#Infrared testing

Explore tagged Tumblr posts

Text

#Certified Infrared Thermographer#Commercial infrared inspection#Electrical infrared analysis#Electrical inspection#Energy loss scan#Heat loss scan#Industrial infrared inspection#Infrared building inspection#Infrared electrical inspection#Infrared inspection near me#Infrared mechanical inspection#Infrared roof inspection#Infrared testing#Infrared thermal imaging#Predictive maintenance#Preventive maintenance#Residential infrared inspection#Roof moisture scan#Thermal imaging#Thermal imaging companies near me

1 note

·

View note

Text

Integrated NDE Solution in Pune: Advancing Industry Standards with Thermography Testing

In today’s industrial landscape, ensuring the integrity, efficiency, and safety of equipment and structures is paramount. Thermography testing, also known as thermographic inspection, has emerged as a crucial non-destructive testing (NDT) method for identifying potential issues in various applications. Integrated NDE Solution in Pune is at the forefront of providing comprehensive thermography testing services, utilizing cutting-edge infrared technology to deliver precise and reliable results. This article explores the significance of thermography testing, its applications, benefits, and the state-of-the-art services offered by Integrated NDE Solution.

Understanding Thermography Testing

Thermography testing is a non-destructive technique used to detect, visualize, and measure thermal patterns on the surface of an object. This method relies on the principle that different materials emit infrared radiation at varying rates based on their temperature. By capturing and analyzing infrared images, thermography testing can identify anomalies such as overheating, insulation defects, moisture intrusion, and electrical faults.

Importance of Thermography Testing

Early Detection: Enables the early identification of potential issues before they escalate into costly failures or accidents.

Predictive Maintenance: Facilitates predictive maintenance by identifying areas of concern and scheduling repairs or replacements proactively.

Energy Efficiency: Helps optimize energy usage by identifying areas of heat loss or inefficiency in buildings and industrial processes.

Safety: Enhances safety by detecting electrical faults, fire hazards, and other potential risks.

Cost Savings: Prevents downtime, reduces repair costs, and extends the lifespan of equipment and structures.

How Thermography Testing Works

Thermography testing involves the following steps:

Preparation: The surface to be inspected is prepared by ensuring it is clean and free from obstructions.

Infrared Imaging: A thermographic camera is used to capture infrared images of the surface.

Analysis: The captured images are analyzed to identify temperature variations, anomalies, and potential issues.

Reporting: A comprehensive report is generated, detailing the findings, recommendations, and corrective actions if necessary.

Applications of Thermography Testing

Thermography testing finds applications across various industries, including:

Building Inspections: Detecting energy leaks, moisture intrusion, and insulation defects in residential and commercial buildings.

Electrical Systems: Identifying overheating components, loose connections, and electrical faults in power distribution systems.

Mechanical Equipment: Monitoring the condition of motors, bearings, and rotating machinery for signs of wear or malfunction.

Process Control: Monitoring temperature variations in industrial processes to ensure efficiency and product quality.

Fire Prevention: Identifying hotspots and fire hazards in electrical panels, equipment, and facilities.

Benefits of Thermography Testing

Non-Destructive: Does not require physical contact with the object being inspected.

Comprehensive: Provides detailed insights into the condition of equipment, structures, and systems.

Real-Time Monitoring: Allows for continuous monitoring of temperature variations and trends.

Cost-Effective: Helps prioritize maintenance efforts and allocate resources efficiently.

Safety Enhancement: Improves safety by identifying potential hazards and risks.

Integrated NDE Solution in Pune: Leaders in Thermography Testing

Integrated NDE Solution in Pune is a trusted provider of thermography testing services, offering expertise, state-of-the-art equipment, and a commitment to quality and safety. Their team of certified thermographers ensures accurate and reliable results, helping clients optimize their operations and mitigate risks.

Comprehensive NDT Services Offered

Thermography Testing

Ultrasonic Thickness Measurement (UTM)

Remote Visual Inspection (RVI)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Portable Hardness Testing

Ferrite Testing

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Manufacturing: Ensuring the reliability and efficiency of production equipment.

Power Generation: Monitoring the condition of turbines, generators, and electrical systems.

Oil and Gas: Detecting leaks, corrosion, and structural defects in pipelines and storage tanks.

Aerospace: Inspecting aircraft components for signs of wear, fatigue, or defects.

Building Construction: Identifying energy leaks, moisture intrusion, and insulation defects in buildings.

Electrical Utilities: Monitoring the condition of power distribution systems, substations, and transformers.

Thermography Testing in Action

Case Study: Industrial Plant Inspection

Integrated NDE Solution was contracted to perform thermography testing at a large industrial plant. Using advanced infrared cameras, the team conducted comprehensive inspections of electrical panels, motors, and rotating equipment. The inspection revealed several overheating components and loose connections, allowing the client to schedule timely repairs and prevent potential failures.

Case Study: Building Energy Audit

A commercial real estate developer enlisted the services of Integrated NDE Solution to conduct a thermography-based energy audit of their properties. The inspection identified areas of heat loss, air leakage, and insulation defects, enabling the client to implement energy-saving measures and improve the overall efficiency of their buildings.

Advanced Thermography Testing Equipment

Integrated NDE Solution in Pune utilizes state-of-the-art thermographic cameras and equipment to ensure accurate and reliable inspections. Some of the advanced equipment includes:

High-Resolution Infrared Cameras: Capture detailed thermal images with high sensitivity and resolution.

Portable Thermal Imaging Devices: Allow for on-site inspections and real-time monitoring of temperature variations.

Thermal Imaging Software: Analyze captured images, generate reports, and identify anomalies with precision.

Drone-Based Thermal Imaging Systems: Conduct aerial inspections of large structures and inaccessible areas.

The Role of Certified Thermographers

Integrated NDE Solution in Pune employs certified thermographers who possess the expertise and training required to conduct accurate and reliable thermography inspections. Their knowledge of thermodynamics, heat transfer, and infrared technology ensures that clients receive high-quality and actionable insights.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is committed to upholding the highest standards of quality and safety in all their services. They adhere to industry best practices, regulatory requirements, and quality management systems to ensure that inspections are performed with precision, reliability, and integrity.

