#oil filtration machine

Explore tagged Tumblr posts

Text

Restore Transformer Oil Quality with Transformer Oil Reclamation Units

Maintaining the health of transformer oil is crucial for the effective performance of transformers. Transformer Oil Reclamation Units by AR Engineering provide a reliable solution to reclaim and purify transformer oils, extending their lifespan and improving the overall performance of electrical transformers.

As India's most trusted brand in oil filtration machines, AR Engineering offers state-of-the-art transformer oil reclamation units that efficiently remove impurities such as water, gases, and particulate matter from used transformer oil. By reclaiming and purifying oil, these systems ensure your transformers perform optimally and have a longer operational life.

Key Features of Transformer Oil Reclamation Units

🔧 Efficient Filtration: Removes dirt, water, and other contaminants from transformer oils 🔧 Improved Oil Performance: Restores the quality of transformer oil for better performance 🔧 Cost-Effective Solution: Reclaims used oil, reducing the need for frequent oil replacement 🔧 Versatile Applications: Works with turbine oils, gear oils, and other industrial oils 🔧 Easy Integration: Can be easily integrated with oil filtration plants, mobile oil filtration systems, and portable oil filtration systems

Our transformer oil filtration systems are designed to remove harmful contaminants from transformer oil and restore it to its original condition, ensuring improved electrical insulation and cooling properties. Whether it's a double-stage oil transformer machine or a two-stage transformer oil filtration plant, AR Engineering provides top-notch equipment that guarantees long-lasting, high-performance results.

For a reliable solution to oil purification and reclamation, look no further than AR Engineering's transformer oil reclamation units. Learn more about how our innovative machines can restore your transformer oil's quality: https://oilfiltermachineindia.com/transformer-oil-reclamation-units.html

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

Contact AR Engineering: Leading Transformer Oil Filtration & Impregnation System Manufacturers

Looking for advanced transformer oil filtration solutions? At AR Engineering, we specialize in manufacturing high-quality high-vacuum transformer oil filtration plants, industrial oil purification systems, and trickle impregnation machines. With our expertise in batch-type trickle impregnating machines, vacuum pressure impregnation plants, and index-type impregnating machines, we offer industry-leading systems that enhance transformer performance and oil quality. Reach out today for inquiries or quotes. Our team is ready to assist with your transformer oil filtration and impregnation needs.

Contact us at: Phone: +91 7758877486

#transformer oil filtration manufacturer#High-Vacuum Transformer Oil Filtration Plants manufacturer#high Vacuum transformer oil dehydration plant manufacturer#Trickle Impregnating Machines manufacturer#Batch Type Trickle Impregnating Machine manufacturer#Index type impregnating machine manufacturer#Vacuum pressure impregnation plants manufacturer#trickle impregnation technique#Industrial Oil purification Systems manufacturer

0 notes

Text

Enhancing Oil Quality with Industrial Oil Purification Systems

Efficient oil purification is critical to ensuring the longevity and performance of industrial machinery. At Conserve Your Oil, we provide cutting-edge Industrial Oil Purification Systems designed to meet the stringent demands of modern industries. Recognized as one of the leading Industrial Oil Purification System manufacturers and suppliers in India, we offer solutions that prioritize efficiency, reliability, and cost-effectiveness.

What is an Industrial Oil Purification System?

An Industrial Oil Purification System is an advanced technology designed to remove contaminants such as water, gases, and solid particles from industrial oils. These systems are essential for maintaining the quality of oils used in various machinery, ensuring operational efficiency and extending equipment lifespan.

Why Choose Our Industrial Oil Purification Systems?

As a trusted manufacturer and supplier in Pune and across India, we deliver high-performance oil purification systems that offer:

Enhanced Productivity: Clean oil reduces wear and tear, leading to improved machinery efficiency.

Cost Savings: Prolonged oil life reduces the need for frequent replacements.

Environmental Benefits: Minimized waste and sustainable oil usage.

Our Expertise in Oil Filtration Solutions

We specialize in a range of oil purification technologies, including:

Industrial Oil Filtration Plants: Comprehensive systems for large-scale industrial operations.

