#gas analysis system

Explore tagged Tumblr posts

Text

Portable Infrared Syngas Analyzer

Esegas brings you the Portable Infrared Syngas Analyzer, a high-precision device for real-time syngas composition analysis. Utilizing advanced infrared technology, it ensures accurate measurements of CO, CO₂, CH₄, and H₂. Lightweight and battery-powered, it offers mobility for field applications, optimizing industrial processes and emission monitoring with ease.

0 notes

Text

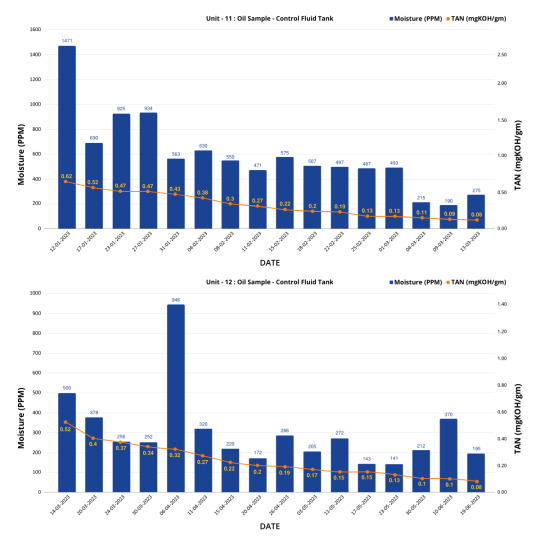

Effectively reducing the TAN Levels of 32kl of FRF Oil

Abating TAN Levels: Minimac's Tailored Solution for Critical Oil Values at India's 9th Largest Coal-Fired Power Plant

Synopsis

In Singrauli, MP, stands a colossal thermal power plant, one of the largest PSUs and the 9th largest coal-fired power station at 4760 MW capacity. Recently, it faced a formidable challenge - high TAN Levels in two 16kl control fluid tanks. To prevent a potential disruption and subsequent shutdown, Minimac provided a customized solution by deploying a specialized machine to lower TAN levels, address moisture, solid contamination and implement effective Nitrogen Blanketing.

Initial Findings

Problems

The client encountered increased TAN levels in two of their Control Fluid Tanks which had a detrimental impact on the operation of servo valves leading to reduced responsiveness, erratic behavior, increased wear and tear, and potential valve malfunction.

Client’s Requirements

To Purify 32kl of FRF Oil

To remove the TAN, Moisture and Solid Contaminants.

To Achieve NAS: ≤ Class 5.

To Achieve TAN: ≤ 0.10 (mg KOH/g).

To Achieve Moisture: ≤ 500 ppm.

Customized Solution.

Solutions

Deploying Minimac’s customized machine at the site along with trained and skilled engineers.

TAN Reduction Systems(20 LPM) equipped with the ion exchange resin to filter and eliminate acid components of oil.

Low Vacuum Dehydrator (100 LPM) to maintain consistent moisture levels in the oil using the vacuum dehydration ensuring smooth turbine operation in its active state.

Oil filtration system(150 LPM) to bring the NAS level of oil to the desired range.

Nitrogen blanketing system to maintain an inert space above the oil in the tank, serving as a barrier between the moisture-laden external air and the FRF oil inside the tank.

Along with the equipment’s installation, our Service Engineer trained the client’s team on the functioning and effective handling of the machine.

Job executed within a limited time-span on the running unit without hindering the client’s operations and control fluid tank system.

Value TypeControl Fluid Tank at UNIT 11Control Fluid Tank at UNIT 12BeforeAfterBeforeAfterNASClass 8Class 4Class 7Class 4TAN0.62 mg KOH/g0.08 mg KOH/g0.52 mg KOH/g0.08 mg KOH/gMoisture Level561PPM275 PPM500 PPM184 PPM

Benefits

Prevented the environment from harm by averting the emission of 3,84,000 kg of CO2e.

Saved 32 kl of Oil from being incinerated.

Extended Oil Life.

Reduced TAN Levels.

Elimination of Oil Replacement Costs.

Cost Saving

This Plant managed to save:

Cost of Oil Replacement: ₹7 Cr. Approx.

Cost of Downtime : ₹1 Cr. Approx.