Customer-Centric Approach

Integrated NDE Solution in Pune prioritizes customer satisfaction and strives to exceed client expectations. They work closely with clients to understand their unique needs, challenges, and objectives, tailoring their services to deliver practical and cost-effective solutions.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical proficiency in thermography testing and NDT services.

Technology: Utilization of advanced infrared cameras, equipment, and software for accurate and reliable inspections.

Quality Assurance: Commitment to upholding the highest standards of quality, safety, and regulatory compliance.

Customer Service: Dedication to delivering exceptional service, responsiveness, and support to clients.

Value: Cost-effective solutions that help optimize operations, enhance safety, and reduce risks.

Conclusion

In conclusion, thermography testing is a powerful tool for identifying potential issues, optimizing operations, and ensuring the safety and reliability of equipment, structures, and systems.

0 notes

Text

well technically the sun only becomes a laser during the "green flash" events of sunrise/sunset/ all other sunlight is just powerful enough by itself to cause blindness in the chaotic-non-polarized form of light

#heheh#physics#fun times#i need to test this green flash laser idea#that it's an infrared laser doubling into green

81K notes

·

View notes

Text

Infrared Gas Toxicity Test Monitor

The Infrared Gas Toxicity Test Monitor from ESE Gas offers precise detection of toxic gases using advanced infrared technology. Our portable FTIR gas analyzer ensures accurate, reliable monitoring for industrial safety, compliance, and workplace protection. Stay ahead with cutting-edge gas analysis solutions.

0 notes

Text

Tracking the Recovery of a Mild Traumatic Brain Injury Patient utilizing a 60-s Combined Functional Near-Infrared Spectroscopy and Psychomotor Testing Approach: A Case Study by Dr. Cory M. Smith in Journal of Clinical Case Reports Medical Images and Health Sciences

Abstract

Identifying and tracking the recovery of patients with mild traumatic brain injuries (mTBI) has remained elusive due to the lack of non-invasive, objective neuroimaging techniques. The purpose of this case study was to provide a proof of concept for performing a combined functional near-infrared spectroscopy (fNIRS) and 60-s psychomotor vigilance testing (60-s PVT) that can identify and track the recovery of a patient with a mTBI. The patient was a 19-year-old female acrobatics and tumbling athlete who was kicked in the left temple by a teammate. Video footage of the injury was utilized to determine the region of impact and weekly fNIRS and 60-s PVT assessments were performed throughout the 10 weeks of recovery. The patient was cleared for activity based upon symptoms at week 7; however, the patient reported increased symptomology during weeks 7 and 8 following exercise. Our fNIRS neuroimaging technique was able to detect the systemic physiological responses associated with mitochondrial dysregulation and oxygen extraction fraction at weeks 1 to 8. Based on our findings, the patient remained injured at week 8, and that the physical activity performed at weeks 7 and 8 may have regressed recovery and induced additional dysfunction resulting in increased recovery time. In conclusion, we were able to identify and track the recovery of our patient with a mTBI using our non-invasive combined fNIRS and 60-s PVT approach. Results provided real time physiological responses associated with the injury throughout the recovery process.

Introduction: Identifying and tracking the recovery of patients with mild traumatic brain injuries (mTBI) has remained elusive due to the lack of non-invasive, objective neuroimaging techniques and that each injury may be unique in its severity, signs and symptoms.1 This present case provides an overview of a novel utilization of functional near-infrared spectroscopy (fNIRS) combined with a 60-s psychomotor vigilance test (60-s PVT) for the monitoring of a patient with a severe mTBI. fNIRS examines the hemodynamic responses in brain tissue by using specific wavelength light absorbance rates to quantify the oxygenated (O2Hb), deoxygenated (HHb), and total hemoglobin (tHb) within a targeted region of the brain.2–4 mTBI’s with associated cerebral damage (e.g., cerebral hemorrhage), require increased nutrient exchange to heal causing greater blood flow to the damaged region when under load.5–8 Furthermore, following a mTBI, moderate to severe cognitive tasks are often contraindicated as they induce a worsening of symptoms.9–11 As a result, complex screening tools may induce greater severity scores immediately following a mTBI or place the patient at increased risk of adverse events such as headaches, nausea, or malaise.12,13 The 60-s PVT utilized in this case study mildly stimulates the major regions of the brain through visual, motor, and cognitive stimuli to induce a hemodynamic shift over the damaged region which would otherwise be undetectable.14,15 To our knowledge this is the longest published tracking of the recovery of a patient with an mTBI using fNIRS following injury onset.16–18 In addition, the present case is novel in that neuroimaging began within 72-hr from the onset of injury, weekly tracking was performed, and the exact time and location of injury was established through video footage of the injury’s occurrence which allowed for precise neuroimaging and tracking of the patient during their recovery.

Our fNIRS technique is ideal for real-world monitoring as it is not as impacted by movement or environmental conditions as the traditionally used electroencephalograms (EEG). In addition, fNIRS is more portable than functional magnetic resonance imagining (fMRI) techniques which are costly and cannot be performed on the field during sporting events.5,19 The fNIRS technology has been shown to have greater spatial resolution than EEG, similar to that of fMRI.2,4,20,21 In addition, fNIRS has slightly lower temporal resolution than EEG, but much greater than that of fMRI. Thus, the portability and unique blend of spatial and temporal neuroimaging resolution makes the use of fNIRS ideal for identifying and tracking mTBI in real-world environments.2,4,20,21 However, previous studies using fNIRS have shown mixed results in its ability to identify mTBI’s.17,18,22–24 We hypothesized that these conflicting results were the result of methodological approaches that included unoptimized post-processing neuroimaging data fusion and mTBI-specific analysis algorithms for regional injury determinations.17,25,26 Furthermore, other fNIRS studies have utilized O2Hb hemoglobin measures in their statistical analyses. However, many studies have reported HHb and tHb as more robust in detecting alterations in cognitive load and neuroplastic changes.3,18,27,28 Therefore, the purpose of this case study was to provide a proof of concept for performing weekly fNIRS (O2Hb, HHb, and tHb) and 60-s PVT monitoring of a unique mTBI patient suffering from severe symptoms.