Oil Filter Machines: Compact and efficient devices for precise filtration.

Oil Filtration Machines: Versatile solutions tailored to various applications.

Oil Filtration Plants: Advanced setups for high-volume filtration needs.

Leading Manufacturer, Supplier, and Exporter

At Conserve Your Oil, we are proud to serve as a leading:

Industrial Oil Purification Systems Manufacturer in Pune and India

Industrial Oil Purification Systems Suppliers in Pune and across India

Exporter of Industrial Oil Purification Systems in Pune and globally

Our systems are engineered to meet international standards, making us a preferred choice for clients worldwide.

Applications of Industrial Oil Purification Systems

Our systems cater to diverse industries, ensuring seamless integration into existing operations:

Power Plants: Maintain the quality of turbine oils for uninterrupted performance.

Automotive Industry: Ensure the efficiency of hydraulic oils and lubricants.

Manufacturing Units: Prolong the life of machinery with clean and purified oil.

Innovative Features of Our Systems

High Efficiency: Removes contaminants with precision.

Robust Construction: Built for demanding industrial environments.

Customizable Solutions: Tailored designs to meet specific requirements.

Easy Maintenance: Simplified operations for hassle-free upkeep.

Trusted for Quality and Innovation

We take pride in our reputation as a leading provider of Industrial Oil Purification Systems in Pune, India, and internationally. Our commitment to innovation and quality has made us the go-to choice for businesses looking to enhance their operational capabilities.

Why Conserve Your Oil?

Experience and Expertise: Years of delivering reliable oil purification solutions.

Comprehensive Product Range: From oil filter machines to industrial oil filtration plants.

Global Reach: Recognized as a trusted exporter of Industrial Oil Purification Systems.

Customer-Centric Approach: Solutions tailored to your unique needs.

#Industrial Oil Purification System Manufacturers#Industrial Oil Purification System Suppliers in India#industrial oil filtration plant#Industrial Oil Purification Systems manufacturer in pune#Industrial Oil Purification Systems suppliers in pune#Industrial Oil Purification Systems exporter in pune#Industrial Oil Purification Systems manufacturer in india#Industrial Oil Purification Systems exporter in india#Industrial oil filtration machines#Industrial oil filtration plant#Oil filter machines#Oil filteration plants#Oil filtration machines

0 notes

Text

Vacuum Oil Filter Machine Manufacturers

Sumesh Petroleum is a leading high-quality Vacuum Oil Filter Machine Manufacturers. Our machines effectively remove impurities and contaminants from oil, extending its lifespan and improving equipment performance. With advanced technology and robust construction, our products are trusted by industries worldwide. Experience the Sumesh Petroleum difference in oil filtration.

0 notes

Text

Transformer oil, the insulating and cooling fluid within your transformers, needs periodic cleaning to maintain its effectiveness. Transformer oil purifiers are your workhorses for this task, removing contaminants that compromise oil quality and transformer performance. But when choosing a purifier, a key decision pops up: single stage or double stage?

0 notes

Text

Top Quality Transformer Oil Filtration Machine

Transformer Oil Filtration Machines are what Rayon Energy specializes in producing and supplying. The company sells a variety of filtration equipment, such as caster wheel, vehicle, and trolley-mounted models. The purpose of the equipment is to increase the operating lifespan of transformers by filtering transformer oil. An ionic reaction column, flow meter, BDV test kit, and inline PPM meter are all included with Rayon Energy's filtering equipment. A completely automatic PLC control panel is another option for the machines. Among the nations that Rayon Energy serves are businesses in South Africa, Cameroon, Nigeria, and other African and Asian nations. Address: KHASRA NO. 1318,Morta Industrial Area,Near Hotel Vivaan Meerut Road, Morta, GHAZIABAD - 201003 U.P

0 notes

Text

Unlike traditional single-stage purifiers, the ZJA Double Stage Transformer Oil Filtration Machine is a two-stage system. This translates to an intensified purification process, tackling contaminants with exceptional finesse. Here's how it works:

Stage 1: Roughing the Seas: The initial stage employs a primary filter and a high-flow vacuum pump. This duo works in tandem to swiftly remove larger particles and water vapor, laying the groundwork for deeper purification.