CO2e Savings

Total Savings =3,84,000 kg of CO2e/0.384 gigagrams of CO2e

Graph

Pictorial Representation

Right to left( LVDH:100LPM, FS :150LPM, TAN Reduction Skid Ion Exchange :20LPM)

Resin Skid-TAN REDUCTION M/C (Ion Exchange 20 LPM)

Before and after oil sample

Know More About - https://www.minimacsystems.com/ Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#chemical cleaning flushing#chemical cleaning#oil filteration#oil filters#oil industry#oil and gas#oil#oil analysis#power industry#steel#mining#metal#oil filtration system#oil filtration machine#oil filtration systems#oil dehydration systems#frf condition systems#frf machine#coalser separator#elc

0 notes

Text

Enhancing Gas Pipeline Management with GIS: Key Benefits and Applications

In the energy and utilities sector, gas pipeline management is complex, requiring precision, safety, and a clear strategy for both existing infrastructure and future expansion. Geographic Information Systems (GIS) have revolutionized pipeline management by providing a spatially accurate, data-rich view of assets. From asset management and leak detection to route planning and demand forecasting, GIS is becoming indispensable for gas companies. This blog delves into the ways GIS transforms gas pipeline management, delivering benefits across safety, efficiency, cost-saving, and planning.

#benefits of using gis for gas pipelines#ensuring gas pipeline safety with gis tools#gas network analysis#gas pipeline asset management#gas pipeline gis mapping services#gas pipeline leak detection using gis#gas pipeline management in gis#gas pipeline mapping software#gas pipeline monitoring tools#gas pipeline risk assessment#gis applications in energy sector#gis for gas pipeline monitoring#gis for infrastructure management#gis in oil and gas industry#gis pipeline maintenance software#gis pipeline monitoring system#gis pipeline route planning#gis software for gas pipeline route optimization#victoryofgoodoverevil#gis solutions for pipeline maintenance and monitoring#gis-based pipeline integrity management#pipeline data management#pipeline geographic information systems#pipeline management solutions#remote sensing for gas pipelines#spatial analysis for gas pipelines#spatial data for gas pipelines

0 notes

Text

Anesthesia Gas Scavenging System Market set to grow at highest pace owing to rising concerns regarding healthcare-associated infections

The anesthesia gas scavenging system is used to collect and filter waste anesthetic gases from patient breathing circuits during general anesthesia procedures. The system provides safe disposal of waste anesthetic gases and vapor, helps in maintaining a clean air environment in the operating room, and prevents pollution. Advantages such as reduced risks of pollution and healthcare-associated infections are driving the demand for anesthesia gas scavenging systems. The system comes equipped with filters to trap and neutralize chemical vapors before venting traces of waste gases to the outside atmosphere. The Global Anesthesia Gas Scavenging System Market is estimated to be valued at US$ 8484.9 Mn in 2024 and is expected to exhibit a CAGR of 9.2% over the forecast period 2023 to 2030. Key Takeaways Key players: Key players operating in the anesthesia gas scavenging system market are INVISTA, Asahi Kasei Corporation, Hyosung Corporation, Zhejiang Huafon Spandex Co. Ltd., Yantai Tayho Advanced Materials Co. Ltd., Indorama Industries Ltd, TK Chemical Corp., Taekwang Industrial Co., Ltd, Jiangsu Shaungliang Spandex Co., Ltd., and Xiamen Lilong Spandex Co. Ltd. Growing demand: Growing number of surgical procedures performed worldwide coupled with rising concerns regarding pollution and healthcare-associated infections is fueling the demand for anesthesia gas scavenging systems. Technological advancement: Leading manufacturers are focusing on development of innovative and portable anesthesia gas scavenging systems integrated with advanced filtration technology to offer maximum protection. Market Trends Portable systems: There is rising demand for portable anesthesia gas scavenging systems that can be easily moved between operating rooms. This is attributed to growing number of ambulatory surgical centers performing short surgical procedures. Sustainable filtration: Key players are investing in research & development activities to introduce sustainable and reusable filtration systems for anesthesia gas scavenging. This helps in reducing operational costs and manual handling of biowaste in the long run. Market Opportunities Emerging markets: Emerging regions such as Asia Pacific and Latin America offer lucrative opportunities for players owing to growing healthcare infrastructure and increasing medical tourism in these regions.