Methods

Patient: The patient was a 19-year-old female acrobatics and tumbling athlete. Prior to enrollment in college, the patient had a history of concussions with prolonged recovery periods. During a synchronized tumbling pass the patient was kicked in the left temple by a teammate, followed by hitting her forehead on the mat during landing. Immediately following the impact, the patient presented with signs and symptoms (e.g., headache, altered mental status) warranting a referral to an emergency department (ED) for further evaluation. At the ED a head computerized tomography (CT) scan revealed that the patient was suffering from a severe mTBI. However, results of the CT scan did not identify a skull fracture or hemorrhaging. An assessment completed by the school’s medical staff after being released from the hospital found the patient was suffering from headaches, visual disturbances, and disorientation. Further, neurocognitive testing revealed substantial deficits in processing speed, reaction time, and executive functioning. The patient was then re-evaluated the day after the initial injury where she reported headaches, disorientation, and fatigue.

In total, the patient was symptomatic for 10 weeks following injury. Video footage of the injury was utilized to determine the region of impact and weekly neuroimaging assessments were performed throughout the 10 weeks. Recovery from the mTBI during this time was marked by a slow and steady decrease in symptoms (e.g., headaches, difficulty sleeping, sensitivity to light/noise, vision issues, dysphasia, emotional disturbances). The patient did not return to any physical activity until seven weeks after the initial injury. However, her activity was early threshold aerobic exercise primarily consisting of cycling while being monitored for increases in reported mTBI signs and symptoms. Due to the prolonged recovery and previous concussion history, the medical team and patient decided that further participation in the sport was not feasible. Thus, the patient medically disqualified from further participation. This project was approved by the institutions IRB (Approval ID#: 2012044), is aligned with the Declaration of Helsinki, and the patient’s consent was provided to publish the data within this case study. This study.29

Functional Near-Infrared Spectroscopy Signal Analysis:

The overall fNIRS-derived hemodynamic responses were monitored each week for 10 weeks of the patient’s recovery beginning after the onset of the injury. The location of placement for the fNIRS sensors were determined based on video footage of the injury and athletic trainers present at the time of injury. fNIRS hemodynamic monitoring were collected over left (Injured) and right (Control) superior temporal region of the patients’ head using a 4x1 optode to receiver layout which was secured to the head with a full head neoprene cap, chin strap, and pressure relief system to maintain sensor placement (OxyMon MKII, Artinis Medical Systems, Einstinweg, Netherlands). The centerpoint of the 4x1 sensor grid was the location of impact and the identical location on the opposing side of the head. Each of the 4 optodes on each region of the head were sampled at 10 Hz for each of the 762 and 848 nm wavelengths utilized to monitor the hemodynamic responses. Each wavelength penetrates through the skull and into the cerebral cortex at a distance of ~2.5 cm. The thickness of the skull was estimated based on the patients age and utilized to calculate a correction factor for the differential pathlength factor (DPF) caused by the refraction of the skull fNIRS signals were performed by filtering for Mayer waves, respiration, and heart pulsation by examining the power density spectrum prior to the continuous wavelet (CWT) analysis. A Morlet Wavelet was utilized for the CWT transform using time-step coefficients without any overlap was then performed. The Wavelet coefficients were determined from the culmination of all the CWT data over each weeks 60-s PVT test and was used to further analyze the CWT Multiscale Peak Detection to quantify the amplitude of each CWT. This analysis allowed for the calculation of fNIRSamp values for O2Hbamp, HHbamp, and tHbamp. Together, these metrics provide the regional cerebral blood flow (tHbamp), metabolic stress (HHbamp), and available oxygen (O2Hbamp) in the Control and Injured regions of the brain. Each hemisphere’s 4 optode grid channels were then summated to provide an individual activation level for each locations site of interest during each week’s 60-s PVT.

Three exploratory t-tests were performed on the mean Control and Injured tHbamp, HHbamp, and O2Hbamp measures, collapsed across the 10 weeks for sufficient data points, to determine the gross differences in hemodynamics throughout the 60-s PVT.

Psychomotor Vigilance Test:

A 60-s PVT was performed each week while wearing the fNIRS neuroimaging sensor on the injured and control regions of the patient’s brain. The 60-s PVT test was performed on a touch screen tablet (iPad 10.2in 9th generation, Apple, Cupertino, CA) using the Research Buddies software (Research Buddies Version 1.53). During to quantify injury severity as it has been suggested that a PVT has difficultly determining differences in patient injury severity scores.14 In a previous study31 that examined healthy, military non-TBI patients suffering from extreme hypoxemia and physical fatigue reported an average 60-s PVT time ranging from 380-450-ms. Taken together, the findings of these previous studies suggest that a 60-s PVT can help to identify deficits and potentially severity, but the 60-s PVT alone is unable determine if an mTBI occurred and its injury severity. However, the addition of our fNIRS neuroimaging technique coupled with the 60-s PVT results may allow for a methodology of tracking the occurrence and severity of mTBI patients.

Functional Near-Infrared Spectroscopy: Neuroimaging:

