, Con 14, Int 26, Wis 14, Cha 8

Base Atk +8/3; CMB +9; CMD +21

Feats Brew potions, Extend spell, Skill focus (Knowledge Arcana), Alchemical affinity, Craft wondrous magic items, Craft magic armors and weapons, Maximize spell, Empower spell.

Skills Appraise +16, Craft(Metal) +28, Craft(Redstone) +28, Fly +10, Knowledge (Arcana +31, Dungeoneering +16, Engineering+28, Nature+16, Geography+16, History+16, Local+16, Nobility+11, Planes +16, Religion+11), Linguistics +2, Perception +10, Profession(engineer)+22, Perform(oratory) +3, Spellcraft +28, Use magic device +19.

Languages Common, Draconic, Dwarf, Giant, Terran, Orchis, Acquan.

Combat gear Headband of mental prowess+4(Int, Wis, Craft metal), Amulet of spell mastery, monocle of flawlessness, Father’s forge hammer, Engineer’s workgloves, Winged boots, Belt of giant strength+2, All tools vest, Traveler’s any tool, Handy haversack, Mallet of building, Clock of resistance+5, Ring of protection+5, Ring of crafting improved(Redstone), Artificer portable lab, Mumbo’s top hat(functions as a Cap of light and a Hedge wizard Conjurer’s cloak), Conduit rod, Scrolls(Planar binding greater, Anywhere but here, Expeditious constructions), Staff of conjuration, Blessed book, Potions(4 Cure Critical wounds, 2 Invisibility, 2 Blur), Wand of Summon monster II, Wizard kit, 15GP.

Spells known Mostly Conjuration spells Forbidden schools: Necromancy, Enchantment (around 45)

Spells typically prepared 9-Portal. 8-Summon monster VIII, Labyrinth 7-Limited wish, Wondrous mansion, Clenched hand, Reflect spells. 6-Mass bull strength, Contingency, Chain lighting, Iron wall, Dispel magic greater. 5-Telekinesis, Teleportation, Summon monster V, Wall of stone, Cone of cold. 4-Elastic sphere, Summon monster IV, Dimensional door, Stoneskin, Black tentacles, Solid fog. 3-Haste, Shrink item, Fireball, Summon monster III, Dispel magic, Resist energy. 2-Make whole, Mirror images, Glitterdust, Summon swarm, Web, See invisibility. 1-Shrink person, Magic missile, Grease, Unseen servant, Mage armor, Shield.

0-All except forbidden schools.

Background Grian and Mumbo lived in a faraway land known for their hermit residents where they are renowned for their incredible talent for architecture and his incredibly complex contraptions respectively. Both of them where building some crazy structure and as always creating some cunning brain-teaser or practical joke to have a laugh while at it. Still, when one day they were about to make their usual pranks and almost detonated each other in the attempt, Grain and Mumbo heard a voice: “Your aid… needed… someone important… lost… will you aid us?” Thinking it was a prank from another Hermit known for his Scars and his fancy Top Hats they went along and accepted only to find themselves transformed and transported into a completely different world. Now they have a mission on hand: Retrieve a lost entity from far away that bestowed part of his powers upon them.

IMPORTANT: None of the images are mine they belong to the following artists in the link. I did this for no profit only for entertainment.

163 notes

·

View notes

Text

Carbon SS weld fittings / How to Choose the Right Carbon Steel Socket Weld Fittings

Introduction

Ganpat Metal Industries, Mumbai, India, is involved in the manufacture, supply, and export of Carbon Steel Socketweld Fittings at par with global quality standards. It is fabricated to cater to all the rigid industry standards, giving reliability and durability to their customers across different industrial applications., we will delve into the intricacies of carbon steel socketweld fittings, covering their product overview, specifications, benefits, applications, and provide a call to action for those seeking top-quality fittings.

Product Overview

Carbon steel socketweld fittings are designed for high-pressure applications and are extensively used in industries such as oil and gas, petrochemicals, power generation, and more. These fittings are engineered to provide a strong, leak-proof connection between pipes, ensuring the integrity of the piping system. The socketweld design involves inserting the pipe into a recessed area of the fitting and then applying a fillet weld around the joint. This method provides a secure and permanent bond, making it ideal for critical applications.

