#ASME Codes

Explore tagged Tumblr posts

Text

Little P.Eng. for Blue Hydrogen and Ammonia Engineering Services: A Comprehensive Engineering Aspect

Table of Contents

Introduction

Blue Hydrogen: An Overview

Importance of Engineering Services in Blue Hydrogen Production

Piping Stress Analysis

Structural Engineering

Seismic Engineering

Tank Design

Pressure Vessel Design

Ammonia Engineering Services: The Connection

Conclusion

1. Introduction

As the world accelerates its efforts to combat climate change, the focus on cleaner energy sources has never been sharper. Blue hydrogen, derived primarily from natural gas with the carbon emissions being captured and stored, presents a viable option in the pursuit of decarbonization. Its potential integration with ammonia production further highlights its significance. At the heart of this transformative energy landscape lies the vital role of engineering services. 'Little P.Eng.', a forerunner in this niche, offers specialized services such as piping stress analysis, structural and seismic engineering, and the design of tanks and pressure vessels. This article delves deep into these pivotal engineering domains and the implications for blue hydrogen and ammonia production.

2. Blue Hydrogen: An Overview

Blue hydrogen is produced when natural gas (primarily methane) undergoes steam methane reforming (SMR) to produce hydrogen and carbon dioxide. Unlike gray hydrogen, where CO2 is released into the atmosphere, blue hydrogen incorporates carbon capture and storage (CCS) technology. This ensures that a significant portion of the carbon emissions are captured and sequestered, making blue hydrogen a cleaner option.

3. Importance of Engineering Services in Blue Hydrogen Production

Engineering services ensure the efficiency, safety, and reliability of blue hydrogen production plants. Key considerations range from handling high pressures and temperatures to mitigating the effects of seismic events. Herein, Little P.Eng.'s expertise comes to the fore.

4. Piping Stress Analysis

Piping systems in hydrogen production facilities face stresses from internal pressures, thermal loads, and dynamic forces. Piping stress analysis ensures that pipes, flanges, and fittings can withstand these stresses without failure.

Objectives:

Safety of the piping system and its associated components.

Compliance with international standards, codes, and best practices.

Reduction of operational disruptions due to piping failures.

Little P.Eng. employs advanced computational tools and methodologies to evaluate the behavior of piping systems under various loading conditions, optimizing design and ensuring longevity.

5. Structural Engineering

Facilities producing blue hydrogen demand robust structures capable of supporting equipment, piping, and personnel.

Key Challenges:

Dynamic loads from equipment and flow-induced vibrations.

Corrosive environments due to the presence of hydrogen, steam, and other chemicals.

Little P.Eng.'s structural engineering services provide innovative solutions, ensuring that structures remain integral and safe throughout their operational life.

6. Seismic Engineering

Many industrial facilities are located in seismic zones. Earthquakes can be catastrophic for hydrogen production facilities, leading to leaks, explosions, and fires.

Seismic Analysis: Little P.Eng. evaluates potential seismic risks and designs structures and systems that can withstand seismic events. This encompasses:

Site-specific seismic hazard assessments.

Design of foundations and structural elements with sufficient ductility and resilience.

7. Tank Design

Storage tanks play a pivotal role in hydrogen and ammonia plants. They store feedstock, intermediate products, and final products.

Design Principles:

Safety: Ensuring that tanks do not leak or rupture.

Efficiency: Maximizing storage capacity while minimizing footprint.

Longevity: Ensuring resistance to corrosion, wear, and tear.

With advanced modeling and simulation, Little P.Eng. optimizes tank designs to meet these principles, while also adhering to strict regulatory standards.

8. Pressure Vessel Design

Pressure vessels in hydrogen production plants hold gases at high pressures. Their design is crucial for safety and efficiency.

Design Aspects:

Material selection to resist hydrogen embrittlement.

Wall thickness determination to withstand internal pressures.

Compliance with international standards, such as ASME codes.

Little P.Eng. employs a rigorous approach to pressure vessel design, ensuring optimal performance and safety.

9. Ammonia Engineering Services: The Connection

Ammonia, NH3, is produced by combining nitrogen from the air with hydrogen. As such, blue hydrogen can provide a clean hydrogen source for ammonia production. The engineering challenges in ammonia production mirror those of blue hydrogen: high pressures, corrosive environments, and the need for robust structures and equipment. Little P.Eng.'s suite of services naturally extends to this domain, further enhancing the synergies between blue hydrogen and ammonia production.