Neuroimaging the contralateral side of the brain as a Control was effective for identifying the hemodynamic and metabolic differences from the Injured region of the brain in our patient as a pre-injury image was unavailable. The relatively consistent tHbamp, HHbamp, and O2Hbamp metrics across the 10 weeks for the Control compared to the Injured side reflects a low neurophysiological load placed on the Control region of the brain typical of a non-mTBI patient during the 60-s PVT (Figure 4).2,26 Furthermore, Figure 5 illustrates the similarities in the neurophysiological load placed on the Control and Injured regions of the brain at the initial 0 to 10-s of the 60-s PVT, however, after 30-s of load a greater hemodynamic and metabolic responses occurred in the Injured but not the Control region of the brain. Thus, the 60-s PVT load placed on the brain was minimal enough to not impact the Control region of the brain while sufficient at stimulating a response from the Injured region of the brain. Therefore, the utilization of a Control region was effective and allowed us to develop a target recovery threshold for the Injured region of the brain to match the tHbamp, HHbamp, and O2Hbamp of the Control region. The combined tHbamp, HHbamp, and O2Hbamp pattern of responses throughout the 10 weeks of recovery indicated maintenance of the patients Oxygen Extraction Fraction (OEF) in the Injured region of the brain. 32 The HHbamp and O2Hbamp ratio remained relatively constant in the Injured region of the brain with a concomitant increase in tHbamp which suggested that greater oxygenation utilization was required in the Injured region of the brain compared to the Control (Figure 4). The overall increased blood flow to the Injured region and increased metabolic demand, as indicated by the greater HHbamp, likely aimed to offset the mTBI associated Ca2+ overload within the patient. Increasing of the patients overall regional blood flow (tHbamp) to the Injured region may reflect a protective mechanism to avoid the catabolic effects of a Ca2+-induced intracellular dysregulation that has been shown to result in the overproduction of free radicals, activation of cell death signaling pathways and stimulation of inflammatory responses.33–35 That is, the fNIRS responses captured throughout the recovery of this patient tracked with the expected systemic physiological responses associated with the maintenance of OEF. Furthermore, it has been well established that mTBI’s result in mitochondrial dysregulation which result in a greater hemodynamic shift to the injured region of the brain to provide sufficient oxygen, dilution, and clearance rates for the metabolic byproducts.33,34 It is hypothesized that the combined mitochondrial dysregulation induced hemodynamic shift was likely the driving factor for the increased metabolic stress (HHbamp) while OEF further stimulated a greater hemodynamic flow to the Injured region of the brain to avoid further injury associated with a buildup of metabolic byproducts. The combined regional cerebral blood flow regulation pattern (tHbamp) and increased metabolic demand captured in this patient indicated that the damage to the patient’s brain was detectable using our fNIRS approach. Furthermore, the combined utilization of our CWT tHbamp, HHbamp, and O2Hbamp methodology allowed for identification of the hemodynamic shifts associated with the injury and increased load induced by the 60-s PVT.

In our patient, all fNIRS metrics that were elevated from weeks 1 to 8 improved to within Control values at week 9 and remained at the Control levels at week 10 (Figure 4). The tracked improvements in all fNIRS measures suggest that this patient’s recovery became physiologically improved at week 9, however, the patient reported minimal symptomology at rest at week 7 which cleared the patient to begin light physical activity. During weeks 7 and 8 the patient reported increased symptomology when exercising which was her rate limiter to perform physical activity. Considering the onset of the symptomology due to exercise and the fNIRS detected hemodynamic shifts associated with mitochondrial dysregulation coupled with OEF, the patient may have been less symptomatic if exercise was resumed at week 9.32,34 Specifically, the improved fNIRS and 60-s PVT metrics at week 9 were closely aligned with the Control and expected reaction time values, respectively, suggesting that our fNIRS approach could track the physiological recovery in this patient (Figure 4). Early physical activity in patients with mTBI’s has been linked to increase metabolic byproduct accumulation, greater hemodynamic shifts, potential reduced recovery rates, and increased symptomology.32,34,36,37 Thus, the elevated tHbamp, HHbamp, and OxyHbamp values at week 8 suggest that the physical activity performed at weeks 7 and 8 may have regressed recovery and induced additional dysfunction, lengthening recovery time. Therefore, further development of this non-invasive neuroimaging approach will provide clinicians with a useful assessment tool to make more informed decisions on the rate of recovery and activity a patient may be prescribed.

Limitations: This was an exploratory case study performed on a single patient to examine the clinical feasibility of the fNIRS and 60-s PVT analysis approach which will need greater refinement and development prior to clinical adoption. We acknowledge that greater data from a larger population should be studied to make this technology useable when real-time accounts or video footage of the injury site is unavailable. Thus, data from this study should not be applied to a broader patient pool until further studies focusing on the refinement and application of this approach is completed. The data from this case study does provide the foundational information needed to replicate the study methodology and highlights the relevance to the clinical community aiming to develop non-invasive mTBI monitoring devices.

Conclusion: In conclusion, the 60-s PVT was capable of detecting deficits in our patient, however, the 60-s PVT alone was unable to determine injury severity. The addition of our fNIRS neuroimaging technique was able to detect the systemic physiological responses over the injured region of the brain that align with mitochondrial dysregulation induced hemodynamic shifts and increased metabolic stress (HHbamp). In addition, tHbamp and HHbamp identified OEF which further stimulated a greater hemodynamic flow to the Injured region of the brain to avoid a buildup of metabolic byproducts. The neuroimaging from the contralateral side of the brain was effective as a Control in our patient as a preinjury image was unavailable. Using the Injured and Control region neuroimaging, we determined the elevated tHbamp, HHbamp, and OxyHbamp values at week 8 suggest that the physical activity performed at weeks 7 and 8 may have regressed recovery and induced additional dysfunction, lengthening recovery time. Therefore, this case study showed that a combined 60-s fNIRS neuroimaging and PVT technique was capable of detecting the patients mTBI and tracked her recovery better than subjective assessments. Furthermore, the physiological data obtained through our non-invasive neuroimaging approach was able to identify the patient’s physiological response including potential mitochondrial dysregulation and OEF. Therefore, the physiological responses and recovery state capture in our patient indicates that the weekly assessments of a combined 60-s fNIRS and PVT approach could provide clinically relevant data on the recovery status and injury severity. Future research should focus on the development of fNIRS threshold values that can be utilized to better identify the severity of a mTBI and its associated physiological responses in a large sample of mTBI patients.

Acknowledgements: We would like to thank the patient for their time and willingness to volunteer for this study. In addition, we would like to thank Baylor Athletics Executive Senior Associate Athletic Director Kenny Boyd, Associate Athletic Director Carrie Rubertino Shearer, and all the athletic trainers who assisted in this project.

