#precision engineering

Explore tagged Tumblr posts

Text

CNC machining precision components

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#metal cnc#cnc metal processing#cnc metal fabrication#cnc metal process#cnc metal machining#cnc metal parts#metal cnc machining#cnc precision machining#precision engineering#precision manufacturing#precision cnc machining

3 notes

·

View notes

Text

Business and Manufacturing in Pune - ANJALI T. PRECISION

Explore Business & Manufacturing in Pune with ANJALI T. PRECISION – delivering high-quality precision components with excellence & reliability.

#Business In Pune#Manufacturing In Pune#Precision Engineering#Quality Manufacturing#ANJALI T.PRECISION

0 notes

Text

Empowering the era of next generation manufacturing

PETECH is committed to using digital technology, creative business models, and operational excellence to transform industries. propelling Malaysia's automation progress by partnerships, education, and training programs. concentrating on innovation to raise competitiveness and productivity in a range of industries.

By implementing disruptive technologies, exchanging state-of-the-art manufacturing techniques, and guiding companies through industrial transformation and economic growth, we propel Malaysia's market expansion.

0 notes

Text

Precision Engineering: Delivering Accuracy for High-Performance Industries

Industries that demand absolute accuracy rely on Precision Engineering to create reliable, high-quality components. At VMS, we specialise in high-precision manufacturing for industries like aerospace or medical devices. Our expert team ensures every product meets the most exacting standards.

Why Precision Engineering Matters

Manufacturing in fields such as aerospace and medical devices requires extreme accuracy. Even the slightest deviation can compromise safety and functionality. Precision Engineering guarantees tight tolerances, flawless finishes, and reliable performance in every component we produce.

Advanced Technology and Expertise

At VMS, we combine cutting-edge technology with skilled craftsmanship to deliver superior results. Our capabilities include:

CNC Machining: Using advanced computer-controlled tools to shape components with microscopic precision.

Quality Control: Implementing rigorous testing and inspection to maintain accuracy at every stage.

Material Expertise: Selecting the best materials to enhance durability and functionality.

Custom Solutions: Designing and manufacturing tailored components that meet specific industry needs.

The VMS Commitment to Excellence

Our approach to Precision Engineering focuses on efficiency, innovation, and reliability. We work closely with clients to understand their unique requirements, ensuring every component performs flawlessly. By using state-of-the-art machinery and industry-leading expertise, VMS guarantees consistency and excellence in every project.

Partner with VMS for Precision Manufacturing

VMS stands as a trusted provider of high-precision manufacturing for critical industries. Whether you need aerospace components or medical device parts, we deliver the accuracy and quality required. Contact us today to discuss your next project and experience the VMS advantage.

Source

0 notes

Text

From Apprentice to Expert: Why Precision Engineering Matters

In the modern manufacturing and engineering industries, precision is everything. From aerospace to automotive, medical devices to robotics, every sector demands accuracy, efficiency, and high-quality output. Mechanical apprentices looking to excel in their careers must embrace the evolving technological landscape and refine their skills to meet these rigorous standards. One of the best ways to achieve this is by enrolling in master precision engineering courses.

Precision engineering is a specialized discipline that focuses on designing and manufacturing high-accuracy components, often with tolerances in the micrometer or even nanometer range. For mechanical apprentices, gaining expertise in precision engineering can significantly boost their employability, technical skills, and career prospects. This article explores why mechanical apprentices should consider enrolling in master precision engineering programs and how it can shape their future in the industry.

Enhancing Technical Competence

Mechanical apprentices often start with foundational skills, learning about materials, machining, and mechanical systems. However, precision engineering takes these skills to the next level. By enrolling in a master precision engineering program, apprentices gain deeper insights into:

Advanced Machining Techniques: Understanding high-precision CNC machining, laser cutting, and ultra-fine manufacturing processes.

Metrology and Quality Control: Learning how to measure components accurately using coordinate measuring machines (CMMs), optical profilers, and interferometers.

Material Science: Understanding how material properties influence machining precision and component performance.

Computer-Aided Design (CAD) and Manufacturing (CAM): Mastering software tools to design and simulate precision components before actual production.

Developing these skills allows apprentices to produce components with extreme accuracy, which is essential for high-tech industries like aerospace, electronics, and biomedical engineering.