10. Conclusion

The transformation of the energy landscape hinges on the adoption of cleaner technologies, and blue hydrogen stands out in this endeavor. The role of engineering services, as championed by Little P.Eng., is paramount, ensuring that the transition is not just sustainable but also safe and efficient. From intricate piping designs to robust structural solutions, the contributions of engineering cannot be overstated. As we gaze into the future of energy, it's clear that the expertise of firms like Little P.Eng. will be at the very heart of this revolution.

Tags:

Engineering Services

Seismic Engineering

Little P.Eng.

Piping Stress Analysis

Structural Engineering

Material Selection

Tank Design

Pressure Vessels

ASME Codes

Clean Energy

Ammonia Production

Steam Methane Reforming

Computational Analysis

Infrastructure Safety

Blue Hydrogen

Carbon Capture

Simulation and Modeling

Ammonia Synthesis

Fluid Dynamics

Industrial Standards

Decarbonization

Load-bearing Structures

Industrial Integrity

Earthquake-Resilient Designs

Energy Transition

Environmental Factors

Hydrogen Storage

Seismic Zones

Foundation Designs

Hydrogen Embrittlement

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Engineering Services#Seismic Engineering#Little P.Eng.#Piping Stress Analysis#Structural Engineering#Material Selection#Tank Design#Pressure Vessels#ASME Codes#Clean Energy#Ammonia Production#Steam Methane Reforming#Computational Analysis#Infrastructure Safety#Blue Hydrogen#Carbon Capture#Simulation and Modeling#Ammonia Synthesis#Fluid Dynamics#Industrial Standards#Decarbonization#Load-bearing Structures#Industrial Integrity#Earthquake-Resilient Designs#Energy Transition#Environmental Factors#Hydrogen Storage#Seismic Zones#Foundation Designs#Hydrogen Embrittlement

0 notes

Text

Two weeks later and it somehow did not occur to me to post the new haircut--i still get my powers restored right 🥺

#ore no kao#though with the week or two it's been maybe that was impacted 🤔#twas time and it also coincided with seeing current faves The Vaccines a third time (after their show with the Kooks last year) 🤩🤩🤩#my new black Pickup Full of Pink Carnations shirt (2nd pic) is nice 😌 (and hopefully wont get holes in it like the white one i got last yr)#want to post a vid or two too though i'm sure Tumblr still has a dumb one-vid-per-post limit 😒#but yeah hiiii#hope January went well lol#also hi newer people 👋🏽#lol between work and my fansubbing hobby and my work translating a game but also getting caught up in its code and learning asm even#(to mod it to enable more voices they didnt include for other non-main characters)#i've been easily distracted 😅#(also still loved the Vaccines' NYC show but i'm jelly of the Midwest shows where they played my fave SUNKISSED off the new album 😭#though the whole album is a banger and what they did play was a blast#also ran so late after stopping work around 3:30 to then finish laundry/ eat lunch/get the haircut/clean up/subway to the show#that i missed Thus Love opening and did kinda want to see them after listening to their stuff for the months since i bought my ticket 😩)#(also i have got to have a cute guy coming with me to shows with my fave bands 😩)#[also that Red Hot calendar though 😵 v good get lol]

88 notes

·

View notes

Text

fuck it be free my notes from last night

#original art!#i do know it is much easier to work out from existing toolsets (i.e. just learn ASM for whatever) but ever since I figured out how to make#CPU out of logic units the idea of working up from there to a full computer has been burning its way through my brain. So opcodes that are#grab bag of stuff that came to mind and a handful of codes from the 6502#along with some loose ideas on memory mapping though im not really educated at all on that.#the idea of a computer that can virtually handle radio is interesting to me though--on top of the more general CPU & Computer & OS#Whatever my CS followers will probably eviscerate me for some glaring flaws and i accept this burden.

2 notes

·

View notes

Text

*pushes up glasses* actually the hard part of coding is putting things on a screen

#wrote debug output for someone else's asm they wrote for school like 2 years ago#cuz it was on github and y'know learning experimenting etc#the original code was like 3 lines long and it has. expanded greatly.

2 notes

·

View notes

Text

My screen's been looking like this for the past Month, help.

#assembly#m68k#ASM#gatoslip#sublime#romhack#rom hack#rom hacking#Yes#i've started indenting my assembly code

4 notes

·

View notes

Text

I have been informed that, despite having a bolted flange joint, this is not ASME approved.