Stage 2: Deep Dive into Purity: The second stage deploys a multi-pronged attack. Precision filters eliminate even the tiniest impurities, while a high-vacuum dehydration system meticulously extracts residual moisture. Additionally, degassing technology whisks away dissolved gases, leaving the oil pristine and ready for action.

0 notes

Text

Rayon India is your one-stop destination for fulfilling all your needs related to Transformer Oil Filtration Machines. With a strong focus on reliability and trustworthiness, we provide machines that ensure efficient and effective filtration of transformer oil. Our commitment to quality and customer satisfaction has made us a trusted name in the industry. Trust Rayon India for all your transformer oil filtration requirements and experience exceptional performance.

0 notes

Text

Microscopic Cooking Oil Filter Machine

Micro Filter King is easy to use & clean. Patent pending technology that removes saturated fat & everything from breadcrumbs to flour by

polishing & extending the life of your cooking oil, giving you the best quality fried food 7 days a week. USA made and parts. Our double

filtration system filters down to a microscopic level catching particles as small as 10 microns, polishing the oil and making it new again.

The cooking oil passes through 2 unique filter systems which force and seal every drop through a microscopic filter process before

returning to the fryer. We call this process the, “Double forced & sealed filtration process” which is the science behind our technology

making it vastly different than many other machines in today’s market.

#Microscopic Cooking Oil Filter Machine#commercial cooking oil filter machine#commercial fryer oil filter machine#cooking oil filter machine for sale#Fryer oil filtration machines.

0 notes

Text

Oil filter press machine uses, types, sizes and process with all details

Oil filter press machine is a commonly used machine in oil production processes, especially in the production of edible oils. It is designed to remove impurities and solid particles from crude oil to produce a high-quality oil. The process of oil filtration typically involves several steps, including the following: Pre-treatment: In this step, the crude oil is cleaned and sorted to remove any…

View On WordPress

0 notes

Text

Enhance Oil Quality with Laser Particle Counters

Maintaining clean oil is vital to ensuring the smooth operation of machinery and extending its lifespan. Laser Particle Counters from AR Engineering are the perfect solution for real-time monitoring of oil cleanliness. These advanced devices are designed to measure particles in oils, such as turbine oils, transformer oils, gear oils, and more, helping industries maintain oil purity and reduce wear and tear on machinery.

AR Engineering is India's most trusted brand in oil filtration machines, offering high-quality laser particle counters for precise oil testing. These counters use laser technology to detect particles in the oil, providing an accurate count of contaminants in real time. With this data, industries can take proactive measures to maintain the health of their systems.

Key Benefits of Laser Particle Counters

✅ High-precision particle detection in turbine oil cleaning systems ✅ Continuous real-time monitoring of oil quality ✅ Easy integration with oil filtration machines, including mobile oil filtration plants and portable oil filtration systems ✅ Ideal for oil filtration systems and oil cleaning machines to maintain operational efficiency ✅ Reduces equipment downtime by detecting contamination early

Laser particle counters are critical tools for industries that rely on clean oil to power their machinery. Whether used in industrial oil filtration systems, transformer oil filtration plants, or gear oil filtration systems, these counters help you ensure optimal performance, reducing the risk of failure due to oil contamination.

At AR Engineering, we specialize in providing innovative and reliable solutions, such as laser particle counters, that make oil filtration and cleaning more effective. By incorporating these counters into your operations, you ensure your machinery remains protected, efficient, and long-lasting.