Expanding Career Opportunities

Employers in the engineering and manufacturing sectors value professionals with specialized skills in precision engineering. By enrolling in a master precision engineering program, apprentices position themselves as top candidates for:

High-precision manufacturing firms

Aerospace and automotive industries

Medical device and instrument manufacturing

Research and development (R&D) roles

Robotics and automation companies

Precision engineering expertise makes mechanical apprentices stand out in the job market, increasing their chances of securing well-paying positions with reputable companies.

Meeting Industry Demands

With industries demanding higher accuracy and tighter tolerances, companies require engineers and technicians who can work with precision equipment and processes. Enrolling in a master precision engineering program equips apprentices with:

Hands-on Experience: Exposure to real-world manufacturing challenges, working with cutting-edge machinery.

Problem-Solving Skills: Learning how to troubleshoot precision-related issues, minimizing errors and waste.

Process Optimization Techniques: Understanding how to improve manufacturing efficiency while maintaining high quality.

These skills ensure that apprentices can contribute effectively to their workplaces, meeting the growing demands of precision industries.

Keeping Up with Technological Advancements

The field of precision engineering is constantly evolving with the introduction of new materials, automation technologies, and digital manufacturing techniques. Master precision engineering programs expose apprentices to the latest trends, including:

Nanotechnology: Understanding manufacturing at the nanoscale for ultra-precise applications.

Additive Manufacturing (3D Printing): Exploring how precision engineering integrates with modern fabrication methods.

Smart Manufacturing and Industry 4.0: Learning about automation, robotics, and AI-driven manufacturing processes.

Laser and Optical Manufacturing Techniques: Gaining expertise in non-contact precision machining and metrology.

By staying ahead of these advancements, mechanical apprentices can future-proof their careers and remain competitive in the job market.

Increased Earning Potential

Higher skill levels often translate to higher salaries. Employers are willing to pay a premium for professionals who can ensure accuracy, efficiency, and quality in manufacturing. Precision engineers typically earn more than general mechanical technicians due to their specialized expertise. By investing in a master precision engineering course, apprentices increase their earning potential and open doors to leadership and managerial roles in the future.

Contributing to Innovation and Research

Precision engineering is at the heart of technological innovation. Many groundbreaking advancements, from space exploration to biomedical implants, rely on precision engineering principles. Apprentices who specialize in this field can contribute to cutting-edge projects, working alongside researchers and scientists to develop new technologies that shape the future.

Conclusion

Mechanical apprentices seeking to advance in their careers must recognize the importance of precision engineering. Enrolling in a master precision engineering program provides them with critical skills, expands their career opportunities, and ensures they remain relevant in a competitive industry. By mastering advanced machining techniques, understanding metrology, and staying updated with emerging technologies, apprentices can position themselves as industry leaders. Investing in precision engineering education is not just a step forward—it is a leap toward excellence and success in the mechanical engineering field.

0 notes

Text

Advantages of Battery Laser Welding Machines in the Manufacturing Industry

In the fast-evolving landscape of battery production, manufacturers are constantly seeking advanced technologies to enhance efficiency, precision, and cost-effectiveness. Battery laser welding machines have emerged as a revolutionary solution, offering a wide array of benefits that cater to the demands of modern energy storage systems. This article explores the advantages of employing battery laser welding machines in manufacturing, highlighting their role in revolutionizing battery production processes.

Unparalleled Precision

Precision is a crucial factor in battery production, where even the tiniest defect can significantly impact performance and safety. Battery laser welding machines provide unparalleled precision, thanks to the focused and concentrated laser beam. This allows for excellent and accurate welds, ensuring the integrity of delicate battery components, such as thin foils and electrodes. As a result, manufacturers can consistently produce high-quality batteries with minimal defects, improving overall reliability and customer satisfaction.

Enhanced Efficiency

Efficiency is a key driver in any manufacturing process, and battery laser welding machines excel in this regard. Their high welding speeds and rapid heat input minimize production cycle times, enabling faster throughput and increased productivity. Additionally, the non-contact nature of laser welding eliminates the need for consumables, reducing downtime for material changes and reducing overall maintenance costs. This efficiency translates into greater output, making laser welding an indispensable technology in meeting the rising global demand for energy storage solutions.