#Anesthesia Gas Scavenging System Market Share#Anesthesia Gas Scavenging System Market Trend#Anesthesia Gas Scavenging System Market Analysis

0 notes

Text

Flue Gas Desulfurization Systems Market Segmentation and Competitive Landscape

#Flue Gas Desulfurization Systems Market growth#Flue Gas Desulfurization Systems Market share#Flue Gas Desulfurization Systems Market size#Flue Gas Desulfurization Systems Market trends#Flue Gas Desulfurization Systems Market demand#Flue Gas Desulfurization Systems Market#Flue Gas Desulfurization Systems Market industry#Flue Gas Desulfurization Systems Market analysis#Flue Gas Desulfurization Systems Market manufacturer#Flue Gas Desulfurization Systems Market companies

0 notes

Text

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

#Flare Gas Recovery System Market – Ireland Industry Analysis#Size#Share#Trends and Forecast 2023 – 2030

0 notes

Text

#Gas Booster Systems Market#Gas Booster Systems Market Size#Gas Booster Systems Market Share#Gas Booster Systems Market Forecast#Gas Booster Systems Market Analysis#Gas Booster Systems Market Trends

0 notes

Text

#Global PA & GA Systems Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Global Anesthesia Gas Scavenging System Market Is Estimated To Witness High Growth Owing To Increasing Focus on Patient Safety

The global Anesthesia Gas Scavenging System Market is estimated to be valued at US$ 5.5 billion in 2022 and is expected to exhibit a CAGR of 5.5% over the forecast period, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Anesthesia gas scavenging systems are used to remove waste anesthetic gases, ensuring the safety of healthcare providers and patients during anesthesia procedures. These systems prevent the accumulation of anesthetic gases in the operating room, maintaining a safe working environment. The advantages of anesthesia gas scavenging systems include reduced exposure to anesthetic gases, decreased risk of adverse health effects, and compliance with safety regulations. B) Market Key Trends: One key trend in the anesthesia gas scavenging system market is the increasing focus on patient safety. Healthcare providers are becoming more aware of the potential risks associated with exposure to waste anesthetic gases. This has led to the implementation of strict safety guidelines and regulations, driving the demand for anesthesia gas scavenging systems. For example, the Occupational Safety and Health Administration (OSHA) in the United States recommends the use of scavenging systems to minimize exposure to waste anesthetic gases. C) PEST Analysis: - Political: Governments across the globe are implementing regulations and guidelines to ensure the safety of healthcare providers and patients. These regulations drive the adoption of anesthesia gas scavenging systems. - Economic: The growing healthcare industry and increasing number of surgical procedures contribute to the growth of the anesthesia gas scavenging system market. - Social: Awareness about the potential health risks associated with waste anesthetic gases is increasing among healthcare providers, leading to higher demand for scavenging systems. - Technological: Advancements in technology have led to the development of more efficient and user-friendly anesthesia gas scavenging systems. D) Key Takeaways: - The Global Anesthesia Gas Scavenging System Market Size is expected to witness high growth, exhibiting a CAGR of 5.5% over the forecast period, due to increasing focus on patient safety. Healthcare providers are increasingly adopting anesthesia gas scavenging systems to comply with safety regulations and minimize the risks associated with waste anesthetic gases. - North America is expected to be the fastest growing and dominating region in the anesthesia gas scavenging system market. The region has well-established healthcare infrastructure and stringent safety regulations, driving the demand for scavenging systems. - Key players operating in the global anesthesia gas scavenging system market include Beacon Medaes, CGA 30 MEDEVICE system by DeviceInformed, MEC medical Ltd., MidMark, Pneumatech Medical Gas Solutions (PMGS), Coltronics system Ltd., Becker pumps, and G.Samaras S.A. In conclusion, the global anesthesia gas scavenging system market is expected to witness substantial growth in the coming years. The increasing focus on patient safety and the implementation of strict safety regulations drive the demand for anesthesia gas scavenging systems. North America is expected to be the fastest growing region, driven by its well-established healthcare infrastructure and stringent safety regulations. Key players in the market are continuously developing new and innovative products to cater to the growing demand for anesthesia gas scavenging systems.