#Mild Traumatic Brain Injury#Near-Infrared Spectroscopy#Psychomotor Testing Approach#Journal of Clinical Case Reports Medical Images and Health Sciences#JCRMHS#Journal of Clinical Case Reports Medical Images and Health Sciences (JCRMHS)| ISSN: 2832-1286

1 note

·

View note

Text

Infrared Thermographic Inspection Services by Thermo Elite: Ensuring Safety & Efficiency

In today’s world, maintaining the safety and efficiency of electrical, mechanical, and structural systems is more critical than ever. One of the most effective ways to achieve this is through infrared thermographic inspection. Thermo Elite specializes in this cutting-edge technology, using high-resolution infrared imaging to identify issues that are invisible to the naked eye. This non-invasive inspection method detects temperature variations that can signal underlying problems, enabling proactive solutions.

What is Infrared Thermographic Inspection?

Infrared thermographic inspection involves capturing heat patterns using specialized infrared cameras. By detecting areas of abnormal heat or temperature differences, this technique can identify problems such as overheating electrical components, moisture intrusion, insulation deficiencies, or mechanical failures. Thermo Elite’s experienced thermographers use this technology to provide comprehensive insights into the health of your systems, making it an essential part of predictive and preventive maintenance.

Why Choose Thermo Elite for Infrared Thermographic Inspection?

Thermo Elite offers expert infrared thermographic inspections designed to ensure optimal performance and safety. Here’s why we’re the trusted choice for businesses and homeowners:

Certified Thermographers: Our team is trained and certified in advanced thermographic techniques, ensuring accurate, reliable results.

State-of-the-Art Technology: Thermo Elite utilizes high-resolution infrared cameras and industry-leading tools to capture detailed thermal images.

Detailed Analysis & Reports: After each inspection, we provide detailed reports with thermal images, findings, and recommended corrective actions to address any issues.

Custom Inspection Plans: We tailor our inspections to your specific needs, offering one-time assessments, regular maintenance checks, or custom solutions for unique systems.

Non-Disruptive Services: Our inspections are quick, non-invasive, and performed without disrupting your operations or daily activities.

Benefits of Infrared Thermographic Inspection

Early Problem Detection: Thermography allows you to detect issues like overheating circuits, loose electrical connections, and structural inefficiencies before they escalate.

Reduced Downtime: By addressing small issues early, you can prevent equipment failures and reduce costly downtime.

Fire Hazard Prevention: Excess heat within electrical systems is a significant fire risk; thermography helps pinpoint and eliminate these dangers.

Improved Energy Efficiency: Identify areas of energy loss or inefficiency to optimize system performance and reduce costs.

Compliance & Safety: Many industries require routine inspections for safety compliance, and thermography is a key part of meeting those standards.

Applications of Infrared Thermographic Inspection

Thermo Elite’s services have broad applications across various industries and environments, including:

Electrical Systems: Detecting loose connections, overloaded circuits, and equipment failures.

Building Inspections: Identifying heat loss, moisture intrusion, and insulation issues.

Mechanical Equipment: Locating wear, misalignment, or excessive friction in moving parts.

Data Centers: Ensuring proper cooling and preventing overheating of critical infrastructure.

Industrial Facilities: Maintaining production equipment and ensuring operational safety.

Thermo Elite’s Inspection Process

Thermo Elite’s infrared thermographic inspections are comprehensive and designed for accuracy. Our certified thermographers use state-of-the-art infrared cameras to capture thermal images of your systems. These images reveal temperature anomalies that could indicate potential problems. After completing the inspection, we provide a detailed report outlining the findings, thermal images, and specific recommendations for corrective actions.

#Infrared thermographic inspection#thermal imaging services#Thermo Elite#electrical safety inspection#energy efficiency testing#preventative maintenance#heat detection technology#building thermography#mechanical equipment inspections

0 notes

Text

Seeing the Unseen: How Infrared Thermography Services Can Save You Time and Money

In the modern world, maintaining efficiency and reducing costs are paramount for businesses across various industries. One powerful tool that has emerged to help achieve these goals is infrared thermography. Infrared Thermography Services are revolutionizing how companies manage maintenance, detect issues, and ensure safety. At RVS Quality Certifications Pvt Ltd., we understand the value of advanced diagnostic tools and offer comprehensive training and consultancy services to help you harness these technologies.

Understanding Infrared Thermography

Infrared thermography is a non-invasive, non-contact method of detecting heat patterns and temperatures on surfaces. By using infrared cameras, technicians can visualize and measure thermal energy emitted by objects. This technology allows for the identification of anomalies that might indicate underlying problems, such as electrical faults, mechanical failures, or insulation deficiencies.

Employing Infrared Thermography provides significant advantages over traditional inspection methods. It enables the detection of issues before they become critical, allowing for preventive maintenance and reducing the likelihood of unexpected downtime. This proactive approach can save businesses substantial amounts of time and money by avoiding costly repairs and ensuring optimal operational efficiency.

Applications Across Industries

Infrared thermography is versatile and applicable in various industries, including manufacturing, construction, energy, and automotive. In manufacturing, it helps in monitoring equipment conditions, detecting overheating components, and ensuring the integrity of electrical systems. In construction, it is used for inspecting building envelopes, identifying moisture intrusion, and verifying insulation performance.

For energy companies, infrared thermography is essential in monitoring power lines, transformers, and substations. It aids in detecting hot spots that could indicate potential failures, thereby preventing power outages. In the automotive industry, it is used for quality control and ensuring the safety of electrical systems in vehicles.

Training and Certification

To effectively utilize infrared thermography, proper training and certification are crucial. At RVS Quality Certifications Pvt Ltd., we offer NDT Level 2 Certification Courses that equip professionals with the necessary skills and knowledge to perform accurate and reliable thermographic inspections. Our courses cover the principles of thermography, equipment handling, data analysis, and report generation.

Achieving NDT Level 2 certification signifies a high level of competence in non-destructive testing methods, including infrared thermography. This certification not only enhances the skill set of professionals but also increases their value in the job market. Companies benefit from having certified personnel who can conduct thorough inspections and contribute to improved maintenance strategies.

Enhancing Safety and Reliability

One of the primary benefits of infrared thermography is its contribution to safety. By identifying potential issues early, businesses can mitigate risks and prevent accidents. For example, detecting overheating electrical components can prevent fires, while identifying structural weaknesses can avoid catastrophic failures in buildings and machinery.