Reduced Production Costs

In the competitive manufacturing landscape, cost optimization is a paramount concern. Battery laser welding machines contribute to cost reduction in multiple ways. Firstly, their precision minimizes material wastage, resulting in fewer rejected components and lower scrap rates. Secondly, the high automation potential of laser welding allows for streamlined workflows, reducing the need for manual labour and associated labour costs. Furthermore, the speed and accuracy of laser welding led to fewer rework cycles, saving time and resources. Over time, these cost-cutting benefits make battery laser welding a financially viable option for large-scale production.

Versatility in Battery Design

Battery designs have become increasingly intricate to cater to diverse applications, from portable electronics to electric vehicles and renewable energy storage. Battery laser welding machines offer unparalleled versatility in welding complex geometries and dissimilar materials. They can handle a wide range of battery cell formats, from cylindrical and prismatic to pouch cells, facilitating the production of custom battery packs tailored to specific applications. This adaptability grants manufacturers the flexibility to stay at the forefront of innovation and adapt to rapidly evolving market demands.

Minimal Heat-Affected Zones

Traditional welding techniques can introduce significant heat into the weld area, potentially causing thermal stress and affecting battery performance and longevity. In contrast, batterylaser welding machines generate minimal heat-affected zones (HAZ) due to their focused and precise energy delivery. This characteristic reduces the risk of damage to temperature-sensitive battery components and preserves the material properties, ensuring the highest level of performance and safety.

Improved Safety Standards

Battery safety is of utmost importance, especially in high-energy applications like electric vehicles and energy storage systems. Battery laser welding machines play a vital role in enhancing safety standards by producing strong and reliable welds. The integrity of laser-welded joints reduces the risk of battery leakages, ensuring that batteries can withstand challenging operating conditions without compromising safety.

Environmental Friendliness

In today's environmentally conscious world, sustainable manufacturing practices are a priority. Battery laser welding machines contribute to eco-friendly production processes in several ways. Their high efficiency and precision result in less material waste, reducing the environmental impact of manufacturing. Additionally, the non-contact nature of laser welding means no fumes or harmful byproducts are emitted during the welding process, creating a cleaner working environment and contributing to a greener manufacturing facility.

Conclusion

The advantages of battery laser welding machines in the manufacturing industry are undeniable. Their precision, efficiency, and ability to reduce production costs make them a game-changer in battery production processes. As energy storage technology continues to advance, battery laser welding machines will play a pivotal role in shaping the future of battery manufacturing, enabling the development of safer, more efficient, and environmentally friendly energy storage solutions. With ongoing research and development, these machines will certainly continue to evolve, empowering manufacturers to meet the growing demands of the global energy landscape.

#Advanced Manufacturing#Battery Manufacturing#Electric Vehicles#Energy Storage#Industrial Automation#Laser Welding#Manufacturing Innovation#Precision Engineering#Renewable Energy#Sustainable Manufacturing

0 notes

Text

Emerging Trends in ASTM Tubes: What's New in 2025?

As the backbone of modern infrastructure and industries, ASTM tubes are witnessing a revolutionary transformation in 2025. These high-standard steel tubes, governed by the American Society for Testing and Materials (ASTM), are experiencing technological innovations and market shifts that are setting new benchmarks for performance and sustainability. At Krystal Global Engineering Limited, we remain committed to staying ahead of the curve, delivering cutting-edge solutions to meet evolving global demands. Here’s what’s trending in ASTM tubes this year:

1. Advanced Material Composition

The use of alloy innovations has taken center stage in ASTM tube manufacturing. Enhanced chromium and nickel compositions are making tubes more resilient against corrosion and high temperatures. These advancements are particularly vital for industries like oil and gas, chemical processing, and power generation, where durability under extreme conditions is non-negotiable.

2. Eco-Friendly Manufacturing Processes

Sustainability is no longer optional. Leading manufacturers are adopting eco-friendly processes such as reducing CO2 emissions and recycling waste materials. The integration of green technologies in production not only reduces environmental impact but also enhances cost efficiency, benefitting end-users across industries.

3. Precision Tubing for High-Tech Applications

With the rise of aerospace and medical industries, the demand for precision tubing is surging. ASTM standards are being adapted to meet stricter tolerances, smoother finishes, and thinner walls. These precision tubes are finding applications in critical environments, such as surgical equipment and spacecraft components.