To read more about the product you can website our website :

#carbon steel socketweld fittings manufacturers#high nickel alloy socketweld fittings stockists#carbon steel socketweld fittings suppliers#high nickel alloy socketweld fittings suppliers#tumblr#aesthetic#love#like#tumblrgirl#follow#instagram#instagood#photography#likeforlikes#s#art#likes#tumblrboy#frasi#grunge#girl#o#cute#fashion#sad#photooftheday#photo#frases#followforfollowback#frasitumblr

8 notes

·

View notes

Text

New 3D printing technique integrates electronics into microchannels to create flexible, stretchable microfluidic devices

The transition from traditional 2D to 3D microfluidic structures is a significant advancement in microfluidics, offering benefits in scientific and industrial applications. These 3D systems improve throughput through parallel operation, and soft elastomeric networks, when filled with conductive materials like liquid metal, allowing for the integration of microfluidics and electronics. However, traditional methods such as soft lithography fabrication which requires cleanroom facilities have limitations in achieving fully automated 3D interconnected microchannels. The manual procedures involved in these methods, including polydimethylsiloxane (PDMS) molding and layer-to-layer alignment, hinder the automation potential of microfluidic device production. 3D printing is a promising alternative to traditional microfluidic fabrication methods. Photopolymerization techniques like stereolithography apparatus (SLA) and digital light processing (DLP) enable the creation of complex microchannels.

Read more.

11 notes

·

View notes

Text

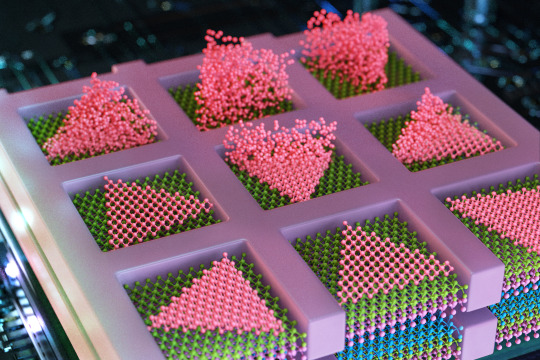

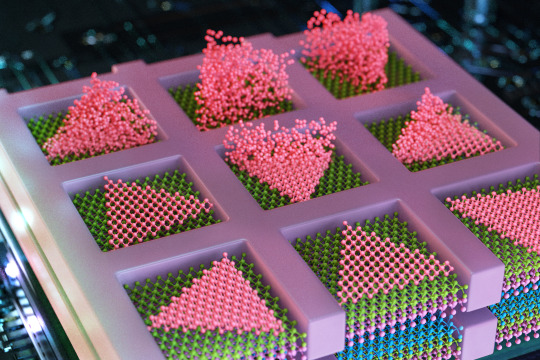

MIT engineers grow “high-rise” 3D chips

New Post has been published on https://thedigitalinsider.com/mit-engineers-grow-high-rise-3d-chips/

MIT engineers grow “high-rise” 3D chips

The electronics industry is approaching a limit to the number of transistors that can be packed onto the surface of a computer chip. So, chip manufacturers are looking to build up rather than out.

Instead of squeezing ever-smaller transistors onto a single surface, the industry is aiming to stack multiple surfaces of transistors and semiconducting elements — akin to turning a ranch house into a high-rise. Such multilayered chips could handle exponentially more data and carry out many more complex functions than today’s electronics.

A significant hurdle, however, is the platform on which chips are built. Today, bulky silicon wafers serve as the main scaffold on which high-quality, single-crystalline semiconducting elements are grown. Any stackable chip would have to include thick silicon “flooring” as part of each layer, slowing down any communication between functional semiconducting layers.

Now, MIT engineers have found a way around this hurdle, with a multilayered chip design that doesn’t require any silicon wafer substrates and works at temperatures low enough to preserve the underlying layer’s circuitry.