RVS Quality Certifications Pvt Ltd. emphasizes the importance of Non Destructive Testing Services in maintaining safety and reliability. Our comprehensive training ensures that professionals are equipped to perform accurate assessments, thereby contributing to safer work environments and more reliable operations.

Cost Savings and Efficiency

Implementing infrared thermography can lead to significant cost savings. By identifying problems before they escalate, businesses can plan maintenance activities more effectively, reduce unplanned downtime, and extend the lifespan of equipment. This proactive approach minimizes the need for emergency repairs, which are often more expensive and disruptive.

For industries that rely heavily on the integrity of their equipment, such as energy and manufacturing, the cost savings from avoiding major failures are substantial. Additionally, by optimizing maintenance schedules and reducing downtime, companies can enhance their overall productivity and operational efficiency.

Specialized Services for Specific Needs

In addition to general applications, infrared thermography is also valuable for specialized inspections. For instance, Tube Inspection Services utilize infrared technology to assess the condition of tubes in boilers, heat exchangers, and other critical equipment. This type of inspection can detect issues such as blockages, corrosion, and leaks, which can significantly impact the performance and safety of the equipment.

#Infrared Thermography Services#NDT Level 2 Certification Courses#Non Destructive Testing Services#Tube Inspection Services

0 notes

Text

#𝗡𝗼𝗻 𝗗𝗲𝘀𝘁𝗿𝘂𝗰𝘁𝗶𝘃𝗲 𝗧𝗲𝘀𝘁𝗶𝗻𝗴 [𝗡𝗗𝗧] 𝐂𝐨𝐮𝐫𝐬𝐞𝐬#Level II#1. Visual Testing (VT)#2. Liquid Penetrant Testing (PT)#3. Magnetic Particle Testing (MT)#4. Ultrasonic Testing (UT)#5. Radiography Testing (RT)#6. Thermal/Infrared Testing (IR)#7. Acoustic Emission Testing (AET)#8. Eddy Current Testing (ECT)#9. Magnetic Flux leakage (MFL)#Contact Us:#Mob:#+919787872866#Email:#[email protected]#Web:#www.cosmostrg.com#WhatsApp Channel :#https://whatsapp.com/channel/0029VaHMYayGufJ45OH4Xo1n#WhatsApp Group :#https://chat.whatsapp.com/IunhDueyuLsEPc9SkB7dlK#NDT#ndtinspection#ndttraining#visualtesting#liquid#penetranttesting#Magnetic#magneticparticletesting

0 notes

Text

Arch Home Inspections Inc. provides indoor air quality (IAQ) tests in Vancouver and the Lower Mainland to ensure a healthy living environment by assessing the quality of the air inside homes and buildings. We have a team of skilled professionals who conduct thorough examinations, analyzing factors such as ventilation, pollutants, and humidity levels. Through precise testing, these services identify potential issues like mold, allergens, or volatile organic compounds that may impact respiratory health. By providing actionable insights, IAQ tests empower residents to take proactive measures, enhancing the overall well-being of their indoor spaces in Vancouver and the surrounding Lower Mainland area. More details at www.archhomeinspections.com

#Indoor Air Quality Test Vancouver and Lower Mainland#Thermal Imaging Inspections Vancouver#Infrared Inspection Vancouver#Commercial Property Inspection Vancouver and Lower Mainland#Home Inspections Surrey#Home Inspections Langley

0 notes

Text

Mighty MURI brings the heat to test new longwave infrared radiometer

NASA’s new Multiband Uncooled Radiometer Instrument (MURI) features a novel bolometer that detects infrared radiation without a cryogenic cooler, greatly reducing the cost and complexity of dispatching infrared radiometers into low-Earth orbit. from NASA https://ift.tt/yegTZvb

0 notes

Text

All-Star Moments in Space Communications and Navigation

How do we get information from missions exploring the cosmos back to humans on Earth? Our space communications and navigation networks – the Near Space Network and the Deep Space Network – bring back science and exploration data daily.

Here are a few of our favorite moments from 2024.

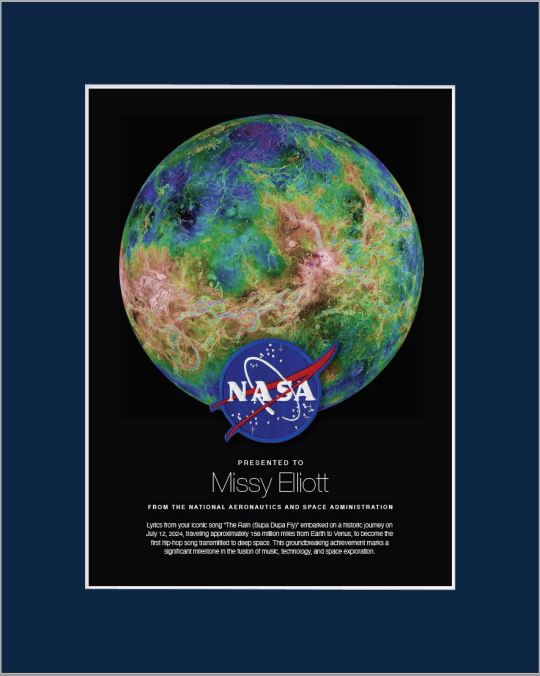

1. Hip-Hop to Deep Space

The stars above and on Earth aligned as lyrics from the song “The Rain (Supa Dupa Fly)” by hip-hop artist Missy Elliott were beamed to Venus via NASA’s Deep Space Network. Using a 34-meter (112-foot) wide Deep Space Station 13 (DSS-13) radio dish antenna, located at the network’s Goldstone Deep Space Communications Complex in California, the song was sent at 10:05 a.m. PDT on Friday, July 12 and traveled about 158 million miles from Earth to Venus — the artist’s favorite planet. Coincidentally, the DSS-13 that sent the transmission is also nicknamed Venus!

NASA's PACE mission transmitting data to Earth through NASA's Near Space Network.

