#chemical cleaning

Explore tagged Tumblr posts

Text

WHAT ARE BYPASS FILTERS?

A bypass filter, also known as a pressure relief valve, is a very important part of an oil filter. When oil is too thick or the filter is clogged, the valve opens. If the valve doesn’t open then the filter may eventually burst.

Bypass filters are designed to remove fine organic and inorganic particles. It also increases the total volume of oil used. Thus, if you have contamination issues and want to extend operating equipment life, extend lube oil & service intervals, and consider adding bypass filters. We can say that Bypass filtration can be considered another aspect to save money and downtime.

Most of the existing manufacturers use ‘full-flow’ oil filters which are designed to protect the component from large particles but they cannot remove soot, water, or silt. Full-flow filters alone cannot keep oil clean for a long-term period. The fine particles which account for most of the contamination can be removed by the bypass filters.

It is advised to do the homework before buying a bypass filter. Some important factors to consider are:

1) Capture efficiency - The higher the beta ratio, the better will be the capture efficiency. A good beta ratio selection can control the escape of particles through the element. It is just like a good shepherd keeping the flock of sheep in a controlled and organized manner in the field.

2) Pressure/flow - Suitably designed filter element has calculated flow and velocity of oil through its microvoids. It is as important as keeping the water stream in a controlled way for gardening purposes. Else, it may spoil the sole purpose of watering.

3) Dirt Holding Capacity - It is not only necessary to have high capture efficiency but also a good filter element capacity is a must-have to retain the collected contamination. A well-engineered element has dedicated space to imprison the unwanted contaminants.

4) Heating element (to eliminate solid and liquid contaminants) - An elevated temperature helps to dislodge the solid contaminants and accelerates the rate of removal of volatile impurities.

5) Type of filtration media - Filter media varies with grade and type of oil widely. This may be a fine filter paper to absolute and depth filter media.

For more such interesting Articles and Case Studies: Click Here

6) Compatibility of fluid - Not every filter element can be used with any grade of oil. A small mistake in element selection can destroy the element as well as may cause a collapse of the entire system.

7) Surface area for the filtration – The higher surface area will give a lower pressure drop across the filter and also helps to achieve higher flow rates.

8) Compact in size - Reduction of size in regards to the filter elements and housing gives us multiple benefits like space and cost-saving, aesthetic look, better maintainability, low recurring expenditure, etc.

9) Inexpensive to use and install - At the end of every engineering and calculation, economics comes into the picture. It is always suggested to go with optimized design and correct sizing to overcome financial constraints.

We don’t need any additional setup to establish a Bypass filtration system; it can be done within the existing skilled limits. Please note that a bypass filtration system can be of great benefit if installed and maintained appropriately and it helps to prevent post-filtration fugitive contamination ingress into the system.

We will be happy to help you in the entire journey of the right filter selection. Contact - [email protected] or WhatsApp us at +91 7030901267.

#minimac#minimacsystems#filter#filter skid#filter replacement#contact minimac#Lube Oil Filter#hydraulic oil#oil cleaning machine#Lube oil cleaning#hydraulic oil cleaning#FRF#oil flushing#transformer oil cleaning#oil condition monitoring#Fluid Power Equipment#electrostatics lube cleaner#coalser separator#Diesel purification systems#chemical cleaning#technology#varnish removal#oil contamination

2 notes

·

View notes

Text

Industrial Tank Cleaning: Ensuring Equipment Operates at Peak Performance

Regulatory Compliance is Key Proper cleaning, maintenance and inspection of industrial tanks and vessels is crucial to maintaining regulatory compliance. Tanks used for manufacturing, food processing, chemical storage and other industrial purposes often contain hazardous materials that must be handled according to strict environmental, health and safety standards. Regulators conduct periodic inspections and companies can face fines or shut downs for noncompliance issues related to contaminated or unsafely maintained tanks. Regular professional tank cleaning helps verify tanks meet all regulatory requirements for safe usage and material storage.

Cleaning Methods Vary by Tank Type and Contents The optimal cleaning method depends on the size and design of the tank as well as the material that was previously contained. For food-grade or potable water tanks, cleaning usually involves a multi-step process of draining residues, rinsing with water, scrubbing internal surfaces, then issuing a final rinse and inspection. Industrial Tank Cleaning that held hazardous chemicals may require specialized cleaning chemicals or equipment like pressure washers depending on the toxicity and properties of the residues. Storage tanks for crude oil, gasoline and other petroleum products usually undergo washing, detergent cleaning and rinsing to remove sludge and potential contaminants. Proper cleaning verification like surface inspections and testing is critical to ensure all traces of the prior contents are completely eliminated.