17K notes

·

View notes

Text

building a random forest tmr to predict hospital readmission rates, to draft practical solutions for this rando hospital to lower their readmission rate which based on the dataset is 46% woah

also theres 1-2 people whos visited the hospital for inpatient care like 15 days a year, and 1 person who’s went through ER 64 times in the year are they good

#gotta drop them outliers but like#iqr? imma use iqr not gon lie#random forest#machine learning#its simple python coding report but I HAVE NEVER CODE IN MY LIFE AND THEY DIDNT TEACH THIS EITHER I DONT UNDERSTAND HOW THIS IS AN ASM#im literally teaching myself how to code#what the heck is the tuition going to#my youtube video spree???

0 notes

Text

Today was almost the day I redownloaded indeed but I think I can stick it out for 3 more months so I don’t have to feel guilty about rounding my time working here to a year on my resume

#today the guy my boss hired to be asm (job I have been doing without reasonable compensation for several months) who I HAVE TO TRAIN#told me boss told him I am breaking dress code (zip hoodie with non job tshirt visible underneath) and shit talked me behind my back for it#1) I have never. once. in 9 months. been given any info on what our dress code is 2) boss has been in the building with me for SIX HOURS#without saying anything to me about this#3) and this is the kicker. the big one. I will give you ONE guess what boss is wearing right now#IF YOU GUESSED ZIP HOODIE WITH NON JOB TSHIRT VISIBLE UNDERNEATH I’D LOVE YOUR HELP IN SLASHING THIS MANS TIRES#hell on earth. hell on earth. hell on earth.

0 notes

Text

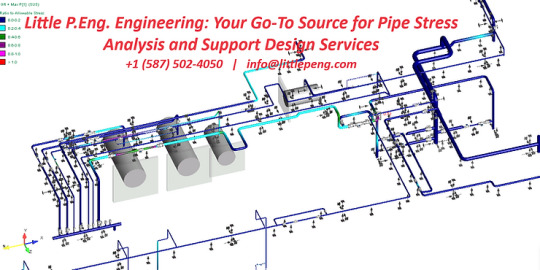

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

The Art of Precision: A Closer Look at LNL Fabrication's ASME Certified Services

In the world of fabrication, precision is paramount. At LNL Fabrication, we have mastered the art of precision, delivering top-notch fabrication services that meet the highest standards of quality and safety. As an ASME Certified fabrication shop near me, we take pride in our ability to design, engineer, and fabricate ASME code vessel shop for the oil and gas industry.

Our Commitment to Excellence

Our commitment to excellence is evident in every project we undertake. From pressure vessel welding near me to complex fabrication solutions, our team of skilled professionals ensures that every detail is meticulously crafted to perfection. We understand the unique needs of the oil and gas industry and are dedicated to providing innovative solutions that exceed expectations.

Comprehensive Services

What sets us apart from other ASME fabricators is our comprehensive approach to fabrication. We offer a wide range of services, including design consultation, material selection, fabrication, testing, and installation. This full-service approach allows us to streamline the fabrication process, ensuring that projects are completed on time and within budget.

Adherence to ASME Code

One of the key aspects of our service is our adherence to the ASME code. As an ASME Certified vessel shop, we adhere to the highest standards of quality and safety in the industry. This certification is a testament to our commitment to excellence and ensures that our customers receive the highest quality products and services.

Experienced Professionals

When you choose LNL Fabrication for your fabrication needs, you can rest assured that you are getting the best in the industry. Our team of experienced professionals has the knowledge and expertise to handle even the most complex projects. Whether you need a custom vessel or a complete fabrication solution, we have the skills and resources to deliver.

Full-Service Offerings

In addition to our ASME certification, we also offer a range of other services to meet your needs. From design and engineering to testing and installation, we are your one-stop shop for all your fabrication needs. Our goal is to provide our customers with the highest quality products and services, and we are committed to exceeding your expectations.

Conclusion

If you are looking for a reliable and experienced fabrication services near me, look no further than LNL Fabrication. Contact us today to learn more about our services and how we can help you with your next project.