#Anesthesia Gas Scavenging System Market#Anesthesia Gas Scavenging System Market Trends#Anesthesia Gas Scavenging System Market Outlook#Anesthesia Gas Scavenging System Market Analysis#Anesthesia Gas Scavenging System Market Forecast#Anesthesia Gas Scavenging System#Anesthesia gas#Closed scavenging systems#healthcare facilities

0 notes

Text

Commercial methane gas analyzer

If you are finding a Commercial Methane Gas Analyzer that delivers high accuracy and reliability, ESEGAS offers advanced solutions for industrial and environmental applications. Our analyzers ensure precise methane detection, compliance, and safety. Trust ESEGAS for cutting-edge gas monitoring technology tailored to your needs.

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

The European Union’s greenhouse gas emissions fell 8.3% in 2023 as a surge in renewable energy installations helped displace coal.

This means the bloc’s emissions have declined 37% since 1990, while its economy has grown 68% over the same period.

The divergence indicates “the continued decoupling of emissions and economic growth,” the European Commission said in an update, adding that the region is on track to reach its target of reducing emissions by at least 55% by 2030.

According to an analysis by the European Environment Agency, based only on existing climate measures and planned actions, the EU will reduce its emissions by 49% by 2030.

Electricity and heating lead the way

Emissions from electricity production and heating under the region’s emissions trading system (ETS) dropped 24% in 2023, compared to the previous year, per the Commission.

Set up in 2005, the ETS is widely viewed as a key driver of the bloc’s decarbonisation. In 2023, it generated revenues of €43.6 billion in 2023 for climate action investments.

However, some sectors are still moving in the wrong direction. For instance, aviation emissions grew 9.5% last year as the sector continued to rebound in the wake of the pandemic.

More to be done

“The EU is leading the way in the clean transition, with another year of strong greenhouse gas emission reductions in 2023,” said Wopke Hoekstra, commissioner for climate action.

“As we head off soon to COP29, we once again demonstrate to our international partners that it is possible to take climate action and invest in growing our economy at the same time,” Hoekstra added. “Sadly, the report also shows that our work must continue, at home and abroad, as we are seeing the harm that climate change is causing our citizens.”

In a separate statement, Leena Ylä-Mononen, executive director of the European Environment Agency, said climate change impacts were “accelerating”, meaning the bloc needed to become more resilient to extreme weather while also slashing emissions.

In the second quarter of 2024, renewables accounted for 52% of all electricity generated in the EU, a 6 percentage point increase in a year. Nuclear generation was up slightly and comprised 24% of the mix, meaning clean sources made up 76% of the region’s total electrical output.

-via The Progress Playbook, November 1, 2024

#europe#eu#carbon emissions#renewables#clean energy#solar power#wind power#environment#climate news#climate action#climate hope#climate change#good news#hope#european union

860 notes

·

View notes

Text

space launch services market trends, flue gas treatment systems market size, flue gas treatment systems market share, space launch services market analysis, space launch services market outlook, space launch services market overview, space launch services market growth, space launch services market segments, space launch services market insights, space launch services market, space launch services market forecast, space launch services market report

#space launch services market trends#flue gas treatment systems market size#flue gas treatment systems market share#space launch services market analysis#space launch services market outlook#space launch services market overview#space launch services market growth#space launch services market segments#space launch services market insights#space launch services market#space launch services market forecast#space launch services market report

0 notes

Text

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

In the world of engineering, precision and safety are paramount, especially when it comes to piping systems. Any miscalculation or oversight can have severe consequences, ranging from safety hazards to costly downtime. This is where Little P.Eng. Engineering steps in as a trusted partner, providing expert pipe stress analysis and support design services to ensure the structural integrity and efficiency of piping systems across various industries.

With a reputation for excellence and a commitment to delivering tailored solutions, Little P.Eng. Engineering has established itself as a go-to engineering consultant for those seeking to optimize their piping systems.

Expertise in Pipe Stress Analysis

At the core of Little P.Eng.'s services is their expertise in pipe stress analysis. This crucial engineering discipline involves assessing the forces, stresses, and displacements acting on piping systems to ensure they operate safely and efficiently. Whether it's static stress analysis, dynamic stress analysis, thermal analysis, or seismic analysis, Little P.Eng. Engineering has a team of highly skilled engineers who are well-versed in these complex assessments.