Safety is Paramount During Tank Cleaning Due to working at heights inside large vessels and potential exposure to toxic materials, safety should always be the top priority during Industrial Tank Cleaning. Cleaning crews use personal protective equipment suitable for the job like chemical resistant gloves, boots, and splash guards or full body suits as needed. Special precautions like gas detectors, ventilating equipment and following confined space entry procedures help protect workers from harmful fumes, oxygen deficiency and other hazards. Signs and barricades around the work area keep other personnel safely away. Properly documented lock out/tag out of Tank systems ensures they cannot be accidentally activated during cleaning. Adhering to stringent safety protocols helps cleaning professionals safely do their important work protecting human health and the environment.

Inspection andCertification Provides Quality Assurance A key part of the cleaning process involves conducting detailed inspections of tank internal surfaces and accessible hard to reach areas once cleaning is complete. Inspectors look for any residues, debris, corrosion or other problems that could impact structural integrity or introduce potential contamination issues if left unaddressed. Any necessary repairs are made at this stage as well. Finally, tanks are re-certified as clean by issuing certificates verifying they meet regulatory and customer specifications for intended service. This quality assurance step gives owners and operators confidence equipment is refreshed and compliant for its next assignment. It also documents due diligence undertaken to maintain regulatory compliance and reduce liability risks.

Preventative Maintenance Extends Tank Life Routine cleaning coupled with preventative maintenance helps industrial tanks and vessels last for decades with minimal downtime. Activities like surface blasting or passing magnetic field devices inside tanks find and remediate hidden corrosion problems before they worsen. Mechanical components like valves, hatches and gauges receive scheduled overhaul to replace worn parts. External painting shields tanks from environmental degradation. Cleaning professionals can also install cathodic protection systems that use benign sacrificial anodes to prevent corrosion damage to buried tanks over the long run. Regular maintenance and proactive repairs allow tanks to resist deterioration and meet design lifetime expectations with lower life cycle costs than deferred or reactive maintenance approaches.

Return on Cleaning Investment is Clear While tank cleaning requires upfront spending, the returns are clear in supporting smooth manufacturing or distribution operations. Downtime from contamination incidents or failures during critical processing is expensive, so preventative cleaning pays dividends. Ensuring storage tanks properly retain materials with no leakage minimizes waste and spill risks that incur high remediation costs. Compliance with regulations avoids potentially massive penalties. Extending asset lifespan through proper maintenance translates to fewer expensive replacement costs down the road. Overall the benefits of industrial tank cleaning in supporting equipment reliability, production continuity, regulatory compliance, safety, and cost avoidance far outweigh the expenditures needed to complete necessary cleaning and inspection services.

In summary, thorough regular industrial tank cleaning coupled with ongoing compliance-focused inspection and maintenance is imperative for facilities that rely on storage vessels and tanks for manufacturing and distribution operations. Protecting workers, the community and the environment while maximizing equipment performance necessitates proactive strategies to remove residues, discover corrosion issues, verify tanks meet standards, and prevent future problems before they impact production or safety. Outsourcing cleaning to experts brings quality assurance and ensures this critical work supports operational continuity, compliance and reduced total cost of ownership over the long run. Get More Insights On, Industrial Tank Cleaning For More Insights Discover the Report In language that Resonates with you

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author: Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/

#Industrial Tank Cleaning#Tank Cleaning#Industrial Maintenance#Cleaning Solutions#Environmental Safety#Chemical Cleaning