In a study appearing today in the journal Nature, the team reports using the new method to fabricate a multilayered chip with alternating layers of high-quality semiconducting material grown directly on top of each other.

The method enables engineers to build high-performance transistors and memory and logic elements on any random crystalline surface — not just on the bulky crystal scaffold of silicon wafers. Without these thick silicon substrates, multiple semiconducting layers can be in more direct contact, leading to better and faster communication and computation between layers, the researchers say.

The researchers envision that the method could be used to build AI hardware, in the form of stacked chips for laptops or wearable devices, that would be as fast and powerful as today’s supercomputers and could store huge amounts of data on par with physical data centers.

“This breakthrough opens up enormous potential for the semiconductor industry, allowing chips to be stacked without traditional limitations,” says study author Jeehwan Kim, associate professor of mechanical engineering at MIT. “This could lead to orders-of-magnitude improvements in computing power for applications in AI, logic, and memory.”

The study’s MIT co-authors include first author Ki Seok Kim, Seunghwan Seo, Doyoon Lee, Jung-El Ryu, Jekyung Kim, Jun Min Suh, June-chul Shin, Min-Kyu Song, Jin Feng, and Sangho Lee, along with collaborators from Samsung Advanced Institute of Technology, Sungkyunkwan University in South Korea, and the University of Texas at Dallas.

Seed pockets

In 2023, Kim’s group reported that they developed a method to grow high-quality semiconducting materials on amorphous surfaces, similar to the diverse topography of semiconducting circuitry on finished chips. The material that they grew was a type of 2D material known as transition-metal dichalcogenides, or TMDs, considered a promising successor to silicon for fabricating smaller, high-performance transistors. Such 2D materials can maintain their semiconducting properties even at scales as small as a single atom, whereas silicon’s performance sharply degrades.

In their previous work, the team grew TMDs on silicon wafers with amorphous coatings, as well as over existing TMDs. To encourage atoms to arrange themselves into high-quality single-crystalline form, rather than in random, polycrystalline disorder, Kim and his colleagues first covered a silicon wafer in a very thin film, or “mask” of silicon dioxide, which they patterned with tiny openings, or pockets. They then flowed a gas of atoms over the mask and found that atoms settled into the pockets as “seeds.” The pockets confined the seeds to grow in regular, single-crystalline patterns.

But at the time, the method only worked at around 900 degrees Celsius.

“You have to grow this single-crystalline material below 400 Celsius, otherwise the underlying circuitry is completely cooked and ruined,” Kim says. “So, our homework was, we had to do a similar technique at temperatures lower than 400 Celsius. If we could do that, the impact would be substantial.”

Building up

In their new work, Kim and his colleagues looked to fine-tune their method in order to grow single-crystalline 2D materials at temperatures low enough to preserve any underlying circuitry. They found a surprisingly simple solution in metallurgy — the science and craft of metal production. When metallurgists pour molten metal into a mold, the liquid slowly “nucleates,” or forms grains that grow and merge into a regularly patterned crystal that hardens into solid form. Metallurgists have found that this nucleation occurs most readily at the edges of a mold into which liquid metal is poured.

“It’s known that nucleating at the edges requires less energy — and heat,” Kim says. “So we borrowed this concept from metallurgy to utilize for future AI hardware.”

The team looked to grow single-crystalline TMDs on a silicon wafer that already has been fabricated with transistor circuitry. They first covered the circuitry with a mask of silicon dioxide, just as in their previous work. They then deposited “seeds” of TMD at the edges of each of the mask’s pockets and found that these edge seeds grew into single-crystalline material at temperatures as low as 380 degrees Celsius, compared to seeds that started growing in the center, away from the edges of each pocket, which required higher temperatures to form single-crystalline material.

Going a step further, the researchers used the new method to fabricate a multilayered chip with alternating layers of two different TMDs — molybdenum disulfide, a promising material candidate for fabricating n-type transistors; and tungsten diselenide, a material that has potential for being made into p-type transistors. Both p- and n-type transistors are the electronic building blocks for carrying out any logic operation. The team was able to grow both materials in single-crystalline form, directly on top of each other, without requiring any intermediate silicon wafers. Kim says the method will effectively double the density of a chip’s semiconducting elements, and particularly, metal-oxide semiconductor (CMOS), which is a basic building block of a modern logic circuitry.