2. Lemme Upgrade You

Our Near Space Network, which supports communications for space-based missions within 1.2 million miles of Earth, is constantly enhancing its capabilities to support science and exploration missions. Last year, the network implemented DTN (Delay/Disruption Tolerant Networking), which provides robust protection of data traveling from extreme distances. NASA’s PACE (Plankton, Aerosol, Cloud, ocean Ecosystem) mission is the first operational science mission to leverage the network’s DTN capabilities. Since PACE’s launch, over 17 million bundles of data have been transmitted by the satellite and received by the network’s ground station.

A collage of the pet photos sent over laser links from Earth to LCRD and finally to ILLUMA-T (Integrated LCRD Low Earth Orbit User Modem and Amplifier Terminal) on the International Space Station. Animals submitted include cats, dogs, birds, chickens, cows, snakes, and pigs.

3. Who Doesn’t Love Pets?

Last year, we transmitted hundreds of pet photos and videos to the International Space Station, showcasing how laser communications can send more data at once than traditional methods. Imagery of cherished pets gathered from NASA astronauts and agency employees flowed from the mission ops center to the optical ground stations and then to the in-space Laser Communications Relay Demonstration (LCRD), which relayed the signal to a payload on the space station. This activity demonstrated how laser communications and high-rate DTN can benefit human spaceflight missions.

4K video footage was routed from the PC-12 aircraft to an optical ground station in Cleveland. From there, it was sent over an Earth-based network to NASA’s White Sands Test Facility in Las Cruces, New Mexico. The signals were then sent to NASA’s Laser Communications Relay Demonstration spacecraft and relayed to the ILLUMA-T payload on the International Space Station.

4. Now Streaming

A team of engineers transmitted 4K video footage from an aircraft to the International Space Station and back using laser communication signals. Historically, we have relied on radio waves to send information to and from space. Laser communications use infrared light to transmit 10 to 100 times more data than radio frequency systems. The flight tests were part of an agency initiative to stream high-bandwidth video and other data from deep space, enabling future human missions beyond low-Earth orbit.

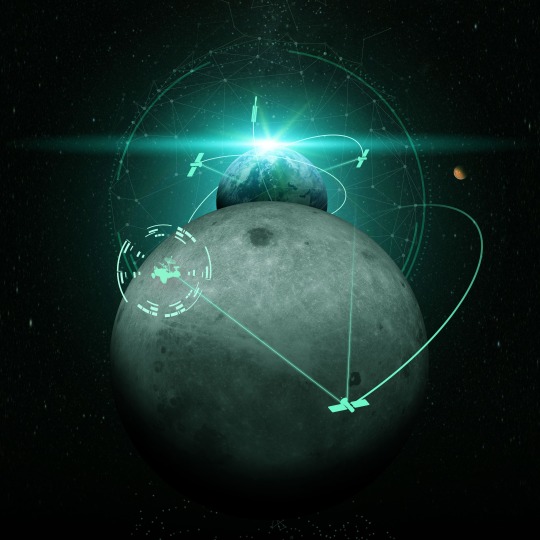

The Near Space Network provides missions within 1.2 million miles of Earth with communications and navigation services.

5. New Year, New Relationships

At the very end of 2024, the Near Space Network announced multiple contract awards to enhance the network’s services portfolio. The network, which uses a blend of government and commercial assets to get data to and from spacecraft, will be able to support more missions observing our Earth and exploring the cosmos. These commercial assets, alongside the existing network, will also play a critical role in our Artemis campaign, which calls for long-term exploration of the Moon.

On Monday, Oct. 14, 2024, at 12:06 p.m. EDT, a SpaceX Falcon Heavy rocket carrying NASA’s Europa Clipper spacecraft lifts off from Launch Complex 39A at NASA’s Kennedy Space Center in Florida.

6. 3, 2, 1, Blast Off!

Together, the Near Space Network and the Deep Space Network supported the launch of Europa Clipper. The Near Space Network provided communications and navigation services to SpaceX’s Falcon Heavy rocket, which launched this Jupiter-bound mission into space! After vehicle separation, the Deep Space Network acquired Europa Clipper’s signal and began full mission support. This is another example of how these networks work together seamlessly to ensure critical mission success.

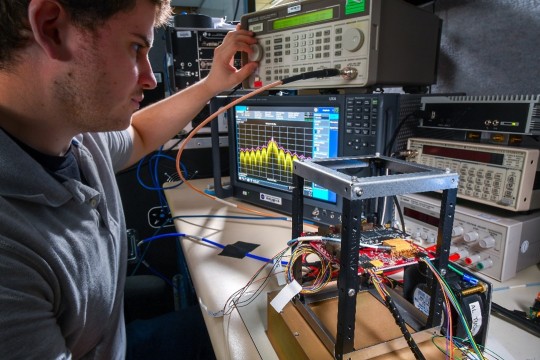

Engineer Adam Gannon works on the development of Cognitive Engine-1 in the Cognitive Communications Lab at NASA’s Glenn Research Center.

7. Make Way for Next-Gen Tech

Our Technology Education Satellite program organizes collaborative missions that pair university students with researchers to evaluate how new technologies work on small satellites, also known as CubeSats. In 2024, cognitive communications technology, designed to enable autonomous space communications systems, was successfully tested in space on the Technology Educational Satellite 11 mission. Autonomous systems use technology reactive to their environment to implement updates during a spaceflight mission without needing human interaction post-launch.

A first: All six radio frequency antennas at the Madrid Deep Space Communication Complex, part of NASA’s Deep Space Network (DSN), carried out a test to receive data from the agency’s Voyager 1 spacecraft at the same time.

8. Six Are Better Than One

On April 20, 2024, all six radio frequency antennas at the Madrid Deep Space Communication Complex, part of our Deep Space Network, carried out a test to receive data from the agency’s Voyager 1 spacecraft at the same time. Combining the antennas’ receiving power, or arraying, lets the network collect the very faint signals from faraway spacecraft.

Here’s to another year connecting Earth and space.

Make sure to follow us on Tumblr for your regular dose of space!