0 notes

Text

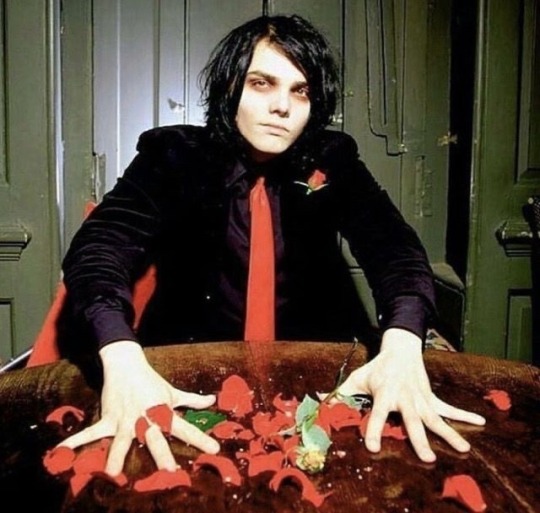

#mcr#my chemical romance#gerard way#swarm tour#myfanart#my art#just cleaning up a sketch#don't mind me#blood cw

1K notes

·

View notes

Text

wylan and the other crows

#basically how i imagine wylan spends time with the other crows#matthias is helping him reach a chemical on a high shelf hhhh#wylan van eck#wesper#six of crows#soc#this has been sitting on my ipad for WEEKS#i wanted to finish this and clean it up but i really have no time#shadow and bone s2#jesper fahey#matthias helvar#inej ghafa#kaz brekker#nina zenik#wylan van sunshine#wesper fanart#kaz and wylan#six of crows fanart#soc fanart#sab#shadow and bone#art#fanart#grishaverse#grishaverse fanart#jack wolfe#yes im still drawing them as theyre portrayed in the show sorry i just rlly like the actors

10K notes

·

View notes

Text

"Legislative momentum against PFAS has surged this year, as at least 11 states enacted laws to restrict the use of “forever chemicals” in everyday consumer products or professional firefighting foam.

The legislation includes bans on PFAS in apparel, cleaning products, cookware, and cosmetic and menstrual products. Meanwhile, lawmakers in some states also passed measures that require industries to pay for testing or cleanup; order companies to disclose the use of PFAS in their products; and mandate or encourage the development of PFAS alternatives, according to Safer States, an alliance of environmental health groups focused on toxic chemicals.

In total this year, at least 16 states adopted 22 PFAS-related measures, according to the group. Since 2007, 30 states have approved 155 PFAS policies, the vast majority of them in the past five years.

The thousands of chemicals categorized as perfluoroalkyl and polyfluoroalkyl substances, or PFAS, do not naturally break down and are found in the blood of 97% of Americans. Some PFAS compounds can harm the immune system, increase cancer risks and decrease fertility...

Earlier this year, the U.S. Environmental Protection Agency released new standards limiting PFAS in drinking water. Water systems have five years to comply with the rules. Even before the EPA action, 11 states had set their own limits on PFAS in drinking water, starting with New Jersey in 2018.

Water utilities and chemical manufacturers are challenging the new EPA standards. But states also are heading to the courthouse: So far, 30 states have sued PFAS manufacturers or key users for contaminating water supplies and other natural resources, according to Safer States...

Sarah Doll, national director of Safer States, said one reason states have been so successful in enacting PFAS limits is that more companies are willing to stop using the chemicals.

“When California restricted PFAS in textiles, all of a sudden you saw companies like REI saying, ‘We can, we’re going to do that. We’re going to move to alternatives,’” Doll said.

In Vermont, state lawmakers in April unanimously approved a measure banning the manufacture and sale of PFAS in cosmetics, menstrual products, incontinence products, artificial turf, textiles and cookware.

“The same as everyone else, like Democrats, we want to make sure that we remove PFAS and get it out of products as soon as we can,” said Vermont Republican state Rep. Michael Marcotte, who said his district includes cosmetics manufacturer Rozelle Cosmetics, in Westfield.

Democratic state Sen. Virginia Lyons, the chief sponsor of the Vermont bill, said it is particularly important to get PFAS out of products that are essential to consumers.

“There are some consumer products where you can say, ‘I don’t need to buy that, because I don’t want PFAS,’” Lyons said. “But it’s really tough to say that [about] a menstrual product.”

California’s latest PFAS measure, which Democratic Gov. Gavin Newsom signed last month, specifically bans the use of PFAS in menstrual products. Democratic Assemblymember Diane Papan, the author of the bill, said it was particularly strong because it covers both intentional and unintentional uses of PFAS, so “manufacturers will have to really be careful about what comes in their supply chain.”

While more states enact laws focused on specific products, Maine is preparing to implement the world’s first PFAS ban covering all consumer goods. The Maine law, which is scheduled to take effect in 2030, will include exceptions for “essential” products for which PFAS-free alternatives do not exist. Washington state has also taken a sweeping approach by giving regulators strict timelines to ban PFAS in many product categories.