“A product realized by our technique is not only a 3D logic chip but also 3D memory and their combinations,” Kim says. “With our growth-based monolithic 3D method, you could grow tens to hundreds of logic and memory layers, right on top of each other, and they would be able to communicate very well.”

“Conventional 3D chips have been fabricated with silicon wafers in-between, by drilling holes through the wafer — a process which limits the number of stacked layers, vertical alignment resolution, and yields,” first author Kiseok Kim adds. “Our growth-based method addresses all of those issues at once.”

To commercialize their stackable chip design further, Kim has recently spun off a company, FS2 (Future Semiconductor 2D materials).

“We so far show a concept at a small-scale device arrays,” he says. “The next step is scaling up to show professional AI chip operation.”

This research is supported, in part, by Samsung Advanced Institute of Technology and the U.S. Air Force Office of Scientific Research.

#2-D#2023#2D materials#3d#ai#AI chip#air#air force#applications#Arrays#Artificial Intelligence#atom#atoms#author#Building#chip#Chip Design#chips#coatings#communication#computation#computer#computer chips#computing#craft#crystal#crystalline#data#Data Centers#Design

2 notes

·

View notes

Text

Choosing the Right Materials for Your Acoustical Enclosure: A Comprehensive Guide

Acoustical enclosures play a crucial role in controlling noise levels in industrial, commercial, and residential environments. The effectiveness of an acoustical enclosure largely depends on the materials used in its construction. Selecting the right materials ensures optimal sound absorption, noise reduction, and durability. This guide explores key material options and factors to consider when designing an acoustical enclosure.

Key Materials for Acoustical Enclosure

Acoustic Foam Panels Acoustic foam is widely used for its excellent sound absorption properties. These lightweight panels are ideal for reducing echo and high-frequency noise. They are commonly used in studios, server rooms, and other applications requiring moderate noise control.

Mass-Loaded Vinyl (MLV) MLV is a dense, flexible material that effectively blocks sound transmission. It is often used as a barrier layer in walls, ceilings, and enclosures. MLV is particularly useful in industrial settings where low-frequency noise, such as that from machinery, needs to be mitigated.

Perforated Metal Panels Perforated metal panels are frequently used in acoustical enclosures for their ability to contain noise while allowing airflow. These panels often incorporate an internal layer of sound-absorbing material, such as fiberglass, for enhanced performance. They are durable and suitable for harsh environments.

Fiberglass Insulation Fiberglass is a popular choice for its high sound absorption coefficient and affordability. It is often combined with perforated metal or other rigid materials to enhance the enclosure’s overall noise reduction capabilities. Fiberglass is commonly used in HVAC systems, industrial machinery enclosures, and generator housings.

Composite Materials Composite materials combine layers of sound-absorbing and sound-blocking elements to provide superior performance. These multi-layered structures are excellent for applications requiring both high and low-frequency noise reduction.

Acoustic Fabric Acoustic fabric is used to cover sound-absorbing materials, providing a visually appealing finish. It also enhances the enclosure’s durability and protects internal components from dust and debris.

Factors to Consider When Selecting Materials

Noise Frequency and Intensity Different materials excel at absorbing or blocking specific frequencies. For high-frequency noise, lightweight, porous materials like acoustic foam are effective. For low-frequency noise, dense materials like MLV or composite panels are better.

Durability and Environment Consider the operating environment of the acoustical enclosure. In industrial settings, materials need to withstand high temperatures, moisture, and physical wear. Perforated metal with a durable coating is ideal for such conditions.

Fire Resistance Fire safety is a critical factor, especially in industrial applications. Materials like fiberglass and MLV often meet fire resistance standards, making them suitable for environments with stringent safety requirements.

Aesthetic Requirements In commercial or residential settings, aesthetics may be important. Acoustic fabrics and decorative panels can be used to match the enclosure with its surroundings.