👉 Learn more: https://oilfiltermachineindia.com/laser-particle-counters.html

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

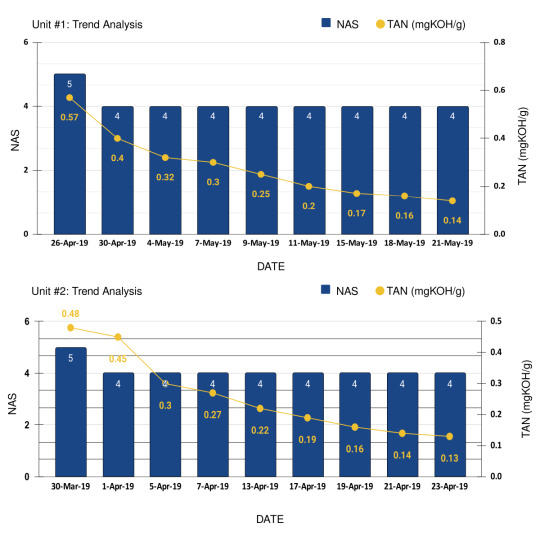

PE fluid reconditioning in turbine EHC system

A 1,320 MW (2 x 660 MW), one of the first and largest supercritical coal-fired power plants using Indo-Chinese turbine EHC system in northern India

Synopsis

The plant was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine. Moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system resulting in by-product formation.

Problems

Degradation of EH oil properties at both the units of the plant.

The installed regeneration system for each EHGC tank of unit #1 and #2 was failing to control neutralization number (TAN value) and showing a rapid increase in the same

The company was unaware of the consequences of increased TAN values like possibilities of failure of servo valve, hunting, power generation loss, unplanned shutdown, etc

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

Remove solid contamination from oil by Superfine filtration

Remove moisture from oil by vacuum Dehydration technology

Reduce Total Acid Number (TAN) by Ion exchange technique.

EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer trained the customer’s team on the functions of the EH oil re-conditioner, FRF maintenance, contamination control, and importance of the oil analysis program.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹78 Lakh approx.

Cost of downtime: ₹5.6 Cr approx

CO2 e Saving

14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e.

Benefits

Extending oil life.

Eliminate oil Replacement cost.

Protect Turbine against hunting.

Increased Turbine reliability.

Subscribe to our Whats App Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#coalescer separator#oil dehydration systems#lvdh full form#mlc lvdh#transformer oil filtration#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#oil filtration#oil filtration system#oil filteration#oil filtration machine#oil filtration systems#oil contamination#frf condition systems#diesel oil purification#hydraulic oil cleaning#chemical cleaning

0 notes

Text

Trusted Transformer Oil Filtration and Impregnation Solutions – AR Engineering Clients Worldwide

AR Engineering: Partnering with Industry Leaders for Reliable Transformer Oil Filtration and Impregnation Solutions

At AR Engineering, we take immense pride in being a trusted name in the manufacturing and supply of transformer oil filtration systems, impregnation machines, and industrial oil purification systems. With decades of experience, we have built a reputation for delivering high-quality, durable, and efficient solutions that cater to a diverse range of industries.

Our success is reflected in the trust and loyalty of our esteemed clients worldwide. From small-scale businesses to large corporations, AR Engineering has been a partner in ensuring efficiency, reliability, and sustainability.

Our Expertise: Comprehensive Solutions for Industrial Needs

1. Transformer Oil Filtration Systems

We are a leading manufacturer of transformer oil filtration systems, including:

High-Vacuum Transformer Oil Filtration Plants: Designed to remove moisture, gases, and solid impurities from transformer oil.

High Vacuum Transformer Oil Dehydration Plants: Ensures the optimal performance of transformers by enhancing oil quality.

2. Advanced Impregnation Machines

Our impregnation machines are known for their precision and reliability, including:

Trickle Impregnating Machines

Batch Type Trickle Impregnating Machines

Index Type Impregnating Machines

These systems ensure superior insulation for components, enhancing their durability and performance.

3. Vacuum Pressure Impregnation Plants

Our Vacuum Pressure Impregnation (VPI) Plants are engineered to deliver high-quality insulation through a vacuum and pressure process, ensuring consistent results across applications.

4. Industrial Oil Purification Systems

As a manufacturer of industrial oil purification systems, we help industries maintain clean oil to improve machinery efficiency, reduce maintenance costs, and extend the lifespan of their equipment.

A Global Client Network

Our products and solutions have earned the trust of clients across the globe. Businesses in India, Saudi Arabia, Jordan, Qatar, Iraq, Nepal, Bangladesh, Zambia, Ecuador, Egypt, and Turkey rely on AR Engineering for their industrial needs.

Why Choose AR Engineering?