#united states#vermont#california#washington#washington state#plastic#pfas#pfas pollution#pfas chemicals#us politics#clean water#consumer protection#new jersey#maine#good news#hope#north america

693 notes

·

View notes

Text

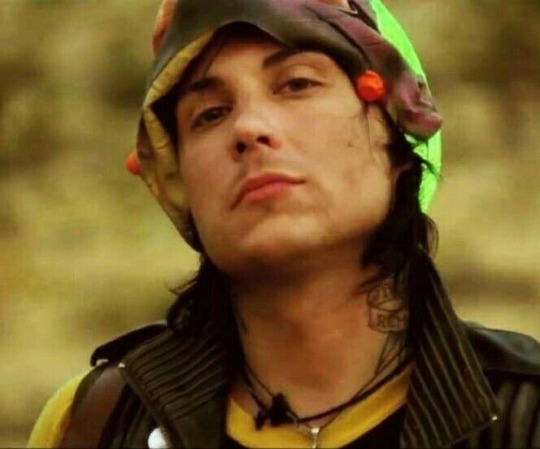

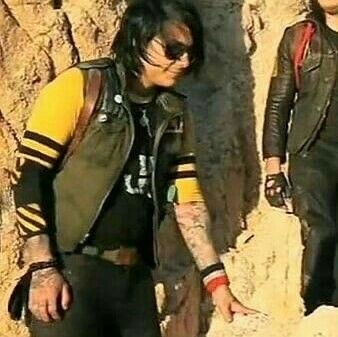

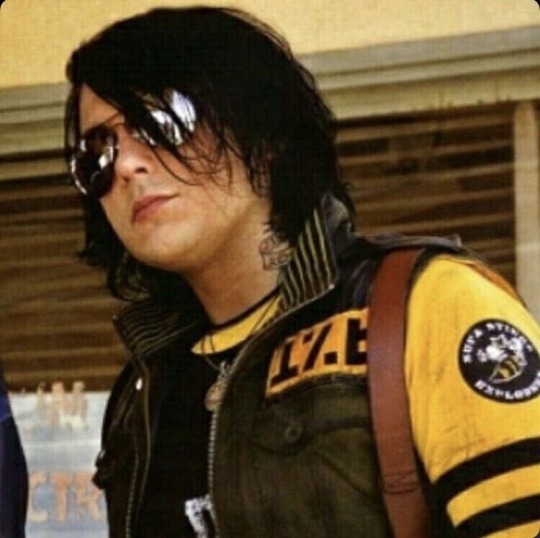

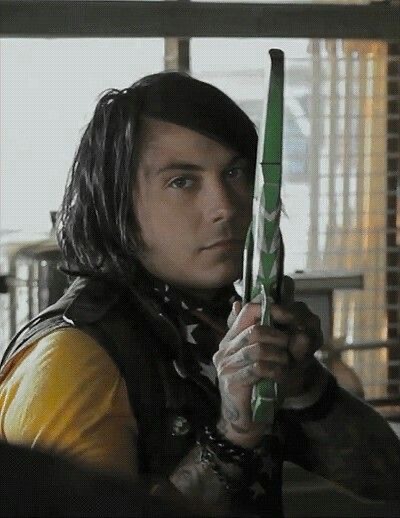

Fun Ghoul 🕷️

#I would listen to ur music but u like boys#moodboard#mcr#my chemical romance#collage#aesthetic#all pics from pinterest#emo scene#mayb1rd#clean#maybird#frank iero#dangerdays#black parade#i brought you my bullets you brought me your love#mikey way#gerard way#ray mcr#ray toro#fun ghoul#jet star#kobra kid#party poison

1K notes

·

View notes

Text

Tip for all artists: if your art starts to feel off and you are not improving it means that your eyes have evolved artistically but your hands didn't. By that I mean that you're better at analyzing but not at drawing. Don't get discouraged if you feel like everything you draw doesn't look good, eyesight evolves faster than learning how to do things properly, so it's easier to spot errors in your art before even learning how to fix them. If you learn and improve your ability will catch up with your critical eye and you'll be at a comfortable spot with your art again. I feel like i'm saying a bunch of nonsense rn but I SWEAR this is real.