1 note

·

View note

Text

what should i code on my minecraft computer

i am planning to code:

snake

conway's game of life

bad apple

i am NOT coding:

doom

minecraft

geometry dash

anything that requires heavy usage of multiplication (i only have an ALU and a shifter)

#minecraft computer#minecraft#minecraft cpu#custom architecture#code#assembly#coding#asm#cpu#8-bit#16-bit

18 notes

·

View notes

Text

Couple Coding in ASM

So there's an interesting thing I noticed about Orka's color coding in ASM and the way it changes between different interactions.

For example, JerShu moments are commonly set during early dawn. There's a cool blue from the moonlight that shades the two, adding a sense of quiet mystique to their interactions.

Maybe it's to invoke a dream-like state where Shuri is stripped bare of her responsibilities and Jeremy is just a boy who misses his parents oh, so much. During the day, there's so much commotion and stress but when they're together at night, it's quiet and lonely, with only the moon watching over them. Because when morning comes, they're forced to return back to their normal lives like a Cinderella story.

On the other hand, NoShu moments are bright like a burning sun. It's a passionate watercolor of orange, pinks, and reds that bloom as they stare into each other's eyes.

It's pure romance the way you couldn't be sure whether the burn on their cheeks was because of the warm heat of the sun or because of something else. For a couple individually driven towards death, Nora and Shuri are experiencing living for the first time, when they're together. The way the light gleams on each other like they're always discovering new things about one another is just so perfectly lovely.

And then there's TheoShu. Theo and Shuri often interact in the morning, like a icy shock to the system. For a man plagued with too much guilt to sleep and a woman trapped in her nightmares, what's a more eerie wake-up call?

TheoShu as a morning motif is so interesting because we're faced with Theo who acts like he's still stuck in a dream where he's fated to be with Shuri and Shuri, who is trying to run away from those dreams and move on with her day. They're never quite on the same page, like the feeling you get when you're debating on getting up on a Monday morning.

Finally. RiShu. I find that Richelieu and Shuri are always in a strange state of limbo when they stumble upon each other. A space that only they know, where the light doesn't shine until Shuri walks in.

Richelieu is a man that exists in the shadows, lurking around in the dark underbrush. But he can't help but be drawn to that woman intruding upon that dark forest he lives in. She gleams like a holy light piercing the black darkness. Shuri knows what it's like to die in that forest and Richelieu wants to know what path she took to get there.

#the fantasie of a stepmother#a stepmother's marchen#stepyapping#shuli von neuschwanstein#nora von nuremberg#jeremy von neuschwanstein#cardinal richelieu#theobold von baden bismarck#noshu#jershu#theoshu#rishu

125 notes

·

View notes

Text

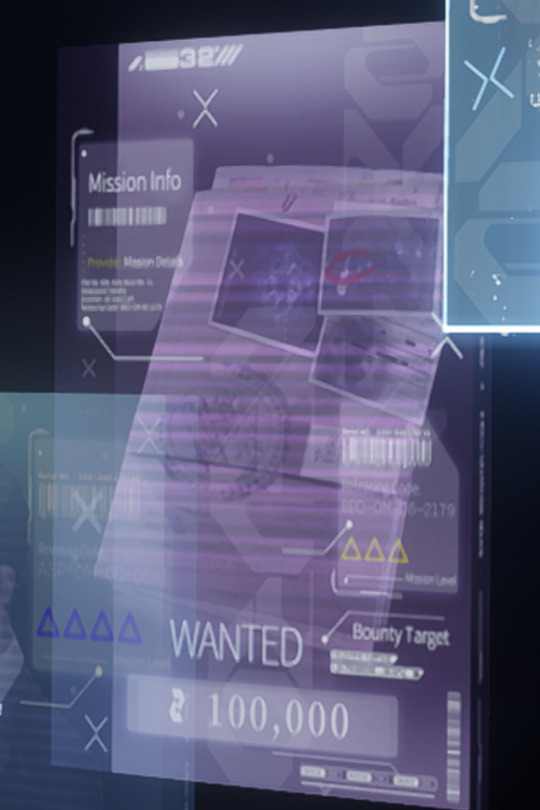

Miscellaneous Characters: Bounty Targets

Ages: Unknown

Details:

In the Hunt Day scene at the Nest, the protaganist stops to look at a series of displays showing wanted figures and their associated bounties. Though they don't show all of them in one shot, we six on the left side as she approaches and then briefly see two more on the right side when she stumbles.

Though a lot of the information was illegible, a few of them were clear enough to make out. I'll write out the following detaild for each that I could suss out:

Message Beside Panel 1:

Reward info is released irregularly. If there is a repeat reward info, the one with the higher price shall prevail.