4. Digital Quality Assurance

Digital transformation is reshaping quality control. Non-destructive testing methods, powered by AI and IoT-enabled sensors, are providing real-time insights into the structural integrity of ASTM tubes. This ensures consistent adherence to specifications and drastically reduces product rejection rates.

5. Customized Solutions for Emerging Markets

With the growth of renewable energy, automotive, and infrastructure sectors, tailored ASTM tube solutions are in high demand. Custom coatings, shapes, and sizes are being developed to cater to niche applications, ensuring maximum efficiency and performance.

At Krystal Global Engineering Limited, we are proud to be part of this transformative journey. Our expertise in ASTM tube manufacturing, coupled with our commitment to innovation, positions us as a trusted partner for industries worldwide.

Stay ahead with us and experience the future of ASTM tubing today. For inquiries and product details, visit our website or contact our expert team.

To Know more about:

#Krystal Global Engineering#ASTM Tubes 2025#Sustainable Manufacturing#Steel Innovation#Precision Engineering

0 notes

Text

Propane Cylinders: From Empty to Essential – A Masterful Touch by Jade Ann Byrne

Propane Cylinders: From Empty to Essential – A Masterful Touch by Jade Ann Byrne The iconic Bernzomatic flame—a symbol of precision and power, ready to ignite ideas and fuel innovation. Jade Ann Byrne captures the essence of utility and artistry in every detail Safety above all: A stark reminder of the energy within. Extreme flammability paired with extreme craftsmanship. Each cylinder, a…

#artisan engineering#Bernzomatic#blue steel#craftsmanship#cylinder recycling#energy innovation#flammability safety#functional design#industrial art#industrial craftsmanship#Jade Ann Byrne#Local Business#precision engineering#propane cylinders#Quality Assurance#reusable materials#safety standards#Service Industry#sustainability

0 notes

Text

How SBJ Nirmal Products Is Empowering Farmers with Reliable Machinery Parts

Modern agriculture depends on durable and efficient machinery, and farmers around the world know that reliable parts are key to keeping their equipment running smoothly. SBJ Nirmal Products, a leader in the agricultural machinery parts industry, has dedicated itself to empowering farmers with high-quality, precision-engineered components. Let’s explore how SBJ Nirmal Products is making a difference in the lives of farmers through innovation, quality, and trust.

Introduction to SBJ Nirmal Products and Its Role in Agriculture

Overview of SBJ Nirmal Products

Based in Ludhiana, Punjab, SBJ Nirmal Products has become synonymous with quality and reliability in the agricultural machinery sector. With over 4,500 products in its catalog, the company has earned a reputation for producing components that enhance the performance and longevity of farming equipment. From rotavator spare parts to stub axles and bearings, SBJ Nirmal caters to the needs of farmers across India and beyond.

The Importance of Reliable Machinery Parts in Modern Farming

In today’s competitive agricultural landscape, downtime can lead to significant losses. Machinery parts that fail under pressure disrupt farming operations and escalate costs. Reliable components, like those from SBJ Nirmal, ensure uninterrupted performance, helping farmers maximize productivity and profitability.

How SBJ Addresses Farmers' Needs

SBJ Nirmal focuses on understanding the challenges faced by farmers. By offering robust solutions, the company ensures that its parts are:

Durable enough to withstand tough farming conditions.

Compatible with various machinery models.

Affordable without compromising on quality.

Key Features of SBJ Nirmal Machinery Parts

Durability and Strength

SBJ Nirmal’s parts are built to last. Made with high-grade materials, these components can endure heavy loads and harsh environmental conditions. Farmers trust SBJ for parts that reduce the frequency of replacements.

Precision Engineering

Every SBJ part is crafted with precision to meet exacting standards. Advanced manufacturing techniques ensure that the components fit perfectly into agricultural machinery, reducing wear and improving efficiency.

Compatibility with Major Machinery Brands

SBJ Nirmal offers parts that are compatible with a wide range of machinery brands, making it easier for farmers to find solutions tailored to their equipment.

Types of Machinery Parts Offered by SBJ Nirmal

Rotavator Spare Parts

Rotavators are essential for soil preparation, and SBJ provides spare parts such as blades, shafts, and gearboxes that ensure smooth operation and enhanced durability.