#I think I inhaled a bunch of chemicals while cleaning#and now I'm having my 'inner reflection on the self' moment#chrona.. rambles abt shit

343 notes

·

View notes

Text

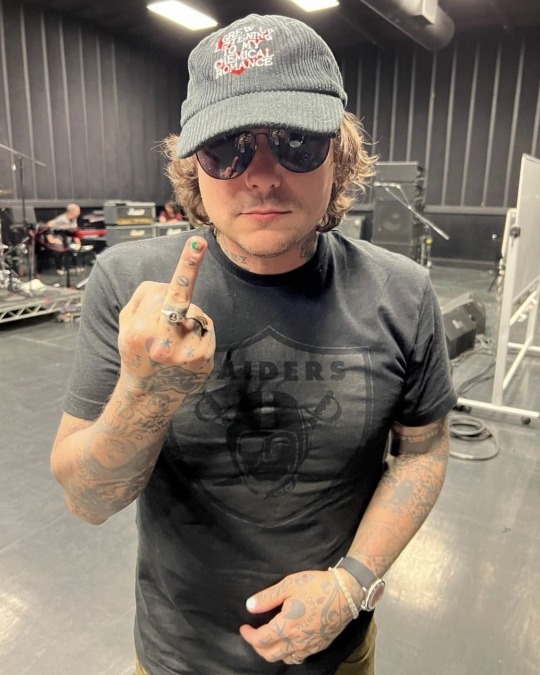

dilf frank iero please save us

#i’m gonna put my head through a wall#i can’t do this anymore#clean up isle my pants!!!#frank iero#my chemical romance#gerard way#ray toro#mikey way#mcr

517 notes

·

View notes

Text

Importance of Filter Carts and how to select the right one?

A lubricant filter cart is an important tool that can be used in many ways. From filtering all types of new and used oil to taking samples and transferring oil, filter carts are considered to be a must-have for an effective lubrication program. Oil filter carts have many benefits; they can be customized to fit any plant as per the uses and specifications. If designed, it can also give a warning if the unit needs servicing.

The uses and importance of filter carts are as follows

For cleaning the lubricants stored

For transferring the filtered oil to a machine or containers

For reconditioning of oil (currently in use)

For flushing (power, line, wand, etc.)

For contamination control functions (hose cleaning)

For meeting cleanliness standards

Subscribe to our Website Blog for more insightful Articles and Case Studies: Click Here

How to select the right filter cart?

If you don’t want your money to get wasted, select the right filter cart considering the below check-points:

Check the type of oil before buying a filter cart because carts are designed as per the viscosity levels. If a plant uses different types of oil then multiple filter carts are to be used.

Choose a filter cart that can be carried easily to the place of its application. Here, you have to consider the source of power as well.

Knowing your oil cleanliness target is very important before you buy filter carts. Don’t depend on the ISO standards entirely to evaluate used oil. Considering the specification of the type of oil is vital. We know that when viscosity increases, the cleanliness level decreases.

Check the oil flow rate. Powerful carts will cost you more, so it’s very important to know the filter’s flow rate before buying.

Customization of filter cart can be done, check before you buy if it matches your requirements or not. For example, the installation of bypass valves, dual filters, etc.

It is always better to take a second opinion than to stick with a single thought. It’s advisable to have a discussion with your filter distributor or manufacturer to find the best option. Remember that the filter cart must be chosen carefully and effectively to meet the cleanliness goals.

Reach us anytime to find the right Filter cart for your Plant - [email protected] or +91 70309 01267

#minimac systems#contact minimac#Oil Purification Systems#oil flushing#filer skid#filter replacements#Condition Monitoring#contract & services#oil purification machine#frf#lvdh#transformer oil cleaning#lube oil#hydraulic oil#chemical cleaning#oil filtration#filter machine#oil cleaning machine

2 notes

·

View notes

Text

So does like… cps not exist in dp?

Cause like.

…

As someone who grew up with the threat of cps. I feel like a mandated reporter ought to have had smth to mandatorially report. Even if they didn’t know about Danny’s alter ego.

Also the fentons are totally fake scientists who know nothing about the scientific process or how to properly form theories and experiments.