Please note. Both parties who offered the reward and took the Bounty shall never disclose names to each other.

Panel 1

Provider: ?

Target: ?

Duration: ? Days Left

Releasing Code: ASP-OM-00-084

Target Details: ?

Mission Level: (four blue triangles)

Bounty: 20,000,000

Serial No.: ?

Panel 2

Provider: Mission Details

Target: ?

Duration: ?

Releasing Code: BPO-OM-??-2179

Target Details: ?

Mission Level: (three yellow triangles)

Bounty: 100,000

Serial No.: USS1-D40-L76CX8

Panel 3

Provider: Mission Details

Target: ?

Releasing Code: ?

Target Info: ?

Duration: ?

Mission Level: (four red triangles)

Bounty: 20,000

Serial No.: ?

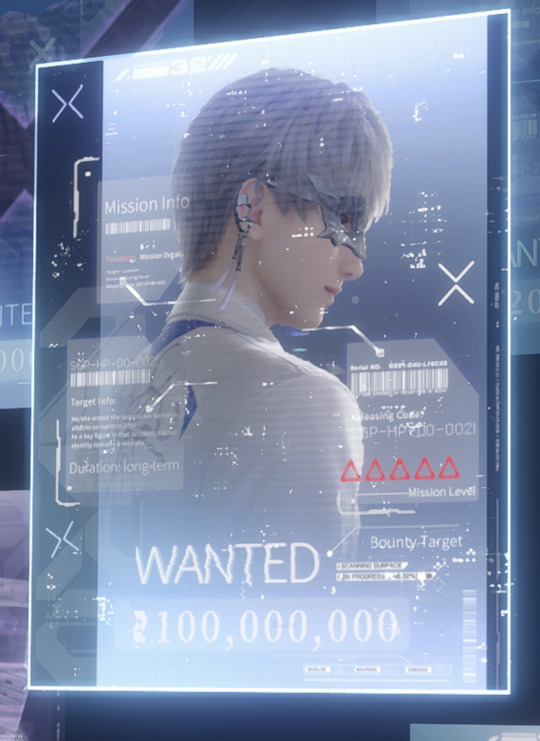

Panel 4

Provider: Mission Details

Target: Lumiere

Duration: Longterm

Releasing Code: SGP-HP-00-0021

Target Details: He/she ended the targeted Wanderer attacks on earth in 2034. As a key figure in that incident, his/her identity remains a mystery.

Duration: long-term

Mission level: (five red triangles)

Bounty: 100,000,000

Serial No.: USS1-D4U-L76CX8

Panel 5

Provider: Mission Details

Target: ?

Releasing Code: ASM-TM-01-1563

Target Info: ? Is suspected to be the advanced species of ? ? that is always witnessed around the World ?. The species aggregates quickly after knocked down.

Duration: 75 days left

Mission Level: (four blue triangles)

Bounty: 20,000,000

Serial No.: ?

Panel 6

Provider: ?

Target: ?

Duration: Closed

Releasing Code: BBP-0W-00-4193

Target Info: Protocore dealer in his 40-50s. 68 inches in height. He has a scar on his left ear. The little finger of his left hand is missing.

Duration: Closed

Mission Level: (three red triangles)

Bounty: 100,000

Serial No.: USS1-D40-L76CX8

Panel 7

Provider: ?

Target: ?

Releasing Code: ASM-TM-01-1563

Target Info: ? Is suspected to be the advanced species of ? ? that is always witnessed around the World ?. The species aggregates quickly after knocked down.

Duration: 75 days left

Mission Level: (four blue triangles)

Bounty: 20,000,000

Serial No.: ?

Panel 8

Provider: Mission Details

Target: ?

Releasing Code: BBP-TW-00-3962

Target Info: Head of the Information Dept. of Leslie Company. She ran away after stealing the company's confidential data and was suspected to hide in Zone N109.

Duration: 3 Days Left

Mission Level: (three red triangles)

Bounty: 100,000

Serial No.: USS1-D40-L76CX8

#love and deepspace#lads#lads linkon city#linkon city#lads miscellaneous characters#love and deepspace miscellaneous characters

88 notes

·

View notes

Text

had my second high definition viewing of atsv in the theater today and here are my favorite details that i missed due to being overwhelmed on my first viewing:

LONG AF POST:

-gwen is literally wearing a rainbow shaped trans pride pin on her jacket with her prom outfit. she's soooo so canon trans <3

-captain stacy HAS A TRANS FLAG PATCH ON HIS POLICE UNIFORM JACKET?????? when i'm telling u my eyes popped out of my head 😳 SHES SO CANON TRANS!!!