1K notes

·

View notes

Text

#𝗔𝗩𝗧 𝗔𝗰𝗮𝗱𝗲𝗺𝘆#𝗛𝗶𝗴𝗵𝗳𝗶𝗲𝗹𝗱 - 𝗨𝗞#1. Food Safety (Level 1 to 4)#2. HACCP (Level 2 to 4)#3. Food Allergen (Level 2 to 3)#4. Nutrition & Health (Level 2 to 3)#𝗔𝗺𝗲𝗿𝗶𝗰𝗮𝗻 𝗛𝗦𝗜 - 𝗨𝗦𝗔#MEDIC First Aid Training#MEDIC First Aid Train the Trainer#𝗡𝗗𝗧 𝗟𝗲𝘃𝗲𝗹 𝟮 𝗖𝗼𝘂𝗿𝘀𝗲𝘀#1. Visual Testing#2. Liquid Penetrant Testing#3. Magnetic Particle Testing#4. Ultrasonic Testing#5. Radiographic Testing#6. Thermal/Infrared Testing#Contact Us:#Mob:#+919361165584#+917530075440#+919655111155#Email:#[email protected]#Web:#www.avtacademy.com#nutrition#nutritioncourse#nutritionsafety#nutritiontrainingcourse#nutritioncourses

0 notes

Text

The Growing Concern Over EMF Pollution Protection in Melbourne

With our increasing reliance on electronic devices, EMF (electromagnetic field) pollution is a growing issue in many cities, including Melbourne. EMFs come from multiple sources like mobile phones, WiFi, Bluetooth, power lines, and even home appliances. Prolonged exposure to EMF radiation has been linked to increased health risks by several studies. As a result, more Melburnians are looking for solutions to reduce EMF exposure - a trend known as EMF pollution protection.

What are the Health Risks of EMF Pollution?

Excessive EMF exposure has been associated with increased chances of cancer, insomnia, headaches, and nausea. The World Health Organization has classified high electromagnetic frequency radiation as a possible carcinogen. Other studies have found EMFs may disrupt cell metabolism and increase free radicals in the body. The long-term effects of constant EMF exposure are still being investigated. However, we know that children and pregnant women are more vulnerable.

Where is EMF Pollution Most Prevalent in Melbourne?

Most EMF radiation comes from our electronic devices at home which means indoor areas near electronics see higher EMF levels. WiFi routers, smartphones, baby monitors, Bluetooth devices, and laptops are common culprits. High EMF areas include bedrooms (with devices kept close to beds), office spaces with multiple tech devices, and living rooms. Outdoor EMF sources include mobile towers, overhead power lines, and smart meters.

Tips to Reduce EMF Exposure at Home

Luckily, there are several easy changes you can make at home to protect yourself from EMF pollution:

Keep your distance - Maintain at least one meter distance from devices when in use. Avoid sleeping with phones and gadgets near your bed.

Rely on wired connections - Use cabled ethernet connections for internet instead of WiFi when possible.

Limit device usage - Reduce use of smartphones, tablets and other electronics to minimize overall exposure.

Advanced EMF Pollution Protection Solutions

For more heavy-duty EMF pollution protection Melbourne residents can turn to EMF shielding and harmonizing technologies like:

EMF Solution - They offer high quality EMF protection products like shielding paints, window films, EMF reducing canopies, and more. Experts assess your home and customize solutions.

Smart meter covers - Special covers block excess EMFs from smart meters.

EMF shielding fabrics - Use in curtains, canopy beds, and drapes to reduce EMF penetration.

The growing research on EMF pollution should make us more conscious of the invisible electronic smog in modern homes. With smart solutions such as those offered by EMF pollution protection Melbourne experts, you can reduce exposure and make your home a safe sanctuary.

#emf pollution protection Melbourne#emf pollution protection#emf#protection#environmental pollution#noise pollution#melbourne#emf pro#emf detector#crop production#emf radiation#emf course#emf testing#emf test#emf meter#emf tester#airpods emf#emf sauna test#low emf portable infrared sauna#lowest emf saunas#sunlighten sauna emf#low emf sauna new zealand#best infrared sauna no emf#no emf sauna#protect your ears#low emf sauna#emf training#electromagnetic radiation#electrification of transportation

1 note

·

View note

Text

#𝗔𝗩𝗧 𝗔𝗰𝗮𝗱𝗲𝗺𝘆#𝗛𝗶𝗴𝗵𝗳𝗶𝗲𝗹𝗱 - 𝗨𝗞#1. Food Safety (Level 1 to 4)#2. HACCP (Level 2 to 4)#3. Food Allergen (Level 2 to 3)#4. Nutrition & Health (Level 2 to 3)#𝗔𝗺𝗲𝗿𝗶𝗰𝗮𝗻 𝗛𝗦𝗜 - 𝗨𝗦𝗔#MEDIC First Aid Training#MEDIC First Aid Train the Trainer#𝗡𝗗𝗧 𝗟𝗲𝘃𝗲𝗹 𝟮 𝗖𝗼𝘂𝗿𝘀𝗲𝘀#1. Visual Testing#2. Liquid Penetrant Testing#3. Magnetic Particle Testing#4. Ultrasonic Testing#5. Radiographic Testing#6. Thermal/Infrared Testing#Contact Us:#Mob:#+919361165584#+917530075440#+919655111155#+919787637876#Email:#[email protected]#Web:#www.avtacademy.com#foodallergn#foodallergns#foodallergies#foodallergyawareness

1 note

·

View note

Text

When it comes to pregnancy testing, accuracy and reliability are of utmost importance. Precision Medical Supply, LLC understands the significance of accurate results and peace of mind during this crucial time.

0 notes

Text

RVS Quality Certifications Pvt Ltd. offers a comprehensive suite of services, including Infrared Thermography Services, that can significantly benefit your operations. Here are six key advantages of these services. Third-Party Inspection Services offer an impartial assessment of your products, processes, and systems. RVS provides these services to ensure compliance with industry standards and regulatory requirements.

#third party inspection services#Infrared Thermography Services#Tube Inspection Services#Phased Array Ultrasonic Testing#Phased Array and TOFD Training

0 notes