Budget Constraints Cost is always a consideration. While high-performance composites provide excellent noise control, they may not fit every budget. Evaluate your noise reduction needs against available resources to make an informed choice.

Conclusion

Selecting the right materials for your acoustical enclosure is essential for achieving the desired noise reduction while maintaining durability and safety. By understanding the properties of various materials and evaluating the specific needs of your application, you can design an effective enclosure that meets both functional and aesthetic requirements. Whether you’re managing noise in an industrial setting or creating a quiet workspace, the right material choice will make all the difference.

2 notes

·

View notes

Text

Metalman Auto Ltd. | 🔗 Harnessing the Power of IoT in Manufacturing! 🔧

At Metalman Auto, we’re leading the charge in integrating Internet of Things (IoT) technology to revolutionize our manufacturing processes. From connected machines to smart sensors, IoT helps us achieve greater efficiency, precision, and safety across all operations. Here’s how we’re leveraging IoT for smarter manufacturing:

1️⃣ Real-Time Monitoring: Stay ahead with continuous machine performance insights. 2️⃣ Improved Safety: Smart sensors ensure the safety of both our workforce and machinery. 3️⃣ Predictive Maintenance: Avoid downtime with automated alerts for potential equipment failures. 4️⃣ Enhanced Efficiency: IoT-driven data optimizes production, reducing waste and boosting output.

Swipe through to see how we’re incorporating IoT into every step of our manufacturing process and shaping the future of smart, connected production!

Let’s Grow Together.

#real time monitoring#Improved Safety#iot#iotsolutions#iot applications#iot platform#iot development services#oem manufacturing#automotive parts#metalman auto#metal fabrication#automotive industry#manufacturer#electric vehicles#car accessories#digitaltransformation#transport technology

1 note

·

View note

Text

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes

Text

Unleashing the Potential of Oxygen-Free Copper: Revolutionizing High-Performance Applications

Oxygen-free high-conductivity copper is another name for oxygen-free copper. A class of wrought copper alloys known as oxygen-free copper is refined using an electrolytic process and exhibits excellent conductivity. In particular, electrolytic refining is required to reduce the oxygen concentration to or below 0.001%. Makers are focused on item testing to make sure that production programs,…

View On WordPress

#advanced metal#aerospace industry#automotive applications#circuit boards#conductivity#copper alloys#corrosion resistance#electrical industry#Electronics#heat exchangers#high-performance materials#market trends#metal fabrication#oxygen-free copper#power transmission#reliability#renewable energy#telecommunications

0 notes

Text

The Effective Role of Powder Coating in Metal Fabrication

When it comes to metal fabrication in Ohio, the importance of powder coating cannot be overstated. Powder coating is a versatile and cost-effective method that plays a pivotal role in enhancing the durability and aesthetics of metal products. In this article, we will explore the benefits of metal fabrication powder coating in Ohio and how it can make a significant difference in the longevity of your metal items.

Powder Coating Unveiled

Powder coating is a dynamic and highly efficient process that involves applying a dry powder to the surface of a metal object. This powder typically comprises finely ground particles of pigment and resin, forming a free-flowing, dry material. It is then electrostatically sprayed onto the metal surface, ensuring a uniform and adhesive layer that covers every intricacy of the object.

Enhanced Durability and Protection

Metal fabrication in Ohio, like anywhere else, often faces numerous challenges. This can include harsh weather conditions, corrosion, and regular wear and tear. Powder coating stands out for its ability to provide a resilient protective layer, which is highly resistant to these environmental adversities. The powder adheres securely to the metal, creating an impervious shield against moisture, oxygen, and corrosion. This level of protection ensures that metal products can withstand Ohio's fluctuating climate and maintain their excellent condition over an extended period.

Versatility in Metal Finishing

One of the outstanding merits of powder coating is its versatility in metal finishing. Ohio businesses can select from a diverse range of colors and textures, enabling them to create a customized, aesthetically pleasing appearance for their products. This flexibility empowers manufacturers to meet specific design and branding requirements, making it a preferred choice for a myriad of industries in Ohio.