-poster outside miles's guidance counselor's office reads: "visions sciences: telling you your story".

-parallel of miles's and gwen's dad kicking things out of general exasperation towards the beginning and end of the movie respectively

-when miles as spidey is talking to his dad and giving him advice (for himself) there's a reference to miles possibly reading vonnegut? (maybe in class??) "if this isn't nice what is" is a collection of kurt vonnegut's commencement speeches. (literally subtitled "advice to the young". the writers were extremely clever for this reference. if not reading it in class, miles has been searching up life advice on his own)

-i barely caught this but i'm PRETTY sure that in miles' room near his door there's a MICHELLE OBAMA presidential race sticker??? was president obama in the earth-1610 dimension michelle obama?? iconic if so

-fedex on earth-1610 is REDEX

-gayatri seems like they took elements of both gwen (police dad) and mj (young model) for her background as i believe i caught her visible on a "zomato" ad billboard (which appears to be the earth-50101 version of ubereats)

-i spent all of hobie's scenes trying to pick up the details of his many pins; but the only one that i could really make out with the quick shot changes besides the union jack pin was the one right above it, which is a three-leaf clover. i wondered if maybe it had some kind of significance to maybe irish independence or smth but i couldn't find anything online that backed that up so not sure what it means. if u know pls drop it in the replies.

-hobie's boots are definitely NOT ladder laced. i KNOW there is concept art and poster art of him with ladder laces but in the actual movie they are 100% crossed. also unlike the poster art, both boots have blue laces, not one blue, one yellow/orange. i wanted to be all on board the ladder lace code train but i'm pretty sure they just made his laces blue so that they could contrast against the red boots and be spidey colors. they probably abandoned the ladder lace part of the visual when someone realized what blue ladder laces meant in lace code. "HAS hobie killed a cop," you ask? given his comic backstory i'd say the odds are HIGH. but i would bet they didn't want people to think that since he's gone through canon event asm-90 ("a police captain close to spider-man is killed by falling rubble during a battle with a nemesis") that there's any possibility THAT was the cop he killed and he's proud of it (since it's supposed to be all abt character development from the ✨trauma✨ of the event)

-during the whole "intervention" scene, while all the other spider-people are facing directly in towards miles and miguel from wherever they are standing in the circle, hobie is the only one whose back is turned. he watches most of the scene over his shoulder. also, during a couple shots facing miles before the entire society of spiders show up, hobie is separated in the shot from all the other main spiders (Peter B, Gwen, Jess, etc) BY MILES. he is visible over one shoulder and everybody else is visible over the other. these two details are great signals of hobie having already MORALLY turned his back on miguel's authoritarianism, as well as giving a nice inverted "devil/angel on the shoulders" nod.

-peter b asks miguel to take a picture of him and mayday since it's her first chase; miguel brushes him off but mayday understands and uses her webshooter to click the camera button on peter b's phone and take a selfie without him noticing 😂😂😂 shes everything to me

-when miguel is pinning miles to the train, after gwen and peter b have caught up, there is a very fast moment when miles calls for help ("PETER!!") and peter doesn't reply to him, but calls out to miguel to calm down (smth like that) instead 🥲 peter for the love of god step up your mentor game and look out for this kid i can't handle it anymore

-when gwen takes the watch hobie made her out of the box, the screen is briefly visible and reads "project botleg". bootleg -> bot -> "botleg"; I SEE YOU HOBIE. people think he's so cool (and he is!!) but he's also just as much of a dork as all the other spiders. what a goofball

-in miles-42's room, a speed bag/speed ball/maize ball is attached to his wall near the door. there are other substantial differences to their rooms, but i think this is clearly a reference to uncle aaron-42's large presence in miles-42's life, given the association from both movies of aaron with the punching bag and miles getting guidance from him/looking to him for support.

-in addition to all the miles-1610 vs miles-42 prowler vs spidey reflection imagery in the end credits, guess who else has several moments of flashing from spider-man colors (red and black at least) to prowler colors (purple and green)?? miguel, that's who. miguel and miles-42/uncle aaron-42 team-up in beyond the spiderverse? or just an extra parallel for the antagonists sharing goals/possibly methods?