Static stress analysis, for example, is employed to evaluate the stresses in stationary piping systems, ensuring they can withstand the pressures and loads they are subjected to during normal operation. Dynamic stress analysis, on the other hand, deals with transient conditions such as startup, shutdown, and water hammer, which can place additional stress on the system.

Ensuring Compliance with Standards

One of the hallmarks of Little P.Eng.'s services is their unwavering commitment to compliance with industry standards and codes. Piping systems must adhere to strict safety and regulatory guidelines, and Little P.Eng. Engineering ensures that all their analyses and designs meet or exceed these standards. Whether it's ASME, ANSI, API, ASTM, or local building codes, clients can trust that their projects are in full compliance.

Customized Solutions for Unique Needs

No two piping systems are identical, and Little P.Eng. Engineering understands this well. They excel in providing customized solutions that align with the specific needs and challenges of each project. Whether it's an oil refinery, a pharmaceutical facility, or a power plant, Little P.Eng.'s team tailors their services to ensure optimal results.

Support Design Expertise

In addition to pipe stress analysis, Little P.Eng. Engineering offers support design services that play a critical role in the stability and longevity of piping systems. Proper support design involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibrations, and stress.

Little P.Eng. Engineering's support design services encompass a range of aspects, including pipe support design, structural analysis, material selection, and installation guidance. These services are crucial in preventing issues like excessive stress, vibrations, misalignment, and premature wear in piping systems.

Commitment to Safety and Quality

Safety is Little P.Eng.'s top priority. Their pipe stress analysis and support design services are driven by a deep commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

Quality assurance is woven into the fabric of Little P.Eng.'s services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process. This approach fosters trust and transparency, key elements in successful engineering projects.

Timely and Efficient Service

In the world of engineering, time is often of the essence. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality. This ensures that clients can rely on them to meet their project deadlines and objectives.

Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members. This dedication to staying at the forefront of technological advancements allows them to provide cutting-edge solutions to their clients.

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

A Pipe Stress Analysis and Support Design engineering consultant offers a range of services to ensure the structural integrity, safety, and efficiency of piping systems in various industries. These services may include:

1. Pipe Stress Analysis:

Static Stress Analysis: Evaluating stresses, forces, and displacements in stationary piping systems.

Dynamic Stress Analysis: Assessing the effects of transient conditions, such as startup, shutdown, and water hammer.

Thermal Stress Analysis: Analyzing the impact of temperature variations on piping materials and components.

Seismic Analysis: Evaluating the response of piping systems to seismic forces and designing for earthquake resistance.

Fatigue Analysis: Predicting the fatigue life of components subjected to cyclic loading.

2. Support Design Services:

Pipe Support Design: Designing supports, hangers, and restraints to prevent excessive movement and stress in piping systems.

Structural Analysis: Evaluating the structural integrity of support structures and ensuring compliance with safety codes.

Material Selection: Recommending suitable materials for support components based on factors like load-bearing capacity and corrosion resistance.

Installation Guidance: Providing recommendations and specifications for the proper installation of supports.

3. Compliance with Standards and Codes:

Ensuring that all designs and analyses meet relevant industry standards, codes, and regulations, such as ASME, ANSI, API, ASTM, and local building codes.

Assisting clients in obtaining necessary permits and approvals for piping system installations or modifications.

4. Customized Solutions:

Tailoring pipe stress analysis and support design services to the specific needs and requirements of each project.

Developing unique solutions for complex or challenging piping system configurations.

5. Failure Analysis and Troubleshooting:

Investigating and diagnosing issues related to piping system failures, leaks, or performance problems.

Recommending corrective actions and retrofits to address identified problems.

6. Hygienic Piping Design (in industries like pharmaceuticals and food production):

Designing piping systems that comply with stringent sanitary and hygiene standards to prevent contamination.

Implementing design solutions that minimize dead legs, reduce the risk of bacterial growth, and facilitate cleaning and sterilization.

7. Stress Testing and Simulation:

Conducting computer simulations and modeling to predict stress and strain behavior under different operating conditions.