Also read for, A Guide to Different Types of Thin Film PVD Coatings

Eco-Friendly Solution

In an era of heightened environmental awareness, adopting eco-friendly practices is paramount for Ohio metal fabrication companies. Powder coating aligns seamlessly with this objective as it is a cleaner and more sustainable alternative compared to traditional wet painting methods. Unlike liquid paints, powder coatings do not release harmful solvents into the environment, making it a greener choice for Ohio businesses keen on minimizing their carbon footprint.

Efficient Application Process

Not only is powder coating eco-friendly, but it is also profoundly efficient. The application process generates minimal waste, as any excess powder can be collected and reused. This enables Ohio metal fabrication companies to reduce material costs while also curtailing expenses related to waste disposal. Furthermore, the process can be automated, allowing for high-volume production with consistent quality, rendering it a cost-effective solution for businesses in Ohio.

Contact Euclid Refinishing Company, Inc. Today

If you're in Ohio and require industrial powder coating services, don't hesitate to get in touch with Euclid Refinishing Company, Inc. at +1(440) 275-3356. Our dedicated team will provide you with a tailor-made solution to meet your metal fabrication and powder coating needs, ensuring your products are both robustly protected and aesthetically enhanced.

Original Source: https://bit.ly/46WOdZj

#industrial powder coating services#metal fabrication powder coating#Industrial coating applicator ohio#metal fabrication powder coating ohio#Austinburg industrial coating pr

0 notes

Text

how i live

I woke at midnight, last night, to a hard sou’westerly and the floor moving in three directions at once — pitching, rolling, rising-and-falling. Now, six hours later, the wind has moderated. Everything is still. The rest of the world is obscured by grey mist and sporadic showers, as if the sky has fallen across the shore.

I climb up a short ladder to the companionway to check that all is well on deck — it’s the first thing I do every morning — then I return to my bunk to download email and read a couple of news sites on a laptop before my wife wakes and we have a cup of coffee together across the varnished teak table that separates our bunks.

We talk about what we want to do today and waste a minute or two trying to agree a time-table before giving up. For half a decade, we have scraped by with a minimum of routine or planning. We are singularly unadept at making lists or coordinating diaries. We end up doing most things together. Today, we will pick up some paint and shackles at a chandlery and find a local metal fabricator to repair or replicate a damaged stainless steel stanchion. We also have to buy some groceries. But first I want to repair our rubber dinghy.

My wife and I live on a 32-foot sailboat. It is a life-raft of sorts. It is also an island on which we are trying to regain an unsettled but sheltered freedom after several years of being homeless. Most days, we feel like castaways, with no hope of ever being rescued.

It’s hard to explain how we ended up here. Moving aboard was not a ‘lifestyle choice’ but an act of quiet desperation. We had dropped out of a life in which I had somehow ended up running two well-known, medium-sized companies, one of them publicly listed — before those roles, I had been a musician, gambler, seaman, smuggler, photographer, magazine editor, and governmental adviser — and we had taken to wandering slowly across Europe, the UK, and North Africa. After a year holed up on the southern coast of Spain, a few miles east of Gibraltar, riding out the worst of the pandemic, we moved to southern Italy, where we acquired, and set about restoring, a small ruin, part of servants’ quarters attached to a 16th century Spanish castle, in a village not far from Lecce, in Puglia. We had just completed the work, two years later, when the local Questura, the office of the Carabinieri that oversees Italian immigration, rejected our third application for temporary residence and issued a formal instruction to us to leave Italy — and Europe’s Schengen zone.

The boat was not something we thought through in any detail. I had spent a lot of time at sea in my youth and had lived on sailing boats of various sizes on the Channel coasts of England and France, as well as in the Mediterranean. Which is to say, I had an understanding of their discomforts. But the prospect of resuming a life that, before we ended up in southern Italy, involved moving every three months — not just from one temporary accommodation to another but from one country to another, so as not to contravene the terms of our largely visa-less travel — had exhausted us. I made an offer on a cheap, neglected, 45-year-old, fibreglass sloop I had come across online and organised a marine surveyor to look it over for me. He gave it a cautious thumbs up.