Stub Axles and Housing

Stub axles are critical for the mobility and balance of machinery. SBJ’s stub axles and housing units are engineered for strength and reliability, minimizing breakdowns.

Bearings, Bushings, and Shafts

Key to reducing friction and wear, SBJ’s bearings, bushings, and shafts are crafted to improve the overall efficiency of farming equipment.

Benefits of Using SBJ Nirmal Products for Farmers

Reducing Maintenance Costs

With SBJ’s durable and long-lasting parts, farmers experience fewer breakdowns and lower maintenance costs, leading to significant savings over time.

Enhancing Machinery Efficiency

High-quality parts improve machinery performance, resulting in better fuel efficiency, smoother operation, and increased productivity.

Supporting Sustainable Farming

SBJ’s commitment to sustainability means producing parts that last longer and reduce waste, aligning with eco-friendly farming practices.

How SBJ Nirmal Ensures Quality in Its Machinery Parts

Stringent Quality Control Procedures

Every product undergoes rigorous quality checks to meet international standards. From material selection to final inspection, SBJ leaves no stone unturned.

Use of High-Grade Materials

SBJ sources premium materials to ensure durability and performance. These materials resist corrosion, wear, and extreme conditions.

Testing for Real-World Conditions

SBJ simulates tough farming environments during testing to ensure that its parts perform reliably in the field.

Farmers’ Testimonials and Success Stories

Real-Life Experiences of Farmers

Farmers who use SBJ Nirmal parts often share stories of reduced downtime and increased efficiency. These testimonials highlight the real-world impact of SBJ’s commitment to quality.

How SBJ Parts Helped Improve Productivity

By minimizing equipment failure and improving operational efficiency, SBJ’s products empower farmers to achieve higher yields and profitability.

SBJ Nirmal’s Commitment to Innovation in Agricultural Technology

Research and Development in Machinery Parts

SBJ invests in R&D to stay ahead of industry trends. This focus on innovation leads to the development of parts that address emerging farming challenges.

Innovations That Drive Farming Success

Recent advancements include:

Lightweight yet strong materials for easier handling.

Enhanced designs for improved performance.

Collaborations with Industry Leaders

SBJ partners with leading agricultural organizations to develop solutions that cater to the evolving needs of farmers.

Accessibility and Global Reach of SBJ Nirmal Products

Distribution Network Across India and Beyond

SBJ’s extensive network ensures that farmers across India and neighboring countries have easy access to its products. The company’s reach extends to:

Bangladesh

Nepal

Sri Lanka

Availability in Key Agricultural Markets

SBJ products are available through authorized dealers and online platforms, making them accessible to a global audience.

FAQs About SBJ Nirmal Products

1. What makes SBJ Nirmal parts different from others? SBJ parts are known for their durability, precision engineering, and affordability, making them a preferred choice among farmers.

2. Are SBJ parts suitable for all farming machinery? Yes, SBJ offers a wide range of parts compatible with major machinery brands.

3. How does SBJ ensure its parts last longer? By using high-grade materials and rigorous testing, SBJ ensures that its parts perform reliably under tough conditions.

4. Can I purchase SBJ parts online? Yes, SBJ parts are available through online platforms and authorized dealers.

5. Are SBJ parts eco-friendly? SBJ’s commitment to sustainability includes using durable materials that reduce waste and promote eco-friendly practices.

6. What after-sales support does SBJ provide? SBJ offers excellent customer support, including guidance on installation and maintenance.

Conclusion: Why Farmers Trust SBJ Nirmal Products

SBJ Nirmal Products has become a trusted partner for farmers by consistently delivering high-quality, reliable machinery parts. With a commitment to innovation, sustainability, and customer satisfaction, SBJ empowers farmers to achieve greater efficiency and productivity in their operations. Whether you need rotavator spare parts, stub axles, or bearings, SBJ Nirmal Products is the name you can rely on.

#SBJ Nirmal Products#agricultural machinery parts#durable machinery parts#rotavator spare parts#stub axles#bearings and bushings#reliable farming components#precision engineering#sustainable farming#machinery maintenance#reducing downtime#high-quality farming parts#efficient farming solutions#global reach#trusted agricultural parts manufacturer#innovation in agriculture

0 notes

Text

The Importance of Precision Engineering in Modern Manufacturing

In today's fast-paced manufacturing industry, precision engineering plays a crucial role in ensuring product quality, efficiency, and durability. Whether it's aerospace, automotive, medical devices, or electronics, precision engineering is vital for producing components that meet the highest standards.