OKAY ANYWAY if ppl want i can try and dig up images of some of these but i figured that would make this post long af so that's all for now folks!! go see across the spider verse again and marvel at how much more fine detail you find like me 🕸🕸🕸

#across the spiderverse#across the spider verse spoilers#atsv#miles morales#gwen stacy#miguel o'hara#hobie brown#peter b parker#mayday parker#captain stacy#jefferson morales#gayatri singh#aaron davis#the prowler#earth 1610#earth 42#earth 50101#trans gwen stacy#this movie is driving me fucking NUTS bro#they are so so so insane for all of this#i can't wait for it to come out on dvd and blu-ray so i can pause it and pick through it more slowly#i'm sure there are SO MANY more things no one has picked up yet#also i tried to only include stuff in this list that i haven't really seen other people talk about#or that i noticed additional details to if i had heard someone reference it#r speaks#r tags

428 notes

·

View notes

Text

I desprately need someone to talk to about this

I've been working on a system to allow a genetic algorithm to create DNA code which can create self-organising organisms. Someone I know has created a very effective genetic algorithm which blows NEAT out of the water in my opinion. So, this algorithm is very good at using food values to determine which organisms to breed, how to breed them, and the multitude of different biologically inspired mutation mechanisms which allow for things like meta genes and meta-meta genes, and a whole other slew of things. I am building a translation system, basically a compiler on top of it, and designing an instruction set and genetic repair mechanisms to allow it to convert ANY hexadecimal string into a valid, operable program. I'm doing this by having an organism with, so far, 5 planned chromosomes. The first and second chromosome are the INITIAL STATE of a neural network. The number and configuration of input nodes, the number and configuration of output nodes, whatever code it needs for a fitness function, and the configuration and weights of the layers. This neural network is not used at all in the fitness evaluation of the organism, but purely something the organism itself can manage, train, and utilize how it sees fit.

The third is the complete code of the program which runs the organism. Its basically a list of ASM opcodes and arguments written in hexadecimal. It is comprised of codons which represent the different hexadecimal characters, as well as a start and stop codon. This program will be compiled into executable machine code using LLVM IR and a custom instruction set I've designed for the organisms to give them a turing complete programming language and some helper functions to make certain processes simpler to evolve. This includes messages between the organisms, reproduction methods, and all the methods necessary for the organisms to develop sight, hearing, and recieve various other inputs, and also to output audio, video, and various outputs like mouse, keyboard, or a gamepad output. The fourth is a blank slate, which the organism can evolve whatever data it wants. The first half will be the complete contents of the organisms ROM after the important information, and the second half will be the initial state of the organisms memory. This will likely be stored as base 64 of its hash and unfolded into binary on compilation.

The 5th chromosome is one I just came up with and I am very excited about, it will be a translation dictionary. It will be 512 individual codons exactly, with each codon pair being mapped between 00 and FF hex. When evaulating the hex of the other chromosomes, this dictionary will be used to determine the equivalent instruction of any given hex pair. When evolving, each hex pair in the 5th organism will be guaranteed to be a valid opcode in the instruction set by using modulus to constrain each pair to the 55 instructions currently available. This will allow an organism to evolve its own instruction distribution, and try to prevent random instructions which might be harmful or inneficient from springing up as often, and instead more often select for efficient or safer instructions.

#ai#technology#genetic algorithm#machine learning#programming#python#ideas#discussion#open source#FOSS#linux#linuxposting#musings#word vomit#random thoughts#rant

8 notes

·

View notes

Text

KNOCK KNOCK

fanart of everyones fav Black coded Marsupial(is an Echidna a Marsupial? idk) did this like the day the knuckles show stuff came out in february or whenever idk the dates by my signature go look lol(i would but i um uh um), only took like 2 and a half hours which is one of my quickest turn arounds on a good looking piece(the heatblast art is still best in terms of time and not-looking-bad-ness), and yeah usual routine asm and i can explain the process do you like knuckles? if you see this i assume yes lol anyway bye bye <3

#digital art#digital illustration#fanart#art#artwork#sonic fanart#sonic the hedgehog#sonic#sonic art#knuckles#knuckles the echidna#knuckles series#knuckles fanart#knuckles wachowski#knux#knuckles the dread

26 notes

·

View notes