I won’t forget my wife’s dolorous expression, a month later, when she saw the boat for the first time. It was in an industrial area of Southampton, on a dreich morning in early spring — bitterly cold, windy, and raining. Around us, the Itchen River’s ebb had revealed swathes of black, foul-smelling mud. Raised far from the sea, on the plains of north-eastern Oklahoma, my wife told me later she had been praying that our journey to this glum backwater was part of some elaborate practical joke.

There is a whole genre of YouTube videos created by those who live on sailboats full-time and voyage all over the world. The most popular, the so-called ‘influencers’, are young(ish) couples or families with capacious, often European-built, plastic catamarans or monohulls. Their videos focus less on the gritty, day-to-day grind of boat maintenance and passage-making and more on sojourns in ancient, stone-built harbours in the Mediterranean, white, sandy beaches and palm-fringed cays in the Caribbean, or improbably blue lagoons and solitary atolls in the South Pacific, where they barbecue fresh fish, paddle-board, kite-surf and practice yoga and aerial silks for the envy of hundreds of thousands of followers. My wife’s and my life aboard together is nothing like any of this.

We are both in our sixties — I am just a year away from seventy — and we have spent more than a decade on the move around the world, at first following eclectic opportunities for employment then, when those opportunities receded, in search of somewhere we might be able to settle with very little money. Four months after moving aboard our boat, we still think of ourselves as vagabond travellers, our boat a shambolic, floating vardo that we haven’t yet managed to turn into a home. We’re not really ‘cruisers’, despite the sense of community we sometimes find among them, but we are seafarers — historically, a marginal existence driven by necessity. A recent, 150-nautical-mile passage westward along the south coast of England was a shakedown during which we learned how to make our aged, shabby vessel more comfortable and easier to handle and to trust her capacity to keep us safe at sea.

She bore the name Endymion when we bought her — after my least favourite poem by John Keats (“A thing of beauty is a joy forever…”) — but we re-named her Wrack. Depending on the source, ‘wrack’ describes seaweeds or seagrasses that wash up along a shore or the scattered traces of a shipwreck, either of which might be metaphors for my wife and me in old age. It is certainly how we feel when we’re not at sea. Life aboard Wrack is spartan — fresh water stored in a dozen polyethylene jerry cans, no hot or cold running water, no refrigeration and when the temperature drops, no heating either — so, from time to time, we concede the cost of berthing in marinas to gain access to on-site laundries, showers, flushing toilets, and wi-fi. Whether we’re berthed or anchored somewhere, we shop for food once a week — mainly vegetables, fruit, bread, pasta, and rice but little dairy and no meat — and eat one meal a day, cooked in the mid-afternoon on a two-burner gas stove.

The days we spend in close proximity to others’ lives ashore remind us how disenfranchised ours have become. We were homeless before we acquired Wrack, but now we are without a legal residence anywhere, even in our ‘home’ countries. We enter and exit borders uneasily as ‘visitors’, our stays limited to 90 or 180 days, depending on where we are. We have no access to banking, insurance, social services or, with a few exceptions, emergency health care. Even the modest Australian pensions we have a right to can only be received if we have been granted residence in countries with which Australia has reciprocal arrangements — and we haven’t. It’s hard even for other live-aboards to understand how deeply we are enmired in this peculiar bureaucratic statelessness. It’s harder for us to deal with it every day.

But life afloat provides consolations. We are ceaselessly attuned to the weather and our boat’s responses to subtle shifts in the sea state, tide and wind even when we are tethered to a dock. We appreciate the shelter — and surprising cosiness — the limited space below decks affords us but the impulse to surrender to the elements and let them propel us elsewhere is insistent. Our best days are offshore, even when the conditions are testing; the world shrinks to just the two of us, our boat and the implacable, mutable sea around us. Whatever problems we face ashore become, at least for the duration of a passage, abstract and insignificant. We sail without a specific destination — ‘towards’ rather than ‘to’, as traditional navigators would have it — and without purpose. Time drifts.