What is Precision Engineering? Precision Engineering refers to the process of designing and manufacturing components with extremely tight tolerances, often in the range of micrometers. This level of accuracy ensures that parts fit together seamlessly, function as intended, and maintain performance over time.

Applications of Precision Engineering

Aerospace: In aerospace, precision components are essential for safety and reliability. From engines to flight controls, precision engineering ensures that every part meets the exact specifications required.

Automotive: In the automotive industry, precision engineering contributes to the production of parts like engine components, braking systems, and steering mechanisms.

Medical Devices: Medical devices such as pacemakers, implants, and diagnostic equipment require high levels of precision to ensure safe and reliable performance.

Benefits of Precision Engineering

Increased Efficiency: Precision engineering reduces the likelihood of defects, leading to fewer reworks and higher production efficiency.

Improved Quality: Components manufactured with precision are more reliable and function optimally.

Cost-Effectiveness: Although initial costs may be higher, precision engineering reduces the likelihood of expensive recalls or repairs in the future.

Conclusion Precision engineering is indispensable in creating high-quality products across various industries. Its role in ensuring accuracy, safety, and performance cannot be overstated.

Visit us for more information-

Ph. No:- 61 3 9551 4371 Gmail- [email protected] Add. 46/48 Licola Cres, Dandenong South VIC 3175, Australia

Website- https://arrowmps.com.au/precision-fabrication/

0 notes

Text

Engineered for durability and precision, our High-Strength Forged Clutches deliver unmatched performance under extreme conditions. Perfect for high-performance vehicles, they provide smooth engagement, enhanced torque transfer, and exceptional reliability. Upgrade your ride with clutches designed to handle the toughest demands and elevate your driving experience.

#Forged Clutch Components#Heavy-Duty Clutch Forging#Custom Forged Clutches#High-Strength Forged Clutches#Precision Engineering#precision machined gears#Precision Forging for Heavy Machinery

0 notes

Text

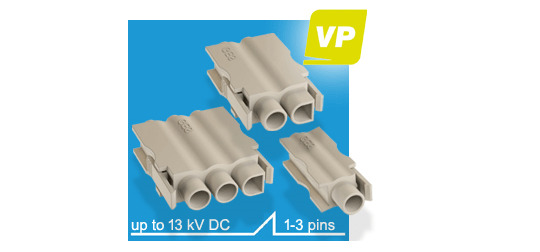

High Voltage Connectors | HV Passive Components | High Voltage Products, GmbH

Check out HV Products' wide range of HV connectors, available in various configurations and designs. Our products are trusted by customers worldwide for their reliability and precision engineering, making them ideal for sensitive industrial and scientific applications.

Contact Us Today!

#High Voltage Connectors#High Voltage Products#HV connectors#HV Passive Components#precision engineering#scientific applications

0 notes

Text

#Business In Pune#Manufacturing In Pune#Precision Engineering#Quality Manufacturing#ANJALI T.PRECISION

0 notes

Text

This certificate course of NTTF will equip students with the necessary skills to operate and set up machine tools within the machining industry. The curriculum focuses on developing general machining skills that align with the requirements identified by the industry.

0 notes

Text

Replace manual latte art with beautiful printed patterns to enhance the appeal of drinks. ☕

📹: Aaron

—

Machine automated latte art involves using advanced espresso machines equipped with technology to create intricate designs on lattes with minimal human intervention, blending precision engineering with artistic expression to produce consistent, high-quality latte art that rivals hand-crafted designs.

📝: @worldartira / X

#latte#cafe latte#latte art#coffee#drinks#coffee latte#espresso machines#precision engineering#artistic expression#coffee pattern print machine#hand-crafted designs

1 note

·

View note

Text

Precision CNC Machining Services for Complex Parts

Explore high-quality CNC machining services that ensure precision and efficiency for complex parts and components. Our advanced CNC machines are designed to handle intricate designs with superior accuracy.

For more information - https://yashlasertek.com/our-process/

0 notes