Performing load testing to validate the performance of pipe supports and restraints.

8. Energy Efficiency Optimization:

Identifying opportunities to improve energy efficiency by optimizing piping system configurations and insulation.

Recommending modifications to reduce heat loss or improve heat transfer.

9. Retrofit and Upgrade Design:

Developing plans and designs for the retrofit or upgrade of existing piping systems to meet current safety and performance standards.

Incorporating advanced technologies and materials for improved reliability and efficiency.

10. Documentation and Reporting:

Generating comprehensive reports, including stress analysis reports, design drawings, specifications, and installation instructions.

Maintaining accurate records of all analyses, designs, and project documentation.

11. Consulting and Expert Witness Services:

Providing expert consulting services for legal matters, including expert witness testimony in cases involving piping system failures or disputes.

12. Project Management and Coordination:

Overseeing and coordinating the implementation of recommended design changes or support installations to ensure proper execution.

Pipe Stress Analysis and Support Design engineering consultants play a crucial role in ensuring the safe and efficient operation of piping systems across various industries, and their services are vital for preventing failures, reducing downtime, and maintaining regulatory compliance.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Little P.Eng.

ASME standards

Engineering expertise

Thermal expansion

Structural integrity

Regulatory compliance

Pipe stress analysis

Documentation

Industrial processes

Engineering consultant

Advanced software

Pressure changes

API standards

Maintenance costs

Optimization

ISO standards

Seismic events

Oil and gas industry

Custom support systems

Inspection readiness

Load-bearing capacities

Compliance standards

Piping systems

Power generation

Fluid dynamics

Petrochemical industry

Support design engineering

Troubleshooting

Temperature fluctuations

Safety analysis

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#ASME standards#Engineering expertise#Thermal expansion#Structural integrity#Regulatory compliance#Pipe stress analysis#Documentation#Industrial processes#Engineering consultant#Advanced software#Pressure changes#API standards#Maintenance costs#Optimization#ISO standards#Seismic events#Oil and gas industry#Custom support systems#Inspection readiness#Load-bearing capacities#Compliance standards#Piping systems#Power generation#Fluid dynamics#Petrochemical industry#Support design engineering#Troubleshooting#Temperature fluctuations

0 notes

Text

An Analysis of the Concept of 'The Grey' in Arcane.

Also, I forgot to mention, but here's another confirmation that Jayce knew about The Grey, as he completely redesigned the mask.

The versions on the left were the last ones before Jayce, specifically designed for the concentrated gas. These still had a pipe outlet and an oxygen tank. In the version designed by Jayce, there was new technology that helped see through the dense Grey via lenses, and it directly filtered the air, eliminating the need for pipes and extra oxygen tanks.

This mask is closer to the one used by the enforcers, with the distinction that the lenses in Jayce's version are even more advanced, not only protecting the eyes but, as I mentioned, offering better vision. (This feature is visibly switchable on and off in ep 2 of s 2.)

Also here's one more thing about the grey:

It disperses quickly, even within a closed office, when it comes into contact with the air. The Grey back then was only present in Zaun because: 1. There was no ventilation system. 2. Since the factories were still in operation, they continued producing the Grey non-stop. Later, these factories were closed, and the Chem-Barons began using it for different products. The only remaining places where the Grey was still present were the closed pipe system and the fissures in the mines where it got trapped. Also, when the Grey was present in Zaun and the ventilation system was running at the same time, what do you think they did with the Grey? They let air flow from Piltover to Zaun, so that the Grey would dissolve as quickly as possible.

The Grey is a fictional gas in a CREATED show where the laws of physics work differently than in our world. Just like magic (Arcane), the Grey cannot be compared to the laws of our universe.

....

False, one-page or one-sentence ragebait posts always spread faster than detailed content, even though, to get an accurate picture,

it's important to examine the details, not just take something out of context without meaning.

If you're interested, you can find more in-depth analyses on my profiley such as why it was Heimerdinger, whose 200 years of neglect and inaction created the entire conflict between Zaun and Piltover.

(or there is the youtube link: https://youtu.be/y7Y__xyDyG8?si=Td3EuTLMMdcFkTko)

Thank you for reading it!

469 notes

·

View notes