At least half of every day is spent maintaining, repairing, or re-organising the boat, an unavoidable and time-consuming part of our days, especially at sea. When we’re at anchor or berthed in a marina, we do what we can to sustain ourselves. Most afternoons are spent prospecting for drips of income from journalism and crowd-funding — a source inspired by those younger YouTube adventurers — or adding a few hundred words to a manuscript for a non-fiction book commissioned by a Dutch publisher, whose patience has been stretched to breaking point. Because of our visitor visa status, we can’t seek gainful employment ashore, and we have long since lost contact with any of the networks that once provided us with a higher-than-average income as freelancers. Our existence, by any definition, is impoverished and perilously marginal, we have little social life, yet we make the effort to appreciate our circumstances, even if it’s just to sit together in silence and absorb the elemental white noise of wind and sea, to do nothing, to not think.

Our precariousness burdens our four adult children, who have scattered to San Diego, Sydney, Berlin and Rome: “Where are you now?” our youngest asks. “How long will you be there?” We speak to each at least once a week. Not all of them long for fixedness but they do want desperately for us to have a ‘real home’, somewhere we can assemble occasionally as a family. We will be grandparents for the first time, soon. Like our few friends, our children worry that we might become lost — in every sense.

My wife and I are uncomfortably aware of our financial and physical vulnerability but at our ages, we can no longer cling to the faint hope that there’s an end to it. We have committed to an unlikely, reckless voyage. All we can do is maintain a rough dead reckoning of its course and embrace the uncharted and the relentless unexpected.

First published in The Idler, UK, 2023.

17 notes

·

View notes

Text

GI Flanges Manufacture in Assam

Assam, a state known for its tea gardens and rich biodiversity, is also carving out a niche in the manufacturing of Galvanized Iron (GI) flanges. With a strategic focus on industrial development, Assam’s manufacturing sector is expanding, particularly in the area of metal fabrication. This growth is driven by both local demand and the potential for export to neighboring states and countries.

Manufacturers in Assam are increasingly adopting advanced technologies to produce high-quality GI flanges. The process typically involves sourcing raw materials from local suppliers, which helps to support the regional economy. After procuring the necessary steel, manufacturers engage in processes like cutting, stamping, and galvanizing to create flanges that are durable and resistant to rust and corrosion. These flanges find application in various industries, including construction, water supply systems, and oil and gas.

The state’s industrial policy actively promotes the MSME sector, providing financial assistance and incentives for new and existing businesses in the manufacturing space. Many small and medium enterprises in Assam are receiving support to upgrade their production facilities and enhance their product offerings. This governmental push is vital for improving the quality of GI flanges manufactured in the state and increasing their competitiveness in the market.

Moreover, the demand for GI flanges is on the rise, fueled by ongoing infrastructure projects and urbanization within Assam. The government’s efforts to improve transportation and connectivity have also opened up new markets for manufacturers, allowing for better distribution of products. The ability to transport finished goods efficiently is crucial for maintaining competitiveness, particularly in regions with emerging markets.

Assam's rich cultural heritage and community values also play a role in its industrial landscape. Many manufacturers are adopting sustainable practices, such as recycling and reducing waste in their production processes. This commitment to sustainability not only helps in protecting the environment but also aligns with the growing consumer preference for eco-friendly products.

As Assam continues to develop its manufacturing capabilities, the GI flange industry is expected to grow significantly. The combination of supportive government policies, a focus on quality, and an increasing demand for infrastructure will drive this sector forward, contributing to the state's economic development and job creation.

#GIFlanges#FlangeManufacturing#IndustrialFlanges#GalvanizedIron#ManufacturingIndia#MetalFabrication#Assam#MakeInAssam#MSMESector#SustainableManufacturing#InfrastructureDevelopment#LocalEconomy#ConstructionIndustry#WaterSupply#OilAndGas#GovernmentSupport#ManufacturingGrowth#EcoFriendlyProducts#JobCreation#CulturalHeritage#EmergingMarkets

2 notes

·

View notes