Proven Track Record Our long-standing relationships with clients testify to the reliability and effectiveness of our solutions.

Innovative Technology We leverage advanced technology to deliver high-performance systems tailored to client requirements.

Commitment to Quality Our products are manufactured to meet stringent quality standards, ensuring long-term value.

Comprehensive Support From consultation to after-sales service, we ensure our clients receive unmatched support at every step.

Industries We Serve

Our solutions cater to a wide array of industries, including:

Power Generation and Distribution

Manufacturing Units

Automotive Sector

Electrical and Electronic Components Industry

Whether you need a transformer oil filtration plant or an advanced impregnation machine, AR Engineering has you covered.

Join Our Growing Network of Satisfied Clients

We invite you to be a part of our extensive network of clients who trust AR Engineering for their industrial needs. Visit transformeroilfiltermachines.com to learn more about our clients and explore our range of solutions.

Our team is committed to providing customized solutions to meet your specific requirements. Let us help you optimize your operations with our reliable products and expertise.

Contact Us Today

Ready to enhance your industrial processes with cutting-edge oil filtration and impregnation systems? Connect with us today and experience the AR Engineering difference.

#transformer oil filtration manufacturer#High-Vacuum Transformer Oil Filtration Plants manufacturer#high Vacuum transformer oil dehydration plant manufacturer#Trickle Impregnating Machines manufacturer#Batch Type Trickle Impregnating Machine manufacturer#Index type impregnating machine manufacturer#Vacuum pressure impregnation plants manufacturer#trickle impregnation technique#Industrial Oil purification Systems manufacturer

0 notes

Text

Keep Your Hydraulics Running Smoothly with Sumesh Petroleum

Ensure optimal performance and extend the life of your hydraulic systems with top-notch filtration machines from Sumesh Petroleum. We offer a comprehensive range of machines designed to remove contaminants, improve oil quality, and minimize downtime. Contact us today to discuss your specific needs and discover how Sumesh Petroleum can keep your hydraulics running smoothly. If you are interested then tap on the link hydraulic oil filtration machine manufacturers.

#Online Transformer Oil Filtration System Manufacturers#hydraulic oil filtration machine manufacturers

0 notes

Note

nexus x v1 eclipse *runs away*

GOD.

The best thing about this is that they are both so similar that they could easily either understand each other and be an incredible duo (couple) or understand each other so well that it makes them hate each other LMAO

Ok but Nexus bringing back Eclipse V1 (since he couldn't bring Solar back, he can bring another Eclipse) to maybe also use him as a distraction for the family but V1 is not easy to handle and Nexus is underestimating it.

Of course Nexus has his NSP and can make V1 do whatever he wants but the idea that V1 never really leaves Nexus' lab and they just spend their time talking or in silence while working it's so good too XD

V1 would instantly have some plan to get something he needs and then betray Nexus (if we go the toxic yaoi route) 😩💥 maybe some Dark Star Power encapsulated or in a filtration machine for safe use. Stealing all the NSP until Nexus is nothing but a shell of what it used to be hehe !

BUT SEE, ALSO, IF WE GO THE LOVE ROUTE. Eclipse V1 talking to Nexus about feelings is almost as impossible as watching Lunar take a shower but I love the idea that neither of them have a problem just being silent together. And sometimes, when they fight, they both show moments of vulnerability that trigger longer and deeper conversations. And maybe they both look at each other and think "you're just like me"

V1 looking at Nexus, thinking how the family allowed something like this to happen a second time, makes his oil boil. How could they push a person to the point where the person ended up destroying himself? Being a grotesque version of what it used to be? It's frustrating, it makes him angry, and as much as he likes to pretend that he doesn't care or that Nexus deserves it for being so permissive and accommodating, he knows that's not the case.

They also kiss in a way that Dark Sun says looks like they are going to eat each other LMAO

#sorry i ended up rambling!#have a good day anon!#tsams#polaris stuffs#the sun and moon show#sun and moon show#non art post#tysm for the ask!#tsams nexus#tsams eclipse#sams nexus#sams eclipse#eclipse v1#sams#polar opinions#also if this was a fanchild request#pls let me know

36 notes

·

View notes