#danny phantom#danny fenton#the fenton’s a+ parenting#let’s have the children clean up the toxic chemicals#and feed them contaminated food#and do nothing about our weaponry targeting our son#and never notice his injuries#or either of their mental health#did I mention the lack of a hospital visit#after their kid had an interdimensional portal injury incident#nah that’s probably fine#anyway#they have better stuff to do right?#let jazz be a kid#let Danny feel safe#someone care for these kids#art#fanart#song art#danny phantom art#dp art

62 notes

·

View notes

Text

"Despite a huge amount of political opposition from the chemical industry, the US Environmental Protection Agency (EPA) announced its first regulations aimed at limiting quantities of PFAs, or ‘forever chemicals,’ in American drinking water.

For decades, Polyfluoroalkyl substances or PFAs have been used for coatings that resist fire, oil, stains, and water and are now found in a wide variety of products like waterproof clothing, stain-resistant furniture, food packaging, adhesives, firefighting spray foams, and non-stick cooking surfaces.

There are thousands of PFAS compounds with varying effects and toxicity levels, and the new EPA regulations will require water utilities to test for 6 different classes of them.

The new standards will reduce PFAS exposure—and thereby decrease the health risk—for 100 million people in the U.S.

A fund worth $1 billion for treatment and testing will be made available to water utilities nationwide—part of a $9 billion investment made possible by the 2021 Bipartisan Infrastructure Law to assist communities impacted by PFAS contamination.

“Drinking water contaminated with PFAS has plagued communities across this country for too long,” said EPA Administrator Michael S. Regan in a statement Wednesday.

Under Regan’s leadership, the EPA began in 2021 to establish a roadmap for dealing with widespread PFAS contamination, and so far they’ve gathered much data, including monitoring drinking water, and begun requiring more reports from businesses about use of the unregulated substances.

The agency reported that current peer-reviewed scientific studies have shown that exposure to certain levels of PFAS may lead to a myriad of health issues that are difficult to specify because of the variety of compounds coming from different places.

Regardless, the 66,000 water utility operators will have five years to test for the PFAS pollution and install necessary technology to treat the contamination, which the EPA estimates that 6%–10% of facilities will need. [Note: Deeply curious where they got a number that low, but anyway.]

Records show that some of the manufacturers knew these chemicals posed health hazards. A few major lawsuits in recent years have been settled that sought to hold chemical companies, like 3M, accountable for the environment damage.""

-via Good News Network, April 13, 2024

#united states#pfas#forever chemicals#epa#environmental protection agency#water quality#water pollution#clean water#good news#hope

478 notes

·

View notes

Text

i miss my wife

#gee doodles#gerard way#gee way#mcr#my chemical romance#mcr fanart#there's like three more doodles but i can't bring myself to clean them for some reasons

145 notes

·

View notes

Text

THREE CHEERS FOR SWEET REVENGE

(Btw I know not all the pictures are from revenge but wtv) THXX SO MUCH FOR ALL THE NOTES ON MY LAST POST LIKE WHAT???!!!! <3

#collage#moodboard#mcr#my chemical romance#aesthetic#all pics from pinterest#emo scene#mayb1rd#clean#revenge era#three cheers for sweet revenge#gerard way#mikey way#ray toro#frank iero#music#spotify#mcr is my life#lgbt#gerard way mcr

296 notes

·

View notes

Text

TW GORE

Frank's tattoos are so pretty but SO hard to draw :')

Reblogs appreciated xoxo

Timelapse on my Instagram account as always

#his lungs are NOT that clean#mcr#artists on tumblr#my chemical romance#my chemical fucking romance#frank iero#my chem#frnkiero#frank iero fanart#frank iero and the cellabration#leathermouth#fanart#mcr fanart#procreate#digital sketch#digital artist#digital drawing#digital painting#digital art#digital illustration#art#artist#small artist#zombie boy#blinkies#2000s#2000s emo#green#zombie

54 notes

·

View notes

Text

took my first adderall and holy shit

i did so much around the house today and its barely 3pm!n!

#cleaned out the front gutters of the house#brushed the whole pool. skimmed all the leaves and shmoo. cleaned the filter basket. measured chemicals and went to the hardware store#put those in#oh and i washed all the dishes and tidied the kitchen after breakfast#learned a new song on guitar#replaced an outlet in the garage. made myself breakfast. took my sister and her friends to the movies. did all the homework i needed to do#howling

21 notes

·

View notes